25 Brilliant Basement Pantry Ideas That’ll Transform Your Storage Game Forever

I remember standing in my cramped kitchen last year, frustrated by overflowing cabinets and expired items hidden in the back corners. Recent studies show that 73% of homeowners struggle with kitchen storage limitations, leading many to explore basement pantry solutions. That’s when I discovered the untapped potential of basement pantry spaces – a game-changing solution that not only expanded my storage capacity but revolutionized how I organize and access my food supplies.

Basement pantries offer 3-5 times more storage capacity than traditional kitchen pantries while maintaining easy accessibility through proper planning and design. Strategic basement pantry implementation can increase home value by 2-4% while reducing monthly grocery waste by up to 30% through improved organization and visibility.

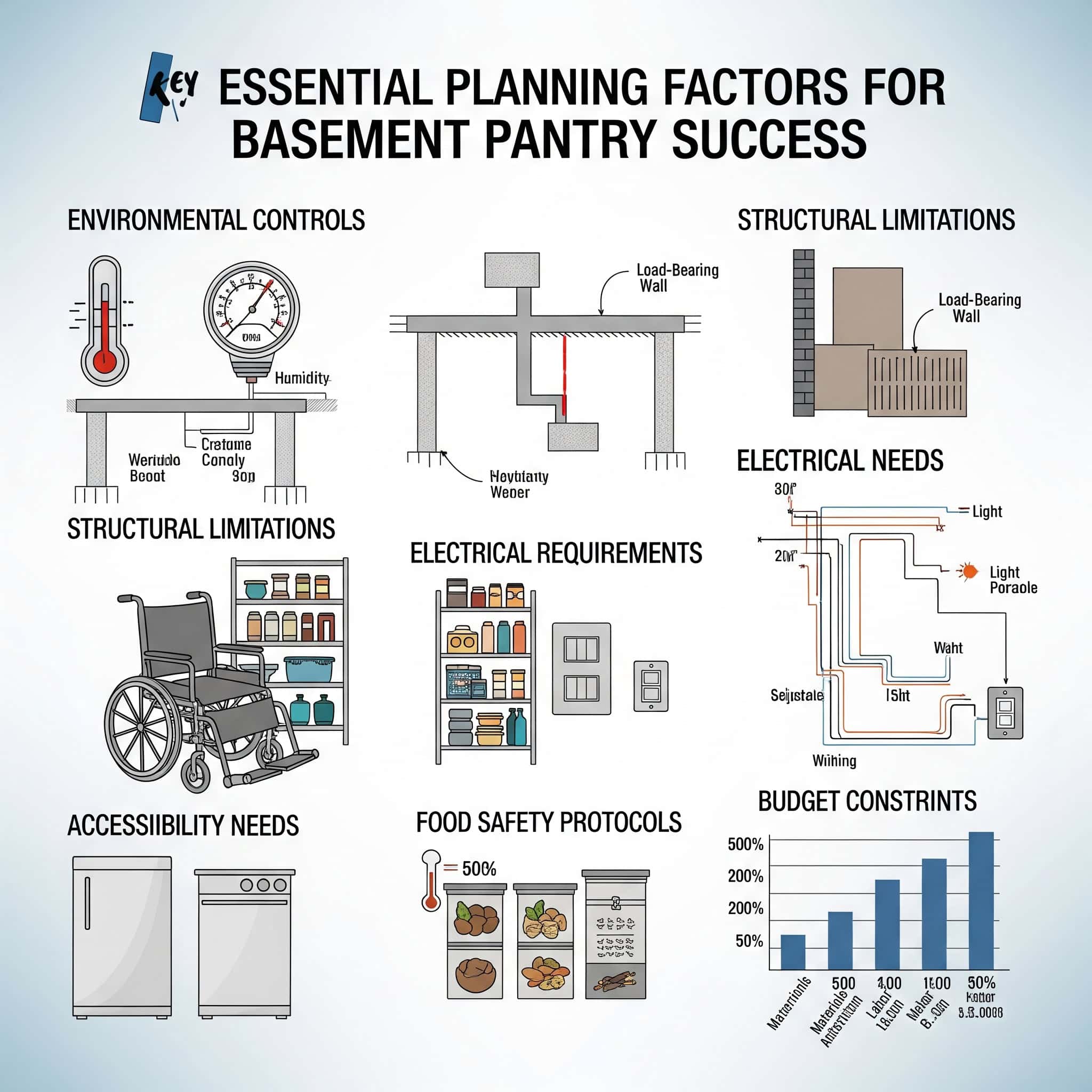

Essential Planning Factors for Basement Pantry Success

Creating a successful basement pantry requires careful consideration of environmental controls, structural limitations, accessibility needs, electrical requirements, food safety protocols, and budget constraints. These foundational elements determine whether your pantry becomes a functional asset or a problematic storage space that compromises food quality and safety.

