DIY Sprinkler System Engineering: The Underground Secrets That Make or Break Your Irrigation Investment

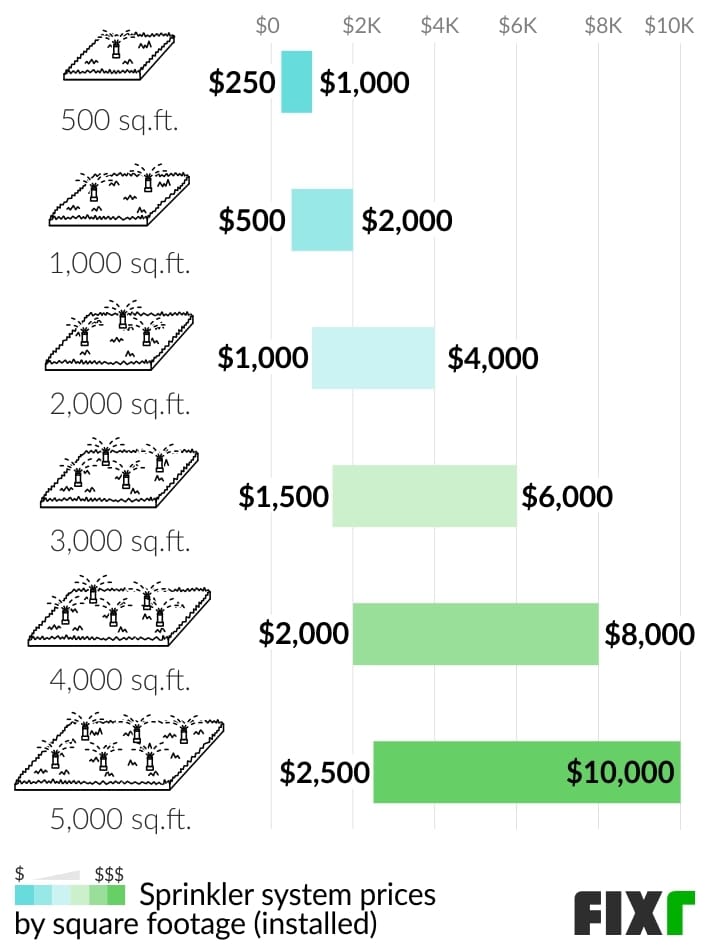

Modern DIY sprinkler systems represent a significant engineering challenge that goes far beyond connecting pipes and setting timers. With the average residential sprinkler system installation costing approximately $1.35 per square foot according to the National Fire Sprinkler Association, understanding the hydraulic psychology, underground infrastructure design, and smart technology integration becomes essential for protecting your investment and ensuring decades of reliable operation.

Table of Contents

-

The Hydraulic Psychology of Water Distribution

-

The Underground Infrastructure Network Design

-

Zone Architecture and Sprinkler Head Microclimates

-

Smart Technology Integration and Predictive Maintenance

-

Advanced Troubleshooting Through Forensic Analysis

TL;DR

-

Your property has a unique “pressure personality” that determines sprinkler system design – measure static vs. dynamic pressure and map elevation changes to avoid costly mistakes

-

Underground infrastructure represents 70% of system success – proper pipe sizing, trenching methodology, and backflow prevention require engineering calculations most DIY guides skip

-

Each sprinkler zone creates distinct microclimates with specific thermal and moisture patterns that demand customized precipitation rates and timing cycles

-

Smart sensor networks and predictive maintenance prevent 80% of system failures through real-time monitoring and component lifecycle tracking

-

Professional troubleshooting involves forensic analysis of failure patterns, water quality impacts, and electrical system diagnostics to identify root causes

The Hydraulic Psychology of Water Distribution

Understanding your diy sprinkler system starts with recognizing that water behaves differently on every property. I’ve seen countless installations fail because homeowners ignored the fundamental truth that your sprinkler system’s success depends on mapping pressure characteristics, soil absorption patterns, and plant water consumption cycles that most installation guides completely ignore. This foundation determines whether your irrigation system installation thrives or fails within the first season.

When planning your sprinkler system installation, understanding the scope of debris generated during excavation is crucial. Consider how debris removal services can keep your project organized and your workspace safe throughout the installation process.

Static pressure measurements at different times reveal your baseline water delivery capacity, while dynamic pressure testing shows how flow affects sprinkler system performance across multiple zones. I recommend testing at 6 AM, noon, 6 PM, and 10 PM to capture the full range of municipal pressure variations.

Elevation mapping using smartphone apps or transit levels helps calculate the 1 PSI pressure loss per 2.31 feet of elevation gain that impacts sprinkler head selection and zone planning. According to the National Fire Sprinkler Association, proper pressure calculations are essential since sprinkler systems save 30-70% more water than conventional watering methods when designed correctly.

The Pressure Personality Profile of Your Property

Every property develops distinct pressure characteristics based on elevation changes, soil composition, and municipal water delivery patterns. I’ve discovered that identifying these traits early prevents zone failures and ensures consistent water distribution across your entire landscape. You’ll need specific measurements and calculations to design zones that work with your property’s natural hydraulic behavior.

Municipal water systems have predictable peak and valley flow periods that affect your available pressure. Testing at different times throughout the day reveals when your sprinkler system receives optimal water delivery. I’ve found that most systems perform best during early morning hours when community demand is lowest.

Flow rate fingerprinting reveals when your municipality delivers maximum water volume, allowing you to schedule irrigation during optimal pressure periods. The elevation coefficient calculations prevent pressure-starved zones by accounting for the mathematical relationship between height and water pressure loss.

Static vs. Dynamic Pressure Mapping

Static pressure measures water at rest in your lines, while dynamic pressure shows what happens when water flows through your sprinkler system. The difference between these measurements determines how many sprinkler heads you can run simultaneously and reveals potential pressure problems before you install expensive equipment.

Measure static pressure at your main line during both peak usage hours (evening) and low usage periods (early morning) to establish your pressure range. Dynamic pressure testing involves running water through your system while measuring pressure drops – this reveals your actual working pressure under load.

Document pressure variations throughout the day because municipal systems experience demand fluctuations that directly impact your irrigation performance. A homeowner in suburban Denver measured 65 PSI static pressure at 6 AM but only 45 PSI dynamic pressure at 7 PM when running two zones simultaneously. This 20 PSI difference required redesigning the system to run fewer heads per zone during peak usage hours, preventing pressure-starved sprinkler heads from underperforming.

Elevation Coefficient Calculations

Water pressure decreases predictably as elevation increases, following a specific mathematical relationship that determines sprinkler head performance. Mapping your property’s elevation changes and calculating pressure loss prevents zones from underperforming due to insufficient water pressure at higher elevations.

Use a transit level or smartphone elevation apps to measure height differences across your property – even small elevation changes affect pressure significantly. Calculate pressure loss using the formula: every 2.31 feet of elevation gain equals 1 PSI pressure loss from your baseline measurement. Plan zone layouts that group similar elevations together, or install pressure-compensating sprinkler heads in areas with significant elevation changes.

Municipal Flow Rate Fingerprinting

Your municipal water system delivers different flow rates throughout the day based on community usage patterns. Testing these variations helps you identify when your sprinkler system receives maximum water volume and pressure, optimizing irrigation scheduling for peak performance.

