DIY Swing Set Construction Secrets: The Engineering Approach Most Builders Never Learn

Most DIY swing set builders focus on basic construction techniques, but I’ve learned that material selection alone determines whether your structure lasts 5 years or 15 years. With lumber costs reaching unprecedented levels – where three 6×6 posts can cost over $170 according to recent DIY project reports – understanding the engineering principles behind swing set construction becomes critical for maximizing your investment.

Table of Contents

- The Hidden Science Behind Material Selection

- Understanding Your Backyard’s Micro-Environment

- Safety Engineering That Actually Works

- Assembly Sequence Strategy

- Predictive Maintenance Systems

- Behavioral Engineering for Real-World Use

- Environmental Integration Methods

- Professional Removal Solutions

TL;DR

- Material selection requires understanding soil interaction, wind patterns, and long-term stress accumulation rather than just comparing wood versus metal

- Assembly sequence determines structural integrity more than tool quality – foundation-first approaches often create problems on uneven terrain

- Children create dynamic loads 300-400% higher than static calculations, requiring different safety margin approaches

- Predictive maintenance using component lifecycle mapping prevents safety hazards and extends structure lifespan significantly

- Environmental factors like drainage engineering and vegetation placement affect durability more than construction materials

- Professional removal services handle weathered hardware, proper disposal, and yard restoration when your swing set reaches end-of-life

The Hidden Science Behind Material Selection

Material selection for DIY swing set construction goes beyond simple wood versus metal comparisons. You need to understand how materials interact with your specific environment, including soil chemistry, moisture patterns, and stress accumulation over time. The real challenge lies in predicting decade-long performance rather than focusing on immediate construction needs.

Environmental science principles determine material longevity in ways most builders never consider. Clay soils retain moisture differently than sandy soils, directly affecting metal corrosion rates and wooden post decay patterns. I’ve seen swing sets in clay-heavy areas show significant rust damage within three years, while identical hardware in sandy soil remains functional for over a decade.

Stress accumulation occurs through expansion and contraction cycles each season. These create microscopic damage that compounds over time until sudden structural failure occurs. The wood fibers separate gradually, metal develops fatigue cracks, and joints loosen incrementally – all invisible until catastrophic failure happens during normal use.

Long-term economics require evaluating how material choices perform under real-world conditions rather than ideal laboratory testing scenarios. That pressure-treated lumber might look identical at the store, but its performance varies dramatically based on treatment quality, moisture content, and grain orientation.

Understanding proper material selection becomes even more critical when considering that many homeowners eventually need professional swing set removal services to handle weathered components and environmental disposal requirements.

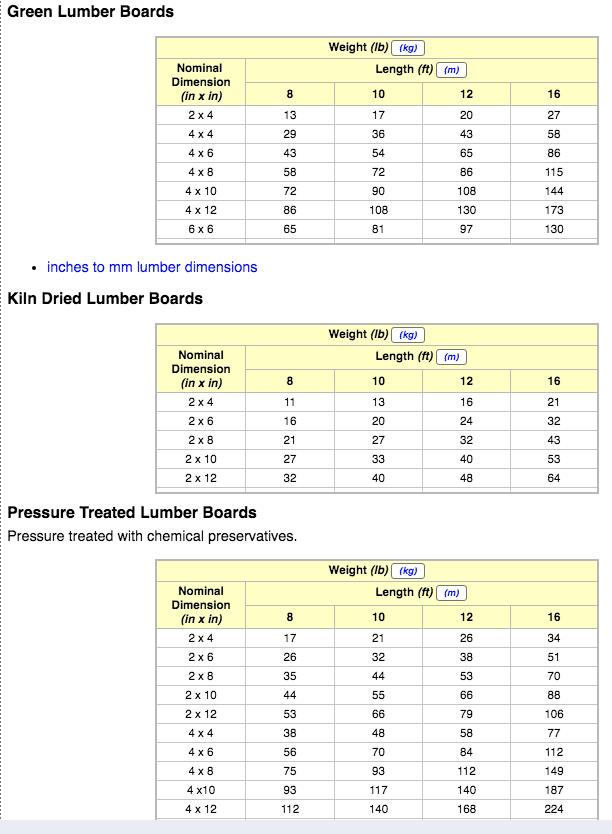

According to DIY project documentation, ActionEcon reports that a 16′ long 4X6 pressure treated board weighs around 112 pounds, demonstrating the significant weight considerations that affect both assembly complexity and long-term structural performance.

Your Backyard’s Micro-Climate Engineering System

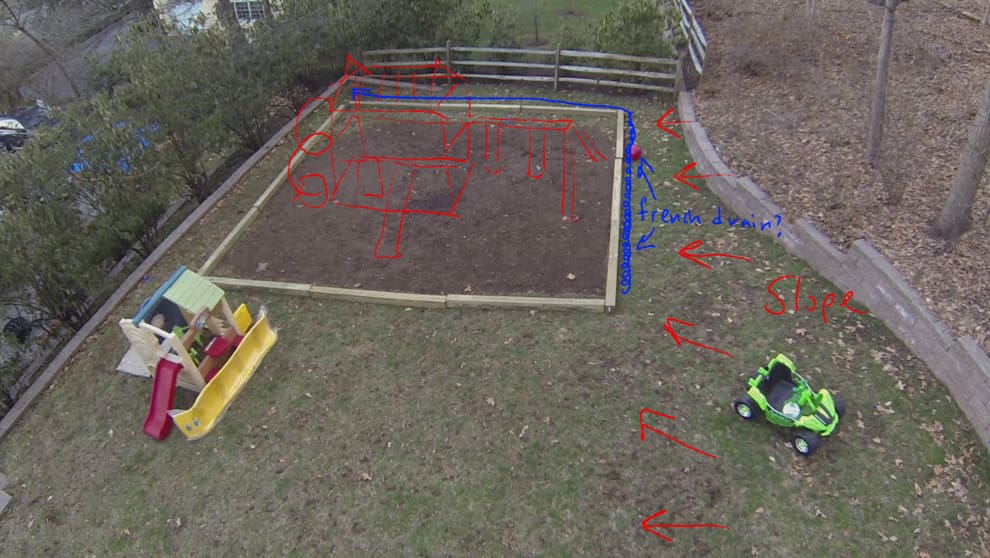

Your DIY swing set operates within a complex ecosystem that includes soil drainage patterns, sun exposure variations, and seasonal weather changes. Most builders position equipment based on available space rather than understanding how environmental factors create stress points and affect structural longevity.

