DIY Room Divider Secrets: How Psychology and Material Science Transform Your Space Forever

Creating sophisticated DIY room dividers requires understanding psychology, materials science, and engineering principles that go far beyond simple space blocking. While room dividers can provide you with privacy, create additional room, and help you achieve a better work/life balance according to Autonomous, the most successful projects integrate multiple approaches that consider both immediate function and long-term satisfaction.

Table of Contents

-

The Behavioral Architecture of Room Division

-

The Material Evolution Lifecycle

-

The IKEA Hack Ecosystem

-

Advanced Curtain Engineering

-

Wall-Integrated Division Systems

TL;DR

-

Room dividers function as psychological tools that control your territorial instincts and reduce visual noise in your brain

-

Every material follows predictable aging patterns – planning for decomposition and reuse saves money and reduces waste

-

IKEA furniture can be transformed into sophisticated room division systems using specific engineering techniques

-

Modern curtain systems use marine-grade hardware and smart technology to create architectural-quality divisions

-

Wall-integrated systems provide permanent solutions without major construction using pressure-mounting and magnetic attachment methods

The Behavioral Architecture of Room Division

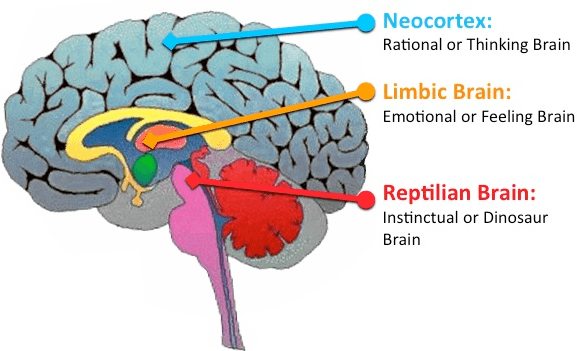

Room dividers work as psychological tools that influence your behavior, mood, and spatial perception rather than just blocking views. Your brain processes divided spaces differently, creating feelings of control and focus that solid walls or open areas can’t provide. Understanding these mental triggers helps you design diy room divider solutions that actually improve how you feel and function in your space.

Your brain craves territorial control – dividers satisfy this need by creating defined boundaries within larger spaces. When you establish clear zones using a diy room divider, you’re tapping into evolutionary programming that makes humans feel secure and productive. Visual distractions overload cognitive processing, and strategic divisions act as mental filters that improve concentration.

When planning your space transformation, consider how decluttering services can prepare your area for optimal divider placement by removing accumulated items that interfere with proper psychological boundaries. This preparation work ensures your diy room divider ideas can be implemented effectively without competing visual elements.

Micro-Environmental Control Theory

Creating defined spaces within larger areas satisfies your innate need for territorial control and privacy. This psychological principle explains why you feel more comfortable and productive in smaller, well-defined areas rather than vast open spaces. Your nervous system responds to spatial boundaries by reducing stress hormones and increasing focus-related neurotransmitters.

Territorial control reduces cortisol production and activates the parasympathetic nervous system. When you implement diy room divider ideas that create clear boundaries, you’re essentially giving your brain permission to relax and focus. Defined boundaries trigger nesting behaviors that improve emotional regulation and task completion.

Spatial hierarchy creates predictable environments that reduce decision fatigue throughout your day. According to This Old House, A basic four-panel folding screen costs $20–$50 at your local big box store, making psychological space division accessible to most budgets while providing immediate territorial control benefits.

The Nest-Within-Nest Phenomenon

Humans naturally create smaller, more manageable spaces within larger ones to feel secure and focused. This behavior stems from evolutionary survival instincts where smaller spaces provided protection and resource control. Modern room dividers tap into this instinct by creating intimate zones that feel psychologically safe and functionally efficient.

Evolutionary psychology drives preference for enclosed spaces with clear sight lines to exits. Smaller spaces reduce sensory input allowing deeper focus and creative thinking. Nested environments create psychological ownership that increases motivation and productivity.

A home office worker struggling with distractions in an open-concept living space can create a “nest-within-nest” using a simple three-panel folding screen positioned at a 45-degree angle behind their desk. This creates a visual barrier that triggers the psychological sense of enclosure while maintaining sight lines to the room’s exit, satisfying both security and focus needs without permanent construction.

Visual Noise Reduction Psychology

Room dividers act as cognitive filters, reducing visual distractions and allowing your brain to process environments more efficiently. Your visual cortex can only handle limited information before becoming overwhelmed. Strategic divisions eliminate competing visual elements that drain mental energy and reduce your ability to concentrate on important tasks.

Visual cortex processing capacity decreases with increased environmental complexity. Selective attention improves when competing visual stimuli are physically blocked. Cognitive load reduction through visual filtering increases working memory capacity.

