25 Deck Steps Ideas That Will Transform Your Outdoor Space Into a Stunning Retreat

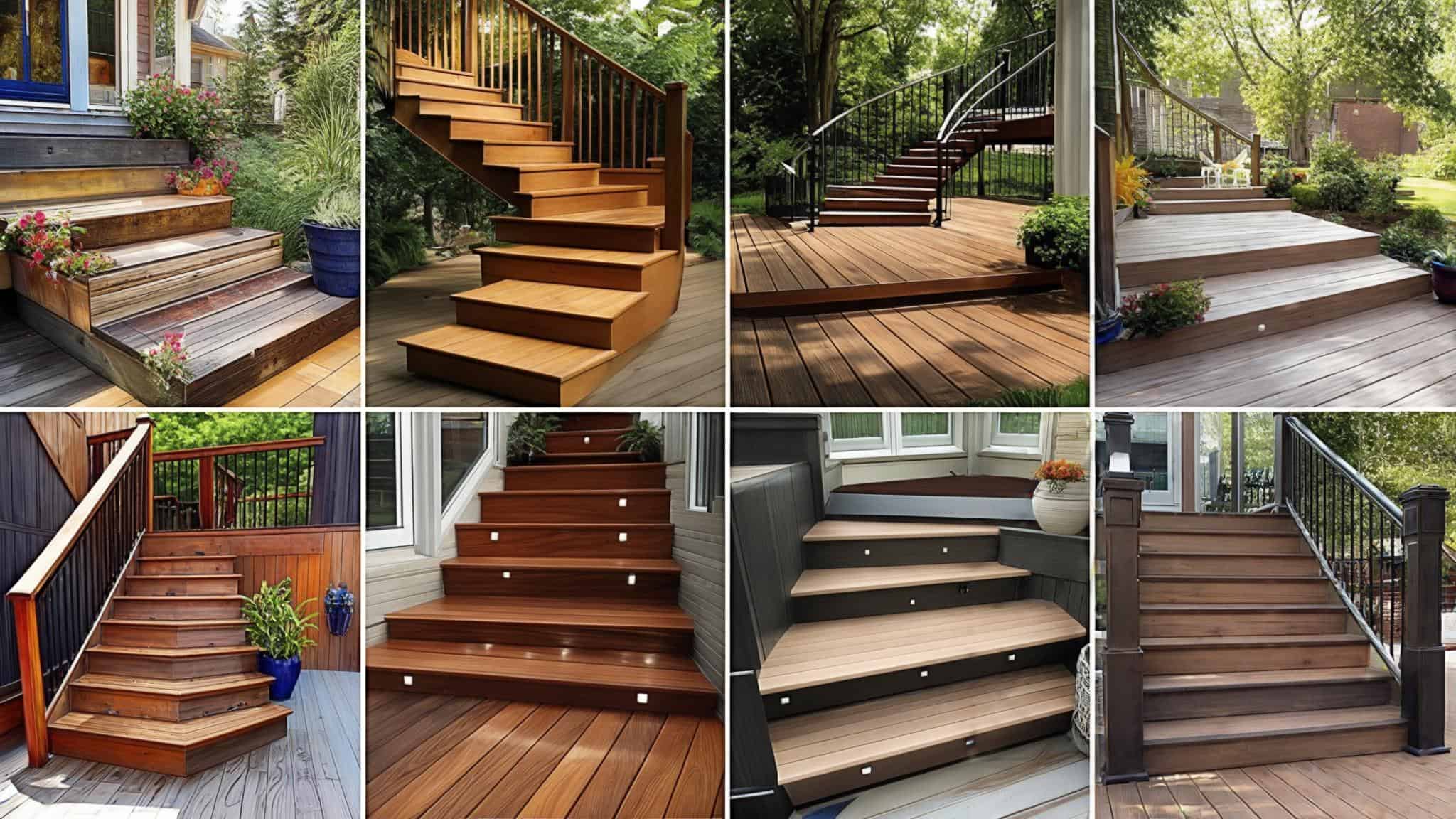

Last summer, I watched my neighbor Dave struggle up his wobbly wooden deck steps for the hundredth time. “I’m gonna fix these someday,” he’d mutter every time they creaked. Well, “someday” finally came last month, and wow – what a difference the right steps can make! His new curved composite steps with built-in planters didn’t just solve the safety issue; they turned his boring backyard into the neighborhood hangout spot. According to TimberTech’s latest design research, curved deck steps and unique shapes are becoming increasingly popular as homeowners seek to elevate their deck designs and naturally blend with landscaping. That transformation got me thinking about how the right deck steps can completely change your outdoor living experience.

Building deck steps isn’t just about getting from point A to point B anymore. Today’s homeowners want steps that serve as architectural features, storage solutions, and even entertainment spaces. You’ve got tons of choices that range from budget-friendly pressure-treated lumber to premium materials that’ll last decades with minimal maintenance.

Table of Contents

-

Essential Considerations for Choosing Deck Steps

-

Traditional Straight Steps (5 Ideas)

-

Curved and Angled Steps (4 Ideas)

-

Multi-Level and Platform Steps (4 Ideas)

-

Integrated Storage and Functional Steps (4 Ideas)

-

Alternative Material Steps (4 Ideas)

-

Specialty and Unique Steps (4 Ideas)

-

Detailed Construction Examples

-

Performance Evaluation Guide

-

How JiffyJunk Supports Your Project

-

Final Thoughts

TL;DR

-

Safety and building codes should drive your initial decision-making process, with most places having rules that say you need 4-8 inch risers and 10+ inch treads