Soil interaction dynamics create microenvironments beneath your swing set that can accelerate or prevent deterioration based on drainage characteristics. I’ve observed identical swing sets installed just 50 feet apart show completely different aging patterns because one sits in a natural drainage depression while the other occupies slightly elevated ground.

Prevailing wind pattern analysis reveals how seasonal forces create specific stress points. When building a swing set, you can prevent catastrophic failures by understanding these patterns during the planning phase. Winter winds from the northwest might seem irrelevant during summer construction, but they’ll test your structure’s weakest joints for the next 15 years.

| Soil Type | Moisture Retention | Metal Corrosion Rate | Wood Decay Timeline | Recommended Foundation Depth |

|---|---|---|---|---|

| Clay | High (7-14 days) | Accelerated | 8-12 years | 30+ inches |

| Sandy | Low (1-3 days) | Moderate | 12-18 years | 24+ inches |

| Loamy | Medium (3-7 days) | Standard | 10-15 years | 24-30 inches |

| Rocky | Variable | Slow | 15+ years | 18-24 inches |

Soil Chemistry and Structural Impact

The ground beneath your swing set creates specific conditions that determine how quickly materials deteriorate. Different soil types affect metal corrosion and wood decay in predictable patterns that you can plan for during initial construction.

Clay versus sandy soil compositions retain moisture at different rates, creating distinct corrosion and decay environments for structural components. Clay acts as a moisture reservoir, keeping metal hardware in constant contact with water and accelerating oxidation processes. Sandy soil drains quickly but can create rapid wet-dry cycles that stress wood fibers through repeated expansion and contraction.

Ground-level moisture affects both surface and subsurface structural elements through different mechanisms that require specific prevention strategies. Surface moisture creates obvious rust and rot problems, but subsurface moisture travels up through capillary action, affecting components that appear completely dry during visual inspections.

Wind Stress Distribution Patterns

Seasonal wind patterns create forces that most DIY swing set builders never consider during planning. Understanding how wind interacts with your swing set design can prevent structural failures and extend equipment lifespan by years through proper positioning and reinforcement.

Dynamic wind loads create stress concentrations at specific joint locations that change based on seasonal weather patterns. Spring storms might hit from the south, while winter winds consistently blow from the northwest. Your swing set experiences these different force vectors throughout the year, gradually loosening hardware that wasn’t designed for multi-directional stress.

Strategic positioning relative to natural windbreaks and terrain features can reduce structural stress while maintaining safe play areas. I’ve seen swing sets positioned behind garages or large trees last significantly longer than identical structures in open areas, simply because the windbreak reduces constant stress cycling.

Recent industry analysis from “Family Handyman” emphasizes that when measuring yard space for swing sets, you must “allow at least a six-foot play perimeter away from fences or sheds,” highlighting how proper positioning affects both safety and structural longevity.

A homeowner in Minnesota positioned their DIY swing set on the south side of their property to maximize sun exposure for faster snow melt, but failed to account for prevailing northwest winter winds. Within two seasons, the constant wind stress caused joint loosening that required complete re-tensioning of all hardware connections. Repositioning the structure behind their garage as a windbreak eliminated the problem entirely.