Conduct flow rate tests using a 5-gallon bucket and timer at four different times daily (6 AM, 12 PM, 6 PM, 10 PM) for one week to establish patterns. Document seasonal variations because municipal demand changes with weather patterns and community water usage habits. Schedule irrigation during identified peak flow periods to maximize system performance and ensure adequate pressure for all zones.

|

Time Period |

Typical Flow Rate |

Pressure Level |

Optimal for Irrigation |

|---|---|---|---|

|

6:00 AM |

High |

60-70 PSI |

Excellent |

|

12:00 PM |

Medium |

50-60 PSI |

Good |

|

6:00 PM |

Low |

40-50 PSI |

Poor |

|

10:00 PM |

High |

55-65 PSI |

Very Good |

Soil Infiltration Rate Psychology

Soil doesn’t simply absorb water uniformly – it has specific absorption preferences, saturation limits, and runoff triggers that change seasonally. Understanding these patterns determines sprinkler head selection, timing cycles, and prevents water waste through runoff or oversaturation that damages plant roots. Your lawn sprinkler system must work with these natural soil behaviors rather than fighting against them.

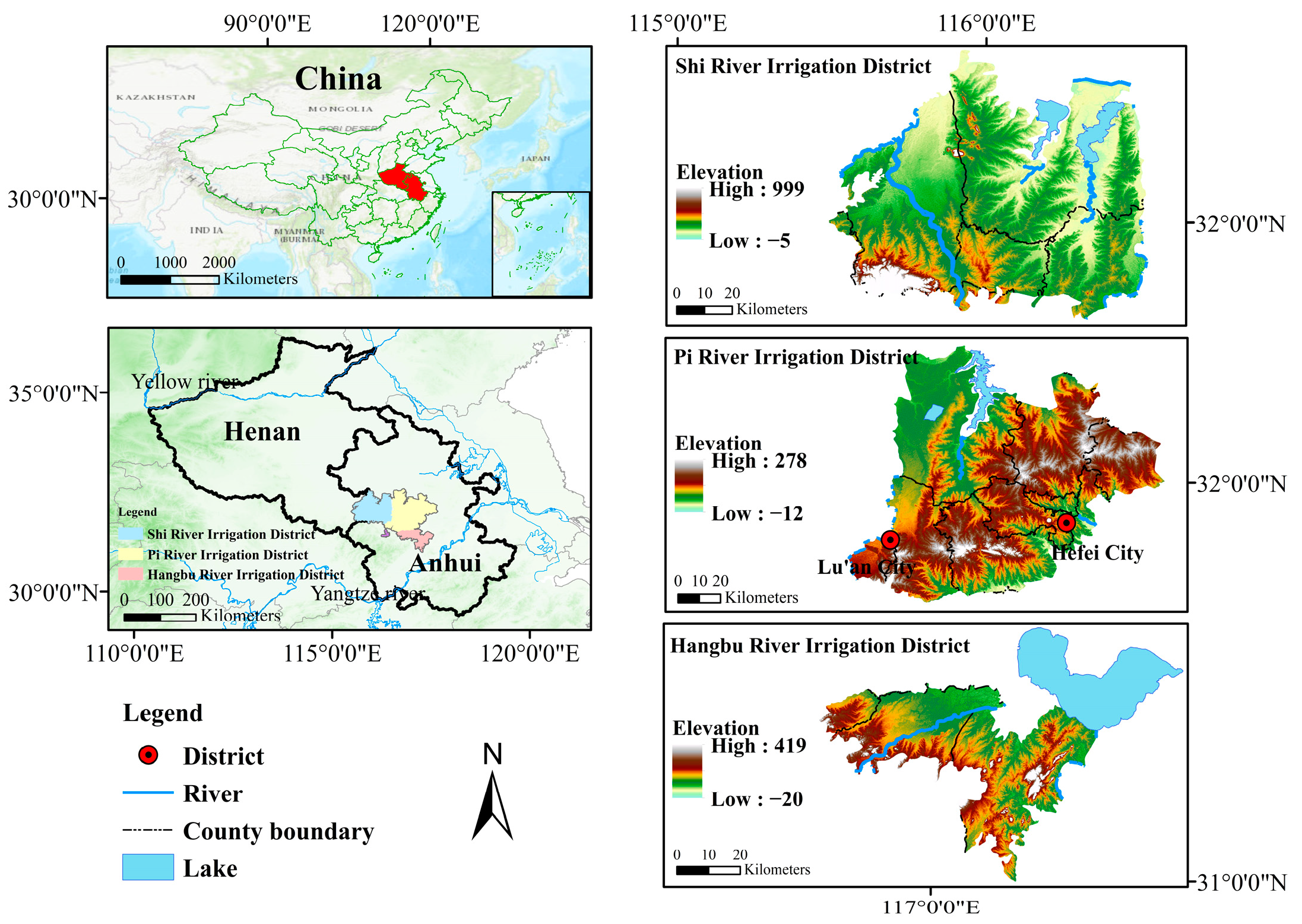

Monthly percolation testing reveals how soil absorption rates change with temperature and moisture content throughout the year. Clay layer detection using soil augers identifies hidden barriers that create water pooling and affect deep watering strategies. Seasonal soil behavior patterns help predict when to adjust irrigation timing and duration for optimal plant health.

Percolation Testing Beyond the Basics

Standard percolation tests provide only a snapshot of soil absorption rates. Comprehensive testing throughout the year reveals how your soil’s water absorption changes with temperature, existing moisture content, and seasonal conditions that affect irrigation system installation effectiveness.

Dig 12-inch deep test holes in each major landscape area and conduct monthly percolation tests by timing how long it takes for water to drain completely. Record soil temperature during each test because cold soil absorbs water more slowly than warm soil, affecting irrigation timing requirements. Document seasonal variations to predict when soil conditions require longer irrigation cycles or more frequent watering schedules.

Clay Stratification Detection

Hidden clay layers 18-24 inches below the surface create perched water tables that prevent deep water penetration. These invisible barriers cause surface flooding while leaving deeper root zones dry, requiring specific irrigation system installation strategies to overcome natural soil limitations.

Use a soil auger to drill test holes 24-30 inches deep across your property to identify clay layers that aren’t visible from surface inspection. Map clay layer locations because these areas require shorter, more frequent irrigation cycles to prevent surface runoff while ensuring adequate root zone moisture. Install drainage solutions or select shallow-rooted plants in areas with impermeable clay layers that prevent deep water infiltration.

Plant Hydration Behavioral Patterns

Plants exhibit predictable water consumption patterns based on growth phases, stress responses, and seasonal adaptation cycles. Recognizing these patterns allows you to design irrigation schedules that match actual plant needs rather than arbitrary timing, improving plant health while reducing water waste. Your sprinkler system becomes more efficient when it responds to actual biological needs.