-

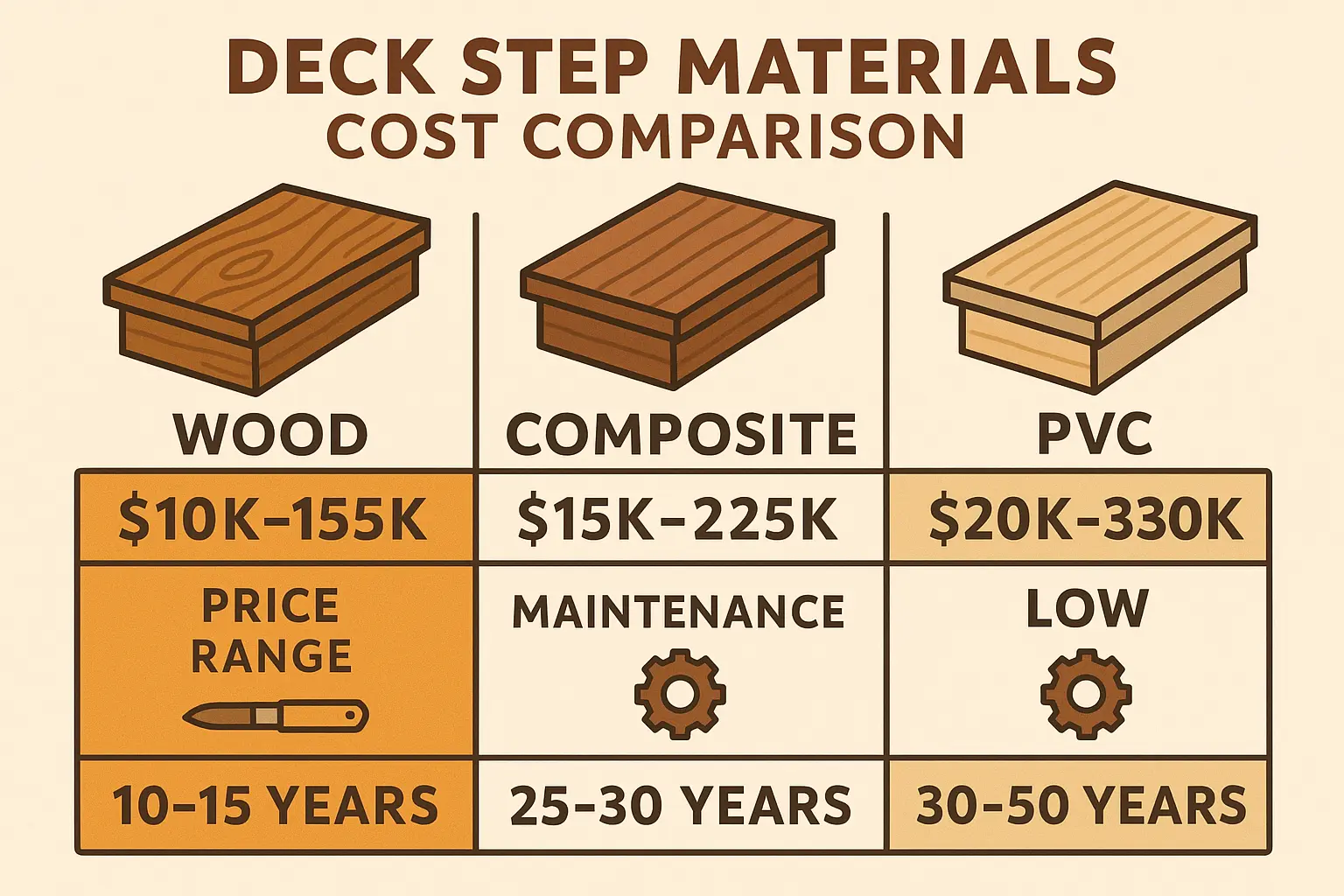

The materials you pick will make or break your budget – composite materials cost more upfront but you’ll never have to stain them again over 25+ years

-

Traditional straight steps offer the best balance of cost, safety compliance, and DIY-friendliness for most homeowners

-

Curved and specialty steps create stunning visual impact but you’ll probably want to call in the pros and have a bigger budget

-

Storage and functional features maximize your investment by solving multiple problems at once

-

Your site conditions like soil drainage, height requirements, and space constraints will eliminate some options entirely

-

Professional debris removal services can streamline your construction timeline and keep your workspace clean and safe

Essential Considerations for Choosing Deck Steps

Before you fall in love with any specific deck steps design, you need to figure out five critical things that will determine which options will actually work for your situation. We’re talking safety and building code compliance, how much maintenance you’re actually willing to do, whether the steps will look good with your house, what you can realistically afford, and what your yard conditions will allow. Once you figure these out, you’ll know exactly which of the 25 options make sense for your specific situation and long-term goals.