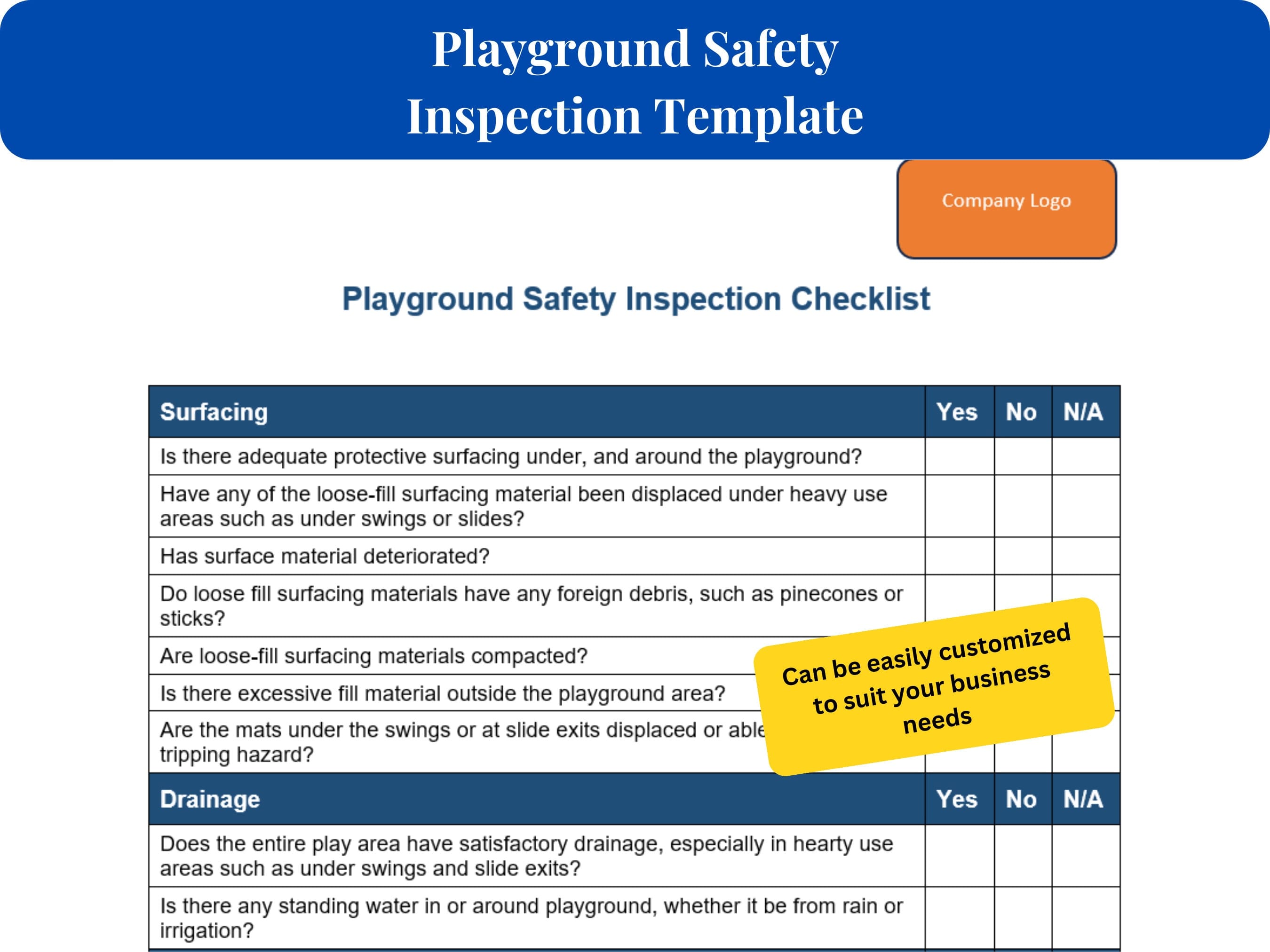

Safety Engineering That Goes Beyond Weight Limits

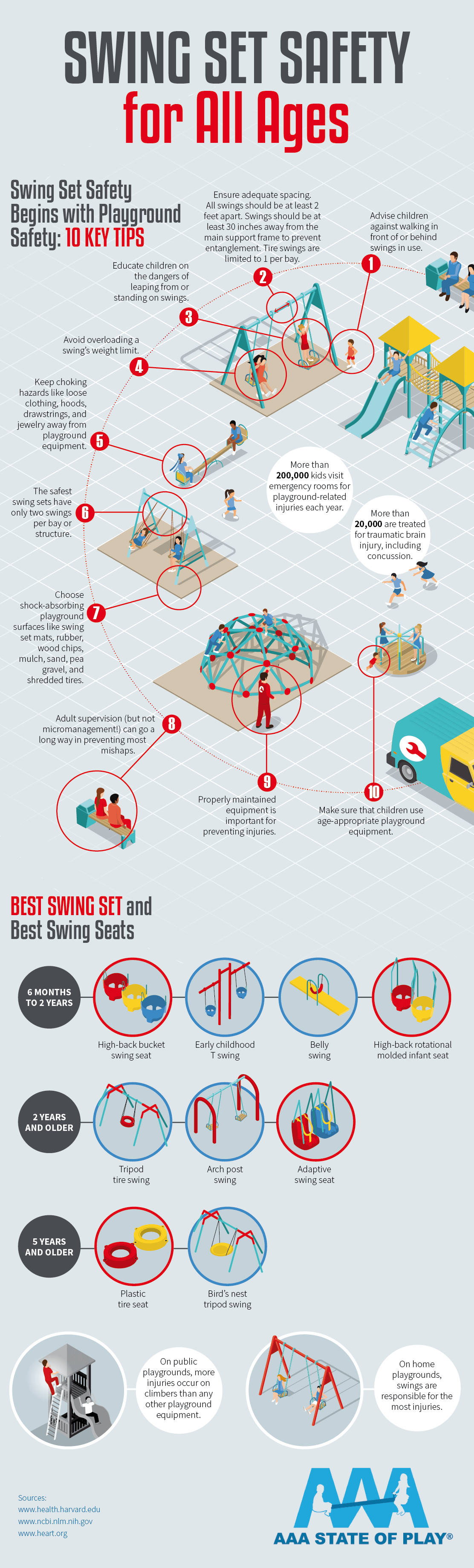

Professional playground equipment uses safety factors that seem excessive to DIY swing set builders, but these margins account for real-world usage patterns that most parents don’t anticipate. Children create forces that exceed static weight calculations by significant margins through dynamic play behaviors.

