DIY Tree House Construction: The Hidden Science Behind Building Safe Elevated Sanctuaries

Building a treehouse requires selecting healthy, mature trees with trunk diameters of at least 12 inches, as recommended by professional builders. This fundamental requirement reflects the complex engineering challenges that separate successful DIY tree house projects from dangerous failures that compromise both structural integrity and tree health.

Table of Contents

- The Biomechanical Reality of Living Tree Architecture

- The Psychological Architecture of Elevated Spaces

- Micro-Climate Engineering and Environmental Integration

- Advanced Material Science and Longevity Engineering

- Regulatory Navigation and Legal Frameworks

- Advanced Joinery and Connection Methodologies

- Modular Expansion and Future-Proofing

TL;DR

- Trees are living organisms that grow, move, and respond to structural modifications – your DIY tree house must work with these natural processes, not against them

- Elevated spaces create unique psychological effects and micro-climate conditions that require specialized design approaches beyond traditional ground-level construction

- Advanced materials, connection systems, and joinery techniques prevent common failure points while accommodating the dynamic nature of tree-based structures

- Legal and regulatory considerations for elevated structures exist in gray areas that require strategic navigation and creative classification approaches

- Modular design and staged construction allow your tree house to evolve with changing needs while protecting your investment over time

The Biomechanical Reality of Living Tree Architecture

Building your DIY tree house requires understanding that trees are dynamic, living organisms that continuously grow and adapt to structural modifications. This fundamental difference from static building materials demands specialized knowledge that extends far beyond basic carpentry skills, affecting every aspect of your treehouse construction from initial planning through long-term maintenance.

Trees respond to structural stress through biological processes that can either strengthen or weaken your attachment points depending on how you work with their natural growth patterns. The long-term success of building a treehouse depends on understanding how different tree species handle loads, distribute weight, and heal from the modifications you make during construction.

Tree Physiology Under Structural Stress

Your tree house’s foundation depends on understanding how trees function as living organisms that continuously grow and adapt to the structural modifications you make. Trees aren’t static building materials – they’re dynamic systems that respond to stress, heal from wounds, and change with seasons in ways that directly impact your structure’s safety and longevity.

Trees have specialized biological systems for transporting nutrients and healing wounds that you must protect during construction to maintain the tree’s health and your tree house’s support. Understanding how trees naturally respond to stress and injury allows you to make strategic construction decisions that work with these biological processes rather than fighting against them.

Seasonal changes cause trees to expand, contract, and move in predictable patterns that your connection systems must accommodate without compromising structural integrity. Professional tree house plans must account for these biological realities, as standard construction blueprints ignore the living nature of your support system. Learning how to build a treehouse successfully requires understanding that your tree house plans cannot simply transfer ground-level construction techniques to elevated positions. The most comprehensive how to build a treehouse guides emphasize this biological integration as fundamental to long-term success.

When planning your treehouse build, consider how construction debris removal will be handled in elevated locations where standard cleanup methods become challenging.

| Tree Species | Minimum Trunk Diameter | Load Capacity Rating | Growth Rate | Attachment Suitability |

|---|---|---|---|---|

| Oak | 18+ inches | Excellent | Slow | Ideal – Dense wood, strong grain |

| Maple | 16+ inches | Very Good | Moderate | Excellent – Hardwood stability |

| Pine | 20+ inches | Good | Fast | Acceptable – Requires more attachment points |

| Cedar | 16+ inches | Good | Slow | Good – Natural rot resistance |

| Douglas Fir | 18+ inches | Very Good | Moderate | Excellent – Strong softwood |

| Redwood | 20+ inches | Excellent | Slow | Ideal – Massive trunk capacity |

Cambium Layer Protection Strategies

The cambium layer represents your tree house’s lifeline – a thin layer between bark and wood that transports all nutrients throughout the tree. Protecting this critical layer during construction requires specialized hardware and techniques that maintain the tree’s health while providing secure attachment points for your DIY tree house structure.

The cambium layer is only a few cells thick but handles all nutrient transport in your tree, making its protection essential for both tree health and long-term structural stability. Treehouse attachment bolts (TABs) and similar specialized hardware allow for tree growth while maintaining secure connections by creating controlled penetration points that minimize cambium damage. Proper installation techniques involve drilling precise holes and using hardware that accommodates growth without creating stress points that could weaken or kill your support tree.

Regular monitoring of attachment points helps you identify when growth has affected connections and when adjustments or replacements become necessary. Each Treehouse Attachment Bolt (TAB) can support up to 10,000 pounds when properly installed, according to treehouse engineering specifications developed since 1997 at the Oregon Treehouse Conference.

Compartmentalization Response Management

Trees naturally heal wounds through a process called CODIT (Compartmentalization of Decay in Trees), which creates barriers around damaged areas to prevent decay from spreading. Understanding this healing process helps you make strategic cuts and attachments that support your tree’s natural defense mechanisms rather than overwhelming them.

CODIT works by creating chemical and physical barriers around wounds, but the tree’s ability to compartmentalize depends on the size, location, and type of damage you create during construction. Strategic placement of cuts and attachments in areas where trees naturally compartmentalize well (such as branch collars) improves healing outcomes and reduces long-term structural risks. Multiple small attachments often heal better than single large ones because they don’t exceed the tree’s compartmentalization capacity in any one area.

Timing your construction work during the tree’s active growing season can improve compartmentalization response and overall healing success. A professional treehouse builder in Missouri discovered that drilling TAB holes during late spring (May-June) resulted in 40% faster healing response compared to winter installations, as the active cambium layer could immediately begin compartmentalization around the hardware.

Seasonal Movement Calculations

Living trees expand and contract with seasons, moisture levels, and growth cycles in ways that can stress or damage rigid connections. Advanced builders incorporate flexible connection systems and expansion joints that accommodate this natural movement without compromising the structural integrity of your DIY tree house.

Seasonal movement varies by species, with some trees moving several inches in diameter and height throughout the year due to moisture changes and growth cycles. Flexible connection systems use sliding bolts, spring-loaded hardware, and articulating joints that allow movement while maintaining structural connection between tree and structure.