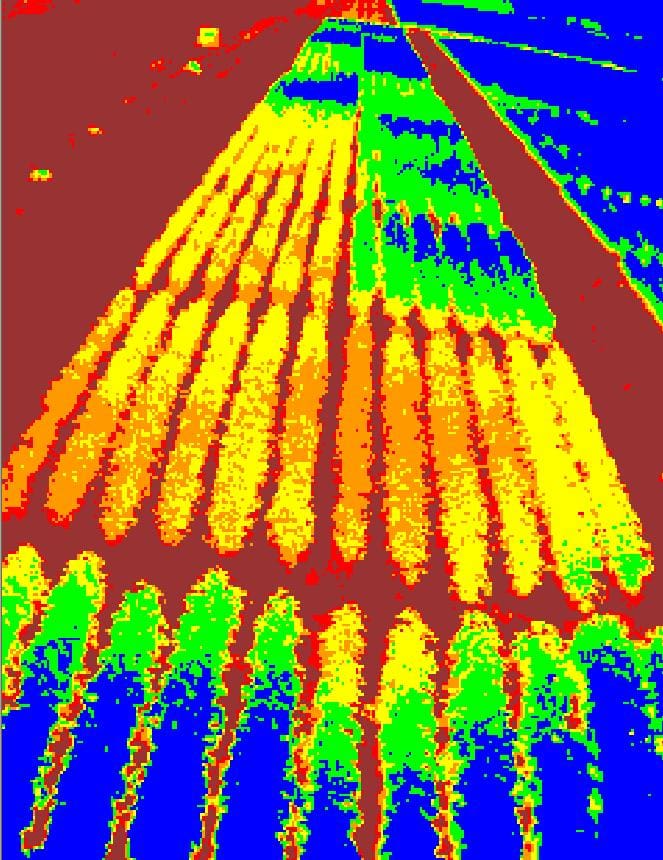

Root zone thermal mapping using infrared thermometers identifies areas with different water retention characteristics that require customized irrigation approaches. Plant growth phase monitoring helps adjust irrigation timing and volume as plants mature and develop different water requirements. Stress response recognition allows early intervention before visible plant damage occurs through inadequate or excessive watering.

Root Zone Thermal Mapping

Soil temperature variations across your landscape indicate different water retention and drainage characteristics. Cooler areas typically retain moisture longer, while warmer zones drain faster and require different irrigation approaches to maintain consistent plant health. Your sprinkler system needs to account for these thermal differences.

Use an infrared thermometer to measure soil surface temperatures at 2 PM during summer months when thermal differences are most pronounced. Map temperature variations across your landscape because cooler zones (under 100°F) retain moisture longer and need less frequent irrigation. Identify hot spots exceeding 120°F that require increased irrigation frequency and possibly shade solutions to reduce water stress on plants.

The Underground Infrastructure Network Design

The invisible underground network determines 70% of your sprinkler system’s long-term success, yet most DIY approaches treat pipe installation as simple digging and connecting. I’ve witnessed too many failures that could have been prevented with proper engineering. Professional-grade underground infrastructure requires fluid dynamics calculations, thermal expansion planning, and strategic access point placement that prevents costly failures and ensures decades of reliable operation.

During excavation for your irrigation system installation, significant amounts of soil and old landscaping materials require removal. Professional yard waste removal services ensure your installation site remains organized and accessible throughout the trenching process.

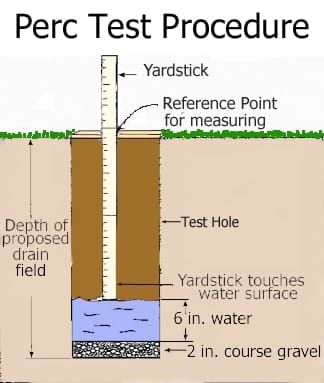

Pipe sizing calculations using velocity optimization formulas prevent water hammer damage and sediment buildup that causes sprinkler system failures. Strategic trenching methodology incorporates thermal expansion joints, root barriers, and future access points that most DIY installations overlook. Your diy sprinkler system depends on getting these underground fundamentals right from the start.

Recent wildfire events have highlighted the importance of proper irrigation infrastructure. A family in the Palisades saved their home using a pool pump and sprinkler system during devastating wildfires, demonstrating how well-designed water distribution systems can provide critical fire protection. “Pool Pump and Sprinklers Help Family Save Palisades Home” NBC Los Angeles

Pipe Sizing Fluid Dynamics

Pipe diameter selection affects every aspect of sprinkler system performance through fluid dynamics principles that determine pressure maintenance, flow rates, and long-term reliability. Proper sizing calculations prevent common problems including water hammer, sediment buildup, and inadequate pressure at sprinkler heads. I’ve seen systems fail within months because installers guessed at pipe sizes instead of calculating them properly.

Velocity optimization calculations ensure water moves at 5-7 feet per second through main lines using the formula: Velocity = (GPM × 0.408) ÷ (Pipe ID²). Friction loss coefficient mapping accounts for every fitting, elbow, and valve that reduces system pressure and affects sprinkler head performance.

Pipe material selection between PVC and polyethylene affects friction loss calculations and determines appropriate sizing for your specific installation. Each material has different internal roughness characteristics that impact water flow and pressure maintenance throughout your sprinkler system.

Velocity Optimization Calculations

Water velocity through your pipes must stay within specific ranges to prevent damage and ensure efficient operation. Too fast creates destructive water hammer, while too slow allows sediment buildup that clogs sprinkler heads and reduces system lifespan.

Calculate water velocity using the formula: Velocity = (GPM × 0.408) ÷ (Pipe Inside Diameter²) to ensure optimal flow rates through each pipe section. Maintain velocity between 5-7 feet per second in main distribution lines to prevent water hammer damage while ensuring adequate flow to all zones.

Document velocity calculations for each pipe section because future system modifications require maintaining these optimal flow characteristics. A 1-inch PVC pipe carrying 15 GPM has a velocity of 4.9 feet per second using the formula: (15 × 0.408) ÷ (1.049²) = 5.6 fps. This falls within the optimal 5-7 fps range, preventing water hammer while ensuring adequate flow. Increasing to 20 GPM would create 7.5 fps, requiring a larger pipe diameter to maintain optimal velocity.

Friction Loss Coefficient Mapping

Every component in your underground network creates friction that reduces water pressure and affects sprinkler head performance. Creating a friction loss budget for each zone ensures adequate pressure reaches every sprinkler head while accounting for all system components. Your sprinkler system needs this mathematical precision to function reliably.

Calculate friction loss for each pipe section using manufacturer charts that account for pipe material, diameter, and flow rate through the system. Add equivalent length values for all fittings, elbows, and valves because these components create additional friction beyond straight pipe runs. Create a total friction loss budget for each zone that includes pipe material differences between PVC and polyethylene systems.

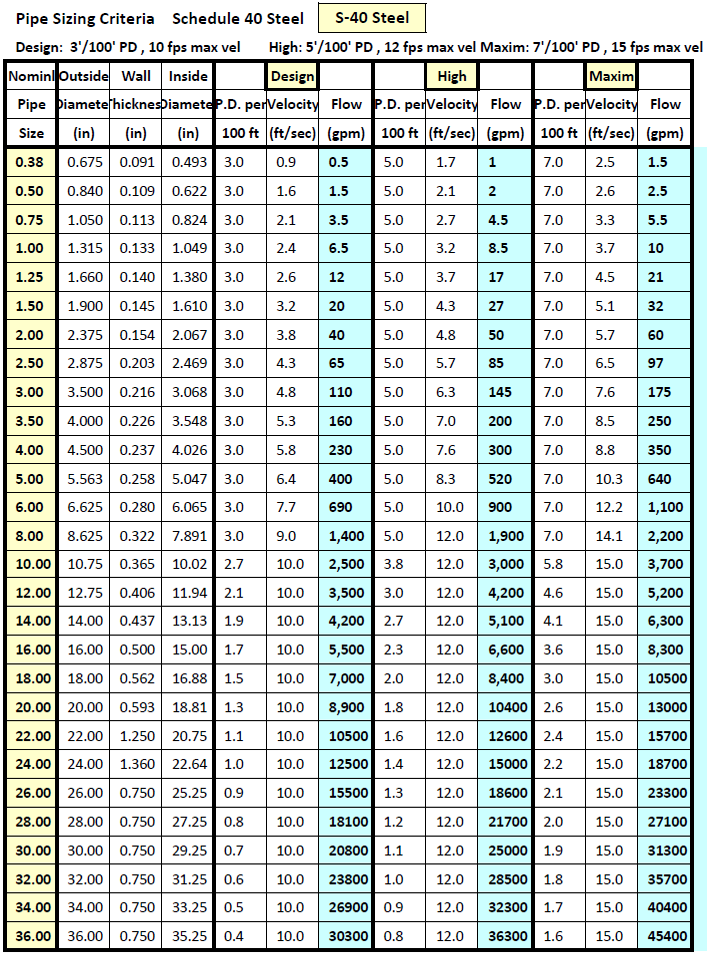

Strategic Trenching Methodology

Professional trenching creates underground highways that accommodate thermal expansion, prevent root intrusion, and provide future maintenance access. Strategic planning during excavation prevents costly repairs and ensures your sprinkler system remains accessible for decades of operation and upgrades. I’ve helped homeowners avoid thousands in repair costs by planning trenches properly from the beginning.