Safety and Building Code Requirements

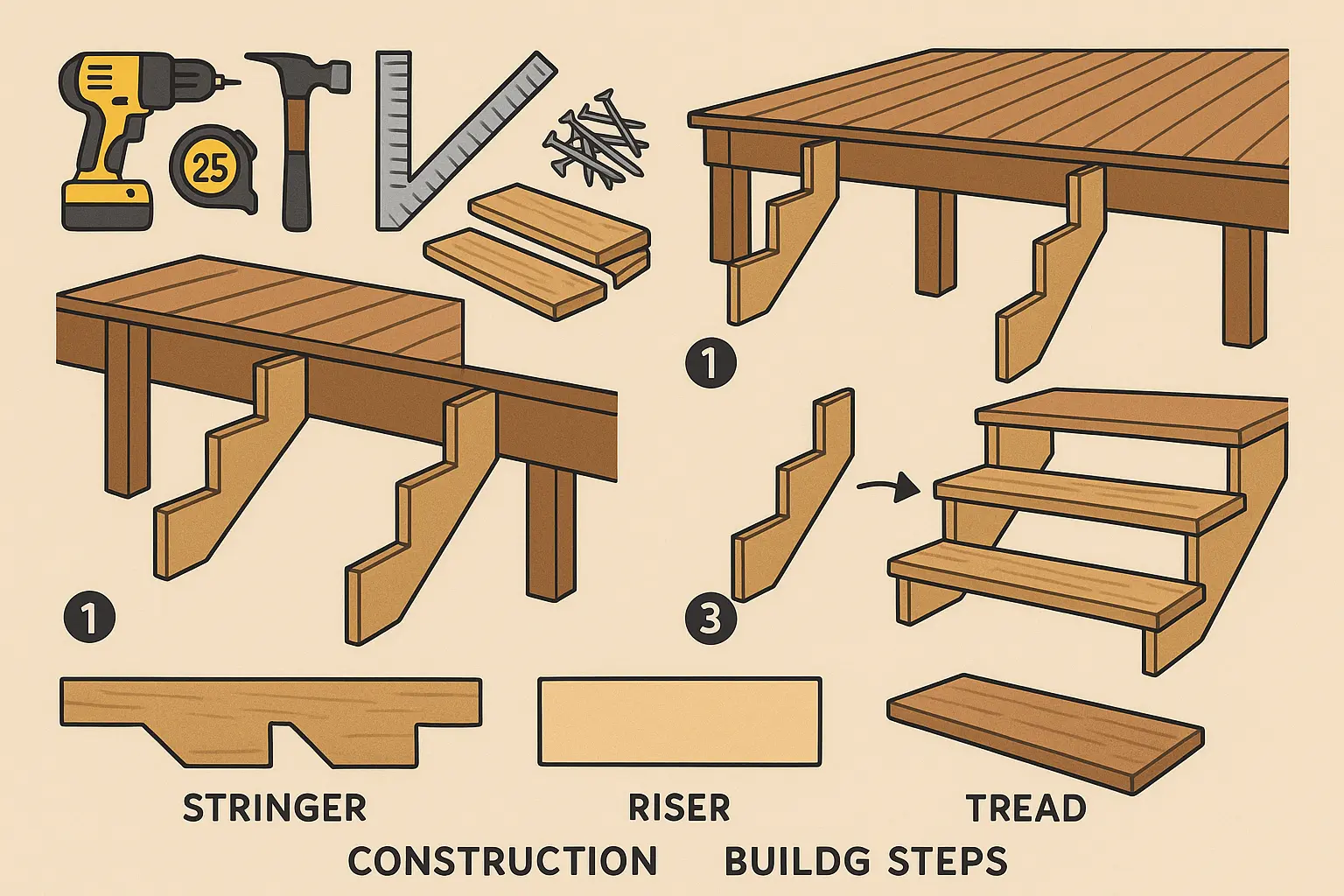

Look, building codes exist because people kept getting hurt on poorly built stairs. Deck stairs are heavily regulated, and for good reason – they’re where most accidents happen. Most places have rules that say risers (the vertical part) need to be between 4-8 inches, with treads (where you actually step) at least 10 inches deep. You’ll need handrails when you have four or more steps, positioned 34-38 inches high.

Here’s something that’ll save you from a nasty fall – your deck stairs must handle at least 300 pounds per square foot. This affects everything from your foundation planning to what materials you can use. And don’t forget about slip resistance, especially if you live somewhere with frequent rain or snow. Trust me, your insurance company will have opinions if someone gets hurt on slippery steps.

Material Durability and Maintenance

Be honest with yourself here – are you actually going to stain those steps every year? Weather resistance should be your top priority when picking materials. UV exposure, moisture, and temperature swings will test every part of your steps over time. Pressure-treated lumber might cost less upfront, but you’ll spend weekends every year staining and sealing. Composite materials cost more initially but can last 25+ years with basically zero maintenance.

Think about what you’ll actually spend over the years, not just the sticker price. I learned this the hard way when my first set of steps started sagging after two winters because I skipped the annual maintenance. Freeze-thaw cycles destroy some materials quickly, while constant humidity rots others. Do the math: no more weekend staining sessions = more time for actually enjoying your deck.

For comprehensive guidance on planning your construction project, including construction waste disposal considerations, make sure you account for all project phases from start to finish.

|

Factor |

Pressure-Treated |

Composite |

Cedar |

Natural Stone |

Steel Frame |

|---|---|---|---|---|---|

|

Initial Cost |

$150-300 |

$400-800 |

$250-450 |

$800-2000 |

$600-1200 |

|

Lifespan (Years) |

10-15 |

25+ |

15-20 |

30-50+ |

25-30 |

|

Annual Maintenance |

High |

Minimal |

Moderate |

Low |

Low |

|

Weather Resistance |

Moderate |

Excellent |

Good |

Excellent |

Excellent |

|

DIY Friendly |

Yes |

Yes |

Yes |

No |

No |

Aesthetic Integration

Picture this: you’re sipping coffee at your kitchen window every morning, looking at your deck steps. Do they make you smile or cringe? Your steps shouldn’t look like an afterthought somebody bolted onto your deck. They need to play nicely with your deck’s style, match your existing colors and materials, and fit the scale of your home. A massive stone staircase might look impressive on Pinterest, but it could make your modest ranch house look ridiculous.

Visual flow matters too – your steps should create a natural transition from deck to ground that feels welcoming, not like you’re descending into a dungeon. Think about the view from inside your house as well as from the yard. Warning: Your neighbors will suddenly find excuses to “chat” once you install beautiful steps.

Budget and Installation Complexity

We’ve all been there – standing at the lumber yard, completely overwhelmed by choices and prices. Material costs range from about what you’d spend on a nice dinner for four ($150-300 for basic pressure-treated) to more than a decent used car ($5,000+ for premium stone). But don’t forget about labor costs if you’re hiring pros, or the value of your weekend time if you’re doing it yourself.