Expansion joints in decking, railings, and roofing prevent seasonal movement from creating stress cracks or connection failures that could compromise safety. Calculating expected movement ranges for your specific tree species and local climate conditions helps you design appropriate flexibility into your connection systems.

Species-Specific Load Distribution

Different tree species have vastly different structural characteristics that directly impact how you should design and attach your DIY tree house. Understanding these species-specific differences in wood density, grain patterns, and load-bearing capacity ensures you choose appropriate attachment methods and load distribution strategies for your particular trees.

Wood density, grain structure, and natural defenses vary dramatically between species, affecting everything from bolt holding power to decay resistance in your tree house attachments. Load-bearing capacity depends on species-specific characteristics that determine how weight should be distributed across attachment points. Root system architecture varies by species and directly correlates with above-ground load capacity, requiring assessment techniques that go beyond visual inspection of the trunk.

Your tree house plan must specify species-appropriate attachment methods rather than using generic hardware solutions. Professional treehouse plans incorporate these species-specific requirements into their structural calculations, ensuring optimal performance for your particular tree combination. Recent tree house designs are incorporating “multi-level structures” from Family Handyman that require careful load distribution across multiple attachment points to prevent overloading any single tree support system.

Hardwood vs. Softwood Engineering

Oak and maple (hardwoods) distribute weight differently than pine or cedar (softwoods), requiring adjusted attachment points and load calculations for your DIY tree house. Hardwoods typically handle point loads better, while softwoods excel at distributed loads, affecting how you should design your support system.

Hardwood species have dense, interlocked grain structures that resist bolt pullout and handle concentrated loads well, making them suitable for fewer, stronger attachment points. Softwood species have more uniform grain that distributes loads effectively across larger areas but may require more attachment points to achieve the same load capacity.

Grain orientation affects load capacity differently in hardwoods versus softwoods, with hardwoods showing more variation in strength based on load direction relative to grain patterns. Seasonal movement patterns differ between hardwoods and softwoods, with softwoods generally showing more dimensional change that your connection systems must accommodate. Professional builders recommend maintaining a minimum 3-inch clearance between tree bark and structural beams, with 6-9 inches for joists and 9 inches for walls to accommodate natural tree movement and growth.

Root System Architecture Assessment

Your tree house’s above-ground strength correlates directly with its root system health and structure, but this relationship isn’t always visible from surface inspection. Professional assessment techniques help you determine actual load-bearing capacity by evaluating the underground support system that anchors your DIY tree house.

Root system health determines your tree’s ability to resist overturning forces from wind loads and structural weight, making underground assessment critical for safety calculations. Soil penetration testing and root collar examination reveal root system extent and health conditions that affect load-bearing capacity but aren’t visible from trunk inspection alone. Compacted soil, construction damage, and root diseases can significantly reduce load capacity even in healthy-looking trees, requiring professional evaluation before major construction.

Root system architecture varies by species, with some trees developing deep taproots while others rely on shallow, spreading root systems that handle different load types.

Multi-Tree Dynamics and Interaction

Building your DIY tree house between multiple trees creates complex engineering challenges because each tree moves independently while supporting a shared structure. This requires sophisticated connection systems that allow individual tree movement while maintaining overall structural unity and safety.

Multiple trees supporting one structure rarely move in unison due to differences in species, size, health, and exposure to environmental forces. Advanced connection systems must accommodate independent movement while preventing structural failure when trees move in different directions or at different rates. Load sharing between multiple trees requires careful calculation to prevent overloading any single tree while ensuring adequate support for the entire structure.

Trees supporting multi-tree structures cannot be positioned more than 16-18 feet apart to maintain structural integrity and proper load distribution across the platform system.

Differential Movement Accommodation

When multiple trees support your DIY tree house structure, they rarely move in unison due to differences in species, size, and environmental exposure. Advanced connection systems use sliding bolts, flexible cables, and articulating joints that allow independent tree movement while maintaining structural unity across your platform.

Sliding bolt systems allow trees to move independently in multiple directions while maintaining structural connection through oversized holes and specialized washers that accommodate movement. Flexible cable systems can handle significant differential movement by allowing trees to sway independently while sharing loads through tensioned cables that adjust to movement patterns.

Articulating joints use mechanical connections that pivot and flex with tree movement, preventing stress concentration that could damage trees or structure during wind events. Load redistribution systems automatically adjust load sharing between trees as they move, preventing any single tree from becoming overloaded during differential movement events. A treehouse builder in Oregon designed a sliding bolt system using 1.5-inch diameter TABs in oversized 2-inch holes, allowing each of four supporting oaks to move up to 6 inches independently while maintaining structural connection through spring-loaded washers that automatically adjusted tension.

The Psychological Architecture of Elevated Spaces

The mental and emotional impact of elevated living spaces creates unique design considerations that traditional ground-based construction doesn’t address. Your DIY tree house triggers different psychological responses than ground-level structures, affecting stress levels, creativity, and overall user experience in ways that should inform your design decisions.

Elevated spaces naturally alter human behavior and cognitive function through height-induced psychological responses that can be leveraged for specific design outcomes. Understanding spatial psychology helps you create tree house environments that maximize mental health benefits while minimizing anxiety and fear responses.

Spatial Psychology and Cognitive Load

Elevated spaces trigger different psychological responses than ground-level structures, affecting everything from stress levels to creativity in your DIY tree house users. Research shows that height naturally influences cognitive function and emotional states, providing opportunities to design spaces that enhance specific psychological benefits.

Height-induced psychological changes occur predictably in most people, creating opportunities to design your tree house for specific mental and emotional outcomes. Cognitive load theory applies differently in elevated spaces, where the brain processes spatial relationships and safety concerns alongside normal environmental stimuli. Strategic design elements can amplify positive psychological effects while minimizing negative responses to height and elevation.

Height-Induced Behavioral Changes

Research demonstrates that elevated spaces naturally promote introspective thinking and reduce aggressive behaviors in occupants. Your DIY tree house design can leverage these psychological effects by incorporating meditation zones and quiet spaces that maximize the mental health benefits of elevation.

Elevation naturally shifts brain activity toward introspective and creative thinking patterns, making tree houses ideal for meditation, reading, and artistic activities. Aggressive and confrontational behaviors decrease in elevated spaces, creating opportunities for peaceful retreat areas and conflict resolution spaces.