Environmental control systems must maintain 50-70°F temperatures with 50-60% humidity levels to prevent food spoilage and mold growth in basement conditions. I’ve seen too many basement pantry ideas fail because homeowners skipped this crucial step. Structural assessments should verify floor joist capacity of 40+ pounds per square foot for fully loaded pantry systems, with proper weight distribution across multiple support points.

|

Planning Factor |

Optimal Range |

Critical Requirements |

Common Issues |

|---|---|---|---|

|

Temperature |

50-70°F |

HVAC zone, insulation |

Seasonal fluctuations |

|

Humidity |

50-60% |

Dehumidifier, vapor barrier |

Condensation, mold |

|

Structural Load |

40+ lbs/sq ft |

Joist assessment, reinforcement |

Sagging floors |

|

Lighting |

50+ foot-candles |

LED fixtures, motion sensors |

Dark corners |

|

Ventilation |

6-8 air changes/hour |

Exhaust fans, intake vents |

Stale air |

|

Electrical |

20+ amp capacity |

GFCI outlets, dedicated circuits |

Overloaded circuits |

Climate Control and Moisture Management

Basement environments naturally present moisture challenges, temperature fluctuations, and humidity issues that can destroy stored food and create unsafe conditions. Effective climate management requires dedicated ventilation systems, dehumidification equipment, moisture barriers, and potentially separate HVAC zones to maintain consistent conditions that preserve food quality and prevent mold growth.

Installing dehumidification systems maintaining 50-60% relative humidity with automatic drainage and backup power options ensures continuous operation. I can’t stress enough how critical this step is – moisture will ruin your entire investment if you don’t address it properly. Implementing vapor barriers on walls and floors combined with proper ventilation systems that exchange air 6-8 times per hour prevents condensation buildup that can destroy both your food and your storage systems.

The Johnson Family’s Climate Control Success Story: The Johnsons transformed their damp basement into a perfect pantry by installing a whole-house dehumidifier connected to their HVAC system, adding a vapor barrier to the concrete walls, and installing an exhaust fan that runs on a timer. Their basement now maintains a steady 55°F and 55% humidity year-round, extending their food storage life by over 200% compared to their previous kitchen pantry storage.

