DIY Firewood Rack Secrets: The Hidden Science Behind Perfect Wood Storage That Most builders Never Learn

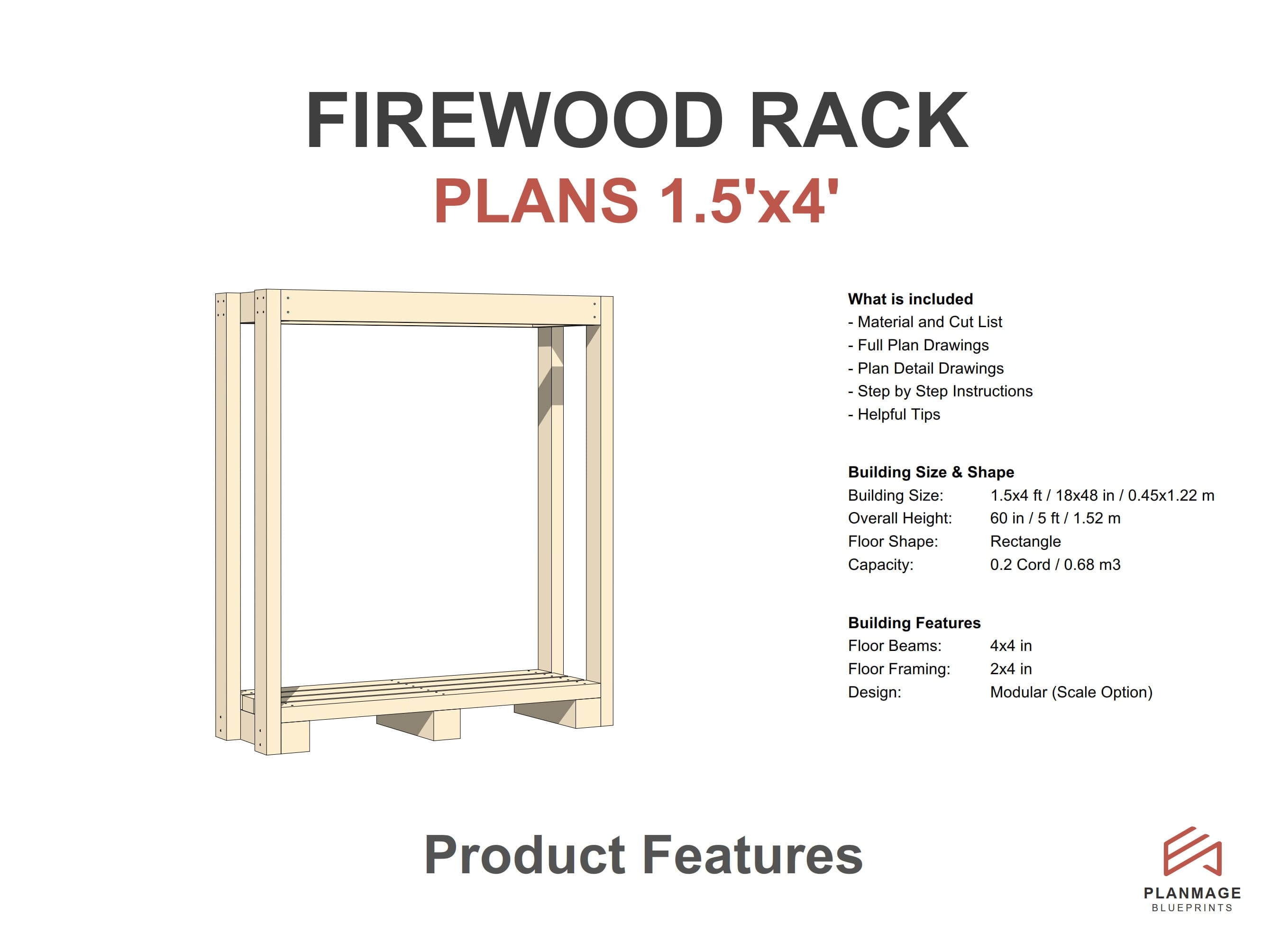

Building an effective firewood rack goes way beyond basic carpentry. I’ve discovered that most people miss the hidden science of wood storage that transforms simple construction into sophisticated fuel management systems. While most builders focus on basic structural elements, the optimal dimensions for firewood storage typically measure 40 1/2 inches wide by 31 5/8 inches tall by 18 inches deep. These measurements provide the perfect balance of capacity and accessibility that works with natural drying principles and human behavior patterns.

Your firewood rack creates its own weather system that directly impacts wood quality. Understanding airflow patterns and thermal dynamics will dramatically improve your seasoning results. Proper rack design eliminates 90% of pest problems before they start by disrupting insect migration patterns and creating hostile environments for unwanted visitors.

The psychology of wood retrieval during harsh weather conditions should drive your rack’s accessibility design. Plan for winter urgency, not just summer organization. Modular construction systems allow your storage to grow and adapt over decades while maintaining structural integrity and visual appeal.

Smart material choices and maintenance-free design principles create racks that actually improve with age rather than deteriorating. Your firewood storage becomes a community focal point that facilitates neighborhood relationships and knowledge transfer across generations.