Cultural Space Programming

Different cultures approach space division in ways that reveal optimal DIY room divider design principles. Japanese, Scandinavian, and Mediterranean traditions offer specific techniques for creating divisions that enhance rather than restrict spatial flow. These cultural approaches provide tested frameworks for designing dividers that feel natural and psychologically comfortable.

Cultural space programming reflects thousands of years of behavioral optimization. Traditional division methods balance privacy needs with social connection requirements. Cross-cultural design principles create universally appealing spatial arrangements.

The resurgence of wavy wooden room dividers reflects this cultural programming, as wavy wooden accent piece stands out because of its modernity and functionality according to Living Etc, demonstrating how 1930s design principles continue to satisfy modern psychological needs for both division and aesthetic appeal.

Japanese Ma Principles in Western Homes

The Japanese concept of “negative space” creates room dividers that define areas through suggestion rather than solid barriers. Ma principles use empty space as an active design element that guides movement and attention without creating claustrophobic feelings. This approach works particularly well in smaller homes where traditional solid dividers would feel overwhelming.

Negative space creates implied boundaries that maintain visual flow while defining function. Suggested divisions allow flexible use patterns that adapt to changing daily needs. Minimal material requirements reduce cost while maximizing psychological impact.

Scandinavian Hygge Boundaries

Creating cozy, defined spaces that promote comfort and well-being through strategic use of natural materials and soft divisions. Hygge principles emphasize warmth and intimacy over strict separation, using textures and lighting to create psychological boundaries. This approach works well for families who need flexible spaces that can serve multiple functions.

Natural materials trigger biophilic responses that reduce stress and improve mood. Soft boundaries maintain family connection while providing individual space. Texture-based divisions create sensory comfort that enhances relaxation responses.

Mediterranean Flow-State Design

Using room dividers to create seamless transitions between indoor and outdoor living concepts. Mediterranean design principles emphasize natural light flow and air circulation while maintaining defined functional areas. This approach works particularly well in climates where indoor-outdoor living is desirable year-round.

Light transmission through divisions maintains circadian rhythm regulation. Air flow considerations prevent stagnant zones that feel uncomfortable. Indoor-outdoor transitions create psychological connections to nature.