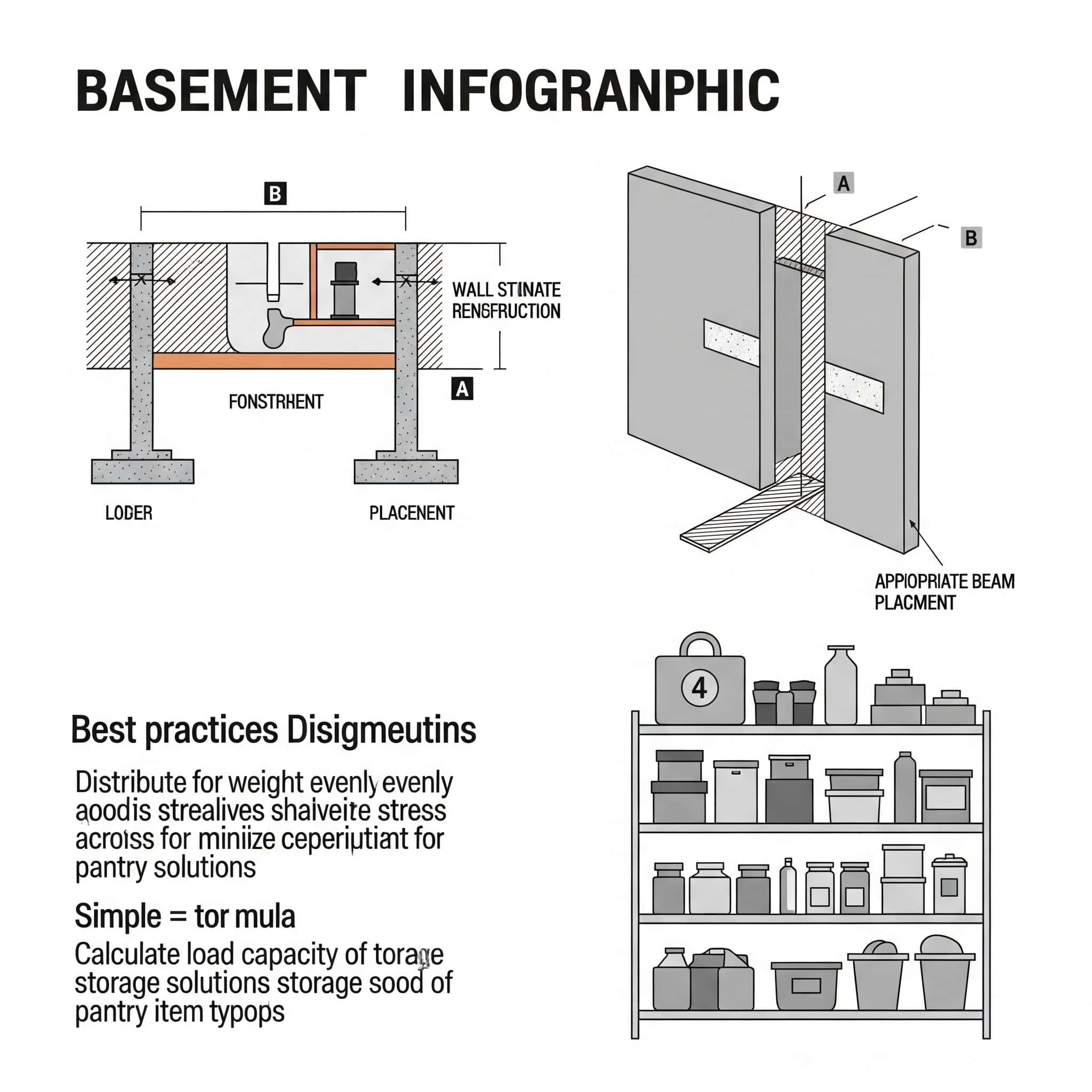

Structural Safety and Weight Distribution

Basement pantries can add substantial weight loads that exceed original structural design parameters. You’ll need professional assessment of floor joists, foundation elements, and load-bearing capacity before installing heavy shelving systems or storing large quantities of food items that could compromise structural integrity.

Calculating total weight loads including shelving (15-25 lbs per linear foot), stored goods (30-50 lbs per shelf), and safety factors before installation prevents costly structural damage. Before implementing your basement pantry ideas, consider professional basement cleanout services to properly assess structural requirements and clear existing clutter that might interfere with your project.

Distributing weight across multiple floor joists using spanning techniques and reinforcement plates prevents concentrated loading that could cause structural damage. I’ve witnessed basement floors sag because homeowners loaded too much weight in one area without proper distribution.

Accessibility and Traffic Flow Design

Proper accessibility planning ensures your basement pantry serves all family members effectively while maintaining safety standards. This includes adequate aisle widths, appropriate lighting levels, clear sight lines, and consideration for users with different heights and mobility requirements when designing layout and storage heights.

Maintaining minimum 36-inch aisle widths for wheelchair accessibility with 42-48 inches preferred allows comfortable two-person passage and cart maneuvering. Positioning frequently used items between 30-60 inches from floor level accommodates users of varying heights without requiring step stools or excessive reaching.

Walk-In Pantry Transformations

Walk-in basement pantries offer the ultimate storage solution by converting entire rooms into dedicated food storage spaces. These designs provide maximum capacity, excellent organization potential, and the ability to create specialized zones for different food categories while maintaining easy access and professional-grade storage conditions.

Walk-in pantries can accommodate 500-1000+ items compared to 100-200 items in standard kitchen pantries, with proper shelving density of 12-16 inches between shelves. Custom built-in systems maximize space utilization by 40-60% compared to freestanding furniture through floor-to-ceiling integration and corner optimization.

1. Traditional Walk-In Pantry with Custom Built-Ins

This comprehensive solution transforms a basement room into a professional-grade storage space with floor-to-ceiling custom cabinetry, adjustable shelving systems, pull-out drawers for heavy items, and specialized storage zones for different food categories. The design includes workspace areas for meal planning and electrical infrastructure for small appliances.

Custom built-ins utilize 85-95% of available wall space compared to 60-70% for freestanding units, with adjustable shelving accommodating packages from 4-18 inches in height. When I helped my neighbor design their walk-in pantry, we discovered that custom solutions provided nearly double the storage capacity of their original plan using store-bought shelving.

2. L-Shaped Walk-In Configuration

L-shaped designs maximize storage capacity in smaller basement spaces by utilizing two perpendicular walls efficiently. This walk-in pantry configuration maintains comfortable traffic flow while eliminating wasted corner space through specialized corner storage solutions and strategic aisle width planning.