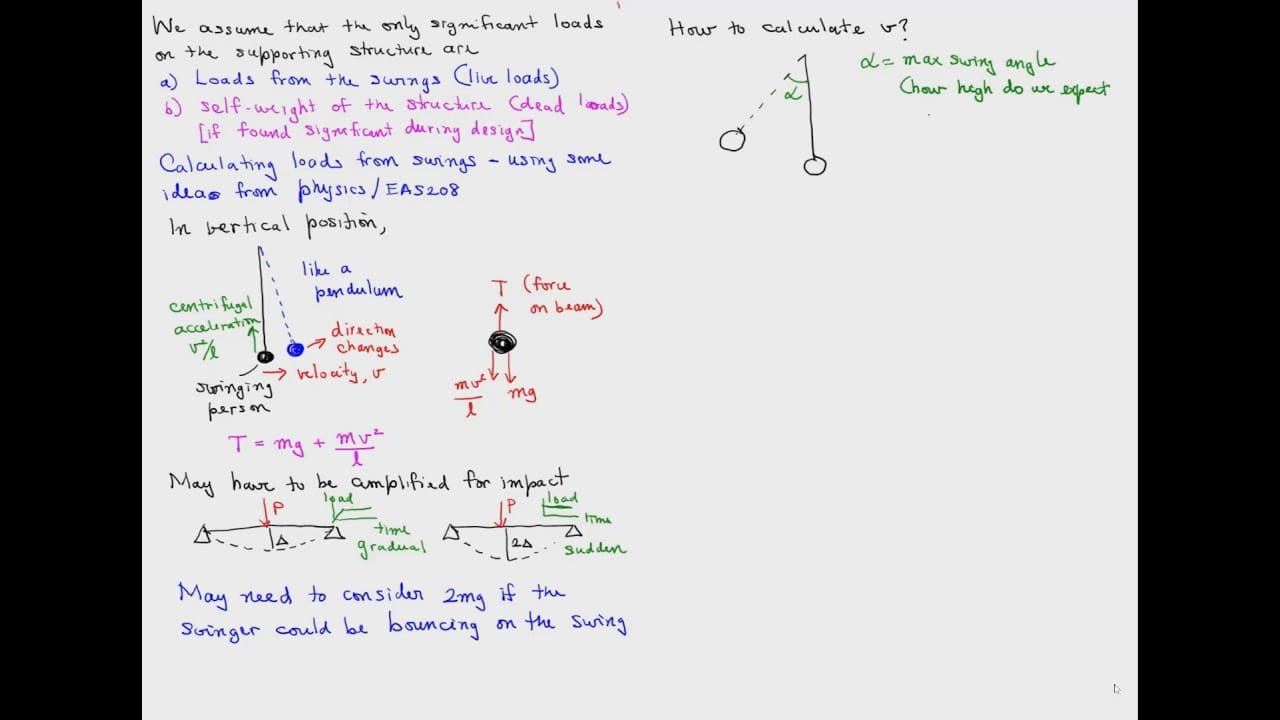

Load distribution misconceptions occur because children generate dynamic forces through unpredictable swing patterns and chain manipulation. A 60-pound child can generate peak loads exceeding 200 pounds during aggressive swinging, and that force concentrates at specific hardware connection points rather than distributing evenly across the structure.

Age-progression planning requires understanding how play patterns evolve and structural demands increase exponentially with user size and strength. The swing set you build for your 5-year-old needs to safely handle your 12-year-old’s increased leverage and risk-taking behavior. Physical development doesn’t scale linearly – a child who doubles in weight might triple their force generation capability.

Weather-induced stress accumulation compounds microscopic damage over time, making seemingly solid structures fail without warning signs. Each freeze-thaw cycle, each summer expansion, each storm creates tiny structural changes that accumulate until sudden failure occurs during normal use.

Professional playground analysis reveals that the total weight of a fully assembled swing set can exceed 350 pounds before adding users, according to ActionEcon’s detailed construction documentation, demonstrating why safety margins must account for both structural mass and dynamic user loads.

Dynamic Load Calculations for Real Play Patterns

Children don’t swing in predictable patterns – they create dynamic loads, twist chains, and generate forces that can exceed static weight calculations by 300-400%. This reality changes how you approach joint reinforcement and hardware selection for long-term safety when building your DIY swing.

Real-world usage patterns include chain twisting, synchronized swinging, and competitive play that creates force multipliers beyond individual user weights. I’ve watched kids deliberately twist swing chains into tight spirals, then release them for spinning motion that generates centrifugal forces the original design never anticipated. These DIY swing modifications create stress patterns that standard weight calculations can’t predict.

Joint reinforcement strategies must account for these dynamic loads rather than relying on static engineering calculations. The hardware that seems adequate for a stationary 100-pound load might fail catastrophically under the dynamic forces generated by a 60-pound child in aggressive motion. This is why professional playground equipment uses hardware rated far beyond apparent requirements.

Industry safety guidelines from “Popular Mechanics” warn that “never fasten swing fittings with a lag screw, which can pull out suddenly and send a kid flying,” emphasizing that proper hardware selection directly impacts user safety during dynamic loading scenarios.

Age-Transition Structural Planning

Building a swing set for a 5-year-old that will safely accommodate a 12-year-old requires understanding how physical development affects leverage and force generation. User size increases create exponential rather than linear increases in structural demands.

Physical development scaling means leverage increases exponentially as children grow, not proportionally to weight gain. A child who gains 30 pounds might develop 100% more force generation capability through increased height, strength, and coordination. Your DIY swing needs to anticipate this progression from the beginning.

Risk tolerance evolution leads older children to seek greater challenges and modify equipment for new experiences. They’ll use swing chains as climbing ropes, attempt to swing higher than intended, and find creative ways to push equipment beyond design limits. Safety margin calculations must account for these intentional misuse patterns during competitive play scenarios.