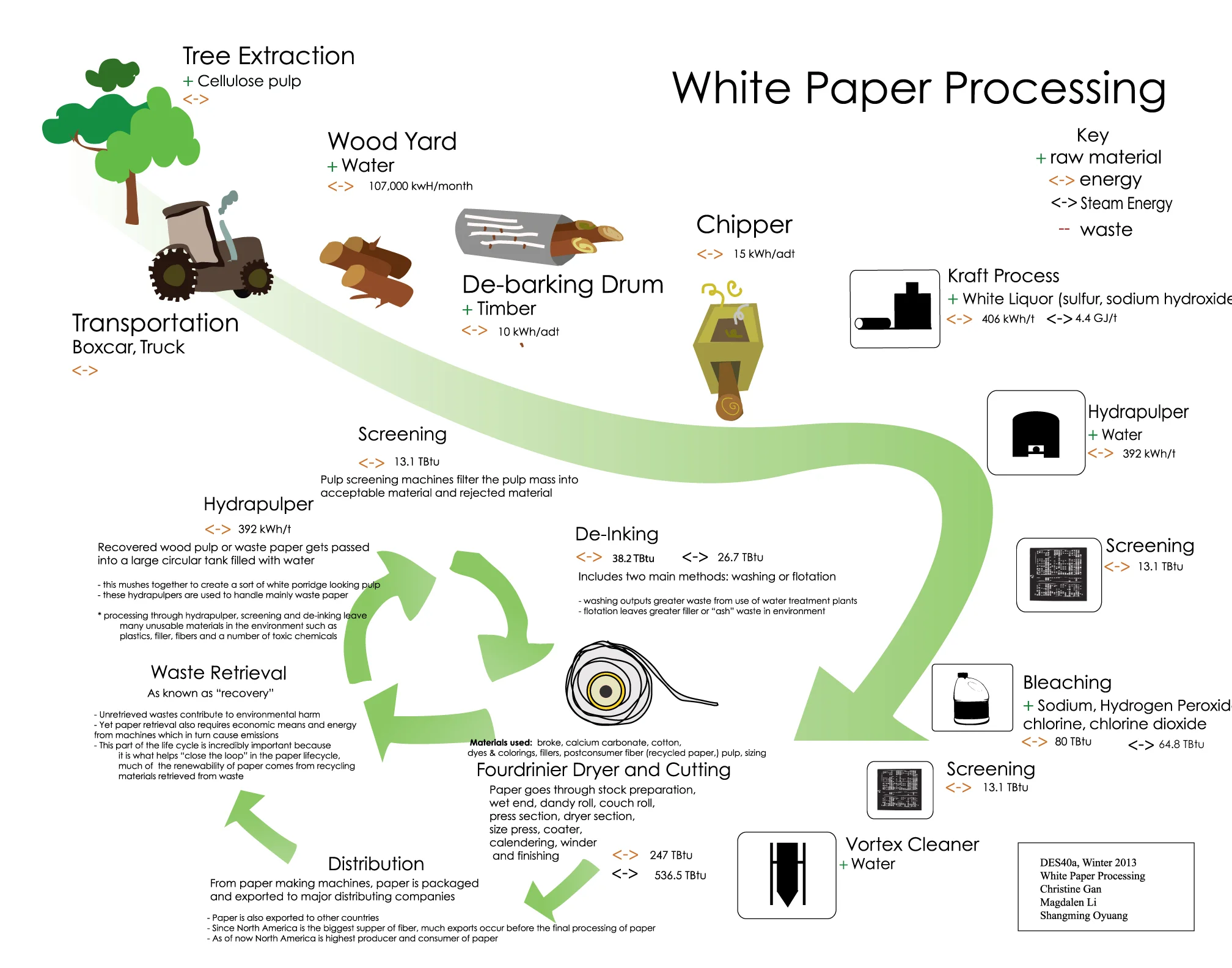

The Material Evolution Lifecycle

Every DIY room divider material changes, adapts, and eventually requires replacement or repurposing following predictable patterns. Understanding these lifecycle stages helps you plan projects that remain functional and attractive over time. Smart material selection considers initial appearance and long-term behavior and end-of-life options.

Material degradation follows predictable timelines that can be planned for during initial design. When you’re developing diy room divider concepts, thinking about how materials will age saves you from disappointment and unexpected replacement costs. Lifecycle planning reduces long-term costs and environmental impact through strategic material choices.

The Biodegradation Timeline

Different materials age following predictable patterns that you can plan for and even incorporate aesthetically into your design. Natural materials develop patina and character over time, while synthetic materials show wear patterns that can be anticipated. Understanding these timelines helps you choose materials that will age gracefully or plan replacement schedules.

Natural materials follow biological decomposition cycles that can be slowed or accelerated through treatment. Synthetic materials experience molecular breakdown that creates predictable failure points. Aesthetic aging can be designed into projects to improve appearance over time rather than degrade it.

|

Material Type |

Initial Appearance Change |

Structural Changes |

Replacement Timeline |

Aesthetic Considerations |

|---|---|---|---|---|

|

Bamboo |

6-12 months (UV fading) |

2-3 years (splitting) |

5-7 years |

Develops silver patina |

|

Pine Wood |

3-6 months (color shift) |

3-5 years (checking) |

8-12 years |

Honey to gray transition |

|

Plywood |

12-18 months (edge swelling) |

4-6 years (delamination) |

10-15 years |

Surface veneer aging |

|

Canvas |

6-9 months (color fade) |

2-4 years (fiber breakdown) |

3-5 years |

Develops texture character |

|

Polycarbonate |

18-24 months (slight yellowing) |

8-10 years (brittleness) |

15-20 years |

Maintains clarity longest |

Natural Material Decomposition Stages

Bamboo, wood, and plant-based dividers follow predictable aging patterns that can be planned for and even aesthetically incorporated into your design. These materials typically show initial color changes within 6-12 months, structural changes within 2-5 years, and require replacement or major maintenance within 5-10 years depending on environmental conditions.

UV exposure accelerates lignin breakdown causing color changes and surface degradation. Moisture cycles create expansion-contraction stress that leads to checking and splitting. Biological activity from insects and fungi can be controlled through proper treatment and maintenance.

Synthetic Material Fatigue Patterns

Plastic, metal, and composite materials develop wear patterns that can be anticipated and designed around. These materials typically maintain structural integrity longer than natural materials but show aesthetic degradation through UV fading, stress cracking, and surface oxidation. Planning for these patterns helps you choose appropriate materials for specific applications.

Polymer chains break down under UV exposure creating brittleness and color changes. Thermal cycling creates stress concentrations at connection points and thin sections. Surface treatments can extend aesthetic life but require periodic renewal for continued protection.

Adaptive Reuse Engineering

Designing room dividers with their second and third life cycles in mind reduces waste and provides future flexibility as your needs change. This approach involves creating modular connection systems and choosing materials that can be easily reconfigured or repurposed. Planning for adaptive reuse often costs little extra initially but provides significant long-term value.