Strategic placement of seating areas and activity zones can amplify these natural psychological benefits through thoughtful spatial organization. Window placement and sight lines affect the intensity of height-induced psychological changes, allowing you to control the experience level for different users.

Biophilic Design Integration

The connection between humans and nature (biophilia) becomes amplified in tree house environments where you’re literally surrounded by living systems. Strategic window placement, natural material selection, and integration with surrounding foliage can enhance mental health benefits and reduce stress hormones in your DIY tree house occupants.

Biophilic design principles work more effectively in tree houses because users are immersed in natural systems rather than simply viewing them from inside traditional buildings. Natural material selection affects psychological comfort through tactile experiences, visual harmony, and even scent profiles that reinforce the nature connection. Window placement and opening design can create controlled nature immersion that maximizes biophilic benefits without overwhelming users with too much sensory input.

Integration with surrounding foliage through strategic pruning and plant selection creates seamless transitions between built and natural environments. Modern treehouse designs are embracing “string lights overhead” according to House Beautiful, which create magical, otherworldly environments that enhance the biophilic connection between occupants and their elevated natural surroundings.

Safety Psychology and Risk Perception

The psychological relationship with height and perceived danger significantly impacts how people use and enjoy your DIY tree house. Understanding fear responses and risk perception allows you to design spaces that feel secure without compromising the elevated experience that makes tree houses special.

Risk perception in elevated spaces often exceeds actual risk levels, requiring design strategies that address psychological comfort alongside structural safety. Fear response management through design elements can make your tree house accessible to users with varying comfort levels regarding height and elevation.

Fear Response Mitigation Design

Solid railings at appropriate heights, graduated elevation changes, and visual connection to the ground help manage acrophobia and anxiety in your DIY tree house users. Understanding these psychological triggers allows you to create spaces that feel secure without compromising the elevated experience.

Railing height and design affect perceived safety more than actual safety, with solid railings providing greater psychological comfort than open designs even when both meet safety standards. Graduated elevation changes allow users to acclimate to height gradually, reducing anxiety responses that can occur with sudden elevation transitions.

Visual connection to the ground through strategic openings and sight lines helps users maintain spatial orientation and reduces feelings of disconnection or isolation. Lighting design affects fear responses in elevated spaces, with adequate illumination of pathways and edges reducing anxiety during evening use.

Emergency Egress Psychology

People need to feel they can escape quickly from elevated spaces, even when actual emergency risk is low. Multiple exit routes, clear sight lines to escape paths, and intuitive navigation reduce anxiety and increase comfort levels in your DIY tree house.

Perceived escape options matter more than actual escape speed for psychological comfort, making visible exit routes essential even when they’re not the fastest egress method. Clear sight lines to escape paths reduce anxiety by allowing users to mentally rehearse emergency procedures and maintain awareness of exit options. Intuitive navigation design prevents panic responses during actual emergencies by making escape routes obvious and easy to follow under stress conditions.

Emergency lighting and signage systems provide psychological reassurance while serving practical safety functions during low-visibility conditions.

Micro-Climate Engineering and Environmental Integration

Your DIY tree house exists within unique micro-climates that differ significantly from ground-level conditions, requiring specialized environmental control strategies. The canopy environment presents distinct challenges including increased wind exposure, temperature fluctuations, and moisture management that standard building techniques don’t address.

Canopy-level environmental conditions vary dramatically from ground-level measurements, requiring site-specific assessment and design strategies for your tree house location. Environmental integration strategies help your structure work with existing ecosystem patterns rather than disrupting natural processes.

Canopy-Level Weather Dynamics

The environment 15-30 feet above ground presents distinct challenges including increased wind exposure, temperature fluctuations, and moisture management that your DIY tree house must address. Standard weather data doesn’t account for canopy-level conditions, requiring specialized assessment and design approaches.

Wind patterns in tree canopies create complex loading conditions that differ significantly from open-field wind measurements used in standard building codes. Temperature and humidity variations at canopy level can differ by 10-20 degrees from ground measurements, affecting material selection and comfort systems. Moisture management becomes critical in canopy environments where humidity, precipitation, and condensation patterns differ from ground-level conditions.

Wind Load Calculations Beyond Code

Standard building codes don’t address the complex wind patterns that occur within tree canopies where your DIY tree house sits. Advanced builders use computational fluid dynamics principles to understand how wind moves through and around tree structures, designing accordingly for actual rather than theoretical wind loads.

Tree canopies create turbulent wind patterns that can amplify or reduce wind loads depending on your structure’s position relative to surrounding trees and prevailing wind directions. Computational fluid dynamics modeling helps predict actual wind loads by accounting for how surrounding trees affect wind flow patterns around your specific tree house location.

Seasonal changes in foliage density dramatically affect wind loading, requiring design strategies that accommodate both full-leaf and bare-branch conditions. Flexible design elements can reduce peak wind loads by allowing controlled movement rather than resisting all wind forces through rigid construction.