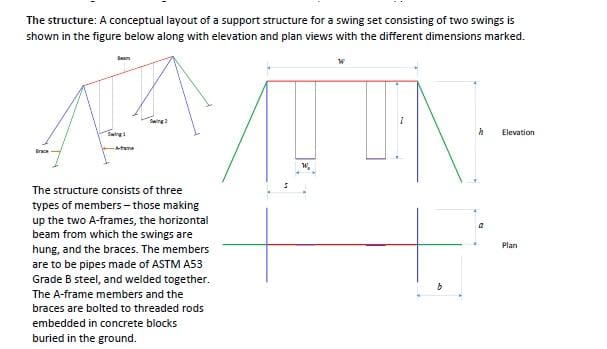

Assembly Sequence Strategy

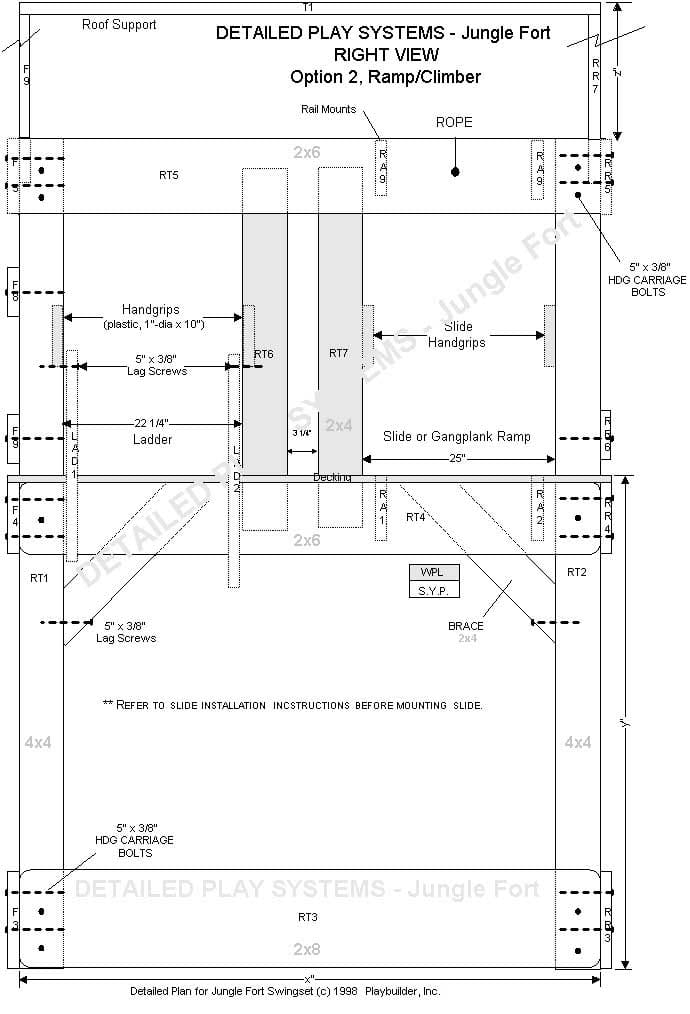

Traditional DIY swing set instructions treat assembly as a linear process, but experienced builders understand that operation sequence determines whether your structure remains square, stable, and safe for years. The order of connecting structural members affects how forces distribute through the frame under load.

Foundation-first approaches can create problems when working on uneven terrain or accounting for natural settling patterns. I’ve seen builders dig perfect holes and set posts in concrete, only to discover that the rigid foundation prevents the structure from accommodating natural ground movement. The result is cracked concrete and loosened joints within the first year.

Joint stress management through proper assembly order determines how forces distribute and whether structures become more stable or gradually loosen over time. When you connect the top beam before the diagonal braces, the structure can rack during assembly, creating permanent stress concentrations that weaken the entire frame. How to build a swing set frame properly requires understanding these force flow patterns.

Pre-stress integration methods allow certain joints to be assembled under controlled tension for improved long-term stability. Professional builders know which connections benefit from slight pre-loading during assembly, creating structures that actually tighten under normal use loads rather than gradually loosening.

Construction documentation shows that proper assembly sequence becomes critical when working with heavy components – a 16′ beam requires 4 people to safely raise according to ActionEcon’s field experience, demonstrating why sequence planning prevents dangerous assembly situations.

Dynamic Leveling Techniques

Instead of fighting natural grade variations, advanced builders use progressive leveling methods that allow structures to find natural equilibrium while maintaining safety standards. This approach prevents the need for major adjustments within the first year of use.

Progressive leveling accommodates natural terrain variations without compromising structural integrity or safety requirements. Rather than forcing level installation on uneven ground, you can design adjustability into the foundation system that allows for minor corrections as the structure settles and the ground shifts seasonally.

Settling prediction and accommodation strategies account for different soil types that settle at different rates over time. Clay soils might remain stable for months before sudden settling occurs during wet seasons, while sandy soils settle quickly but predictably. Your DIY swing set foundation needs to accommodate these different patterns.

A DIY builder in Colorado attempted to level their swing set on a 3-degree slope by digging level holes for each post. After six months, differential settling caused the structure to rack and loosen all joint connections. The solution involved installing adjustable post bases that allowed for seasonal movement while maintaining structural integrity – a technique that prevented complete reconstruction.

Pre-Stress Integration Methods

By assembling certain joints under controlled tension, you can create structures that actually become more stable under normal use loads rather than gradually loosening over time. This technique requires understanding how forces flow through connected structural members.

Controlled tension assembly creates structures that self-tighten under normal loads rather than loosening through use cycles. When you understand which joints benefit from slight pre-loading during assembly, the resulting structure actually improves with use rather than degrading. This DIY swing construction technique separates professional-quality installations from typical backyard projects.

Force distribution optimization occurs when structural members are connected in sequences that complement natural load paths. The forces generated by swinging motion follow predictable paths through your structure. When assembly sequence aligns with these natural force flows, joints remain tight and stable for years longer than randomly assembled structures.

Predictive Maintenance Systems

Most DIY swing set owners operate in reactive maintenance mode, addressing problems after they become visible. Professional playground managers use predictive maintenance strategies that can be adapted for residential use to prevent safety hazards and extend structure life.

Component lifecycle mapping identifies different aging rates for various parts based on function, material, and exposure to stress and weather. Your swing chains might need replacement every 5-7 years, while the main frame could last 15-20 years with proper care. Understanding these different timelines allows you to budget for maintenance and prevent safety hazards.

Hardware degradation follows predictable failure patterns that allow proactive replacement before safety hazards develop. Bolts loosen gradually, chains stretch incrementally, and protective coatings fail in predictable sequences. When you track these patterns, you can replace components before they become dangerous rather than after accidents occur.

Environmental damage accumulation from UV exposure, moisture cycles, and temperature fluctuations creates cumulative damage following predictable patterns. Each summer’s UV exposure weakens plastic components slightly, each winter’s freeze-thaw cycle creates microscopic cracks, and each storm deposits corrosive materials. These effects compound over time until sudden failure occurs.

Similar to how professional garage cleanout services systematically organize and remove accumulated items, predictive maintenance requires systematic tracking of component conditions before problems become overwhelming.

Component Lifecycle Mapping

Different parts of your DIY swing set age at different rates based on their function, material composition, and exposure to environmental stressors. Understanding these patterns allows you to replace components before they become safety hazards while optimizing maintenance costs.

Hardware degradation timelines for bolts, chains, and connectors follow predictable patterns based on material composition and environmental exposure. Galvanized hardware might last 8-12 years in moderate climates but only 5-7 years in coastal areas with salt exposure. Stainless steel components cost more initially but can extend service life to 15-20 years in harsh environments.