Modular design principles allow components to be recombined in different configurations. Standardized connection systems enable easy disassembly and reassembly. Material selection should consider multiple potential applications beyond initial use.

Modular Breakdown Protocols

Creating connection systems that allow easy disassembly for repurposing individual components extends the useful life of your materials and provides flexibility for future projects. These systems use mechanical fasteners rather than adhesives and design joints that can be accessed and operated without special tools.

Mechanical fasteners maintain strength through multiple assembly cycles unlike adhesives. Accessible joint design allows disassembly without damaging surrounding materials. Component standardization enables mixing elements from different projects.

Modular Disassembly Checklist:

-

Use only mechanical fasteners (screws, bolts, clips)

-

Avoid permanent adhesives or welded joints

-

Label components for easy identification during reassembly

-

Document connection patterns with photos before disassembly

-

Store hardware in labeled containers by component type

-

Test reassembly process before final project completion

Seasonal Transformation Systems

Building room dividers that can be modified or completely reconfigured based on changing needs and seasons maximizes their utility and keeps your space feeling fresh. These systems incorporate interchangeable elements and adjustment mechanisms that allow major changes without complete reconstruction.

Seasonal needs vary significantly in light transmission, air flow, and thermal properties. Interchangeable components allow single framework to serve multiple functions throughout the year. Quick-change mechanisms enable frequent reconfiguration without tools or expertise.

Summer-Winter Configuration Swaps

Designing dividers with interchangeable panels for seasonal light and airflow needs helps maintain comfort year-round while using the same basic structure. Summer configurations typically emphasize air circulation and light control, while winter setups focus on warmth retention and cozy atmospheres.

Summer panels prioritize air permeability and UV protection over thermal insulation. Winter configurations use dense materials and warm colors to create psychological warmth. Quick-swap mechanisms allow seasonal changes to be completed in under an hour.

Holiday Integration Mechanisms

Built-in features that allow room dividers to incorporate seasonal decorations without structural modifications keep your space festive while maintaining functionality. These features include integrated hanging points, display surfaces, and lighting systems that can be activated when needed.

Integrated hanging systems distribute decoration weight safely across the structure. Hidden wiring allows seasonal lighting without visible extension cords or temporary installations. Modular display surfaces can be added or removed based on specific holiday requirements.

The IKEA Hack Ecosystem

IKEA furniture systems possess unique properties that can be transformed into sophisticated room dividers far beyond their original storage purpose. The modular design, standardized dimensions, and affordable pricing of IKEA pieces make them ideal building blocks for custom division solutions. Understanding the engineering principles behind these transformations unlocks creative possibilities that rival expensive custom installations.

Modular IKEA systems use standardized dimensions that enable predictable stacking and connection methods. Mass-produced hardware and components reduce costs while maintaining structural integrity for room division applications. When you’re exploring diy room divider ideas, IKEA pieces offer tested engineering that takes the guesswork out of structural planning.

The Kallax Metamorphosis

IKEA’s most popular storage unit transforms into dynamic room division solutions through vertical integration and mobility enhancements. The cube-based design provides natural visual rhythm while offering integrated storage that traditional dividers lack. Multiple units can be combined to create floor-to-ceiling installations that rival built-in solutions.

Cube geometry creates visual interest while maintaining structural stability when stacked. Integrated storage eliminates need for separate furniture pieces in divided spaces. Standardized dimensions allow precise planning for any ceiling height or room configuration.

Vertical Integration Techniques

Stacking and connecting multiple Kallax units creates floor-to-ceiling dividers with integrated storage that maximizes both function and visual impact. This technique requires careful attention to weight distribution and ceiling attachment to prevent tipping. Proper installation creates impressive installations that appear custom-built.

Weight distribution calculations prevent top-heavy configurations that could tip over. Ceiling anchor points transfer lateral loads to building structure rather than relying on friction. LED integration between units creates architectural lighting effects that enhance the installation.

A 450-square-foot studio apartment can be transformed using three Kallax 4×4 units stacked vertically to create a floor-to-ceiling room divider. The bottom unit houses media equipment and books, the middle unit displays decorative items with integrated LED strips, and the top unit stores seasonal items. Ceiling attachment using L-brackets into joists prevents tipping while maintaining the clean aesthetic of a built-in installation.

Mobility Enhancement Systems

Adding wheels and pivot mechanisms makes Kallax dividers easily repositionable for flexible space arrangements. Mobile dividers require weighted bases to prevent tipping while maintaining smooth movement across different floor surfaces. Proper caster selection ensures quiet operation and floor protection.

Heavy-duty furniture casters support loaded weight while enabling smooth movement. Weighted bases using concrete pavers lower center of gravity for stability during movement. Soft-close hinges enable folding configurations that store compactly when not needed.