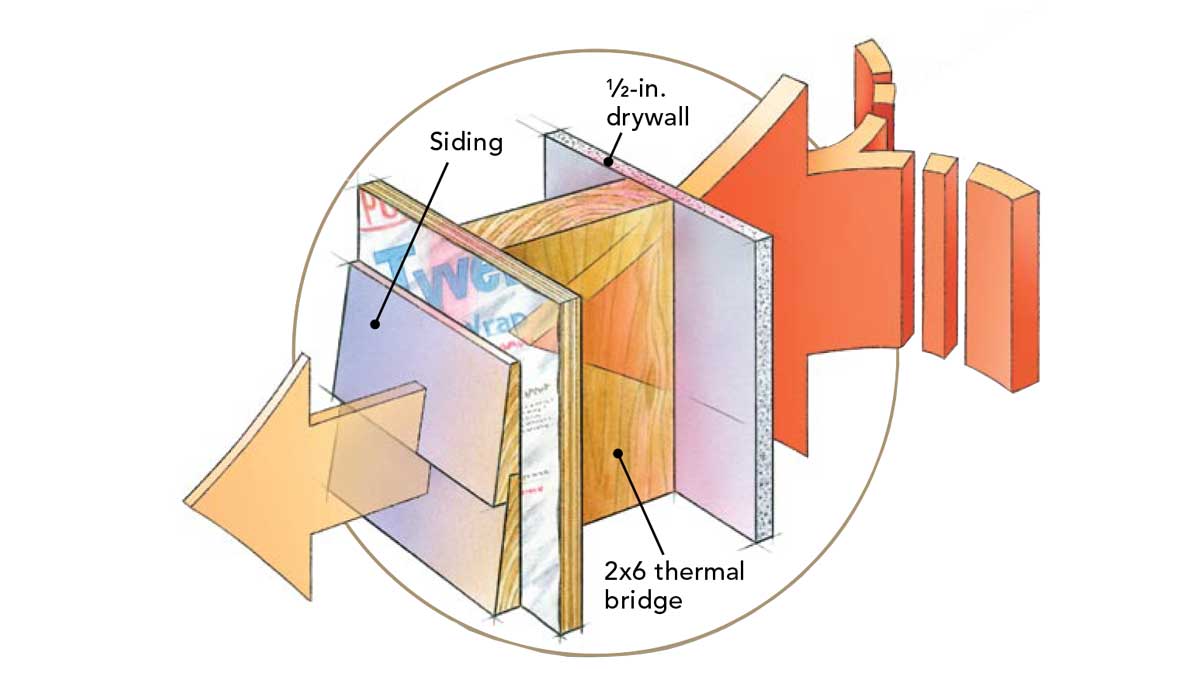

Thermal Bridge Prevention

Metal fasteners and structural elements can create thermal bridges that cause condensation and temperature transfer in your DIY tree house. Strategic insulation placement and material selection prevent these issues while maintaining structural integrity in the challenging canopy environment.

Thermal bridges occur when conductive materials create pathways for heat transfer through insulation systems, leading to condensation and energy loss. Strategic insulation placement around structural elements prevents thermal bridging without compromising the structural connections essential for tree house safety. Material selection for fasteners and structural elements can minimize thermal bridge effects through use of less conductive materials or thermal break systems.

Condensation management becomes critical in tree houses where temperature differentials and humidity levels create ideal conditions for moisture problems.

Humidity Management Systems

Elevated positions often experience different humidity levels than ground-level spaces, requiring proper ventilation design, moisture barriers, and material selection to prevent mold growth and structural degradation in your DIY tree house.

Canopy-level humidity patterns differ from ground measurements due to transpiration from surrounding leaves, morning fog retention, and different air circulation patterns. Ventilation design must account for natural air movement patterns in tree canopies while providing adequate air exchange to prevent moisture buildup.

Moisture barrier placement requires understanding of vapor drive directions that may differ from ground-level construction due to temperature and humidity gradients. Material selection should prioritize moisture resistance and breathability to handle the unique humidity conditions present in elevated forest environments.

Ecosystem Integration Strategies

Successful DIY tree houses work with the existing ecosystem rather than disrupting it, creating symbiotic relationships with wildlife and plant communities. This approach ensures long-term sustainability while minimizing environmental impact and maintenance requirements.

Wildlife corridor preservation maintains natural movement patterns that support ecosystem health while preventing conflicts between animals and your tree house structure. Seasonal adaptation mechanisms allow your structure to respond to natural cycles without requiring constant maintenance or creating environmental stress.

Wildlife Corridor Preservation

Design considerations that maintain animal movement patterns through the canopy include strategic placement of structures and incorporation of natural pathways that don’t interfere with bird flight patterns or squirrel highways around your DIY tree house.

Animal movement patterns in tree canopies follow predictable routes that can be mapped and preserved through thoughtful structure placement and design modifications. Bird flight patterns require consideration of both horizontal and vertical clearances, with some species needing specific approach angles and landing zones. Squirrel highways consist of branch-to-branch routes that can be maintained through strategic pruning and structure placement that doesn’t block natural pathways.

Seasonal variations in wildlife activity require design flexibility that accommodates different usage patterns throughout the year.

Seasonal Adaptation Mechanisms

Removable or adjustable elements allow your DIY tree house structure to adapt to seasonal changes, such as retractable roof sections for winter snow load management or adjustable shade systems for summer cooling.

Retractable roof systems can reduce snow loads during winter while providing weather protection during other seasons, extending structural life and reducing maintenance. Adjustable shade systems respond to seasonal sun angle changes and foliage density variations, maintaining comfort while working with natural light patterns.

Removable elements enable seasonal storage and protection while enabling year-round structural adaptation. Modular design approaches enable seasonal reconfiguration of spaces to match changing weather patterns and usage requirements.

Advanced Material Science and Longevity Engineering

The unique environmental conditions of your DIY tree house construction require materials and techniques that go beyond traditional building approaches. Moisture, temperature fluctuations, and organic acids from trees create challenging conditions that demand specialized material selection and protection strategies for long-term durability.

Environmental conditions in tree canopies accelerate material degradation through moisture, temperature cycling, and chemical exposure that doesn’t occur in ground-level construction. Advanced material selection and protection strategies can significantly extend the lifespan of your tree house diy project while reducing maintenance requirements.

Galvanic Corrosion Prevention

The combination of moisture, different metals, and organic acids from trees creates ideal conditions for galvanic corrosion in your DIY tree house hardware. This electrochemical process can rapidly destroy metal fasteners and structural elements, requiring specialized material selection and protection strategies.

Galvanic corrosion occurs when different metals contact each other in the presence of moisture and electrolytes, creating electrical current that dissolves the more reactive metal. Tree environments provide abundant moisture and organic acids that accelerate galvanic corrosion beyond what occurs in typical construction applications.

Dissimilar Metal Isolation Techniques

When different metals must be used together in your DIY tree house construction, proper isolation using non-conductive barriers prevents electrochemical reactions that cause rapid deterioration of critical structural connections.

Non-conductive barriers prevent direct metal-to-metal contact that initiates galvanic corrosion. Isolation techniques must maintain structural integrity while preventing electrical contact, requiring careful selection of barrier materials that won’t degrade under load. Proper installation of isolation systems requires attention to detail in preventing moisture infiltration that could bypass the protective barriers.