Some designs need specialized tools or skills that might push you toward professional installation. Others are perfect weekend DIY projects. Be brutally honest about your capabilities and available time. If you can build a bookshelf, you can handle basic pressure-treated steps. If you’ve never used a circular saw, maybe start with something simpler or budget for professional help.

Environmental and Site Factors

Your dirt, drainage, and local frost line will make or break your step installation. Poor drainage can undermine even the best-built steps, while unstable soil might require serious foundation work that doubles your costs.

The height difference between your deck and ground will eliminate some options entirely. Space constraints matter too – you can’t build wraparound steps if your neighbor’s fence is three feet away. These aren’t fun considerations, but ignoring them leads to expensive do-overs.

Traditional Straight Steps (5 Ideas)

Traditional straight steps are the reliable workhorses of deck construction – they get the job done safely, meet codes easily, and won’t break the bank. These five options range from basic weekend warrior projects to premium materials that’ll outlast your mortgage. All of them are relatively DIY-friendly and work great with standard handrails.

1. Classic Pressure-Treated Lumber Steps

Pressure-treated lumber is still the go-to choice when you want functional steps without breaking the bank. You’ll use 2×12 pressure-treated stringers spaced 16 inches apart, with 2×10 treads and 5/4″ deck boards for the walking surface. The whole thing typically costs $150-300 for a basic 3-4 step setup.

Installation needs a framing square for cutting stringers, galvanized bolts for attachment, and basic carpentry skills. The biggest downside? You’ll be out there every year with stain or sealer to prevent rot and keep them looking decent. But hey, with proper maintenance, they’ll serve you well for 10-15 years, and that’s not bad for the price.

Real Project Example: Sarah from Denver built pressure-treated lumber steps for her 8×12 deck last spring. She spent $220 on materials including three 2×12 stringers, pressure-treated 2x10s for treads, and galvanized hardware. The project took her one weekend using basic tools she already owned. After one year, the steps remain solid, though she’s planning to apply deck stain this spring to keep them looking good and extend their life.

2. Cedar Box Steps

Cedar brings natural rot resistance and gorgeous grain patterns that beat pressure-treated lumber’s greenish tint any day. You’ll build these using cedar 2x10s for the frame and cedar deck boards for treads, creating an enclosed box design that doubles as storage space underneath.

The natural oils in cedar fight off insects and decay, though annual sealing helps maintain that rich color and extends lifespan. Expect to pay 30-50% more than pressure-treated options, but you’ll get way better looks and less maintenance headaches. Your back will thank you for choosing lighter materials too.

3. Composite Material Steps

Composite materials like Trex, TimberTech, or similar brands are the ultimate “set it and forget it” solution. You’ll use composite stringers and treads that laugh at fading, splintering, and moisture damage. No more annual staining or sealing – just occasional cleaning with soap and water.

Installation follows the same techniques as wood construction, but you’ll need specific fasteners designed for composite materials. The upfront cost is brutal – often 2-3 times pressure-treated lumber – but the 25+ year lifespan with minimal maintenance makes the math work. The good news? Your steps will outlast your mortgage.

4. Pressure-Treated with Composite Treads

This hybrid approach gives you the best of both worlds – budget-friendly pressure-treated lumber for the hidden structural frame with composite deck boards for the walking surfaces where it actually matters. You’ll save money on the parts nobody sees while investing in low-maintenance treads that handle daily wear and weather.

Color matching between frame and treads takes some planning, but many manufacturers offer complementary schemes. This approach typically adds $100-150 to your material costs compared to all-wood construction while eliminating the need to stain your treads every year.

5. Treated Lumber with Anti-Slip Strips

Safety-conscious homeowners often add anti-slip strips to standard pressure-treated deck stairs, especially in areas with frequent rain or snow. Aluminum or composite strips attach to tread edges after construction, giving you enhanced traction without destroying your budget.

These strips screw or stick in place, and they’re particularly valuable for high-traffic steps or homes with elderly residents. The added safety feature costs $20-40 per step but can prevent costly accidents and insurance claims. Picture this: you’re hosting a barbecue and someone’s grandma is navigating your steps in the dark – these strips could save the day.

Curved and Angled Steps (4 Ideas)

Curved and angled steps create serious visual impact and can blend beautifully with landscape features, but they’ll cost 2-4 times more than straight steps and usually need professional installation. These designs work particularly well for contemporary homes or properties with curved deck edges, though most require pros due to complex cutting and structural requirements.

6. Curved Wraparound Steps

Curved steps create an elegant, flowing transition that works beautifully with landscape features or curved deck edges. Construction requires bent laminated stringers or multiple straight sections with small angle cuts to fake the curve. Each stringer gets individually cut and fitted, making this a job for experienced carpenters who know what they’re doing.

The foundation work is equally complex, needing multiple concrete footings that follow the curve path. Materials often include special engineered wood that bends without breaking, with composite or cedar for visible surfaces. Expect to invest $2,000-4,000 for a typical installation, with 3-5 days required for completion. You might want to call in the pros for this one.

7. Angled Corner Steps

Positioning deck stairs at 45-degree angles to your deck corners maximizes usable yard space while creating interesting visual lines. This design works particularly well for corner decks or situations where straight steps would interfere with landscaping or other yard features.

The angled approach can incorporate landings for direction changes or simply provide a more direct path to frequently used yard areas. Additional support posts are often needed at angle points, and the structural calculations become more complex than straight step construction. But the result can be really striking.

8. Fan-Shaped Steps

Fan-shaped deck stairs start narrow at the deck and widen as they descend, creating a grand entrance effect that makes your deck feel more substantial and welcoming. The widening design requires custom stringer cutting and careful planning to maintain consistent measurements.