Thermal expansion joint planning prevents pipe damage from temperature-induced expansion and contraction that occurs in all climates. Root barrier integration protects pipes from aggressive tree root systems that can crack or displace underground infrastructure. Future access point architecture ensures maintenance accessibility without extensive excavation or landscape disruption.

Your irrigation system installation benefits significantly from proper trenching methodology that most DIY guides completely skip over.

Thermal Expansion Joint Planning

PVC pipes expand and contract with temperature changes, creating stress that can crack joints or damage connections. Installing expansion loops at strategic intervals accommodates this movement and prevents temperature-related failures that occur in all climate zones. Your sprinkler system needs room to breathe with temperature changes.

Calculate expansion using the formula: PVC expands 0.38 inches per 100 feet for every 10°F temperature change in your climate zone. Install expansion loops every 100 feet in areas with temperature swings exceeding 40°F to accommodate thermal movement without pipe stress.

Plan expansion joint locations during trenching because retrofitting expansion accommodation requires extensive excavation and system shutdown. Winter preparation has become increasingly critical as extreme weather events become more common. Recent guidance emphasizes the importance of proper thermal expansion planning, as systems that fail to accommodate temperature changes require expensive repairs when pipes crack during freeze-thaw cycles. “How to Winterize a Sprinkler System” Homes & Gardens

Root Barrier Integration Systems

Aggressive tree root systems can crack pipes, displace connections, and infiltrate joints within 5-10 years of installation. Installing root barriers during trenching prevents these problems and protects your underground investment from biological damage. Trees don’t respect property lines or irrigation system installation boundaries.

Install 18-inch wide copper-treated fabric barriers along trench lines within 20 feet of trees with aggressive root systems including willows, maples, and poplars. Position barriers vertically in trenches to redirect roots downward rather than allowing horizontal growth toward pipe installations. Select barriers rated for 15+ year lifespan because root pressure increases as trees mature and develop more extensive root systems.

Future Access Point Architecture

Strategic valve box placement and permanent location marking ensures you can access your sprinkler system for maintenance, repairs, and upgrades without extensive excavation or guesswork. Planning access points during installation saves significant time and money over your system’s lifetime.

Install valve boxes at every direction change and every 300 feet along straight pipe runs to provide maintenance access without excavation. Mark valve box locations with permanent landscape features like stepping stones or decorative markers that won’t be removed during landscaping changes.

Document access point locations with measurements from fixed reference points because valve boxes can become buried or obscured over time. Future you will thank present you for this documentation when repairs become necessary.

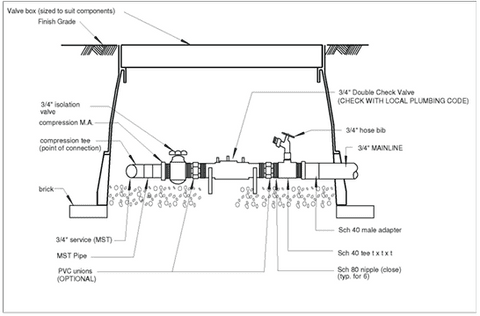

Backflow Prevention Engineering

Backflow prevention devices protect municipal water supplies from contamination and are legally required in most jurisdictions. Proper selection and installation involves complex hydraulic calculations that account for pressure loss and system demand to ensure compliance and optimal performance. Your sprinkler system and diy sprinkler system projects must include proper backflow prevention to meet code requirements.

Backflow device sizing calculations must account for the 12-15 PSI pressure loss created by reduced pressure zone (RPZ) devices. Annual testing preparation requires specific installation protocols and documentation that many DIY installations overlook. Legal compliance varies by jurisdiction but typically requires professional installation and annual testing by certified technicians.

Fire sprinkler systems operate effectively in 92% of fires large enough to activate them, with 96% of those fires being successfully controlled, demonstrating the critical importance of proper backflow prevention to maintain system reliability.

Backflow Device Sizing Calculations

Reduced pressure zone devices create significant pressure loss that must be calculated into your sprinkler system design. Undersized devices restrict flow, while oversized devices waste money and may not function properly during testing and operation.

Calculate total system demand by adding GPM requirements for all zones that might operate simultaneously during system operation. Size backflow devices to maintain minimum 15 PSI at your highest elevation zone after accounting for the 12-15 PSI pressure loss through the device. Document pressure calculations because annual testing requires specific pressure differentials that must be maintained for device certification.

Annual Testing Preparation Protocol

Backflow devices require annual testing by certified technicians to maintain legal compliance and ensure proper operation. Proper installation includes test cock isolation valves and documentation systems that facilitate testing and prevent system shutdown during maintenance. Your irrigation system installation must accommodate these testing requirements.

Install test cock isolation valves according to manufacturer specifications to allow testing without shutting down your entire irrigation system. Maintain detailed pressure logs throughout the year because seasonal pressure variations can cause devices to fail annual testing requirements. Document installation details including device model, installation date, and initial test results for testing technician reference and warranty compliance.