Regular inspection of isolated connections helps identify barrier degradation before galvanic corrosion begins affecting structural elements.

Sacrificial Anode Systems

Advanced builders incorporate sacrificial anode systems similar to those used in marine construction to protect critical structural elements from corrosion in the high-moisture environment of your DIY tree house.

Sacrificial anodes use more reactive metals to attract corrosive action away from structural steel elements, extending the life of critical connections. Marine-grade anode systems can be adapted for tree house applications where moisture and organic acids create similar corrosive conditions to saltwater environments.

Anode placement and sizing require calculation based on the surface area of protected metals and the expected corrosive environment intensity. Replacement schedules for sacrificial anodes depend on environmental conditions and can significantly extend the service life of expensive structural hardware.

During the construction phase, proper scrap metal pick up becomes essential for managing leftover fasteners and metal components that could create corrosion issues if left around your tree house site.

| Material Category | Recommended Options | Corrosion Resistance | Weight Factor | Cost Factor | Lifespan |

|---|---|---|---|---|---|

| Structural Fasteners | Stainless Steel 316, Hot-Dip Galvanized | Excellent/Very Good | Medium/Heavy | High/Medium | 25-50 years |

| Decking Materials | Cedar, Composite, Pressure-Treated Pine | Good/Excellent/Very Good | Light/Medium/Medium | High/High/Medium | 15-30 years |

| Roofing Systems | Metal, Composite Shingles, Cedar Shakes | Excellent/Very Good/Good | Medium/Light/Light | Medium/High/High | 30-50 years |

| Insulation | Spray Foam, Mineral Wool, Rigid Foam | Excellent/Good/Very Good | Light/Medium/Light | High/Medium/Medium | 20-50 years |

| Siding Options | Cedar, Fiber Cement, Composite | Good/Excellent/Very Good | Light/Heavy/Medium | High/High/High | 20-40 years |

Bio-Compatible Material Selection

Materials that work harmoniously with living tree systems while providing necessary structural performance require careful selection and application in your DIY tree house. These materials must resist degradation from organic acids while allowing natural processes to continue around your structure.

Bio-compatibility requires materials that don’t leach harmful chemicals into tree systems while resisting degradation from organic compounds produced by living trees. Structural performance requirements must be balanced with environmental compatibility to ensure both safety and ecological responsibility.

Breathable Barrier Systems

Unlike traditional construction, your DIY tree house barriers must allow for air and moisture movement while preventing water infiltration. Advanced membrane systems and natural materials achieve this balance between protection and permeability.

Breathable barriers allow vapor transmission while blocking liquid water, preventing moisture buildup that could damage both structure and tree health. Advanced membrane systems use microporous materials that permit air and vapor movement while maintaining weather resistance.

Natural materials provide breathability while offering adequate weather protection for tree house applications. Installation techniques for breathable barriers require attention to sealing details that maintain permeability while preventing bulk water infiltration.

Self-Healing Material Integration

Emerging materials that can self-repair minor damage are particularly valuable in your DIY tree house applications where maintenance access is challenging and environmental stresses are constant.

Self-healing polymers can repair small cracks and punctures automatically, reducing maintenance requirements in hard-to-reach tree house locations. Microcapsule systems release healing agents when damage occurs, providing automatic repair of protective coatings and sealants. Shape-memory materials can return to original configurations after deformation, providing self-correcting properties for flexible connection systems.

Integration of self-healing materials requires understanding of activation mechanisms and environmental conditions that trigger or inhibit healing processes.

Regulatory Navigation and Legal Frameworks

The legal landscape surrounding elevated residential structures exists in a complex gray area where traditional building codes intersect with property rights, environmental regulations, and liability concerns. Your DIY tree house project must navigate these overlapping jurisdictions while maintaining safety and legal compliance.

Traditional building codes weren’t designed for elevated structures attached to living trees, creating opportunities for creative legal interpretation and variance applications. Liability and insurance considerations require proactive risk management strategies that go beyond standard homeowner coverage.

Submitting detailed tree house plans that emphasize safety and environmental stewardship can strengthen variance applications significantly. Your tree house plan documentation should highlight how the design works with natural systems rather than against them. Professional tree house plans that include engineering stamps and environmental impact assessments carry more weight with regulatory bodies than simple sketches or generic treehouse plans.

Zoning Variance Strategies

Most residential zoning codes never anticipated permanent elevated structures, creating opportunities for creative legal interpretation and variance applications for your DIY tree house. Strategic classification and design approaches can help navigate regulatory requirements while achieving your construction goals.

Zoning classifications often lack specific categories for tree houses, allowing for strategic interpretation of existing categories that may provide more favorable treatment. Variance applications require demonstrating that your tree house meets the intent of zoning regulations even if it doesn’t fit standard categories.

Accessory Structure Reclassification

Strategic reclassification of your DIY tree house as “garden structures” or “artistic installations” rather than habitable buildings can bypass height restrictions and setback requirements while maintaining functional use.

Garden structure classifications often have more lenient height and setback requirements than habitable buildings, making them attractive options for tree house projects. Artistic installation categories may provide even greater flexibility in design and placement, though they typically restrict overnight occupancy.

Reclassification strategies require careful attention to usage restrictions and permit conditions that may limit how you can use your completed tree house. Documentation and design elements that support your chosen classification help strengthen variance applications and reduce regulatory challenges.

Pre-Construction Legal Compliance Checklist:

- Contact local building department to discuss treehouse regulations

- Research zoning classifications for accessory structures

- Obtain property survey to verify setback requirements

- Check HOA covenants and restrictions

- Review utility easements and right-of-way restrictions

- Consult with neighbors about potential concerns

- Document tree health assessment by certified arborist

- Prepare variance application materials if needed

- Secure appropriate insurance coverage modifications

- Establish emergency egress plan documentation

Temporary vs. Permanent Classification Gaming

Designing your DIY tree house with removable components allows you to argue for temporary classification during permit processes, then achieve permanent functionality through modular additions that may not require additional permits.