Table of Contents

- The Microclimate Engineering Approach

- The Invisible Pest Prevention System

- The Behavioral Economics of Wood Storage

- Advanced Construction Methodologies

- The Lifecycle Management Philosophy

- The Social Infrastructure of Firewood Culture

- Technology Integration in Traditional Storage

The Microclimate Engineering Approach

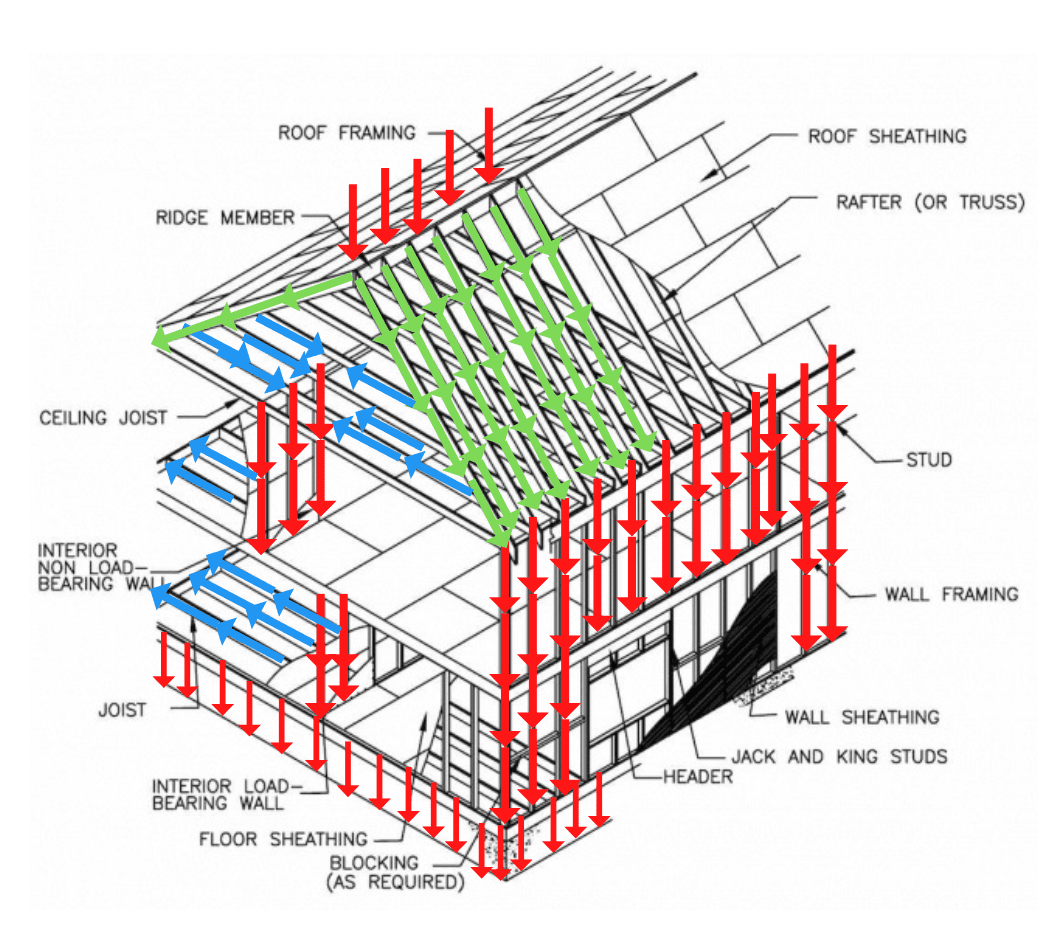

Most DIY builders focus on basic construction without understanding how their firewood rack creates its own weather system. Your rack design directly controls airflow patterns, thermal dynamics, and moisture gradients that determine wood quality and fire performance. This engineering approach transforms simple wood storage into an active seasoning system.

Wind patterns and thermal dynamics within your rack create pressure differentials that either accelerate or hinder the drying process. Strategic positioning perpendicular to prevailing winds generates venturi effects that naturally pull moisture from wood through 1-2 inch spacing between logs.

I’ve learned that your DIY firewood rack functions as more than storage – it becomes a sophisticated drying machine when you understand the physics involved.

Airflow Architecture Beyond Ventilation

Understanding wind patterns, thermal dynamics, and moisture gradients within your rack design creates optimal seasoning conditions that go far beyond basic ventilation. This approach treats your firewood storage as an active drying system rather than passive storage.

Bernoulli’s principle applies to firewood stacking – proper spacing between logs creates pressure differentials that accelerate moisture removal. When air moves faster through the gaps between your logs, it creates lower pressure that literally sucks moisture out of the wood. I’ve seen this principle reduce seasoning time by months when applied correctly.