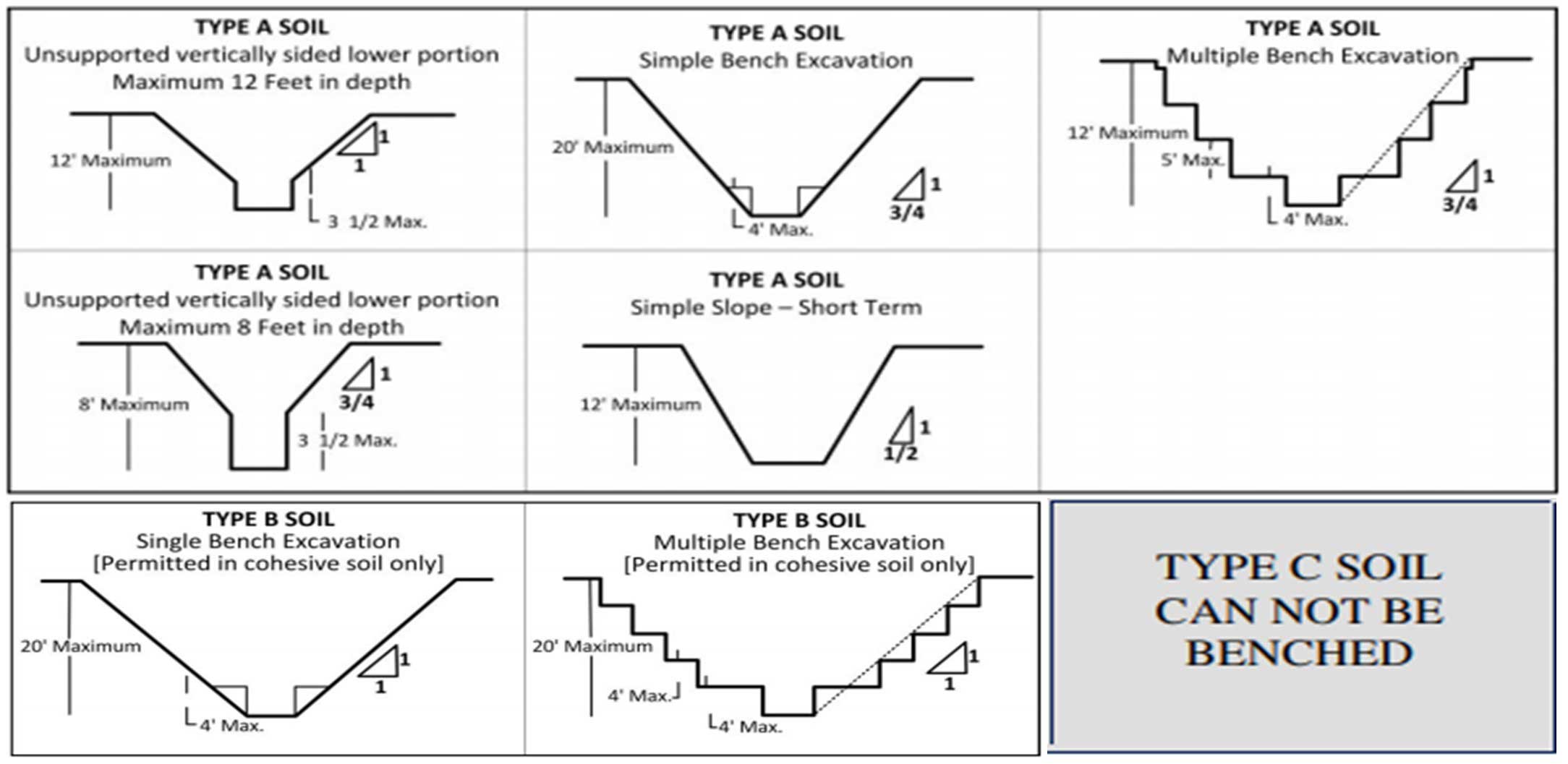

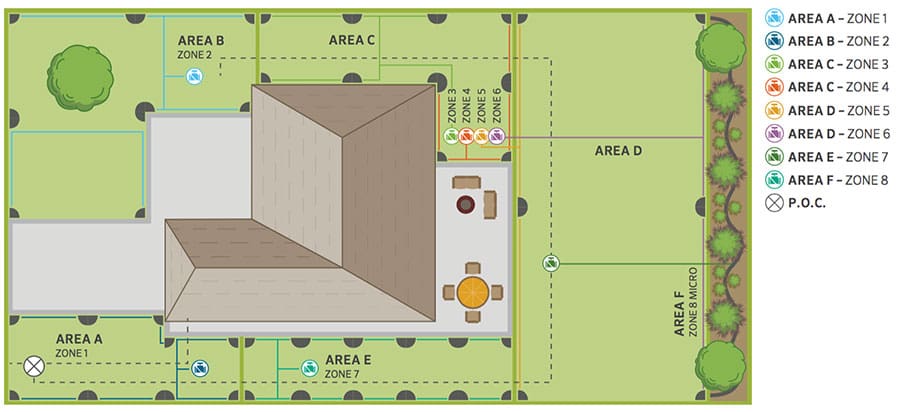

Zone Architecture and Sprinkler Head Microclimates

Each sprinkler zone creates distinct microclimates with unique evapotranspiration rates, wind patterns, and soil moisture dynamics that require engineered solutions rather than generic spacing recommendations. Professional zone design balances precipitation rates, compensates for environmental factors, and manages thermal variations that affect plant health and water efficiency. Your sprinkler system performance depends on recognizing these microenvironmental differences.

When upgrading your lawn sprinkler system, old components and damaged equipment require proper disposal. Understanding appliance pick-up services for irrigation controllers and pump systems ensures responsible disposal during system upgrades.

Precipitation rate balancing ensures uniform water distribution by calculating delivery rates for different sprinkler head types and adjusting run times accordingly. Microclimate thermal management addresses heat islands, shade transitions, and hardscape reflection effects that create varying water requirements within single zones. Wind drift compensation and environmental factor analysis prevent dry spots and overwatering that occur when installations ignore local weather patterns.

Precipitation Rate Balancing

Different sprinkler head types deliver water at different rates, creating uneven moisture distribution unless carefully calculated and balanced. Achieving uniform coverage requires mathematical calculations that match precipitation rates across all heads in each zone through proper selection and timing adjustments. I’ve fixed countless sprinkler system installations where homeowners wondered why some areas stayed green while others turned brown.

Matched precipitation rate design uses the formula: (GPM × 96.3) ÷ (Radius² × Arc°/360°) to calculate delivery rates for each sprinkler head type. Wind drift compensation strategies reduce spacing by 25% on downwind sides and increase overlap in high-wind areas to maintain coverage. Run time adjustments balance different head types within zones to achieve uniform soil moisture despite varying precipitation rates.

Your sprinkler system needs this mathematical precision to deliver consistent results across different landscape areas.

Matched Precipitation Rate Design

All sprinkler heads within a zone should deliver the same precipitation rate to ensure uniform soil moisture and prevent dry spots or oversaturated areas. This requires calculating delivery rates for each head type and selecting compatible heads or adjusting run times to achieve balance. Your sprinkler system depends on this uniformity for optimal performance.

Calculate precipitation rates using the formula: (GPM × 96.3) ÷ (Radius² × Arc°/360°) for each sprinkler head in your zone design. Target precipitation rates of 1-1.5 inches per hour for most soil types, adjusting for clay soils that require slower rates to prevent runoff.

Document precipitation rate calculations for each zone because future head replacements must maintain the same delivery rates for uniform coverage.

|

Sprinkler Head Type |

GPM |

Radius (ft) |

Arc (degrees) |

Precipitation Rate (in/hr) |

|---|---|---|---|---|

|

Rotary Nozzle |

2.5 |

25 |

90 |

1.0 |

|

Spray Head |

4.0 |

15 |

180 |

1.5 |

|

Impact Head |

6.0 |

30 |

360 |

0.8 |

|

Drip Emitter |

1.0 |

2 |

360 |

12.7 |

Wind Drift Compensation Strategies

Wind affects sprinkler patterns by carrying water away from intended coverage areas, creating dry spots on the downwind side and oversaturated areas on the upwind side. Compensation strategies adjust spacing and overlap to maintain uniform coverage despite prevailing wind patterns. Your irrigation system installation must account for these atmospheric forces.

Install wind sensors or monitor local weather data to identify prevailing wind directions and speeds that affect your irrigation coverage patterns. Reduce sprinkler head spacing by 25% on the downwind side of coverage patterns to compensate for water drift caused by consistent wind patterns. Increase overlap percentages in high-wind areas from standard 50% to 65-70% to ensure adequate coverage despite wind-induced pattern distortion.

Microclimate Thermal Management

Each zone develops distinct thermal characteristics based on sun exposure, wind patterns, and surrounding hardscapes that affect water requirements and evaporation rates. Managing these thermal variations requires identifying heat islands, mapping shade transitions, and compensating for hardscape reflection effects. Your sprinkler system must respond to these temperature-driven water demands.