L-shaped layouts provide 30-40% more storage than single-wall designs while maintaining 42-inch minimum aisle widths for comfortable movement and access. The corner areas that typically become dead space transform into highly functional storage zones with the right planning.

3. Galley-Style Walk-In Pantry

Galley-style walk-in pantries work perfectly in narrow basement spaces by placing shelving systems on both sides of a central walkway. This design maximizes storage density while maintaining excellent organization and visibility of stored items through strategic shelf depth and spacing.

Galley designs achieve storage densities of 15-20 items per linear foot of wall space with 12-14 inch shelf depths preventing items from hiding behind others. I’ve found this configuration particularly effective for families who buy in bulk but have limited basement width to work with.

4. Walk-In Pantry with Central Island

Larger basement areas can accommodate central islands that provide additional storage, food preparation workspace, and staging areas for meal planning. Islands create efficient workflow patterns while adding counter space for package opening, sorting, and organization tasks.

Central islands add 25-35% more storage capacity while providing 15-20 square feet of workspace for food preparation and organization activities. The walk in pantry becomes a true food preparation hub rather than just storage space.

5. Multi-Zone Walk-In Pantry

Multi-zone designs create distinct areas within walk-in pantries for different storage needs including dry goods, canned items, beverages, bulk storage, and specialty items. Each zone maintains optimal conditions for its specific food categories while supporting efficient organization and rotation systems.

Zone-based organization reduces food waste by 20-30% through improved visibility and rotation while accommodating different storage requirements for various food categories. These walk in pantry ideas work especially well for large families or those who entertain frequently.

Space-Maximizing Storage Solutions

Space-efficient storage solutions focus on maximizing every inch of available basement space through vertical storage systems, pull-out mechanisms, rotating units, and modular components. These solutions work well in basements with limited floor space or existing structural constraints that prevent major renovations.

Vertical storage systems can increase capacity by 200-300% compared to standard shelving by utilizing full ceiling height with proper anchoring and safety features. Pull-out and rotating mechanisms improve access efficiency by 50-70% while reducing time spent searching for items in deep storage areas. Even smaller basements can accommodate impressive walk-in pantry functionality with the right space-maximizing approach.

6. Floor-to-Ceiling Shelving Systems

Floor-to-ceiling shelving maximizes vertical space utilization with adjustable components that accommodate different package sizes. These systems require proper anchoring to wall studs and include safety features like shelf lips to prevent items from falling during access or seismic activity.

Floor-to-ceiling systems utilize 90-95% of vertical space with adjustable shelving every 2-4 inches to accommodate various package heights from spice jars to bulk containers. The key is ensuring your anchoring system can handle the full weight load when every shelf is completely stocked.

7. Pull-Out Pantry Cabinets

Pull-out cabinet systems bring stored items from deep spaces directly to you, eliminating the need to reach into dark corners or move items to access others. These systems use heavy-duty slides and multiple tiers to maximize storage while maintaining easy access to all items.

Pull-out systems with full-extension slides rated for 100+ pounds provide complete access to items stored up to 24 inches deep, eliminating lost or forgotten items. I’ve installed these in several walk-in pantry projects, and they consistently receive the most positive feedback from homeowners.

8. Rotating Corner Storage Units

Corner spaces often become dead storage areas in basement pantries. Rotating storage units solve this problem by bringing items from the back of corner spaces to the front with simple rotation, maximizing storage in otherwise difficult-to-access areas.

Rotating corner units recover 60-80% of typically unusable corner space while providing easy access to items through 270-degree rotation mechanisms. These units work particularly well in walk-in pantry designs where corners might otherwise become forgotten zones.

9. Under-Stair Storage Integration

The space under basement stairs offers unique storage opportunities when properly designed with custom-fitted shelving systems. This area works well for items used less frequently or seasonal storage while maintaining accessibility through thoughtful height and depth planning.

Under-stair storage can provide 20-40 cubic feet of additional storage space with custom shelving that follows stair angles and maximizes headroom clearance. Don’t overlook this valuable real estate when planning your basement storage strategy.

10. Modular Storage Systems

Modular storage components offer flexibility for changing needs through reconfigurable shelving, bins, and organizational elements. These systems adapt as family size changes, dietary requirements evolve, or storage needs shift over time without requiring complete redesign.

Modular systems provide 40-60% more flexibility than fixed installations while maintaining structural integrity through standardized connection points and load distribution. The Miller Family’s Modular Success: When the Millers started their basement pantry project, they chose a modular wire shelving system that could grow with their needs. Starting with basic shelving for $800, they gradually added pull-out bins, wine racks, and specialized organizers over two years. Their system now stores over 400 items in a 6×8 foot space, and they’ve reconfigured it three times as their storage needs evolved without purchasing entirely new components.