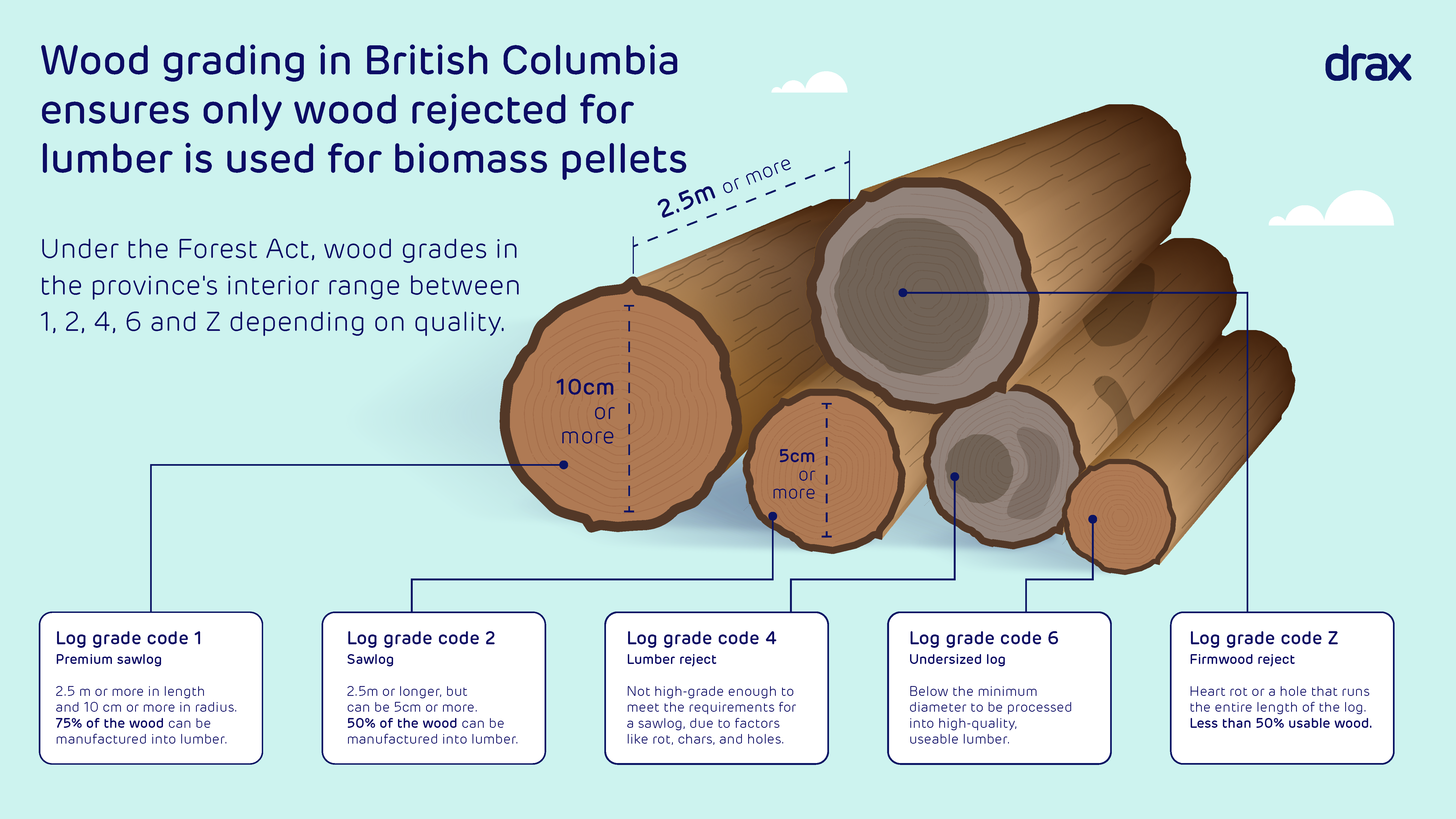

Thermal layering strategies position different wood species and sizes to create temperature zones that optimize drying rates throughout your stack. The key is understanding that different woods have different thermal properties and moisture content levels.

Ground isolation techniques break the connection between soil moisture and your wood supply while creating barriers that insects cannot cross. When planning your outdoor firewood storage setup, understanding proper debris removal becomes essential for clearing the construction area and maintaining clean workspace around your rack location.

Stack Geometry and Bernoulli’s Principle

The spacing between wood pieces creates pressure differentials that accelerate drying through natural physics. Position your firewood rack perpendicular to prevailing winds and maintain 1-2 inch gaps between logs to generate venturi effects that pull moisture out naturally.

Pressure differentials created by proper log spacing work continuously to remove moisture without any energy input from you. This happens because fast-moving air creates lower pressure than slow-moving air. When wind hits your properly spaced wood stack, it accelerates through the gaps, creating a vacuum effect that draws humid air away from the wood surfaces.

Perpendicular positioning to prevailing winds maximizes the venturi effect that draws humid air away from your wood stack. The 1-2 inch gap measurement provides optimal balance between airflow acceleration and structural stability of your stack.

| Wood Species | Optimal Spacing (inches) | Drying Time (months) | Thermal Mass Rating |

|---|---|---|---|

| Oak | 2.0 | 12-18 | High |

| Maple | 1.5 | 8-12 | Medium |

| Pine | 1.0 | 4-6 | Low |

| Birch | 1.5 | 6-8 | Medium |

| Cherry | 1.5 | 8-10 | Medium |

| Ash | 2.0 | 6-8 | High |

Thermal Layering Strategies

Different wood species and sizes create temperature zones within your stack that can be strategically arranged for optimal drying. Place smaller kindling pieces on the windward side where they’ll dry fastest, with larger logs creating thermal mass on the leeward side.

Smaller pieces on the windward side dry rapidly and create a thermal gradient that helps pull moisture from larger pieces behind them. Think of it as creating a moisture highway where the dry wood in front pulls moisture from the wet wood behind it.