This design works with both wood and composite materials, though the complex cuts are easier with composite boards that won’t split on you. The visual impact is substantial, but so is the material waste from custom cutting, which bumps up overall project costs.

9. Serpentine Steps

Serpentine steps follow gentle S-curves that can integrate beautifully with existing garden paths or natural terrain features. This design creates a unique, artistic appearance that serves as a landscape focal point while providing functional access.

The complexity is high – requiring detailed planning, skilled installation, and often custom-fabricated components. However, the result is truly distinctive deck steps that enhance your entire landscape design. This option works best when integrated with professional landscape design services. Warning: Your neighbors will definitely have opinions about these.

Multi-Level and Platform Steps (4 Ideas)

Multi-level and platform steps break up long vertical distances into manageable chunks while creating opportunities for rest areas, seating, and landscaping integration. These designs work particularly well for tall decks or sloped terrain, though they require substantial foundations and more complex planning than single-flight steps.

10. Cascading Platform Steps

When you’re dealing with a really tall deck, cascading platforms break the journey into manageable segments while creating opportunities for rest, seating, or decorative elements. Each platform functions as a mini-deck with proper footings and structural support.

This design works particularly well for tall decks where a single flight of deck stairs would be intimidating or exhausting to navigate. The platforms can incorporate built-in planters, seating, or simply provide breathing room during the climb. Think of them as rest stops on your journey from deck to yard.

11. Split-Level Landing Steps

A central landing with deck stairs splitting in two directions provides access to different yard areas while creating an impressive architectural feature. The central landing requires substantial foundation work but offers opportunities for built-in seating, planters, or decorative elements.

This design works great for properties where you want access to multiple outdoor activity areas – maybe steps leading to a garden on one side and a patio or fire pit area on the other. The structural requirements are significant, but the functionality and visual impact justify the investment.

12. Terraced Garden Steps

Integrating deck steps into terraced landscape design creates beautiful transitions that serve multiple purposes. These steps often combine traditional structural materials with hardscaping elements like stone or pavers, incorporating drainage systems for planted areas.

The maintenance includes both structural upkeep and landscape care, but the result is steps that function as garden features rather than simple access routes. This approach works particularly well for sloped properties where terracing is already part of the landscape design.

13. Multi-Width Platform Steps

Varying platform widths create dynamic visual interest while providing different functional zones. Wider platforms can serve as gathering areas or display spaces for plants and decorative elements, while narrower sections maintain the primary access function.

Each level requires individual structural planning and support, allowing you to customize the design for specific site conditions and intended uses. This flexibility makes it possible to work around existing landscape features or utility locations that you can’t move.

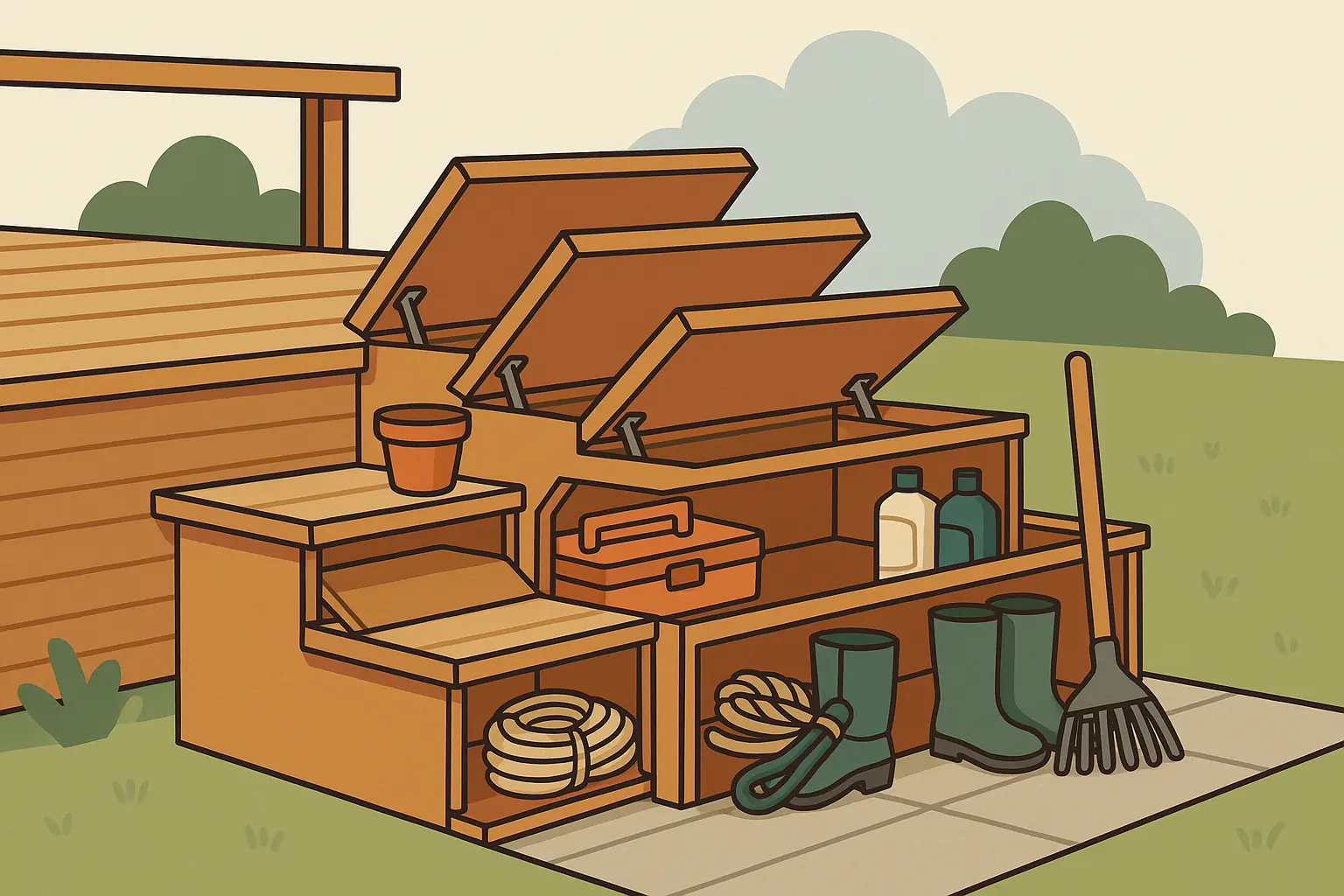

Integrated Storage and Functional Steps (4 Ideas)