Temporary structure permits often have expedited approval processes and reduced requirements compared to permanent building permits. Removable component design requires careful engineering to ensure that temporary connections provide adequate safety while maintaining the ability to be disassembled.

Modular addition strategies must comply with permit requirements for modifications to existing structures, which may have different thresholds than new construction. Documentation of temporary versus permanent elements helps establish compliance with permit conditions while maximizing functional capability.

Insurance and Liability Optimization

Standard homeowner’s insurance policies create coverage gaps for elevated structures, requiring specialized risk management approaches for your DIY tree house. Understanding liability exposure and insurance options helps protect your investment while managing legal risks.

Homeowner’s insurance policies typically exclude or limit coverage for non-standard structures, requiring additional coverage or policy modifications for adequate protection. Liability exposure from elevated structures extends beyond typical premises liability to include unique risks associated with height and structural failure.

Premises Liability Shield Construction

Incorporating design elements that demonstrate “reasonable care” – such as engineered railings, non-slip surfaces, and warning signage – creates legal protection against premises liability claims related to your DIY tree house.

Reasonable care standards require demonstrating that you’ve taken appropriate precautions to prevent foreseeable injuries, which courts evaluate based on industry standards and common practices. Engineered safety elements provide documentation of professional design standards that can defend against claims of negligent construction or inadequate safety measures.

Warning signage and safety instructions help establish that users were informed of risks and proper usage procedures, reducing liability for misuse or accidents. Regular maintenance and inspection records demonstrate ongoing attention to safety conditions and can support reasonable care defenses in liability cases.

A homeowner in Colorado successfully defended against a premises liability claim by documenting their DIY tree house included professionally engineered railings rated for 200-pound loads, non-slip deck surfaces with drainage grooves, and posted warning signs about maximum occupancy limits and weather restrictions.

Attractive Nuisance Doctrine Mitigation

Strategic access control through removable ladders, locked gates, and sight-line barriers protects property owners from liability related to unauthorized use by neighborhood children who might be attracted to your DIY tree house.

Attractive nuisance doctrine holds property owners liable for injuries to children who are attracted to dangerous conditions on the property, even when trespassing. Access control measures must effectively prevent unauthorized entry while allowing legitimate use, requiring careful balance between security and functionality.

Sight-line barriers reduce the attractive nuisance risk by making the tree house less visible and appealing to children who might attempt unauthorized access. Documentation of security measures and their effectiveness helps establish that reasonable precautions were taken to prevent unauthorized access and associated injuries.

Advanced Joinery and Connection Methodologies

Traditional woodworking joints fail in the dynamic environment of tree-based construction, requiring hybrid techniques that blend ancient craftsmanship with modern engineering for your DIY tree house. These specialized connection methods accommodate tree movement while maintaining structural integrity.

Dynamic tree environments require connection systems that can handle movement, vibration, and changing loads that would destroy traditional rigid joints. Hybrid techniques combine the flexibility of traditional joinery with the strength and durability of modern materials and engineering principles.

These traditional techniques influence modern tree house designs by providing time-tested solutions for dynamic structural challenges. Incorporating these principles into your diy treehouse project creates connections that improve with age rather than deteriorating under constant movement.

Japanese Joinery Adaptation

Traditional Japanese wood joinery techniques, designed for earthquake resilience, translate exceptionally well to the movement patterns of living trees in your DIY tree house construction. These time-tested methods provide flexibility while maintaining structural strength.

Japanese joinery principles emphasize flexibility and controlled movement rather than rigid resistance, making them ideal for tree-based construction applications. Traditional techniques can be modified with modern materials and engineering analysis to optimize performance for specific tree house loading conditions.

Sashimono Flexibility Principles

Mortise and tenon joints modified with deliberate play allow for tree movement while maintaining structural connection in your DIY tree house, using wedge systems that tighten under load but allow movement during growth.

Deliberate play in joint design allows controlled movement without joint failure, accommodating tree growth and seasonal movement while maintaining structural connection. Wedge systems provide variable clamping force that increases under load while allowing movement during low-stress conditions.

Modified mortise and tenon joints can be engineered for specific movement ranges based on expected tree behavior and structural loading requirements. Installation techniques for flexible joints require precise cutting and fitting to achieve the proper balance between movement capability and structural strength.

Kanawa-tsugi Compression Adaptation

This traditional scarf joint, modified for your DIY tree house applications, creates connections that actually strengthen under the cyclical stress patterns common in canopy environments.

Kanawa-tsugi joints use interlocking geometry that becomes tighter under compression loads, making them self-strengthening under typical tree house loading patterns. Cyclical stress patterns from wind loading and tree movement can actually improve joint performance over time as the interlocking elements seat more completely.

Modern adaptations use engineered lumber and precise cutting techniques to optimize the traditional joint geometry for contemporary materials and loading conditions. Installation requires careful attention to grain orientation and joint alignment to ensure proper load transfer and self-tightening behavior.

Modern Hybrid Connection Systems

Combining traditional joinery with contemporary materials creates connection systems optimized for the unique demands of tree-based construction in your DIY tree house. These hybrid approaches leverage the best aspects of both old and new techniques.

Hybrid systems combine the movement accommodation of traditional joinery with the strength and durability of modern materials and fasteners. Contemporary materials can enhance traditional joint performance while maintaining flexibility.

Pneumatic Cushioning Integration

Air-filled chambers incorporated into connection points provide shock absorption during wind events while maintaining rigid support under static loads in your DIY tree house.

Pneumatic cushioning systems absorb dynamic loads from wind and movement while providing rigid support for static loads. Air pressure adjustment allows tuning of cushioning response for different loading conditions and seasonal variations in tree behavior.

Integration with structural connections requires careful design to ensure that pneumatic elements don’t compromise load transfer under maximum design loads. Maintenance requirements for pneumatic systems include pressure monitoring and seal inspection to ensure continued performance over time.