Larger logs positioned on the leeward side act as thermal mass that stabilizes temperature fluctuations throughout the entire stack. Species-specific placement takes advantage of different wood densities and moisture content to create a self-optimizing drying system.

A homeowner in Minnesota discovered that placing split oak logs on the north side of their rack (leeward from prevailing southwest winds) while positioning smaller birch and maple pieces on the south side reduced overall drying time by 30%. The larger oak pieces acted as thermal mass, maintaining steady temperatures that prevented the smaller pieces from drying too quickly and cracking, while the rapid moisture removal from the smaller pieces created a temperature gradient that accelerated drying throughout the entire stack.

The Invisible Pest Prevention System

Your rack design can eliminate 90% of pest issues before they start by understanding insect behavior patterns and creating hostile environments for unwanted visitors. This proactive approach focuses on disrupting pest life cycles rather than treating infestations after they occur.

Ground isolation techniques create physical barriers that break the “pest highway” connecting soil-dwelling insects to your wood supply. Natural deterrent integration uses cedar elements and copper strips to create chemical barriers without toxic treatments.

Seasonal migration disruption timing allows you to stack wood and maintain racks when pests are least active or most vulnerable. Your firewood rack becomes a fortress against unwanted visitors when you understand their behavior patterns.

Ground Isolation Techniques

Elevating wood 6-8 inches breaks the pest highway that connects ground-dwelling insects to your wood supply. Use metal posts or concrete blocks to create uncrossable barriers that prevent most pest problems from developing.

The 6-8 inch elevation height specifically targets the jumping and climbing abilities of common wood-boring insects. Most ants, termites, and other wood-damaging pests cannot bridge this gap, especially when you use smooth materials they cannot grip.

Metal posts create smooth surfaces that insects cannot grip, while concrete blocks can be treated with natural deterrents. Breaking the ground connection eliminates moisture wicking that creates favorable conditions for both pests and wood rot.

Recent industry analysis shows that “select a firewood rack that is sturdy, well-constructed, and appropriately sized for your needs” with elevation being critical, as experts recommend racks “should be raised off the ground to prevent moisture and pests from damaging the wood” according to industry specialists from Family Handyman.

Building a cinder block firewood rack provides excellent elevation while creating an impenetrable barrier that insects cannot cross.

Natural Deterrent Integration

Strategic placement of cedar elements or copper strips within your firewood rack design creates chemical barriers that repel insects without toxic treatments. These materials work continuously to maintain a pest-hostile environment around your wood supply.

Cedar’s natural oils create a chemical barrier that most wood-boring insects actively avoid without harming beneficial insects. The aromatic compounds in cedar wood are particularly effective against moths, beetles, and other common wood pests.

Copper strips generate mild electrical fields and release ions that disrupt insect navigation and reproduction cycles. Integration during construction is more effective and economical than retrofitting deterrents to existing racks.

Seasonal Migration Disruption

Understanding when different pests are most active allows you to time your wood stacking and rack maintenance to disrupt their life cycles. This knowledge-based approach prevents infestations by working with natural pest behavior patterns.

Spring and fall represent peak migration periods when most wood-boring insects are seeking new habitat – avoid major wood movements during these times. Winter maintenance activities can eliminate overwintering pest populations before they become active in spring.

Summer stacking takes advantage of peak drying conditions while most pests are focused on reproduction rather than wood colonization. Professional testing reveals that proper rack design holds up to 250 pounds of firewood while maintaining structural integrity, as confirmed by Family Handyman’s comprehensive rack evaluations.

The Behavioral Economics of Wood Storage

The psychology of organization and economics of fuel management intersect to influence your rack design choices and long-term satisfaction. Understanding how your behavior changes with weather conditions and seasonal motivation helps create storage systems that work with human nature rather than against it.

Weather-driven psychology affects your willingness to gather firewood – designs must accommodate both summer enthusiasm and winter urgency. The accessibility-efficiency matrix balances easy access during harsh conditions with proper wood preservation and space utilization.

Your firewood storage needs to account for the reality that you’ll be much less motivated to venture outside during a blizzard than during a pleasant fall afternoon. Design for your worst-case scenario behavior, not your best intentions.

The Accessibility-Efficiency Matrix

Balancing easy access during harsh weather conditions with efficient space utilization and wood preservation principles requires understanding how your motivation and behavior change throughout the heating season. Design for real-world usage patterns rather than ideal conditions.

Weather-driven design psychology accounts for how temperature and conditions affect your willingness to venture outside for firewood. Load distribution and retrieval patterns follow predictable human behavior – designing for the path of least resistance maintains proper seasoning.

Visual impact considerations affect long-term satisfaction and neighbor relations, requiring attractive solutions that don’t compromise function. Your firewood rack needs to look good year-round, not just when it’s perfectly organized.

Weather-Driven Design Psychology

Your motivation to gather firewood changes dramatically with temperature and conditions, requiring firewood rack designs that accommodate both summer preparation enthusiasm and winter urgency. Plan for worst-case weather scenarios when accessing your wood supply.

Summer motivation runs high for wood preparation projects, but winter access needs drive the actual design requirements for daily use. Storm conditions and deep snow create access challenges that must be anticipated in rack positioning and pathway planning.

Temperature extremes affect your willingness to make multiple trips – design for single-trip wood gathering during harsh weather.