The Billy Bookcase Revolution

Converting linear storage into curved and angled room division systems creates organic spatial flow that feels more natural than straight divisions. Multiple Billy bookcases can be arranged in flowing shapes using geometric principles and custom connecting hardware. This approach works particularly well in open floor plans where rigid divisions would feel harsh.

Geometric arrangement principles create flowing curves using straight linear elements. Custom connecting brackets enable secure angular connections between individual units. Curved arrangements create multiple functional zones while maintaining visual continuity.

Curve Creation Mathematics

Using geometric principles to arrange multiple Billy bookcases in flowing, organic shapes requires careful planning but creates stunning results. The key involves calculating proper angles between units and creating secure connections that maintain structural integrity. Proper execution creates installations that appear professionally designed.

String and stake mapping ensures accurate curve layout before permanent installation. 15-30 degree angles between units create smooth curves without structural stress. Metal angle brackets provide secure connections while allowing angular flexibility.

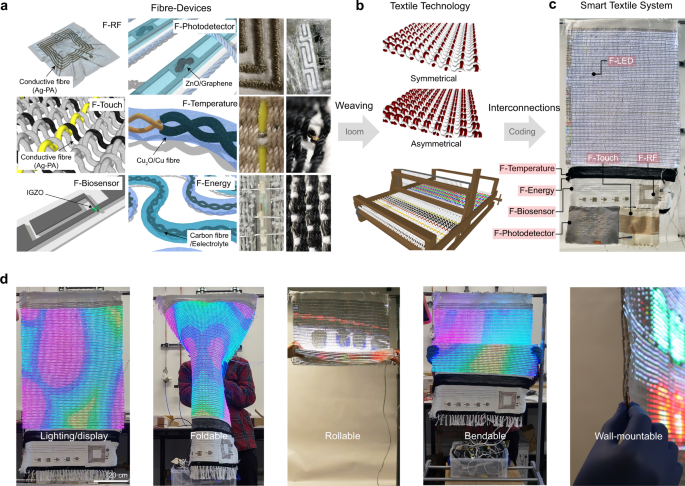

Advanced Curtain Engineering

Modern curtain-based room division systems move far beyond simple hanging fabric to create sophisticated architectural elements. These systems use marine-grade hardware, engineered suspension methods, and smart technology integration to provide functionality that rivals solid dividers. Proper engineering creates curtain systems that control light, sound, and airflow while maintaining elegant aesthetics.

Marine-grade hardware provides durability and load capacity far exceeding standard curtain systems. Engineered suspension distributes fabric weight evenly to prevent sagging and premature wear. Professional curtain systems can cost significantly more than DIY alternatives, with DIY room dividers offering a cost-effective solution where you can create your own for a fraction of the cost compared to custom installations that can run thousands of dollars.

When you’re planning a diy room divider curtain system, understanding the engineering principles behind professional installations helps you achieve similar results at a fraction of the cost. The key lies in selecting appropriate hardware and understanding load distribution principles.

Tension and Suspension Physics

Understanding load distribution and fabric behavior enables curtain systems that function as true architectural elements rather than decorative accessories. Proper tension systems prevent sagging while allowing controlled movement. Cable-based suspension provides invisible support that maintains clean sight lines.

Load distribution calculations ensure hardware can support fabric weight plus wind loads from HVAC systems. Cable tensioning systems provide adjustable support that compensates for fabric stretch over time. Invisible support systems maintain clean aesthetics while providing necessary structural capacity.

Cable Tensioning Systems

Marine-grade hardware creates invisible support systems for heavy fabric dividers that maintain clean aesthetics while providing robust functionality. Aircraft cable and tensioning hardware distribute loads effectively across ceiling structures. Proper installation creates systems that operate smoothly for years without maintenance.

Aircraft cable provides high strength-to-diameter ratio for minimal visual impact. Ceiling-mounted pulleys enable smooth fabric movement while distributing loads to structural elements. Cable tensioners allow precise adjustment to maintain proper fabric positioning.

Weighted Hem Engineering

Various weighting systems control fabric drape and movement to create predictable behavior in different airflow conditions. Removable weight systems allow seasonal adjustments while magnetic integration enables quick attachment to metal elements. Proper weighting prevents billowing while maintaining elegant drape characteristics.

Fabric pockets allow weight adjustment without permanent modifications to curtain panels. Chain weights provide gentle draping while steel shot creates dramatic vertical falls. Magnetic strips enable quick attachment to metal framework elements for temporary configurations.

Smart Fabric Integration

Incorporating technology into curtain-based room dividers enhances functionality through color-changing capabilities and automated control systems. LED integration creates dividers that can change ambiance and visual weight on command. Smart controllers enable programming for different times of day or activities.