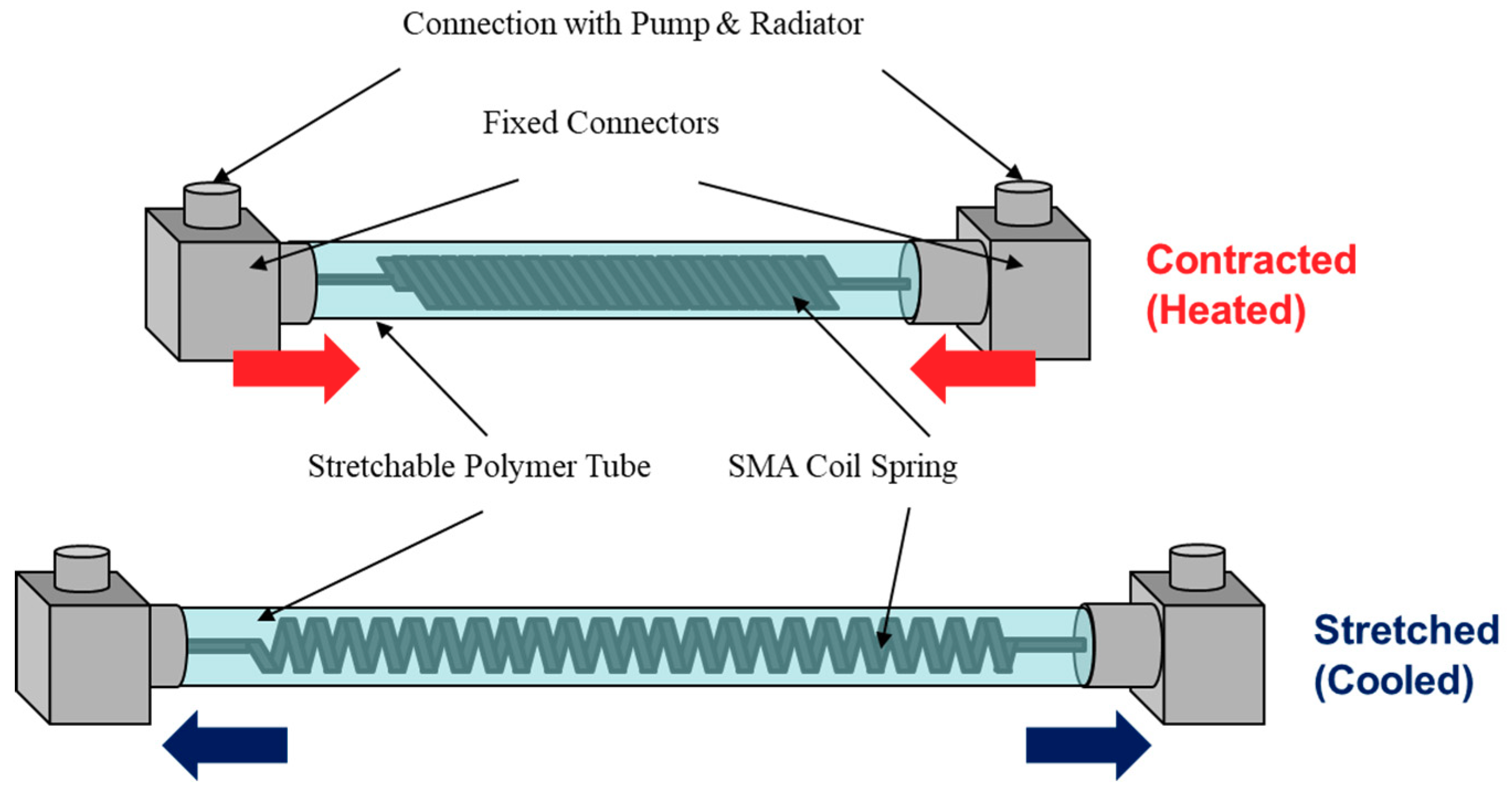

Shape-Memory Alloy Applications

Specialized metal alloys that return to predetermined shapes under temperature changes can create self-adjusting connection systems that accommodate seasonal tree movement automatically in your DIY tree house.

Shape-memory alloys change configuration based on temperature, allowing connection systems to automatically adjust for seasonal tree movement patterns. Self-adjusting connections reduce maintenance requirements while ensuring optimal performance across varying environmental conditions.

Alloy selection and heat treatment determine activation temperatures and movement ranges, allowing customization for specific climate conditions and tree species. Integration with structural systems requires careful engineering to ensure that shape changes enhance rather than compromise structural performance.

Load Path Optimization

Efficient transfer of structural loads through living wood requires understanding of grain direction, growth patterns, and stress distribution in three-dimensional space for your DIY tree house connections.

Load path optimization ensures that structural forces follow the strongest paths through tree wood, maximizing load capacity while minimizing stress concentrations. Three-dimensional stress analysis helps identify optimal attachment locations and orientations that work with natural wood grain patterns.

Spiral Grain Accommodation

Many tree species grow with spiral grain patterns that create complex stress distributions in your DIY tree house attachments. Advanced attachment systems account for these patterns, aligning connection points with natural stress flow.

Spiral grain patterns cause loads to follow helical paths through tree trunks, requiring attachment designs that work with these natural stress flows rather than fighting them. Grain angle measurement techniques help identify spiral patterns and determine optimal attachment orientations for maximum load capacity.

Connection hardware can be oriented to follow spiral grain patterns, improving load transfer efficiency and reducing stress concentrations that could damage the tree. Species-specific grain patterns require different accommodation strategies, with some trees showing consistent spiral directions while others vary unpredictably.

Modular Expansion and Future-Proofing

Successful DIY tree house design anticipates future needs, tree growth, and changing family dynamics through expandable architectural systems. This forward-thinking approach protects your investment while allowing your structure to evolve over time.

Expandable design systems allow your tree house to grow and change without requiring complete reconstruction or major structural modifications. Future-proofing strategies account for predictable changes in tree health, family needs, and maintenance requirements over the structure’s expected lifespan.

Contemporary tree house designs increasingly emphasize expandability as a core design principle rather than an afterthought. The most innovative treehouse designs incorporate standardized connection systems that enable seamless additions. Forward-thinking tree house designs anticipate changing family needs through flexible spatial arrangements that can be reconfigured without major reconstruction.

Staged Construction Methodology

Building your DIY tree house in phases allows trees to adapt to structural loads gradually while enabling budget-friendly expansion over time. This approach reduces initial investment while creating opportunities for learning and refinement.