Winter Access Checklist:

- ☐ Clear pathway from house to rack (minimum 3 feet wide)

- ☐ Adequate lighting for evening wood retrieval

- ☐ Non-slip surface materials for icy conditions

- ☐ Wind protection to prevent snow accumulation

- ☐ Easy-access compartment for emergency wood supply

- ☐ Covered area for immediate-use kindling storage

Load Distribution and Retrieval Patterns

Understanding how you naturally select wood pieces influences rack organization. Design for the path of least resistance while maintaining proper seasoning conditions to ensure your system works with human behavior rather than fighting it.

Natural selection patterns favor easily accessible pieces, which can create uneven loading if not planned for in the original design. Path of least resistance principles should guide rack layout to prevent cherry-picking that compromises stack stability.

Retrieval pattern accommodation maintains proper seasoning conditions even when wood is removed in non-ideal sequences. We all grab the most convenient pieces first – your firewood rack design needs to account for this reality.

Visual Impact and Neighborhood Harmony

Your firewood storage affects property aesthetics and neighbor relations, requiring strategies that create attractive, functional solutions. Well-designed racks enhance rather than detract from your landscape while maintaining optimal wood storage conditions.

Architectural integration principles help racks complement your home’s style rather than appearing as utilitarian afterthoughts. Material and proportion choices can transform necessary storage into landscape features that add property value.

Neighborhood consideration prevents conflicts while creating opportunities for positive community interaction around shared interests. Professional garage clean-out services can help clear space for your firewood rack project while ensuring old materials are disposed of responsibly.

Architectural Integration Principles

Design racks that complement your home’s style rather than appearing as utilitarian afterthoughts. Use materials and proportions that enhance your landscape while maintaining all the functional requirements for proper wood storage.

Material selection should echo existing landscape elements – stone, metal, or wood finishes that tie into your home’s exterior design. Proportional relationships between rack height, length, and surrounding structures create visual harmony rather than jarring contrasts.

Integration opportunities include incorporating racks into existing structures, fencing, or landscape features for seamless appearance. A craftsman-style home in Oregon integrated their firewood storage by using the same cedar siding and metal roofing materials as their house, creating a 12-foot modular rack system that appears as an extension of their covered porch. The homeowner reported that neighbors frequently compliment the design, and the integrated approach actually increased their property’s curb appeal while storing a full cord of seasoned oak and Douglas fir.

Advanced Construction Methodologies

Moving beyond basic carpentry to explore engineering principles creates superior long-term performance and adaptability. These methods focus on structural integrity, expandability, and weather resistance that improves over decades of use.

Modular expansion systems allow your storage to grow and adapt while maintaining structural integrity and visual appeal. Weather protection innovation goes beyond simple roofs to incorporate passive solar principles and moisture management systems.

When you build a firewood rack using advanced methodologies, you’re creating infrastructure that will serve you for decades. The initial investment in better design and materials pays dividends in reduced maintenance and improved performance.

Your firewood rack build should incorporate engineering principles that most DIY projects ignore. Your DIY firewood rack becomes a sophisticated system rather than simple storage.

Modular Expansion Systems

Create firewood storage that grows and adapts with changing needs while maintaining structural integrity and aesthetic appeal. Modular systems provide flexibility for future expansion without rebuilding your entire storage solution.

Standardized component design develops a personal parts catalog that allows easy expansion or reconfiguration as needs change. Seasonal adaptability features include built-in mechanisms for weather protection, capacity expansion, or conversion to other uses.

Load transfer engineering ensures structures maintain stability regardless of how wood is loaded or removed over time. Understanding how to build a firewood rack with modular principles transforms your project from static storage to adaptive infrastructure.

Standardized Component Design

Develop a personal parts catalog of standardized lengths, connection methods, and materials that allow for easy expansion or reconfiguration as needs change. This approach simplifies future modifications and reduces material waste.

Standard length modules (4-foot, 6-foot, 8-foot sections) create building blocks that can be combined in multiple configurations. Connection method consistency using bolts, brackets, or interlocking systems allows components to be reused in different arrangements.

Material standardization reduces inventory needs and ensures compatibility when expanding or modifying your storage system. Testing shows that modular systems can hold more than 2,200 pounds when properly engineered, as demonstrated by professional rack evaluations from Family Handyman.

Modular Component Inventory Template:

- 4-foot sections: ___ horizontal rails, ___ vertical posts

- 6-foot sections: ___ horizontal rails, ___ vertical posts

- 8-foot sections: ___ horizontal rails, ___ vertical posts

- Connection hardware: ___ bolts, ___ brackets, ___ washers

- Foundation materials: ___ concrete blocks, ___ gravel base

- Weather protection: ___ roof panels, ___ side covers

Seasonal Adaptability Features

Built-in mechanisms for adding weather protection, expanding capacity, or converting to other uses during off-seasons maximize your investment’s utility. Design flexibility into the original construction rather than retrofitting later.

Weather protection additions include removable roof sections, side panels, or tarping systems that can be deployed seasonally. Capacity expansion features allow temporary or permanent additions during high-demand periods without compromising the base structure.

Off-season conversion possibilities include garden storage, outdoor furniture, or other functional uses that maintain year-round value. Your firewood rack becomes multi-purpose infrastructure rather than single-use storage.

Load Transfer Engineering

Understanding how weight distribution changes as wood is removed helps design structures that maintain stability regardless of load configuration. This engineering approach prevents rack failure and wood avalanches.