LED integration requires fabric selection based on light transmission properties. Smart controllers enable automated responses to time, occupancy, or environmental conditions. Power delivery systems must be planned during initial installation to avoid visible wiring.

Color-Changing LED Integration

Weaving LED strips into fabric creates dividers that can change ambiance and visual weight through programmable lighting effects. This technology transforms static fabric into dynamic architectural elements that respond to changing needs throughout the day. Proper integration maintains fabric drape while providing even light distribution.

Fabric welding creates permanent channels for LED strips without compromising drape characteristics. Light transmission testing ensures even illumination without hot spots or dark areas. Power delivery through ceiling or floor channels eliminates visible wiring while enabling control access.

Modern game rooms are increasingly incorporating smart lighting systems, as indirect LED strips give the space a distinctly modern feel, and has the added benefit of being less likely to cause glare issues on television screens according to Family Handyman, demonstrating how smart fabric integration serves both aesthetic and functional purposes.

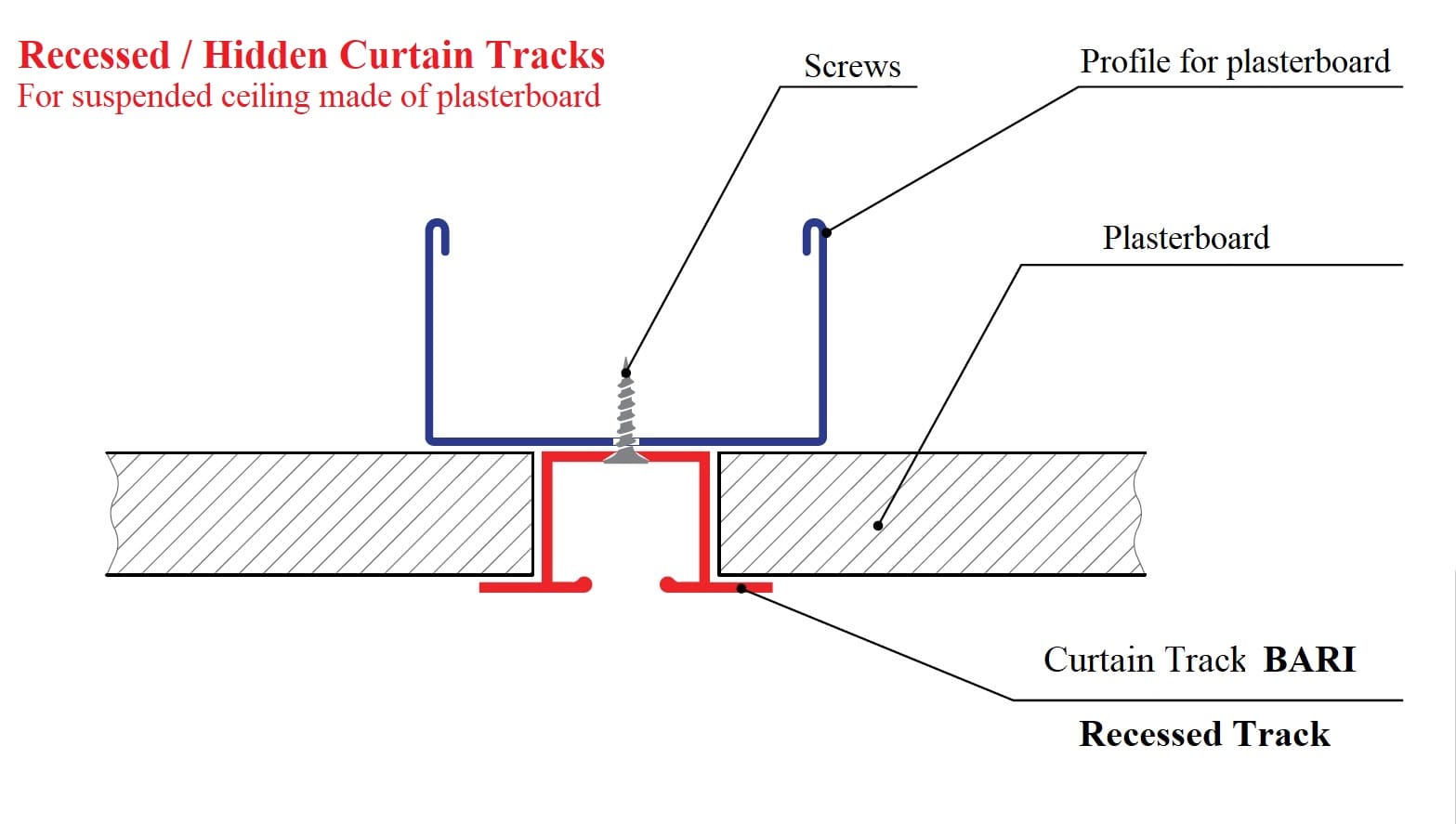

Wall-Integrated Division Systems

Permanent yet removable room dividers that integrate directly with existing wall structures provide sophisticated solutions without major construction requirements. These systems use building structure for support while maintaining removability for rental situations or future changes. Proper integration creates installations that appear built-in while preserving flexibility.