Storage and functional steps maximize your investment by solving multiple problems at once – providing deck access while incorporating features like storage compartments, planters, seating, and lighting systems. These designs require more complex construction and weatherproofing but provide serious added value by addressing multiple outdoor living needs in a single structure.

14. Built-In Storage Steps

Storage deck steps solve two problems at once – providing deck access while creating weatherproof storage for seasonal items, pool supplies, or gardening tools. The construction requires hinged treads or side-access panels with proper weatherproofing to prevent moisture damage to stored items.

Double-wall construction with vapor barriers keeps contents dry, while marine-grade hinges and latches withstand weather exposure. Screened vents prevent moisture buildup without letting pests in. Expect to invest $1,500-3,000 for a 4-step configuration, but you’ll gain valuable storage space that might otherwise require a separate shed.

When planning your storage step project, consider garage clean out services to help organize items you’ll be storing in your new compartments.

Real Project Example: Mike in Portland built storage steps for his pool deck, incorporating waterproof compartments for pool chemicals, cleaning equipment, and seasonal cushions. He used marine-grade plywood with rubber gaskets and stainless steel hinges, spending $1,800 on materials. The project took three weekends to complete, but now he has 12 cubic feet of organized storage that’s easily accessible yet completely weatherproof.

15. Planter Box Steps

Integrating planters into your deck stairs design creates beautiful transitions between hardscaping and landscaping. Cedar or composite construction works well for the planter boxes, with proper drainage systems essential to prevent water damage to the structural components.

Plant selection should consider the sun and shade conditions around your steps, as well as how big your chosen plants will get. Trailing plants can soften hard edges, while taller specimens provide natural screening. The maintenance includes both structural care and regular plant watering and seasonal care – so don’t pick this option if you kill houseplants.

16. Seating Integrated Steps

Wide deck steps with built-in bench seating serve dual purposes as access routes and outdoor furniture. The seating areas typically need 18-inch minimum depth for comfortable use, with additional structural support to handle seating loads safely.

This design works particularly well for entertaining areas where guests naturally gather during parties. The integrated approach eliminates the need for separate outdoor furniture while creating natural conversation areas. Construction complexity increases due to the additional structural requirements, but the functionality justifies the extra effort.

17. Lighting Integrated Steps

Built-in lighting enhances both safety and ambiance, with LED strip lighting or individual step lights providing illumination for evening use. The electrical planning should happen during the design phase, with proper outdoor-rated fixtures and appropriate control systems.

Control options include timer switches, motion sensors, or manual switching, depending on your preferences and usage patterns. Low-voltage LED systems are energy-efficient and relatively easy to install, though running electrical lines is best done during initial construction rather than trying to retrofit later.

Alternative Material Steps (4 Ideas)

Alternative material steps move beyond traditional wood construction to incorporate stone, concrete, steel, and masonry options that offer superior durability and unique looks. While these materials typically require higher upfront investments and specialized installation skills, they provide decades of service with minimal maintenance and can significantly boost property values.

18. Natural Stone Steps

Natural stone deck stairs using flagstone, bluestone, or regional stone varieties create elegant, permanent installations that can last generations. The foundation work is critical – requiring proper base preparation and often concrete footings to prevent settling and cracking.

The upfront investment is substantial, but the longevity makes stone steps cost-effective over time. Different stone types offer various colors and textures, allowing you to match regional architectural styles or personal preferences. You’ll definitely want to call in the pros for this one due to the specialized skills required.

19. Concrete Steps with Decorative Finish

Poured concrete deck stairs offer exceptional durability and design flexibility, with decorative finishes like stamped patterns, exposed aggregate, or integral coloring creating attractive surfaces. The material can be formed to virtually any shape or size, accommodating complex designs that would be difficult with other materials.

Professional installation is essential for proper reinforcement and finishing, but the result is extremely long-lasting with minimal maintenance requirements. Concrete steps handle freeze-thaw cycles well when properly constructed and can support heavy loads without concern.

For projects involving concrete demolition of existing structures, professional removal services can prepare your site efficiently.

|

Step Type |

Installation Time |

Skill Level Required |

Weather Resistance |

Lifespan |

Maintenance Level |

|---|---|---|---|---|---|

|

Pressure-Treated |

1-2 days |

DIY Friendly |

Moderate |

10-15 years |

High |

|

Composite |

1-2 days |

DIY Friendly |

Excellent |

25+ years |

Minimal |

|

Natural Stone |

3-5 days |

Professional |

Excellent |

30-50+ years |

Low |

|

Concrete |

2-4 days |

Professional |

Excellent |

30-40 years |

Low |

|

Steel Frame |

2-3 days |

Professional |

Excellent |

25-30 years |

Low |

|

Curved/Custom |

3-7 days |

Professional |

Varies |

Varies |

Varies |

20. Steel Frame Steps

Galvanized or powder-coated steel stringers create clean, modern appearances that complement contemporary home designs. The treads can be wood, composite, or metal grating, depending on your aesthetic preferences and maintenance tolerance.