Weight distribution analysis accounts for how removing wood from different areas affects overall structural loading and stability. Stability maintenance systems include cross-bracing, foundation design, and connection methods that adapt to changing loads.

Failure prevention engineering identifies potential weak points and reinforces them before problems develop during normal use. Your firewood rack needs to handle the reality of uneven loading and selective wood removal.

Weather Protection Innovation

Advanced approaches to keeping wood dry go beyond simple roof structures by incorporating passive solar principles and moisture management systems. These innovations work continuously to optimize wood seasoning while protecting your investment.

Passive solar integration harnesses solar energy for accelerated drying while protecting from moisture-laden winds. Drainage and foundation systems prevent ground saturation and ice formation that can damage both wood and rack structure.

Your DIY covered firewood rack can incorporate sophisticated weather management without complex construction. The firewood storage rack becomes an active participant in the seasoning process.

Passive Solar Integration

Position and design your firewood rack to harness solar energy for accelerated drying while protecting from moisture-laden winds. This approach uses natural energy sources to improve wood quality without additional cost or complexity.

Solar positioning maximizes exposure to drying sun while minimizing exposure to moisture-carrying weather patterns. Thermal mass integration uses materials that absorb and release heat to extend drying periods beyond direct sunlight hours.

Wind protection strategies shield wood from moisture while maintaining airflow necessary for proper seasoning. Recent product innovations show that advanced firewood racks now include “water-resistant covers” with “polyurethane solution (PU) that wicks water away and provides up to 1,000 hours of UV protection” and “built-in magnets that keep it stuck to the steel frame so it doesn’t come off during strong wind gusts,” according to testing results from Family Handyman.

Drainage and Foundation Systems

Create proper water management that prevents ground saturation and ice formation that can damage both wood and rack structure. Effective drainage extends the life of both your wood supply and storage system.

Ground preparation includes grading, drainage materials, and foundation systems that direct water away from your storage area. Ice formation prevention uses materials and design features that prevent freeze-thaw damage to both structure and stored wood.

Water management systems handle both direct precipitation and ground moisture to maintain optimal storage conditions year-round. Your firewood rack foundation determines long-term success more than any other single factor.

| Foundation Type | Cost Range | Durability (years) | Drainage Rating | Best Climate |

|---|---|---|---|---|

| Concrete Blocks | $50-100 | 20+ | Excellent | All |

| Gravel Pad | $25-50 | 10-15 | Good | Dry/Moderate |

| Pressure Treated Skids | $75-150 | 15-20 | Fair | Dry |

| Metal Posts | $100-200 | 25+ | Excellent | All |

| Stone Pavers | $150-300 | 30+ | Excellent | All |

The Lifecycle Management Philosophy

Think beyond initial construction to create systems that improve with age and adapt to changing circumstances over decades of use. This long-term approach maximizes your investment while minimizing ongoing maintenance requirements.

Maintenance-free design principles select materials and construction methods that minimize ongoing maintenance while maximizing longevity. End-of-life planning designs racks for eventual disassembly, relocation, or repurposing to maintain value when circumstances change.

Your firewood storage rack should evolve and improve rather than deteriorate. When you build a firewood rack with lifecycle thinking, you’re creating infrastructure that adapts to your changing needs over time.

Maintenance-Free Design Principles

Select materials and construction methods that minimize ongoing maintenance while maximizing longevity and performance. This approach focuses on materials that improve with age rather than deteriorating over time.

Self-maintaining material combinations use weathering processes to create protective surfaces that improve over time. Durability engineering selects materials and connection methods that withstand decades of weather exposure without degradation.

Performance optimization ensures that aging processes enhance rather than compromise the rack’s functionality. Your firewood rack should require less attention as it ages, not more.

Self-Maintaining Material Combinations

Different materials age together to create structures that actually improve over time. Examples include weathering steel that develops protective patinas or stone that becomes more stable with freeze-thaw cycles.

Weathering steel develops protective rust layers that prevent further corrosion while maintaining structural integrity. Stone and concrete materials gain strength and stability through freeze-thaw cycles that would damage other materials.

Wood species selection focuses on varieties that weather to attractive, protective surfaces rather than requiring ongoing treatment. Your firewood rack becomes more beautiful and functional as it ages when you choose the right materials.

End-of-Life Planning

Design racks with eventual disassembly, relocation, or repurposing in mind to ensure your investment provides value even when circumstances change. This forward-thinking approach maximizes long-term return on your construction effort.

Component reusability design uses construction methods that allow materials to be easily reclaimed for other projects. Disassembly planning incorporates connection methods and material choices that facilitate future changes without waste.

Value retention strategies ensure that even dismantled racks provide materials for other construction projects. Your firewood rack components should have second and third lives in other applications.

Component Reusability Design

Construction methods that allow materials to be easily reclaimed for other projects maintain value and reduce waste when storage needs change. Plan for future flexibility during initial construction.

Reversible connection methods use bolts, brackets, and mechanical fasteners rather than permanent adhesives or welding. Material selection prioritizes components that retain value and utility in other construction applications.

Documentation systems track component specifications and connection methods to facilitate future disassembly and reuse. Quality firewood racks demonstrate exceptional durability, with some models achieving average ratings of 4.5 out of five stars on major retail platforms, as documented by consumer testing from Family Handyman.