Wall integration utilizes existing structural elements for support without permanent modifications. Removable systems maintain rental compliance while providing functionality of permanent installations. When you’re developing diy room divider wall solutions, understanding how to work with existing structure opens up possibilities that seem impossible at first glance.

Stud-Mounted Track Systems

Utilizing wall framing to support sophisticated sliding and folding divider mechanisms creates smooth operation with professional appearance. Hidden installation techniques conceal hardware while providing robust support for heavy panels. Multi-panel coordination enables complex movement patterns that maximize space efficiency.

Stud mounting distributes loads to building structure rather than relying on drywall anchors. Hidden rail installation maintains clean aesthetics while providing necessary structural support. Multi-panel systems require precise coordination to prevent binding during operation.

Hidden Rail Installation

Concealing track systems within ceiling cavities or wall recesses creates clean aesthetic lines while providing robust support for sliding panels. Routing techniques create flush-mounted installations that appear integrated with building architecture. Proper backing ensures adequate support for operational loads.

Oscillating multi-tools create precise channels for flush-mounted rail installation. Backing boards between joists provide continuous support across entire track length. Weight capacity testing ensures system can handle maximum panel loads plus operational forces.

Multi-Panel Coordination

Synchronizing multiple sliding panels to move in predetermined sequences maximizes space efficiency while preventing operational conflicts. Bypass systems allow panels to slide past each other for complete opening. Numbering systems ensure consistent positioning for optimal function.

Panel overlap calculations ensure complete closure while allowing bypass operation. Bypass brackets enable panels to slide past each other without interference. Soft-stop mechanisms prevent damage from excessive force during operation.

|

Panel Configuration |

Space Efficiency |

Installation Complexity |

Cost Range |

Best Applications |

|---|---|---|---|---|

|

Single Sliding |

50% opening |

Low |

$200-400 |

Small spaces, simple division |

|

Bi-fold |

75% opening |

Medium |

$400-800 |

Medium spaces, frequent access |

|

Multi-panel Bypass |

90% opening |

High |

$800-1500 |

Large spaces, maximum flexibility |

|

Accordion Style |

95% opening |

Medium |

$300-600 |

Irregular spaces, complete closure |

|

Pocket Door Style |

100% opening |

Very High |

$1000-2000 |

Premium installations, invisible storage |

Pressure-Mounted Anchoring

Secure floor-to-ceiling connections without permanent wall modifications use spring tension and friction to create stable installations. Telescoping systems adjust to accommodate seasonal building movement while maintaining secure attachment. Distributed load techniques prevent damage to ceiling and floor surfaces.

Spring tension calculations ensure adequate holding force without surface damage. Telescoping adjustment accommodates seasonal building movement and settling. Load distribution prevents point loading that could damage ceiling or floor materials.

Pressure-mounted systems offer significant advantages over permanent installations, with barn doors becoming increasingly popular as room dividers, and you can install one with a DIY kit from your local hardware store for less than $200 according to This Old House, though pressure-mounted alternatives eliminate the need for permanent wall modifications entirely.

Telescoping Pole Physics

Understanding spring tension and friction coefficients achieves stable vertical support that can be installed and removed without tools. Proper adjustment creates secure attachment that withstands normal operational forces while remaining removable. Safety factors prevent over-tensioning that could cause structural damage.

Spring constant calculations determine required compression for secure attachment. Friction coefficient analysis ensures adequate holding force across different surface materials. Safety factor calculations prevent over-tensioning while maintaining operational security.

Distributed Load Techniques

Spreading weight across multiple contact points prevents ceiling and floor damage while maintaining secure attachment. Protective padding distributes loads while preventing surface marking. Adjustment mechanisms accommodate different ceiling heights and surface irregularities.

Surface area calculations determine minimum contact area for safe pressure distribution. Protective padding prevents surface damage while maintaining friction characteristics. Pressure documentation enables consistent reinstallation after removal.

Magnetic Attachment Innovation

Rare earth magnets provide removable yet secure divider mounting that works with existing metal elements in building structure. Neodymium integration creates instant attachment systems that require no tools or permanent modifications. Safety systems prevent unexpected detachment during normal use.