Specialized Organization Systems

Specialized storage solutions address specific food categories and storage requirements that standard shelving cannot accommodate effectively. These systems include climate-controlled areas, bulk storage solutions, traditional preservation methods, and emergency preparedness storage with proper rotation and inventory management.

Specialized storage systems can extend food life by 50-200% through optimal environmental conditions and proper rotation protocols. Climate-controlled storage maintains precise temperature and humidity ranges for wine (55-60°F, 60-70% humidity) and root vegetables (32-40°F, 85-95% humidity). These specialized areas can transform your walk-in pantry into a comprehensive food preservation center.

11. Temperature-Controlled Wine & Beverage Storage

Wine and beverage storage requires precise temperature control, humidity management, vibration dampening, and UV protection to maintain quality. These systems include dedicated cooling units, proper storage angles, and separate zones for different beverage types with appropriate accessibility features.

Wine storage systems maintain 55-60°F temperatures with ±2°F stability and 60-70% humidity while protecting against vibration and UV exposure that can damage wine quality. Even in a walk-in pantry setting, dedicated wine storage zones preserve your investment while adding sophistication to your basement space.

12. Bulk Storage Solutions

Bulk storage systems accommodate warehouse-style purchasing with large food-grade containers, airtight sealing systems, and rotation protocols. These solutions include measuring tools, labeling systems, and pest prevention measures while maintaining easy access for daily use.

Bulk storage containers with airtight seals can extend dry goods storage life by 300-500% while reducing packaging waste and providing cost savings of 20-40% through bulk purchasing. I’ve helped families save thousands annually by implementing proper bulk storage systems in their basement pantries.

13. Root Cellar Integration

Traditional root cellar principles can be integrated into basement pantries to create optimal storage conditions for potatoes, onions, carrots, and other vegetables. These areas maintain cool temperatures and higher humidity levels that extend produce life significantly compared to standard storage.

Root cellar conditions (32-40°F, 85-95% humidity) can extend potato storage life from 2-3 weeks to 4-6 months while maintaining nutritional value and preventing sprouting. This traditional approach works beautifully within modern walk-in pantry designs.

14. Canning & Preservation Station

Home canning and preservation stations include dedicated workspace, equipment storage, and proper ventilation for safe food preservation activities. These areas accommodate canning supplies, preservation equipment, and storage for homemade preserved goods with appropriate labeling and rotation systems.

Canning stations require 15-20 square feet of workspace with proper ventilation (150+ CFM) and electrical capacity for pressure canners and other preservation equipment. Integrating these stations into your walk-in pantry creates a complete food processing and storage hub.

15. Emergency Food Storage System

Emergency preparedness storage focuses on long-term food storage with proper rotation systems, inventory tracking, and climate control for extended shelf life. These systems include backup power considerations, manual access during outages, and security measures for valuable long-term storage.

Emergency storage systems can maintain food viability for 10-30 years through proper packaging, temperature control (50-70°F), and rotation protocols that ensure freshness and nutritional value. Your walk-in pantry can serve double duty as both daily storage and emergency preparedness center.

|

Storage Type |

Temperature Range |

Humidity Level |

Storage Life Extension |

Special Requirements |

|---|---|---|---|---|

|

Wine Storage |

55-60°F |

60-70% |

5-10+ years |

Vibration dampening, UV protection |

|

Root Vegetables |

32-40°F |

85-95% |

300-400% increase |

Ventilation, separate compartments |

|

Bulk Dry Goods |

50-70°F |

10-15% |

300-500% increase |

Airtight containers, pest control |

|

Canned Goods |

50-70°F |

50-60% |

2-5 years |

Rotation system, stable shelving |

|

Emergency Foods |

50-70°F |

10-15% |

10-30 years |

Oxygen absorbers, mylar bags |

|

Frozen Storage |

-10 to 0°F |

N/A |

12-24 months |

Backup power, temperature alarms |

Smart Technology Integration

Technology integration transforms basement pantries into smart storage systems with inventory tracking, automated lighting, climate monitoring, and digital organization tools. These solutions improve efficiency, reduce waste, and provide real-time information about storage conditions and inventory levels.

Smart pantry systems can reduce food waste by 25-40% through automated expiration tracking and inventory management while providing real-time alerts for restocking needs. Automated systems improve energy efficiency by 15-30% through smart lighting and climate controls that operate only when needed. Even traditional walk-in pantry designs benefit enormously from smart technology integration.