Steel construction offers exceptional strength and longevity when properly treated against corrosion. The modern aesthetic works particularly well with industrial or contemporary architectural styles, though it might look out of place with traditional home designs. Yes, your HOA might have opinions about these.

21. Brick and Mortar Steps

Clay brick construction with mortar joints creates traditional appearances that work particularly well with brick homes or colonial architectural styles. The construction requires masonry skills and proper foundation work to ensure long-term stability.

Climate considerations are important – freeze-thaw cycles can damage improperly constructed masonry. In cold climates, you’ll need freeze-thaw resistant materials and proper drainage to prevent ice damage. Professional masonry work ensures proper techniques and material selection.

Specialty and Unique Steps (4 Ideas)

Specialty and unique steps represent cutting-edge design approaches that create dramatic visual impact through innovative construction techniques and materials. These options typically require professional engineering and installation but can transform ordinary deck access into architectural statements that significantly enhance property appeal and value.

22. Floating Steps

Individual treads that appear to “float” without visible support create striking minimalist aesthetics perfect for contemporary homes. The construction uses hidden steel brackets or fancy engineering tricks that make steps look like they’re floating without actually defying gravity.

The engineering requirements are significant – each tread must be properly supported while maintaining the illusion of floating. Professional structural analysis ensures safety while achieving the desired visual effect. This option works best with modern architectural styles where clean lines are valued over traditional charm.

23. Glass Panel Steps

Tempered glass panels with metal framework create sophisticated, modern appearances while allowing natural light to reach areas beneath the deck stairs. The transparency can make spaces feel larger and more open, though you’ll be cleaning them constantly to maintain the look.

Safety considerations include proper non-slip treatments on walking surfaces and appropriate structural support for the glass panels. The maintenance requirements are higher than traditional materials, but the unique appearance justifies the extra effort for many homeowners who want something truly distinctive.

24. Reclaimed Material Steps

Salvaged materials from renovation projects create environmentally friendly deck steps with unique character that can’t be replicated with new materials. Reclaimed lumber, bricks, or stone each bring historical appeal and sustainability benefits to your project.

Material preparation may require cleaning, treatment, or modification to ensure structural integrity and weather resistance. The extra effort results in one-of-a-kind appearances with stories and character that new materials simply can’t match. Plus, you’ll have great conversation starters at parties.

Before starting your reclaimed material project, consider construction debris removal to clear your workspace of old materials.

25. Modular/Prefab Steps

Pre-manufactured step systems designed for easy assembly offer DIY-friendly alternatives to custom construction. These systems typically include detailed instructions and all necessary hardware, with standardized components ensuring consistent quality and fit.

Customization options are limited compared to custom-built steps, but the trade-off is quick installation and predictable costs. Many systems can be assembled in a single day, making them attractive for homeowners who want professional results without the complexity of custom construction.

Detailed Construction Examples

This section gives you the real deal on both simple and complex step options, including what you’ll actually spend, how long it takes, and what you’re getting into. Simple examples focus on DIY-friendly projects that weekend warriors can tackle, while complex examples detail professional-grade installations that require specialized skills and equipment.

Simple DIY Projects

Classic pressure-treated steps represent the most accessible option for DIY homeowners. You’ll need 2×12 stringers spaced 16 inches apart, 2×10 treads, and 5/4″ decking material for the walking surface. Total materials cost around $200 for a basic 3-step setup.

The construction process starts with cutting stringers using a framing square to ensure consistent measurements. Attach stringers to the deck frame using galvanized bolts or structural screws, then install treads working from bottom to top. Basic carpentry skills and standard tools are sufficient for completion.

Composite tread upgrades follow the same structural approach but substitute composite deck boards for the walking surfaces. This adds $100-150 to material costs while eliminating annual maintenance requirements – a worthwhile investment that’ll save you weekends of staining.

Step-by-Step DIY Example: Tom built basic pressure-treated steps for his 10×16 deck using three 2×12 stringers, five 2×10 treads, and galvanized carriage bolts. His material list included: 3 pressure-treated 2x12x8′ boards ($45), 5 pressure-treated 2x10x4′ boards ($60), galvanized hardware ($25), and deck stain ($35). Total cost: $165. He cut stringers Saturday morning, attached them to the deck frame, and installed treads Sunday afternoon, finishing the whole project in one weekend with basic tools.

Complex Professional Installations

Curved wraparound deck stairs require detailed planning and specialized skills that put them firmly in professional territory. The planning phase involves site measurement and curve calculations, followed by material selection and foundation planning.

Construction uses special engineered wood that bends without breaking for curved stringers or multiple straight sections with small angle cuts to fake the curve. Multiple concrete footings follow the curve path, with each stringer individually cut and fitted. The timeline typically runs 3-5 days for experienced contractors, with total costs ranging $2,000-4,000 depending on size and materials.

Built-in storage steps require double-wall construction with vapor barriers to create waterproof storage compartments. Marine-grade hinges and latches provide weather resistance, while screened vents prevent moisture buildup. The construction complexity and specialized hardware typically result in $1,500-3,000 costs for a 4-step configuration with storage.

Performance Evaluation Guide

This evaluation framework helps you assess each of the 25 deck steps ideas against the five key things we talked about earlier, giving you practical guidance for narrowing your options based on your specific priorities, site conditions, and budget reality. The evaluation covers safety compliance, maintenance requirements, how they’ll look with your house, cost factors, and environmental suitability.

Safety and Building Code Compliance

Traditional straight steps, concrete steps, and natural stone steps earn excellent compliance ratings because they easily meet standard building codes with consistent measurements and straightforward handrail installations. These options provide reliable safety performance without requiring special engineering or permits.

Curved and platform deck stairs generally achieve good compliance but may need additional engineering for complex designs. Custom solutions can meet codes but might need professional structural analysis to ensure proper load distribution and safety factors.