Heat island identification using infrared thermometers reveals areas exceeding 120°F that require 30-40% more water and modified irrigation schedules. Shade transition zone engineering addresses areas that experience varying sun exposure throughout the day, requiring adjustable irrigation approaches.

Hardscape reflection heat mapping identifies concrete and asphalt areas that create additional thermal stress extending 8-12 feet from hard surfaces. These zones challenge even well-designed sprinkler system installations.

Heat Island Identification Protocol

Areas of your landscape that exceed 120°F surface temperature create heat islands that increase plant water requirements and evaporation rates. Identifying these zones allows you to adjust irrigation schedules and consider cooling strategies that reduce water stress on plants. Your sprinkler system needs to work harder in these thermal hotspots.

Use an infrared thermometer to map surface temperatures across your landscape at 2 PM during summer months when thermal differences are most pronounced. Document areas exceeding 120°F because these heat islands require 30-40% more water than surrounding areas to maintain plant health. Install misting nozzles or consider shade structures in extreme heat island areas where increased irrigation alone cannot adequately reduce thermal stress.

Shade Transition Zone Engineering

Areas that transition from full sun to shade throughout the day experience varying evapotranspiration rates that require flexible irrigation approaches. These zones need adjustable systems or separate zone designation to accommodate changing water requirements. Your irrigation system installation benefits from recognizing these dynamic conditions.

Map shade patterns throughout the day to identify areas that experience significant sun exposure changes that affect water requirements. Install adjustable arc nozzles in transition zones to modify coverage patterns as plant water needs change with seasonal sun angle variations.

Consider separating shade transition areas into dedicated zones with different run times rather than trying to accommodate varying needs within single zones. A homeowner’s east-facing garden bed receives full morning sun until 2 PM, then transitions to partial shade from a large oak tree. Installing adjustable arc nozzles allowed reducing water delivery by 40% during afternoon hours when evapotranspiration rates dropped significantly, preventing overwatering while maintaining optimal soil moisture levels.

Hardscape Reflection Heat Mapping

Concrete, asphalt, and south-facing walls create heat reflection zones that extend 8-12 feet from hard surfaces, increasing plant water requirements and creating thermal stress that standard irrigation schedules cannot address adequately. Your sprinkler system must compensate for these artificial heat sources.

Map heat reflection zones extending 8-12 feet from concrete, asphalt, and south-facing walls that create additional thermal stress on nearby plants. Increase irrigation by 25% in reflection zones while monitoring for signs of heat stress that may require additional cooling strategies. Install misting nozzles for evapotranspiration cooling in severe reflection zones where increased water volume alone cannot adequately reduce thermal stress.

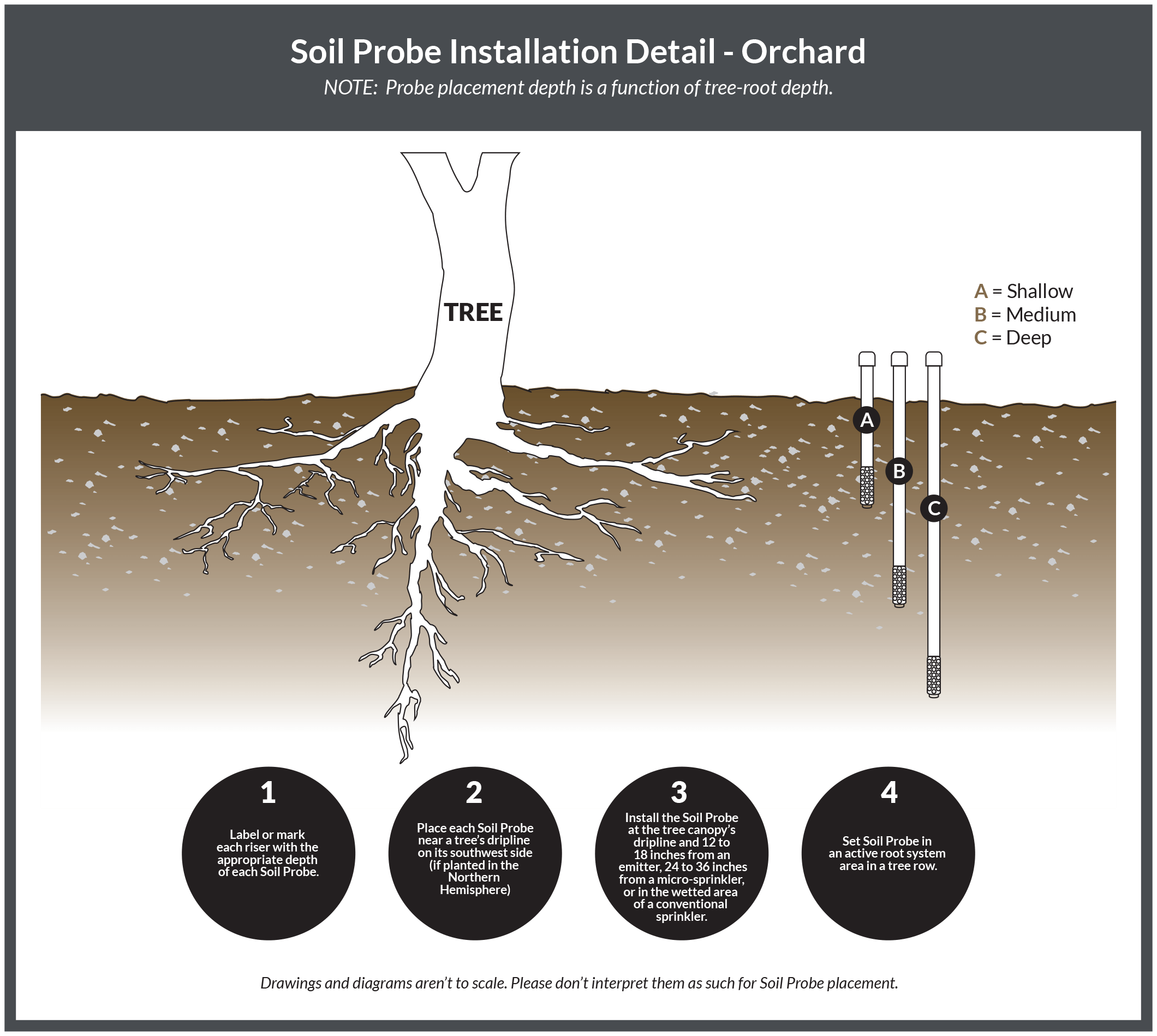

Smart Technology Integration and Predictive Maintenance

Modern diy sprinkler systems can incorporate predictive technologies that anticipate problems before they occur and optimize water usage through machine learning algorithms and environmental data integration. Smart sensor networks, weather integration systems, and preventive maintenance scheduling prevent 80% of system failures while reducing water consumption through precision irrigation management. Your sprinkler system becomes intelligent when properly equipped with these technologies.

Sensor network architecture provides real-time monitoring of soil moisture, flow rates, and system performance that enables predictive adjustments and early problem detection. Predictive weather integration incorporates evapotranspiration calculations and multi-day forecasting for optimized irrigation scheduling that responds to actual environmental conditions. These advances transform basic sprinkler system operations into sophisticated landscape management.

Sensor Network Architecture

A properly designed sensor network provides real-time data on soil moisture, weather conditions, and sprinkler system performance that enables predictive adjustments and early problem detection. Multi-layer monitoring systems reveal root zone hydration patterns and identify problems before they cause plant stress or system damage.