Wear pattern recognition helps identify early deterioration signs before they become obvious safety concerns. Chain links develop slight elongation before visible wear appears, bolt threads show microscopic damage before loosening becomes apparent, and wood develops soft spots before visible rot occurs. Learning to recognize these early indicators prevents safety hazards.

| Component | Expected Lifespan | Inspection Frequency | Replacement Indicators | Cost Impact |

|---|---|---|---|---|

| Swing Chains | 5-7 years | Monthly | Link elongation, surface rust | Low |

| Bolts/Hardware | 8-12 years | Quarterly | Loosening, corrosion | Medium |

| Wooden Posts | 12-18 years | Annually | Soft spots, checking | High |

| Metal Frame | 15-20 years | Annually | Joint movement, coating failure | High |

| Swing Seats | 3-5 years | Monthly | Cracking, UV fading | Low |

Hardware Degradation Timelines

Bolts, chains, and connectors follow predictable failure patterns based on material composition, environmental exposure, and usage intensity. Learning these timelines allows proactive replacement before components become safety hazards.

Metal fatigue patterns in hardware components develop according to stress cycles and environmental conditions. Each swing cycle creates microscopic stress in chains and bolts, gradually weakening the metal structure. High-use swing sets might accumulate thousands of stress cycles per month, accelerating fatigue development compared to occasional-use equipment.

Corrosion progression rates vary by hardware material and protective coatings under specific environmental conditions. Zinc plating might provide 5-7 years of protection in dry climates but only 2-3 years in humid coastal areas. Understanding your local environment helps predict when DIY swing hardware will need replacement.

Environmental Damage Recognition

UV exposure, moisture cycles, and temperature fluctuations create cumulative damage that follows predictable patterns. Knowing what signs to look for and when they typically appear allows for proactive protection measures that extend overall structure life.

UV degradation affects different materials at different rates, creating specific visual and structural indicators of deterioration. Plastic components fade and become brittle, wood surfaces gray and check, and protective coatings chalk and peel. These changes occur gradually but accelerate once protective barriers fail.

Moisture cycle damage accumulates through freeze-thaw expansion and contraction that creates microscopic structural changes over time. Water penetrates tiny cracks, freezes and expands, then thaws and allows deeper penetration. This cycle repeats hundreds of times over multiple seasons, gradually destroying material integrity from within.

Economic Optimization Strategies

Most DIY builders don’t consider long-term economics of initial choices, leading to expensive surprises when components need replacement or upgrade. Understanding upgrade versus replace decisions can transform simple DIY swing sets into evolving play structures.

Modular design integration allows future modifications that grow with family needs rather than requiring complete replacement. When you plan for expansion during initial construction, adding features becomes straightforward rather than requiring structural modifications. A simple DIY swing set can evolve into a complete play system through planned additions.

Component standardization using industry-standard hardware and dimensions makes future repairs and upgrades significantly easier and less expensive. Custom hardware might seem creative during construction, but standard components remain available for decades while custom parts become impossible to replace.

Salvage value planning helps optimize both initial investment and eventual disposal decisions by understanding which components retain value over time. Quality hardware maintains resale value, treated lumber can be repurposed for other projects, and metal components have scrap value that offsets disposal costs.

Behavioral Engineering for Real-World Use

Traditional swing set plans assume orderly use patterns, but children transform play equipment into something entirely different than intended. This reality requires a fundamentally different approach to structural planning that accounts for chaotic and competitive usage patterns.

Multi-user dynamics create resonance patterns and load combinations that single-user calculations cannot predict accurately. When two children swing in rhythm, they can generate forces that exceed the combined individual loads by significant margins. Your DIY swing set needs to handle these amplified dynamics without compromising stability during synchronized motion events.

Age-transition accommodation requires understanding how play patterns evolve and physical capabilities change over time. The gentle swinging motion of a 4-year-old transforms into aggressive competitive swinging by age 8, then evolves into creative equipment modification by age 12. Each phase creates different structural demands that must be anticipated during initial construction.

Competitive usage escalation occurs naturally as children push equipment beyond intended limits during play. They’ll attempt to swing higher, jump farther, and find creative ways to challenge themselves and each other. Safety margin calculations must account for these intentional misuse patterns that occur during normal childhood development.

Multi-User Dynamics Problem

When multiple children use a DIY swing set simultaneously, they create resonance patterns and load combinations that single-user calculations can’t predict. The structure must accommodate these amplified dynamics without compromising stability during synchronized motion events.

Synchronized motion amplification occurs when children swing in rhythm, generating forces that exceed combined individual loads by significant margins. Two 60-pound children swinging in perfect synchronization can generate peak loads exceeding 500 pounds at the attachment points – far beyond the 120 pounds their static weights would suggest.

Social clustering effects create concentrated stress points that shift based on group dynamics and seasonal preferences rather than distributing evenly across equipment. Children naturally gravitate toward specific swings or areas, creating wear patterns and stress concentrations that don’t match the uniform loading assumptions of typical DIY swing designs.

Synchronized Motion Amplification

Two children swinging in rhythm can generate forces that exceed the combined individual loads by significant margins. Understanding these resonance effects helps inform design choices that maintain safety margins even during intensive synchronized use.

Resonance frequency calculations must account for multiple users creating harmonic motion patterns that amplify structural stress. When swing frequencies align, the resulting forces can double or triple beyond simple addition of individual loads. Your DIY swing structure needs hardware rated for these amplified forces, not just the static weight of users.

Load amplification factors increase exponentially rather than additively when users synchronize their motion patterns. The physics of resonance means that small timing alignments create large force multiplications. Professional playground equipment accounts for these effects through oversized hardware and reinforced connection points.

Competitive Usage Escalation

Children naturally push equipment beyond intended limits during play competition. Understanding these behavioral patterns helps inform design choices that maintain safety margins even when users attempt to exceed normal operating parameters.

Risk tolerance evolution leads children to seek greater challenges and modify equipment to create new experiences. What starts as gentle swinging evolves into height competitions, jumping contests, and creative equipment modifications. Your DIY swings need to anticipate these progressions and maintain safety margins throughout the evolution.

Safety margin calculations must account for intentional misuse patterns that occur during competitive play scenarios. Children will attempt to swing standing up, jump from maximum height, and use chains as climbing ropes. These behaviors aren’t accidents – they’re predictable developmental patterns that require engineering consideration.