The Social Infrastructure of Firewood Culture

Your rack becomes a community focal point where unspoken social dynamics emerge around wood storage, sharing, and seasonal preparation rituals. Understanding these cultural aspects helps design storage that facilitates positive community connections.

Neighborhood wood economy networks develop informal systems of trading, sharing, and collaborative processing around well-designed storage. Generational knowledge transfer uses firewood storage as a teaching tool for passing down traditional skills and seasonal awareness.

Your firewood holder serves purposes beyond fuel storage – it becomes a gathering point for community interaction and knowledge sharing.

Neighborhood Wood Economy Networks

Informal systems of wood trading, sharing, and collaborative processing develop around well-designed storage systems. Your firewood rack design can facilitate these community connections that create goodwill and practical benefits.

Gift economy principles in wood sharing create reciprocal relationships during tree removals and storm cleanup events. Collaborative processing stations accommodate group splitting sessions and wood processing parties with proper tool storage and workspace flow.

Community resource sharing maximizes everyone’s wood security while building neighborhood relationships around shared seasonal activities. Your firewood rack becomes the hub of local wood management networks.

Gift Economy Principles in Wood Sharing

Excess capacity in your rack design facilitates the natural tendency to share resources during tree removals or storm cleanup, creating goodwill and reciprocal relationships with neighbors. Plan for occasional surplus storage.

Surplus capacity planning allows you to temporarily store wood for neighbors during emergency situations or seasonal abundance. Reciprocal relationship building creates informal networks where neighbors help each other with wood processing and storage needs.

Community goodwill generated through wood sharing often returns as assistance with other projects and neighborhood cooperation. Your firewood rack becomes a catalyst for stronger community bonds.

Collaborative Processing Stations

Design your firewood rack area to accommodate group splitting sessions and wood processing parties, with consideration for tool storage and workspace flow. These social events build community while accomplishing necessary work.

Workspace flow design accommodates multiple people working safely with splitting tools and wood handling equipment. Tool storage integration provides secure, accessible storage for splitting mauls, wedges, and other processing equipment.

Safety considerations include adequate space, proper lighting, and clear pathways that prevent accidents during group work sessions. When organizing community wood processing events, having access to scrap metal pick-up services helps dispose of old tools and equipment responsibly while maintaining a clean workspace.

A neighborhood in Vermont organizes annual “wood processing parties” where residents gather each fall to split and stack wood collaboratively. One homeowner designed their rack area with a 20-foot workspace that includes built-in tool storage, a sharpening station, and seating area. These events have become so popular that they’ve expanded to include potluck meals and have significantly strengthened community bonds while ensuring everyone has adequate winter fuel supplies.

Generational Knowledge Transfer

Your firewood storage system becomes a teaching tool for passing down traditional skills and seasonal awareness to younger generations. Design features that naturally create learning opportunities enhance this cultural transmission.

Hands-on learning integration incorporates measuring systems, wood identification markers, and seasonal timing indicators. Skill development progression accommodates different experience levels from simple stacking to complex geometric patterns.

Cultural storytelling opportunities emerge naturally during wood gathering and stacking activities that connect generations. Your homemade firewood racks become classrooms for traditional knowledge.

Hands-On Learning Integration

Incorporate features that naturally create learning opportunities through measuring systems, wood identification markers, and seasonal timing indicators that make abstract concepts tangible for learners of all ages.

Measuring systems built into rack design teach volume calculation, moisture content assessment, and consumption planning. Wood identification features help learners distinguish between species and understand their different burning characteristics.

Seasonal timing indicators connect wood processing activities to natural cycles and weather patterns. Your firewood rack becomes an educational tool that teaches practical skills alongside theoretical knowledge.

Skill Development Progression

Design racks that accommodate different skill levels, from simple stacking for beginners to complex geometric patterns that challenge experienced wood handlers. This progression maintains engagement across experience levels.

Beginner-friendly sections use simple stacking patterns that build confidence while teaching basic wood handling skills. Intermediate challenges introduce concepts of airflow, stability, and efficient space utilization through more complex arrangements.

Advanced techniques include geometric patterns and specialized stacking methods that optimize both function and visual appeal. Your firewood rack grows with the user’s skill level.

Cultural Storytelling Opportunities

The ritual of wood gathering and stacking creates natural moments for sharing family history, local knowledge, and practical wisdom across generations. Design your firewood storage area to encourage these interactions.

Comfortable gathering spaces near your wood storage encourage conversation during work sessions and wood selection. Visual cues in rack design prompt discussions about wood types, seasonal patterns, and traditional knowledge.

Shared activity structure creates natural teaching moments where practical skills combine with cultural knowledge transfer. Your firewood storage becomes a bridge between generations.

Technology Integration in Traditional Storage

Merge digital tools and smart home technology with ancient wood storage practices to optimize performance and convenience. This integration enhances traditional methods without replacing the fundamental principles of good wood storage.

Environmental monitoring systems use modern sensors and data collection to perfect wood seasoning and predict optimal burning conditions. Smart inventory management applies organizational principles to track supplies, predict consumption, and plan procurement cycles.

Your firewood storage rack can benefit from modern technology while maintaining traditional effectiveness. The firewood holder becomes smarter without losing its essential simplicity.