Floating steps, glass panel steps, and very wide fan steps need special attention and typically require professional engineering review. These designs may need special permits or inspections, adding time and cost to your project timeline.

Maintenance and Durability Assessment

Composite materials, concrete, steel frame, and natural stone earn top marks for low maintenance requirements. Composite deck steps can last 25+ years with minimal upkeep, while concrete and stone installations can serve for 30-50+ years with occasional sealing or minor repairs.

Cedar and pressure-treated lumber with composite treads fall into the moderate maintenance category, requiring annual inspection and periodic refinishing. With proper care, these options provide 15-20 year lifespans at reasonable maintenance costs.

Basic pressure-treated lumber and reclaimed materials require the highest maintenance commitment, with annual staining and sealing recommended for optimal performance. These options typically last 10-15 years depending on climate conditions and how good you are about actually doing the maintenance.

|

Design Category |

Safety Rating |

DIY Feasibility |

Cost Range |

Best Use Cases |

|---|---|---|---|---|

|

Traditional Straight |

Excellent |

High |

$150-800 |

Most homes, budget-conscious |

|

Curved/Angled |

Good |

Low |

$800-4,000 |

Contemporary homes, unique sites |

|

Multi-Level/Platform |

Good |

Medium |

$600-3,000 |

Tall decks, sloped terrain |

|

Storage/Functional |

Good |

Medium |

$500-3,000 |

Space-limited properties |

|

Alternative Materials |

Excellent |

Low |

$800-5,000+ |

Long-term investment focus |

|

Specialty/Unique |

Variable |

Low |

$1,500-8,000+ |

Architectural statement pieces |

Budget and Complexity Analysis

Budget-friendly DIY options include pressure-treated lumber, modular systems, and basic composite installations. Material costs range $150-500, with weekend project timelines for handy homeowners using standard tools.

Mid-range investments encompass cedar steps, composite upgrades, and storage integration projects. Total costs typically run $500-1,500, potentially requiring specialized tools and 2-3 day project timelines.

Premium investments include curved deck stairs, stone installations, steel frame construction, and floating step designs. Project costs range $1,500-5,000+, with professional installation recommended and 1-2 week timelines including planning phases. The real question isn’t whether you can afford these – it’s whether they fit your long-term goals and lifestyle.

How JiffyJunk Supports Your Deck Steps Project

Look, let’s be real about construction projects – they’re messy. Really messy. I’ve seen homeowners spend more time hauling debris than actually building, and that’s just crazy. You didn’t sign up to become a professional trash hauler when you decided to upgrade your deck steps.

That’s where JiffyJunk comes in, and honestly, they’re a game-changer for projects like this. Whether you’re ripping out those old rotting steps that have been embarrassing you for years or dealing with the mountain of cardboard and plastic wrap that comes with new materials, these folks handle it all.

Professional deck removal services can efficiently clear existing structures before your new installation begins.

Here’s what they’ll take off your hands: those sketchy old wooden steps you’re finally replacing, all the construction debris from tearing up your site, the ridiculous amount of packaging that comes with modern building materials, any landscaping mess from clearing the area, and even that old patio furniture you’re replacing with fancy built-in seating options.

But here’s the cool part – they don’t just grab your stuff and run. They actually clean up after themselves, sweeping and sanitizing your work area. I know, revolutionary concept, right? Plus, they’re not just tossing everything in a landfill. If your old stuff is still decent, they’ll donate it. If it can be recycled, they handle that too.

The scheduling thing is huge. Construction never goes according to plan (trust me on this), so when you suddenly need debris removed because the weather cleared up or your materials arrived early, they can often come the same day. No more having that debris pile sitting there making your neighbors wonder what disaster struck your yard.

For larger renovation projects, consider construction waste disposal services that handle multiple phases of debris removal throughout your project timeline.

And get this – starting at just $100, it’s often cheaper than making multiple trips to the dump yourself. Plus, you don’t have to figure out what goes where or deal with disposal fees. Give them a call at (844) 543-3966 or check out jiffyjunk.com. Your back will thank you, and you can focus on the fun part – actually building something awesome.

For comprehensive project planning, including appliance disposal during outdoor kitchen upgrades, professional services can streamline your entire renovation process.

Final Thoughts

Okay, we’ve covered a lot of ground here – 25 different ways to get from your deck to your yard without looking like you’re navigating an obstacle course. The truth is, there’s no single “perfect” choice that works for everyone. Your neighbor’s gorgeous curved stone steps might be completely wrong for your ranch house and weekend warrior budget.

Here’s what I want you to remember: start with safety, always. I don’t care how pretty those Pinterest-worthy floating steps look – if they don’t meet code or aren’t right for your family’s needs, they’re not for you. Your insurance company and your grandmother’s ankles will thank you for choosing boring-but-safe over Instagram-worthy-but-sketchy.

That said, don’t let anyone convince you that “functional” has to mean “ugly.” Even basic pressure-treated steps can look great with the right stain and some thoughtful landscaping around them. And if you’ve got the budget for composite or stone, go for it – you’ll be enjoying those steps long after you’ve forgotten what they cost.

The maintenance thing is real, folks. I’ve watched too many homeowners choose wood steps, skip the annual maintenance, and then act shocked when they start falling apart after five years. Be honest with yourself about whether you’re actually going to stain those steps every year or if you’re better off spending more upfront for something that takes care of itself.

And please, please don’t try to DIY something that’s beyond your skill level just to save money. There’s no shame in calling professionals for the complex stuff. Your steps need to be safe and code-compliant, and sometimes that means swallowing your pride and writing a check.

Whatever you choose, remember that good deck steps should make your outdoor space more enjoyable, not give you something else to worry about. They’re an investment in your daily happiness – and trust me, you’ll notice the difference every single time you step outside.