16. Smart Inventory Management Systems

Smart inventory systems use barcode scanning, smart scales, and mobile apps to track pantry contents, expiration dates, and automatically generate shopping lists. These systems integrate with meal planning software and home automation systems for comprehensive household management.

Smart inventory systems can track 500+ items with automatic expiration alerts and reorder suggestions while integrating with grocery delivery services for seamless restocking. I’ve watched families cut their grocery shopping time in half while reducing food waste dramatically with these systems.

17. Automated Lighting Systems

Automated lighting includes motion sensors, timer controls, LED strip lighting, and zone-based activation that illuminates specific areas as needed. These systems improve safety, reduce energy consumption, and provide optimal visibility for reading labels and accessing stored items.

Motion-activated LED systems provide 40,000+ hour lifespans while reducing energy consumption by 75-85% compared to traditional lighting with instant-on capability and adjustable sensitivity. Your walk-in pantry becomes more functional and energy-efficient with proper lighting automation.

18. Climate Monitoring & Control

Smart climate systems use wireless sensors to monitor temperature, humidity, and air quality throughout the pantry space. These systems provide smartphone alerts, data logging for trend analysis, and automated ventilation controls that maintain optimal storage conditions.

Wireless sensor networks provide ±1°F temperature accuracy and ±3% humidity precision with real-time alerts and automated responses to maintain optimal storage conditions. This technology ensures your walk-in pantry maintains perfect conditions even when you’re away from home.

19. Vacuum-Sealed Storage Solutions

Vacuum-sealing stations extend food storage life by removing air that causes spoilage and oxidation. These systems include dedicated workspace, storage for bags and accessories, and proper ventilation for equipment operation while maintaining organization and labeling protocols.

Vacuum-sealed storage can extend food life by 300-500% for dry goods and 200-300% for frozen items while reducing storage volume by 50-75% through air removal. This technology maximizes your walk-in pantry capacity while preserving food quality.

20. Digital Organization Labels

Digital labeling systems use QR codes, smart tags, and mobile apps for advanced organization and inventory tracking. These systems provide detailed information about contents, expiration dates, and storage instructions while supporting multiple users and remote access capabilities.

Digital labeling systems can store unlimited information per item including purchase dates, expiration tracking, nutritional data, and recipe suggestions accessible through smartphone scanning. The Chen Family’s Smart Pantry Transformation: The Chens invested $1,200 in smart pantry technology including a barcode scanner app, wireless temperature sensors, and smart LED strips. Their system now automatically tracks 300+ items, sends expiration alerts to their phones, and maintains perfect storage conditions. They’ve reduced food waste by 35% and cut grocery shopping time in half through automated shopping list generation. The system paid for itself in food savings within 18 months.

Multi-Functional Basement Designs

Multi-purpose basement designs combine pantry storage with other household functions to maximize space utilization and efficiency. These solutions integrate laundry facilities, home offices, craft storage, exercise equipment, and guest preparation areas while maintaining organization and functionality for all purposes.

Multi-functional designs can increase basement utility by 200-400% through strategic space sharing while maintaining dedicated zones for different activities. Proper planning prevents cross-contamination between functions through moisture barriers, ventilation systems, and organizational protocols. When planning multi-functional spaces, efficient garage clean-out services can help you understand space optimization principles that apply to basement organization projects.

21. Pantry-Laundry Combination

Combining pantry storage with laundry facilities requires careful moisture management, proper ventilation, and separation of wet and dry areas. These designs include storage for cleaning supplies separate from food items while maintaining efficient workflow patterns for both functions.

Pantry-laundry combinations require moisture barriers and dedicated ventilation (200+ CFM) to prevent humidity from laundry operations affecting food storage areas. I’ve designed several of these combinations, and the key is creating physical barriers between the wet and dry zones while maintaining convenient access to both areas.

22. Home Office Integration

Home office integration creates dedicated workspace for meal planning, household management, and recipe organization. These areas include filing systems, computer workstations, and technology infrastructure while complementing food storage organization and accessibility.

Office integration requires dedicated electrical circuits for computer equipment and data cabling while providing 25-30 square feet of workspace for household management activities. The synergy between meal planning and food storage creates remarkable efficiency gains for busy families.

23. Craft & Hobby Storage Combination

Craft and hobby storage shares organizational principles with pantry systems through similar container types, labeling systems, and accessibility requirements. These combinations maximize basement utility while maintaining clear separation between food and craft supplies.