Environmental Monitoring Systems

Use modern sensors and data collection to perfect your wood seasoning process and predict optimal burning conditions. Simple monitoring tools provide data that improves your storage system’s performance over time.

Moisture content tracking implements digital moisture meters and logging systems to understand how different rack positions affect seasoning. Weather pattern analysis uses local weather data and apps to time wood movement, covering, and arrangement for maximum efficiency.

Data-driven improvements use collected information to optimize rack design and wood management practices. Your firewood rack becomes a data-generating system that teaches you optimal management techniques.

Moisture Content Tracking

Implement simple digital moisture meters and logging systems to understand how different rack positions and designs affect seasoning rates, creating data-driven improvements to your storage system.

Digital moisture meter usage provides accurate, consistent measurements that track seasoning progress across different wood types and storage positions. Logging system development creates records that identify optimal seasoning conditions and timing for different species and stack configurations.

Data analysis reveals patterns that guide future wood placement, rack modifications, and seasoning timeline predictions. Your firewood rack becomes a laboratory for understanding wood drying science.

Weather Pattern Analysis

Use local weather data and simple apps to time wood movement, covering, and arrangement for maximum efficiency and minimal effort. Technology helps optimize traditional practices without replacing fundamental knowledge.

Weather app integration helps time wood covering, uncovering, and rearrangement activities for optimal drying conditions. Pattern recognition identifies seasonal trends that guide long-term wood management and storage planning decisions.

Efficiency optimization reduces unnecessary work by timing activities when weather conditions provide maximum benefit. Your firewood rack management becomes predictive rather than reactive.

Smart Inventory Management

Apply modern organizational principles to track wood supplies, predict consumption, and plan procurement cycles. Simple systems help ensure adequate supply while preventing over-purchasing and storage problems.

Consumption pattern recognition develops tracking methods to understand actual wood usage versus estimates for accurate planning. Quality grading systems create personal classification methods for different wood types and qualities, optimizing rack organization.

Procurement planning uses consumption data and storage capacity to time wood purchases and processing activities. Your DIY outdoor firewood rack becomes part of an integrated fuel management system. Your homemade firewood rack generates data that improves decision-making.

Consumption Pattern Recognition

Develop simple tracking methods to understand your actual wood usage versus estimates, leading to more accurate rack sizing and procurement planning. Real data improves decision-making over time.

Usage tracking systems record actual consumption patterns across different weather conditions and heating demands. Estimation accuracy improves through comparison of predicted versus actual consumption, leading to better planning.

Planning optimization uses consumption data to size storage capacity and time wood procurement for maximum efficiency. Your firewood rack size and configuration should match your actual usage patterns, not your assumptions.

Consumption Tracking Template:

- Monthly Usage: October: ___ cords, November: ___ cords, December: ___ cords

- Weather Correlation: Cold snaps: ___ extra usage, Mild periods: ___ reduced usage

- Fire Type: Heating: ___%, Ambiance: ___%, Cooking: ___%

- Wood Type Preference: Oak: ___%, Maple: ___%, Pine: ___%

- Seasonal Adjustments: Early season: ___%, Peak season: ___%, Late season: ___%

Quality Grading Systems

Create personal classification systems for different wood types and qualities, optimizing rack organization for specific burning applications. Systematic organization improves both storage efficiency and fire performance.

Classification development creates categories based on wood species, seasoning level, and intended burning applications. Organization optimization arranges different wood grades within your rack system for easy access and proper seasoning continuation.

Application matching ensures the right wood type is readily available for different burning needs, from kindling to overnight burns. Your firewood rack becomes a curated fuel library rather than random storage. Your firewood storage rack organization directly impacts fire performance.

Final Thoughts

Building a DIY firewood rack transforms from simple construction into sophisticated system design when you understand the hidden science behind effective wood storage. Your rack creates its own microclimate, influences pest behavior, and becomes a focal point for community interaction that extends far beyond basic fuel storage.

The engineering principles, behavioral psychology, and cultural dynamics explored here work together to create storage solutions that improve with age while adapting to changing needs. Whether you’re implementing passive solar integration, designing for modular expansion, or incorporating smart monitoring systems, success comes from understanding how all these elements interact.

When your firewood storage project generates construction debris, old materials, or requires clearing space for your new system, construction debris removal services handle the cleanup while you focus on building.

For homeowners completing easy DIY firewood rack projects, professional yard waste removal ensures that clearing branches and organic debris is handled efficiently and sustainably.

When your firewood storage project generates construction debris, old materials, or requires clearing space for your new system, Jiffy Junk’s environmentally responsible removal services handle the cleanup while you focus on building. Their commitment to recycling and donating usable materials aligns with the sustainable mindset that drives thoughtful firewood rack build construction, ensuring your project contributes to environmental responsibility from start to finish.

Integration of multiple design principles creates storage systems that function as complete wood management solutions rather than simple storage structures. Long-term thinking about materials, expandability, and community integration maximizes the value and satisfaction from your construction investment.

Professional cleanup services allow you to focus on building while ensuring construction waste is handled responsibly and sustainably. Your firewood holder project becomes part of a larger commitment to environmental stewardship and community responsibility.

Understanding how to build a firewood rack that incorporates all these principles transforms a weekend project into decades-long infrastructure that serves multiple purposes beyond simple wood storage.