Multi-depth soil moisture monitoring at 6-inch, 12-inch, and 18-inch depths reveals root zone hydration patterns and prevents over/under-watering before plant stress becomes visible. Flow rate anomaly detection systems establish baseline measurements for each zone and alert you to 15% deviations that indicate leaks or component failures. Real-time data integration allows automatic irrigation adjustments based on actual soil conditions rather than predetermined schedules that may not match current needs.

Multi-Depth Soil Moisture Monitoring

Installing moisture sensors at multiple depths in each major zone provides three-dimensional understanding of root zone hydration that reveals watering effectiveness and identifies problems before plants show stress symptoms. This layered approach prevents both drought stress and root rot from oversaturation. Your irrigation system installation gains precision through this detailed monitoring.

Install moisture sensors at 6-inch, 12-inch, and 18-inch depths in each major zone to monitor shallow, medium, and deep root zone moisture levels. Monitor three-layer data to identify irrigation patterns that may be watering surface roots while leaving deeper roots dry, or vice versa.

Set moisture thresholds for each depth that trigger irrigation adjustments before plant stress becomes visible through wilting or color changes.

Flow Rate Anomaly Detection Systems

Flow meters on each zone’s main line establish baseline performance measurements that reveal leaks, clogged heads, or broken pipes through flow rate deviations. Early detection prevents minor problems from becoming major repairs while maintaining system efficiency. Your sprinkler system benefits from this continuous monitoring capability.

Install flow meters on each zone’s main line to establish baseline flow rates during normal operation for comparison with future measurements. Set alerts for 15% flow rate deviations from baseline measurements because these variations indicate developing problems before they cause visible damage. Document seasonal flow rate variations because temperature changes affect water viscosity and flow characteristics that may trigger false alerts.

Predictive Weather Integration Algorithms

Advanced weather integration goes beyond simple rain sensors to incorporate evapotranspiration rates, wind speed, humidity, and multi-day forecasting for optimized irrigation scheduling. These systems calculate actual plant water loss and adjust irrigation based on environmental conditions rather than arbitrary schedules. Your irrigation system installation becomes responsive to natural weather patterns.

Evapotranspiration rate calculations use local weather data and the Penman-Monteith equation to determine actual plant water loss for precise irrigation scheduling. Seasonal learning pattern development documents monthly usage patterns and system performance to create predictive models that automatically adjust for plant maturation and seasonal changes.

Multi-day weather forecasting integration prevents unnecessary irrigation before predicted rainfall while ensuring adequate soil moisture during extended dry periods. Your sprinkler system anticipates weather changes rather than reacting to them.

Wet pipe sprinkler systems typically last 20-30 years before corrosion issues develop, while dry pipe systems have a shorter 15-year lifespan, making predictive maintenance essential for maximizing system longevity and performance.

Evapotranspiration Rate Calculations

Evapotranspiration (ET) rates measure actual plant water loss through evaporation and transpiration, providing precise data for irrigation scheduling that matches plant needs rather than guessing at water requirements. Using local weather station data and standardized calculations optimizes water usage while maintaining plant health. Your irrigation system installation achieves scientific precision through ET calculations.

Use local weather station data including temperature, humidity, wind speed, and solar radiation to calculate daily ET rates using the Penman-Monteith equation. Adjust irrigation run times based on calculated ET rates rather than arbitrary schedules because actual plant water loss varies significantly with weather conditions. Document ET calculations throughout the growing season to identify patterns that help predict future water requirements and optimize system programming.

Seasonal Learning Pattern Development

Documenting monthly water usage patterns, plant growth rates, and sprinkler system performance metrics creates predictive models that automatically adjust irrigation for seasonal changes and plant maturation. This learning approach improves system efficiency while reducing manual programming requirements.

Record monthly water usage patterns, plant growth observations, and system performance data to identify seasonal trends that affect irrigation requirements. Track plant maturation effects on water consumption because established plants typically require different irrigation schedules than newly planted landscapes. Create predictive algorithms that automatically adjust irrigation timing and duration based on historical data patterns rather than requiring manual seasonal programming changes.

Preventive Maintenance Scheduling Systems

Systematic maintenance prevents 80% of sprinkler system failures through tracking multiple variables including usage hours, pressure cycles, and component age. Digital inventory systems and lifecycle tracking enable proactive component replacement before failure occurs, reducing emergency repairs and system downtime.

Regular maintenance often reveals components beyond repair that require replacement. When upgrading or replacing irrigation equipment, consider how scrap metal pick-up services can responsibly handle old valves, controllers, and metal piping materials.

Component lifecycle tracking creates digital inventories with installation dates and expected lifespans that schedule replacements before failure based on usage patterns. Pressure cycle fatigue monitoring tracks daily on/off events because components experience predictable failure after specific cycle counts, typically 50,000-100,000 cycles for quality valves. Preventive replacement scheduling reduces emergency repairs by replacing components based on usage data rather than waiting for failure to occur.

Component Lifecycle Tracking

Creating a digital inventory of every sprinkler system component with installation dates, manufacturer specifications, and expected lifespans enables proactive maintenance scheduling that prevents failures. Tracking usage patterns and environmental stress factors improves replacement timing accuracy.

Create digital records for every system component including installation dates, manufacturer specifications, warranty periods, and expected lifespans based on usage conditions. Schedule component replacements before expected failure dates based on manufacturer recommendations adjusted for your specific usage patterns and environmental conditions. Track environmental stress factors like extreme temperatures, water quality issues, and usage frequency that may accelerate component aging beyond standard lifespan expectations.

Pressure Cycle Fatigue Monitoring

Sprinkler system components experience fatigue failure after specific numbers of pressure cycles (on/off events), making cycle tracking essential for predicting component replacement needs. Quality valves and controllers typically handle 50,000-100,000 cycles before requiring replacement.

Track daily pressure cycles by counting system on/off events because each cycle creates stress that accumulates toward component failure thresholds. Document seasonal pressure variations and usage frequency changes that affect cycle counts and component stress levels throughout the year. Schedule component inspections and replacements based on cycle count data rather than arbitrary time intervals because usage patterns vary significantly between installations.

Advanced Troubleshooting Through Forensic Analysis

Professional sprinkler diagnostics involve detective work that analyzes failure patterns, water staining, and component wear to identify root causes rather than treating symptoms. Forensic analysis of hydraulic failures, water quality impacts, and electrical system problems reveals underlying issues that prevent recurring problems and extend system lifespan. Your sprinkler system failures tell stories when you know how to read them.

When troubleshooting reveals extensive system damage requiring replacement, professional estate cleanout services can efficiently handle the removal of damaged irrigation infrastructure and landscape debris during major system overhauls.

Hydraulic failure pattern recognition examines valve diaphragms, pipe joints, and sprinkler head wear patterns that reveal installation quality and environmental stress factors. Water quality impact assessment through TDS testing and pH monitoring identifies mineral buildup and corrosion issues that affect system longevity and performance. Your diy sprinkler system benefits from this investigative approach to problem-solving.

Hydraulic Failure Pattern Recognition

Sprinkler system failures leave forensic evidence that reveals underlying problems when you understand how to read the signs. Examining failure patterns in valves, pipes, and sprinkler heads provides diagnostic information that identifies root causes and prevents recurring problems.

Valve diaphragm deterioration signatures show specific crack patterns that indicate pressure spikes, chemical exposure, or installation problems that caused the failure. Pipe joint failure archaeology reveals installation quality through stress patterns and corrosion signs that help prevent similar failures in other system areas. Sprinkler head wear pattern analysis identifies water quality issues through specific erosion and mineral buildup patterns that predict future component failures.