Craft storage integration can utilize 60-80% of pantry organizational systems including clear containers, labeling protocols, and modular shelving while maintaining separate zones. The organizational skills transfer beautifully between food and craft storage, creating cohesive basement functionality.

24. Exercise Equipment Storage

Exercise equipment storage creates dual-purpose areas that convert between storage and workout space. These designs include secure mounting systems, proper flooring, and air circulation planning while maintaining quick conversion capabilities between functions.

Exercise integration requires 100-150 square feet of convertible space with proper flooring (rubber/foam) and ventilation systems that support both storage access and workout activities. Wall-mounted equipment and fold-away systems maximize flexibility in these shared spaces.

25. Guest Preparation Station

Guest preparation stations combine pantry storage with hospitality supplies including linens, toiletries, entertaining items, and gift wrapping materials. These areas maintain separate storage conditions for different item types while providing easy access for guest preparation activities.

Guest preparation areas require 15-25 square feet of dedicated space with storage systems accommodating items requiring different environmental conditions than food products. This combination works particularly well for families who entertain frequently or have regular overnight guests.

Professional Implementation Strategies

Professional implementation ensures basement pantry projects meet safety codes, structural requirements, and performance expectations. This includes permit requirements, contractor selection, project timeline management, and quality control measures that prevent costly mistakes and ensure long-term functionality.

Professional installation reduces project failure rates by 60-80% through proper planning, code compliance, and quality materials while providing warranties and ongoing support. Permit requirements vary by location but typically include electrical work exceeding 20 amps, structural modifications affecting load-bearing elements, and HVAC installations requiring ductwork modifications. Professional implementation often begins with comprehensive estate cleanout services to properly assess basement conditions and clear existing storage before renovation begins.

|

Project Phase |

Duration |

Key Activities |

Professional Requirements |

Estimated Cost Range |

|---|---|---|---|---|

|

Planning & Design |

1-2 weeks |

Measurements, permits, material selection |

Architect/designer consultation |

$500-$2,000 |

|

Preparation |

3-5 days |

Cleanout, demolition, utilities |

General contractor, electrician |

$1,000-$3,000 |

|

Infrastructure |

1-2 weeks |

Electrical, HVAC, moisture control |

Licensed electrician, HVAC tech |

$2,000-$8,000 |

|

Installation |

1-2 weeks |

Shelving, cabinetry, finishing |

Carpenter, installer |

$3,000-$15,000 |

|

Technology Setup |

2-3 days |

Smart systems, testing, training |

IT specialist, system integrator |

$500-$3,000 |

|

Final Inspection |

1 day |

Code compliance, quality check |

Building inspector |

$200-$500 |

Planning and Design Phase

Proper planning includes detailed measurements, structural assessments, electrical planning, and permit acquisition before beginning construction. This phase determines project feasibility, identifies potential challenges, and establishes realistic timelines and budgets for successful completion.

Planning phases should include 3D modeling and load calculations to identify potential issues before construction begins, reducing change orders by 40-60%. The investment in thorough planning pays dividends throughout the entire project timeline.

Construction and Installation

Construction phases require coordination between multiple trades including electrical, HVAC, and carpentry work. Proper sequencing prevents delays and ensures quality installation while maintaining safety standards throughout the project timeline.

Professional installation typically requires 2-4 weeks for complete basement pantry projects with proper sequencing of electrical, structural, and finish work. The coordination between trades makes professional management essential for complex installations.