Neodymium magnets provide exceptional holding force in compact packages suitable for integration. Magnetic receptors can be installed using construction adhesive without permanent structural modifications. Safety tethers provide backup retention in case of magnetic failure or unexpected loads.

Neodymium Integration Strategies

Embedding powerful magnets within divider frames enables instant attachment to metal surfaces while maintaining clean aesthetics. Magnetic mapping identifies existing metal elements that can serve as attachment points. Strength testing ensures adequate holding force for operational requirements.

Metal element mapping identifies existing attachment points without requiring new installations. Magnetic strength testing accounts for air gaps and surface irregularities that reduce holding force. Degradation monitoring ensures continued performance as magnetic strength decreases over time.

A rental apartment with steel door frames and HVAC ducts can utilize neodymium magnets embedded in lightweight aluminum frames to create instantly removable room dividers. By mapping existing metal surfaces and testing magnetic holding strength, renters can create sophisticated space division without violating lease agreements or leaving permanent modifications.

Magnetic Attachment Safety Checklist:

-

Test magnetic strength on actual mounting surfaces

-

Install safety tethers as backup retention

-

Document magnetic degradation over time

-

Use protective padding to prevent surface scratching

-

Calculate safety factors for dynamic loads

-

Plan for easy removal without surface damage

Having a reliable partner becomes essential when these sophisticated room divider projects reveal the need for space preparation or eventual reconfiguration. Jiffy Junk’s comprehensive approach helps Sacramento residents tackle the preparation work that sophisticated installations require – from clearing accumulated items that interfere with proper measurements to removing outdated fixtures that conflict with new systems.

Their white glove service proves particularly valuable when wall-integrated systems reveal hidden storage areas or when seasonal transformations require temporary furniture removal. For businesses experimenting with flexible workspace configurations, Jiffy Junk’s commercial services enable quick space resets as divider strategies evolve, ensuring minimal disruption to operations.

Ready to transform your space with sophisticated room dividers? Contact Jiffy Junk today to prepare your area for installation success.

Final Thoughts

Creating sophisticated DIY room dividers requires understanding psychology, materials science, and engineering principles that go far beyond simple space blocking. Your success depends on planning for the complete lifecycle of your installation – from initial psychological impact through material aging to eventual reconfiguration or disposal.

The most successful projects integrate multiple approaches: psychological principles that make spaces feel comfortable, material selection that ages gracefully, and engineering solutions that provide long-term functionality. Whether you choose IKEA hacks, advanced curtain systems, or wall-integrated solutions, the key lies in understanding how each element contributes to both immediate function and long-term satisfaction.

Successful room divider projects require integration of psychological, material, and engineering considerations rather than focusing on single aspects. Lifecycle planning from initial installation through eventual reconfiguration maximizes value and minimizes waste. Professional preparation and support services enable more sophisticated installations while reducing project risk and complexity.

DIY Room Divider Project Planning Template:

Phase 1: Assessment & Design

-

Measure space dimensions and ceiling height

-

Identify electrical outlets and HVAC considerations

-

Determine primary function (privacy, storage, aesthetic)

-

Set budget parameters including material and labor costs

-

Research local building codes and rental restrictions

Phase 2: Material Selection

-

Calculate material quantities with 10% waste factor

-

Source hardware and fasteners from reputable suppliers

-

Test material samples in actual lighting conditions

-

Verify compatibility with existing decor elements

-

Plan for seasonal adaptation requirements

Phase 3: Installation & Testing

-

Prepare workspace and protect surrounding surfaces

-

Complete structural connections before aesthetic elements

-

Test all moving parts and adjustment mechanisms

-

Document installation process for future modifications

-

Schedule regular maintenance intervals

Advanced Material Comparison for Long-Term Performance:

|

Performance Factor |

Bamboo |

Reclaimed Wood |

Metal Frame + Fabric |

Polycarbonate Panels |

Composite Materials |

|---|---|---|---|---|---|

|

UV Resistance |

Poor (6 months) |

Variable (1-3 years) |

Excellent (10+ years) |

Good (5-8 years) |

Excellent (15+ years) |

|

Moisture Tolerance |

Fair |

Poor to Good |

Excellent |

Excellent |

Excellent |

|

Maintenance Frequency |

Annual |

Bi-annual |

Minimal |

Annual cleaning |

Minimal |

|

Repairability |

Difficult |

Moderate |

Easy |

Moderate |

Difficult |

|

End-of-Life Options |

Compostable |

Repurposable |

Recyclable |

Recyclable |

Limited options |

|

Cost per Square Foot |

$15-25 |

$20-40 |

$30-60 |

$25-45 |

$40-80 |