A family in Texas discovered their 8 and 10-year-old children were using their swing set chains as climbing ropes, creating loads the hardware wasn’t designed to handle. Rather than simply forbidding the behavior, they installed dedicated climbing rope attachments using rated hardware, channeling the competitive behavior into safer activities while maintaining the swing set’s primary function.

Environmental Integration Methods

Most DIY approaches treat the landscape as something to overcome rather than partner with, missing opportunities to create more durable and aesthetically pleasing installations. Working with natural systems creates better long-term outcomes than fighting environmental conditions.

Drainage engineering determines structural lifespan more than any other single factor, yet most builders focus only on immediate installation concerns. Proper water management implemented during initial construction prevents expensive problems that are difficult to address after your DIY backyard swing set installation is complete.

Vegetation integration strategies can provide structural benefits through windbreak development while preventing root system interference. Strategic landscaping reduces wind stress while enhancing property value through attractive design integration. The key is understanding how different plant species develop over time and planning accordingly.

Freeze-thaw cycle management becomes critical in climates with temperature fluctuations around freezing points. Each winter cycle creates expansion and contraction forces that gradually loosen joints and crack materials. Your DIY swing set needs to accommodate these forces rather than resist them.

Drainage Engineering for Longevity

Water management around swing sets determines structural lifespan more than any other single factor. Proper drainage systems implemented during initial construction prevent expensive problems that are difficult to address after installation is complete.

Surface water diversion through proper grading channels water away from structural elements while maintaining safe play surfaces. This requires understanding how water moves across your specific terrain during various weather conditions. A slight grade adjustment during installation can prevent years of moisture-related deterioration.

Subsurface moisture control affects both metal corrosion and wood decay from below ground level through different mechanisms. Ground moisture travels up through capillary action, affecting components that appear completely dry during surface inspections. Moisture barriers and drainage systems implemented during construction prevent these hidden problems.

Surface Water Management

Proper grading channels water away from structural elements while maintaining safe play surfaces throughout different seasons. This requires understanding how water moves across your specific terrain during various weather conditions.

Grading techniques must account for seasonal water flow patterns that change based on precipitation and ground saturation levels. Spring snowmelt creates different drainage challenges than summer thunderstorms or fall leaf accumulation. Your DIY swing set site preparation needs to handle all these seasonal variations.

Play surface safety requires balancing drainage effectiveness with maintaining level areas for safe equipment use. Too much slope creates runoff but makes the area unsafe for play, while insufficient slope causes pooling that accelerates structural deterioration. Finding the right balance requires understanding both drainage principles and safety requirements.

Subsurface Moisture Control

Ground moisture affects both metal corrosion and wood decay from below through mechanisms that aren’t visible during regular inspections. Implementing barriers and drainage systems during initial construction prevents problems that are expensive to address later.

Moisture barrier installation techniques prevent ground water from reaching structural elements through capillary action and direct contact. Simple plastic sheeting under posts can extend their lifespan by years, while proper drainage aggregate prevents water accumulation around foundations.

Drainage system design must account for seasonal water table fluctuations and soil permeability characteristics. What works during dry summer months might fail during wet spring conditions when the water table rises and soil saturation changes drainage patterns completely.

Vegetation Integration Strategies

Plants around swing sets can provide structural benefits or create maintenance problems depending on species selection and placement decisions. Strategic landscaping reduces wind stress while enhancing property value through attractive design integration.

Natural windbreak development through strategic plantings can reduce structural stress while creating attractive landscaping features. Trees and shrubs positioned to block prevailing winds can significantly extend swing set lifespan by reducing constant stress cycling. The key is choosing species that provide protection without creating maintenance problems.

Root system interference prevention requires understanding how different plant species develop underground growth patterns over time. Some trees send roots horizontally for distances exceeding their height, while others develop deep taproots that don’t interfere with surface structures. Planning for these growth patterns prevents future conflicts.

Just as professional yard waste disposal services understand the importance of proper vegetation management, swing set builders must consider how plant growth affects structural integrity over time.

An easy DIY swing set installation can become complicated when vegetation planning is ignored. I’ve seen beautiful installations compromised within five years because aggressive root systems undermined foundations or overgrown shrubs created maintenance access problems.

Swing Set Maintenance Checklist:

☐ Monthly Inspections

– Check all bolts and hardware for tightness

– Inspect swing chains for wear or elongation

– Examine swing seats for cracks or UV damage

– Test all moving parts for smooth operation

☐ Quarterly Assessments

– Measure post stability and check for movement

– Inspect wood for soft spots or checking

– Evaluate drainage around foundation areas

– Check protective coatings and finishes

☐ Annual Maintenance

– Deep clean all components

– Apply protective treatments to wood surfaces

– Lubricate moving hardware

– Document component condition for lifecycle tracking

☐ Seasonal Preparations

– Winter: Remove or secure loose components

– Spring: Inspect for freeze-thaw damage

– Summer: Check UV protection and ventilation

– Fall: Clear debris and prepare for weather

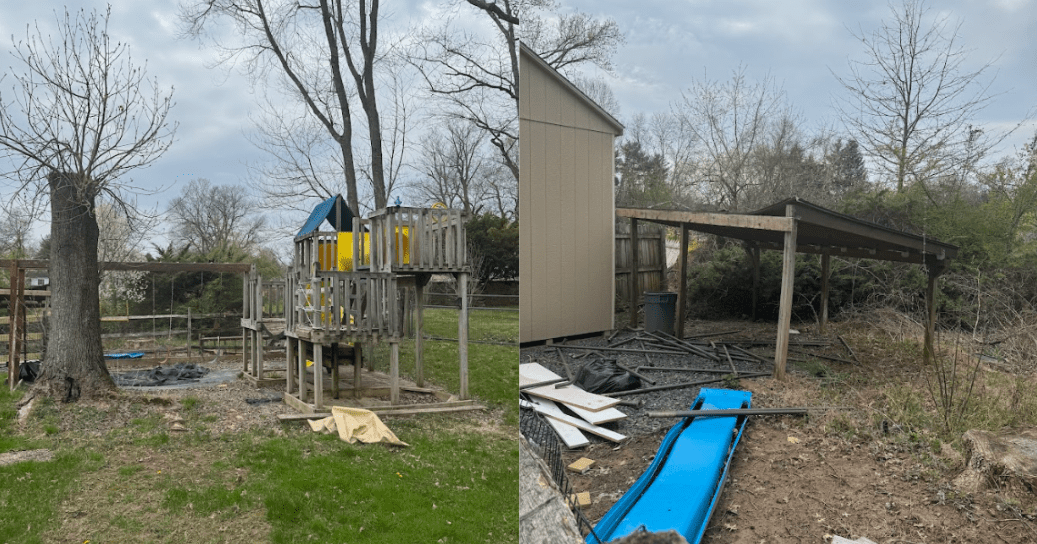

Professional Removal Solutions

When your thoughtfully constructed swing set eventually requires removal due to age, family changes, or property modifications, the disassembly process presents unique challenges that many homeowners underestimate. Weathered hardware, treated lumber disposal, and yard restoration often reveal unexpected complications.

Weathered hardware removal requires specialized tools and techniques to prevent property damage during disassembly processes. Bolts that installed easily when new become seized and corroded after years of weather exposure. Standard tools often prove inadequate for safe removal without damaging surrounding structures or landscaping.

Environmental disposal regulations for treated lumber and metal components vary by location and require proper sorting for compliance. Many municipalities prohibit treated lumber in regular waste streams, while metal components have recycling value that shouldn’t be wasted. Understanding these requirements prevents disposal violations and maximizes material recovery.

Yard restoration after removal often reveals foundation impacts and soil compaction that require professional remediation. Years of concentrated foot traffic and structural loading create soil conditions that prevent immediate replanting or alternative use. Professional restoration addresses these hidden impacts that DIY removal often overlooks.

Similar to other outdoor equipment removal challenges, professional debris removal services understand the complexities of weathered hardware and proper disposal methods that homeowners often overlook.

Jiffy Junk’s experience with playground equipment removal means we understand these complexities before they become problems. Our systematic approach ensures complete removal while protecting surrounding landscaping and property features you want to preserve. The team’s environmental responsibility focus means your swing set components are sorted for maximum recycling potential, with metals recovered and suitable wood materials diverted from landfills.

This professional approach eliminates common DIY removal pitfalls: incomplete hardware extraction that creates safety hazards, improper material disposal that violates local regulations, and yard damage that requires expensive restoration. Instead, you’re left with a clean slate ready for your next outdoor project.

Final Thoughts

Building a DIY swing set using engineering principles rather than basic construction methods creates structures that last longer, perform better, and provide safer play experiences for your family. The investment in understanding material science, environmental integration, and behavioral engineering pays dividends through reduced maintenance costs and extended equipment life.

However, every structure eventually reaches the end of its useful life. When that time comes, professional removal services handle the complexities of disassembly, proper disposal, and yard restoration with the same attention to detail you invested in the original construction. This approach ensures your property is ready for whatever comes next while maintaining environmental responsibility throughout the process.

Whether you’re planning new construction or dealing with construction debris removal, understanding the complete lifecycle of outdoor structures helps optimize both initial investment and eventual disposal decisions.

Engineering-based construction methods create measurable improvements in safety margins, structural longevity, and maintenance requirements compared to standard DIY approaches. The additional planning and material investment during construction pays for itself through extended service life and reduced maintenance costs over the structure’s lifetime.

Professional removal services provide value through specialized expertise in weathered hardware extraction, environmental compliance, and property restoration. When your swing set reaches end-of-life, professional removal ensures proper material handling and site restoration that DIY approaches often overlook.

Long-term planning for both construction and eventual removal optimizes the complete lifecycle investment while maintaining environmental responsibility standards. Understanding these principles from the beginning helps create better outcomes throughout the entire ownership experience.

Pre-Assembly Planning Template:

Site Assessment Phase:

– ☐ Measure available space (minimum 6ft clearance all sides)

– ☐ Test soil drainage with 12-inch deep water test

– ☐ Identify prevailing wind direction and seasonal patterns

– ☐ Mark underground utilities location

– ☐ Calculate sun exposure hours throughout day

Material Specification Phase:

– ☐ Select lumber grade based on soil chemistry analysis

– ☐ Verify hardware corrosion resistance ratings

– ☐ Plan component delivery and storage sequence

– ☐ Prepare tool inventory and backup equipment

– ☐ Schedule helper availability for heavy lifting phases

Assembly Readiness Phase:

– ☐ Pre-drill all hardware holes before lifting beams

– ☐ Organize components by assembly sequence

– ☐ Establish level reference points across build area

– ☐ Prepare concrete mixing station and materials

– ☐ Set up safety perimeter and emergency procedures

Advanced Load Distribution Analysis:

Understanding how forces travel through your swing set frame helps prevent the joint failures that plague many DIY installations. When a child generates peak swing forces, the energy doesn’t distribute evenly – it concentrates at specific connection points where different materials and grain directions meet.

The most critical load path runs from swing attachment points down through the top beam, into the vertical supports, and finally into the ground connection. Each transition point in this path creates stress concentration that compounds over thousands of swing cycles. Professional engineers design these transitions with specific hardware and joint geometries that distribute forces across larger surface areas.

Soil Bearing Capacity Calculations:

Different soil types support vertical loads at dramatically different rates. Clay soils may provide excellent bearing capacity when dry but become unstable during wet seasons. Sandy soils offer consistent support but require deeper foundations to prevent lateral movement during dynamic loading.

The standard residential approach of digging holes “until they look deep enough” ignores the engineering reality that soil bearing capacity determines long-term stability more than hole depth. A 24-inch deep hole in compacted clay may provide better support than a 36-inch hole in loose sand, but only if you understand the soil characteristics and design accordingly.