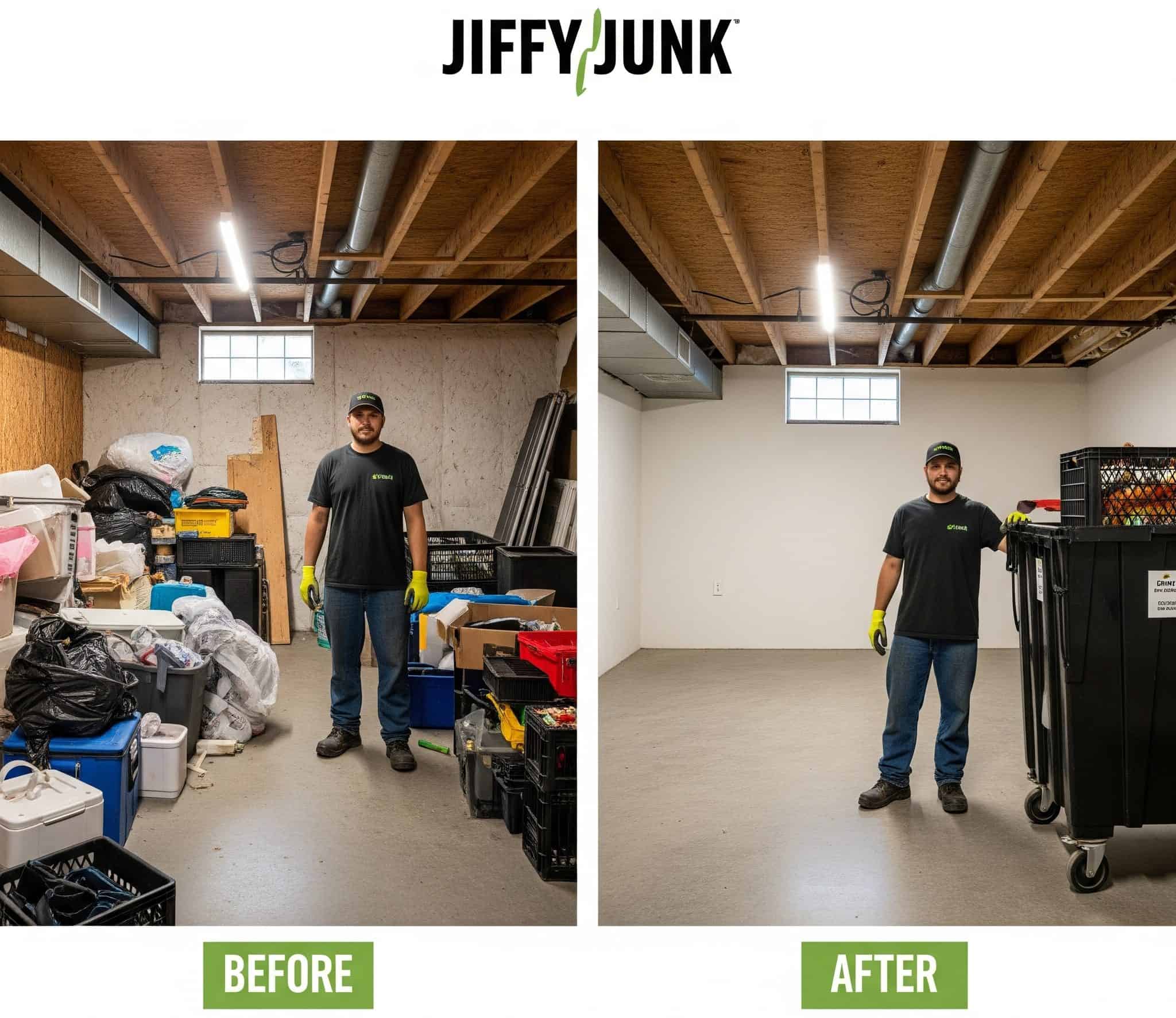

How Jiffy Junk Supports Your Pantry Project

Creating your dream basement pantry often starts with clearing out accumulated clutter, old storage systems, and unwanted items that prevent optimal space utilization. Jiffy Junk provides professional cleanout services that prepare your basement for transformation while handling disposal responsibly through recycling and donation programs.

Professional cleanout services can recover 30-50% more usable space than DIY efforts through systematic removal and proper disposal of accumulated items. Eco-friendly disposal practices ensure 60-80% of removed items avoid landfills through recycling and donation programs that benefit local communities.

Whether you’re planning a simple storage upgrade or comprehensive basement renovation, our decluttering services help create the clean foundation necessary for successful pantry implementation projects. For comprehensive basement preparation, consider our specialized hoarding cleanout services that address challenging accumulation situations while maintaining dignity and respect throughout the process.

Ready to transform your basement into the ultimate pantry space? Contact Jiffy Junk today for professional cleanout services that’ll give you the clean slate you need to implement these amazing storage solutions.

Final Thoughts

Basement pantries represent one of the most practical and valuable home improvements you can make. Whether you choose a simple shelving system or a comprehensive smart storage solution, the key lies in proper planning and understanding your specific needs.

Remember that successful basement pantry projects require attention to environmental controls, structural considerations, and long-term maintenance. Don’t rush the planning phase – invest time in understanding your space, your storage needs, and your budget constraints before beginning construction.

The 25 ideas we’ve covered offer solutions for every basement type, budget level, and storage requirement. Start with your most pressing storage challenges and build from there. Your future self will thank you every time you easily find exactly what you need in your perfectly organized basement pantry.

Basement pantry investments typically provide 150-200% return on investment through reduced food waste, bulk purchasing savings, and increased home value. Proper implementation can reduce weekly grocery shopping time by 30-40% while improving meal planning efficiency and reducing food-related stress.