Valve Diaphragm Deterioration Signatures

Valve diaphragms fail in predictable patterns that reveal the cause of failure when you know how to read the signs. Different crack patterns indicate pressure problems, chemical exposure, or installation issues that help prevent similar failures in other system components. Your sprinkler system valves provide diagnostic clues through their failure modes.

Examine valve diaphragms for radial cracks that indicate pressure spikes, concentric circles that suggest chemical exposure, and edge tearing that points to installation problems. Document crack patterns because similar stress conditions likely affect other valves in your system that may require preventive replacement or system modifications. Identify root causes of diaphragm failure such as water hammer, chemical contamination, or debris infiltration that must be addressed to prevent recurring valve problems.

Pipe Joint Failure Archaeology

Failed pipe joints reveal installation quality and stress conditions through specific failure patterns that help identify problems before they affect other system areas. Reading these forensic signs prevents similar failures and improves overall system reliability. Your sprinkler system underground network provides evidence of installation practices and environmental stresses.

Look for white stress marks around fittings that indicate over-tightening during installation, while brown staining suggests galvanic corrosion from dissimilar metal connections. Document joint failure patterns because similar installation techniques or material combinations likely exist elsewhere in your system requiring inspection or replacement. Identify environmental factors like soil movement, thermal stress, or chemical exposure that contributed to joint failure and may affect other system components.

Sprinkler Head Wear Pattern Analysis

Sprinkler head nozzles develop specific wear patterns that reveal water quality issues and predict future failures when you understand how to interpret the signs. Different erosion patterns indicate mineral content, pH problems, or debris contamination that affects system-wide performance. Your sprinkler system heads become diagnostic tools through their wear characteristics.

Examine nozzle wear patterns because calcium buildup creates specific groove patterns while sand content causes uniform erosion that indicates different water quality issues. Document wear patterns across different zones because water quality problems typically affect the entire system and require filtration or treatment solutions. Use wear pattern analysis to predict replacement schedules for other sprinkler heads experiencing similar water quality conditions throughout your system.

Water Quality Impact Assessment

Municipal water chemistry directly affects sprinkler system longevity through mineral buildup, pH effects on materials, and bacterial growth in stagnant lines. Regular testing and documentation of water quality parameters helps predict maintenance needs and prevent premature component failure. Your sprinkler system responds to water chemistry in predictable ways.

Total dissolved solids mapping through quarterly testing identifies mineral content that clogs nozzles and corrodes fittings, requiring filtration systems when readings exceed 500 ppm. pH buffer zone calculations determine when water chemistry falls outside the 6.8-7.2 optimal range that accelerates corrosion or increases mineral precipitation. Water quality documentation helps predict component replacement schedules and identify treatment needs before problems affect system performance.

Total Dissolved Solids Mapping

High mineral content in irrigation water clogs sprinkler nozzles and corrodes metal fittings over time. Regular TDS testing identifies when mineral levels require filtration systems or component upgrades to handle the increased maintenance demands of hard water. Your sprinkler system longevity depends on understanding these chemical challenges.

Test TDS levels quarterly using a digital meter because seasonal variations in municipal water treatment affect mineral content throughout the year. Install filtration systems when TDS readings consistently exceed 500 ppm because higher mineral content accelerates nozzle clogging and fitting corrosion. Document TDS trends over time to predict when component replacement schedules need acceleration due to increased mineral exposure and wear rates.

pH Buffer Zone Calculations

Water pH outside the optimal 6.8-7.2 range accelerates material degradation through increased corrosion or mineral precipitation. Monitoring pH levels and installing adjustment systems when necessary protects system components and maintains optimal performance.

Test water pH regularly because readings below 6.5 accelerate metal corrosion while pH above 8.5 increases calcium precipitation that clogs system components. Install pH adjustment systems when readings consistently fall outside the 6.8-7.2 optimal range for irrigation equipment longevity and performance. Document pH variations throughout the year because municipal water treatment changes seasonally and may require different adjustment strategies during different periods.

Electrical System Forensics

Controller and valve electrical problems create diagnostic patterns that reveal moisture intrusion, voltage irregularities, and grounding issues. Understanding these electrical forensics helps identify root causes and prevent recurring problems that cause system failures and unreliable operation. Your sprinkler system electrical components provide diagnostic information through their failure characteristics.

Solenoid resistance fingerprinting using multimeter measurements reveals short circuits, open circuits, and degradation patterns that predict valve failure before complete breakdown occurs. Wire insulation degradation tracking through annual resistance testing identifies underground wire problems before they cause zone failures and require extensive excavation for repairs. Electrical system documentation helps predict maintenance needs and identify installation problems that may affect multiple system components over time.

Solenoid Resistance Fingerprinting

Solenoid electrical resistance measurements provide diagnostic information about valve condition and predict failures before they occur. Establishing baseline measurements and tracking changes over time enables proactive maintenance that prevents system downtime. Your sprinkler system valves communicate their health through electrical characteristics.

Measure solenoid resistance with a multimeter because new solenoids typically read 20-60 ohms while readings below 10 ohms indicate short circuits and infinite resistance means open circuits. Document baseline resistance readings for all valves during installation to establish comparison standards for future diagnostic testing and maintenance scheduling. Track resistance changes over time because gradual increases or decreases indicate developing problems that require attention before complete valve failure occurs.

Wire Insulation Degradation Tracking

Underground wire insulation fails predictably based on soil chemistry and moisture exposure, making annual testing essential for preventing zone failures. Tracking insulation resistance helps schedule wire replacement before failures occur that require extensive excavation.

Test insulation resistance annually using a megohmmeter to measure wire condition because underground installations experience predictable degradation from soil chemistry and moisture. Replace wire bundles when insulation resistance drops below 1 megohm because further degradation typically accelerates and leads to complete failure within one season. Document wire installation details including burial depth, conduit usage, and soil conditions that affect degradation rates and help predict replacement schedules for different system areas.

Final Thoughts

Your diy sprinkler system represents a significant investment in your property’s value and your family’s outdoor enjoyment. The engineering principles covered in this guide separate successful long-term installations from costly failures that require complete replacement within a few seasons. Understanding hydraulic psychology, underground infrastructure design, and smart technology integration transforms your irrigation project from basic lawn watering into a sophisticated landscape management system.

The forensic troubleshooting techniques and predictive maintenance strategies we’ve discussed prevent 80% of common system failures while optimizing water usage and plant health. When you implement these professional-grade approaches, your DIY installation will perform reliably for decades while adapting to changing landscape needs and environmental conditions.

However, even the best-planned projects generate debris, failed components, and landscape waste that requires proper disposal. When your installation uncovers old irrigation debris, generates excess soil from trenching, or requires removal of failed system components, Jiffy Junk’s professional removal services ensure your project stays organized and your property remains accessible. Their same-day service capability means you won’t have construction debris cluttering your workspace while you perfect your irrigation system.

Professional-grade DIY installations require engineering calculations and systematic approaches that most basic guides overlook, but these techniques ensure long-term success and optimal performance. Predictive maintenance and smart technology integration prevent most system failures while optimizing water usage, making the initial investment in quality components and proper installation worthwhile.

Project debris removal and site cleanup become essential when installations generate significant waste or require removal of failed components – professional removal services keep projects organized and properties accessible throughout the installation process.

Ready to tackle your DIY sprinkler system project? Contact Jiffy Junk today for professional debris removal services that keep your installation organized and your property clean throughout the entire process.