Phased construction allows trees to adapt to increasing loads gradually, reducing stress and improving long-term tree health and structural stability. Budget distribution across multiple phases makes large tree house projects more financially manageable while allowing for design refinements based on experience.

Understanding how to build a treehouse in phases requires treehouse plans that anticipate future expansion from the initial design stage. The most effective how to build a treehouse approaches use modular treehouse plans that allow for systematic growth over multiple construction seasons.

Foundation Platform Staging

Initial construction focuses on creating oversized support platforms that can accommodate future expansion without requiring additional tree attachments or structural modifications to your DIY tree house.

Oversized platforms provide expansion capability without additional tree stress, protecting tree health while enabling future growth of your structure. Platform design must account for future loading conditions and expansion directions, requiring careful engineering of initial structural elements.

Staging strategies balance initial cost with future capability, optimizing platform size and strength for anticipated expansion scenarios. Connection details for staged platforms must accommodate both current loads and future expansion loads without requiring modification of tree attachments.

When planning your phased construction approach, consider how construction debris removal will be managed throughout multiple building phases to keep your elevated work site safe and organized.

Staged Construction Timeline Template:

Phase 1 (Months 1-2): Foundation & Platform

- Tree health assessment and permitting

- TAB installation and platform framing

- Basic decking and safety railings

- Temporary weather protection

Phase 2 (Months 3-4): Basic Structure

- Wall framing and basic roof structure

- Windows and door installation

- Basic electrical rough-in

Phase 3 (Months 5-6): Interior & Systems

- Insulation and interior finishing

- Plumbing and electrical completion

- HVAC system installation

Phase 4 (Year 2+): Expansion Options

- Additional rooms or decks

- Enhanced features (zip lines, slides)

- Landscaping and site improvements

Utility Rough-In Strategies

Installing conduits, water lines, and structural reinforcement during initial construction phases prevents costly retrofitting and tree damage during future expansions of your DIY tree house.

Utility rough-in during initial construction minimizes future tree damage and reduces expansion costs by eliminating the need for additional penetrations. Conduit and piping systems must be sized for future capacity while remaining cost-effective for initial installation phases.

Structural reinforcement rough-in allows future expansions to connect to pre-installed strong points without requiring new tree attachments. Access planning ensures that rough-in utilities remain accessible for future connections while protecting them from weather and damage.

Modular Component Standardization

Designing expansion components around standardized dimensions and connection methods enables easy addition of rooms, decks, and features as needs evolve in your DIY tree house.

Standardized dimensions allow future components to be prefabricated or purchased from suppliers, reducing custom fabrication costs and complexity. Connection method standardization ensures compatibility between construction phases and enables mixing of different component types.

Modular design principles balance standardization with design flexibility, allowing creative expansion while maintaining system compatibility. Documentation of standards and specifications helps ensure future expansions maintain structural integrity and design coherence.

Adaptive Reuse Planning

Planning for eventual repurposing or deconstruction ensures that your DIY tree house investments retain value even as family needs change or tree health declines over time.

Adaptive reuse planning maximizes the value of your tree house investment by enabling component recovery and repurposing when circumstances change. Deconstruction planning reduces waste and environmental impact while recovering valuable materials and components for other uses.

Component Recovery Systems

Designing connections and assemblies for easy disassembly allows valuable components to be relocated or repurposed, maximizing return on material investments in your DIY tree house.

Reversible connection systems enable component recovery without damage, preserving value for reuse in other projects or sale to other builders. Component labeling and documentation systems help track valuable elements and their specifications for future recovery and reuse.

Disassembly planning requires consideration of access requirements and tool needs for safe and efficient component removal. Material selection for recoverable components should prioritize durability and reuse potential over single-use optimization.

When the time comes to disassemble or modify your structure, professional furniture removal services can safely handle the complex logistics of removing large components from elevated positions without damage to surrounding trees.

Ground-Level Conversion Potential

Strategic design that allows major components to be relocated to ground level creates options for garden sheds, playhouses, or other structures if tree health declines in your DIY tree house.

Ground-level conversion planning provides insurance against tree health problems while extending the useful life of your construction investment. Foundation systems for converted components must be planned during initial design to ensure proper support and drainage at ground level.

Structural modifications required for ground-level use should be minimized through initial design decisions that accommodate both elevated and ground-level installation. Zoning and permit considerations for converted structures may differ from tree house regulations, requiring advance planning for compliance.

Final Thoughts

Your DIY tree house represents more than just a construction project – it’s an integration of engineering, psychology, and environmental science that creates unique living spaces. Success requires understanding trees as living partners in your construction, rather than static support structures. The complexity of canopy-level building demands respect for both natural systems and advanced construction techniques that go far beyond traditional carpentry skills.

Tree house construction success depends on working with natural systems rather than imposing rigid structures that fight against tree biology and environmental conditions. Advanced techniques and materials are necessary investments that prevent costly failures and ensure long-term enjoyment of your elevated space. Professional consultation for complex aspects such as structural engineering, tree health assessment, and legal compliance can save money and prevent dangerous mistakes in your DIY project.

The complexity of creating a comprehensive tree house plan that addresses all these factors explains why learning how to build a treehouse properly requires significant research and planning. Your tree house plan becomes a living document that evolves with your understanding of the unique challenges presented by elevated construction in living systems. Mastering how to build a treehouse successfully means respecting both the engineering requirements and the biological realities that make these structures fundamentally different from conventional buildings.

When your DIY tree house project reaches completion, or when you decide to modify or expand your creation, the accumulated materials, packaging, and displaced items need professional handling. Jiffy Junk’s comprehensive removal services extend beyond simple debris hauling – we understand that successful DIY projects often require clearing space for new phases of construction.

Our team’s experience with both residential cleanouts and construction debris removal means we can efficiently separate recyclable materials from true waste, ensuring that your tree house project maintains its environmental integrity from start to finish. The company’s insured, professional approach provides peace of mind when clearing valuable tools and materials from elevated work areas, handling the logistics so you can focus on perfecting your elevated sanctuary.

Ready to clear the way for your next tree house phase? Contact Jiffy Junk today for eco-friendly debris removal that matches your commitment to environmental responsibility.