DIY Paint Booth Engineering: The Advanced Systems Most Builders Never Consider

Most DIY builders think creating a professional-grade paint booth means throwing up some plastic sheeting and adding a fan. I’ve seen countless garage warriors spend hundreds of dollars on basic setups only to get orange peel finishes and contamination issues that ruin their projects. The truth is, even simple PVC frame booths measuring 7 feet in height can achieve professional results when properly engineered, but you need to understand the complex atmospheric chemistry and contamination control systems that separate amateur from professional outcomes.

When planning your DIY paint booth construction, understanding the construction debris removal requirements becomes crucial for managing waste materials generated during booth assembly and future maintenance. You’re going to generate more waste than you think, and proper planning prevents headaches later.

Table of Contents

- The Micro-Environment Engineering Challenge

- The Modular Transformation System

- The Waste Stream Integration Approach

- The Performance Validation Framework

- The Regulatory Navigation Maze

TL;DR

- Professional DIY paint booth results require understanding atmospheric chemistry, vapor density layers, and electrostatic discharge prevention

- Modular booth systems maximize space utility through rapid deployment ventilation and collapsible containment walls

- Waste stream integration creates cost recovery opportunities through overspray recovery and solvent reclamation systems

- Performance validation using empirical testing protocols ensures your booth meets professional specifications

- Regulatory compliance strategies help navigate fire codes, insurance requirements, and environmental permits

The Micro-Environment Engineering Challenge

Building a DIY paint booth involves way more than basic construction – you’re creating a controlled micro-environment that manages chemical interactions, temperature gradients, and contamination at the molecular level. Most builders focus on walls and ventilation but completely miss the invisible atmospheric chemistry that determines both finish quality and safety outcomes.

Paint particles and solvents create complex chemical interactions within confined spaces that directly affect spray patterns and finish quality. I’ve watched DIY painters struggle with inconsistent coverage patterns without realizing their booth’s atmospheric conditions were working against them. The chemistry happening in your booth is just as important as the paint you’re spraying.

Temperature gradients and molecular weight differences cause invisible stratification layers that require specific extraction point positioning. You can’t just stick a fan anywhere and expect good results. Different solvents behave differently based on their molecular weight, creating layers within your booth that affect how paint particles move and settle.

Contamination control at the microscopic level prevents finish defects that aren’t visible during booth construction. Those tiny particles floating around will embed themselves in your wet paint, creating defects that show up under good lighting. Your DIY paint booth needs to address contamination sources you can’t even see.

Atmospheric Chemistry Management

Understanding how paint particles, solvents, and ambient air interact within your confined space determines both finish quality and health safety. Different molecular weights create invisible layers that affect spray patterns and require strategic ventilation design. Your homemade paint booth becomes a chemistry lab whether you realize it or not.

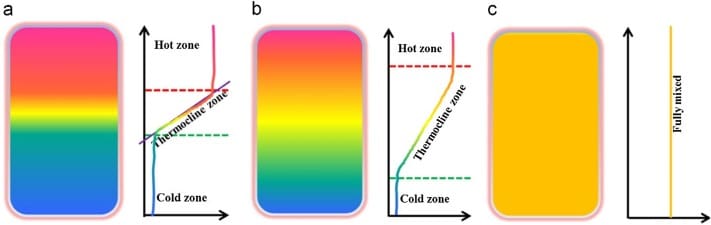

Vapor density stratification occurs when different paint solvents separate by molecular weight, creating distinct layers within your booth. Heavier solvents sink to the floor while lighter ones rise to the ceiling. This creates zones where your spray gun behaves differently, affecting coverage and finish quality.

Proper extraction point positioning must account for the heaviest solvents you’ll use to prevent dead air pockets. I’ve seen DIY paint booth setups where painters couldn’t figure out why certain areas of their projects had different finishes – the problem was dead air zones where contaminated air wasn’t being extracted properly.

Temperature monitoring at multiple heights reveals airflow patterns that aren’t visible but critically affect paint application. Professional painters recommend maintaining at least 3 feet of distance from the car to booth walls to allow proper air circulation and paint droplet settling, as documented in automotive forum discussions where experienced builders share booth spacing requirements.

Vapor Density Stratification

Different paint solvents have varying molecular weights, creating invisible layers within your booth that affect spray patterns and require specific extraction points. Heavier vapors settle while lighter ones rise, creating zones that impact both safety and finish quality. Your DIY paint booth ventilation system needs to account for this invisible chemistry.

Install temperature sensors at floor, mid-level, and ceiling positions to map thermal gradients that indicate vapor movement. These sensors will show you what’s really happening in your booth atmosphere. The data reveals patterns you can’t see but that directly affect your paint job quality.

Map airflow patterns using smoke pencils before first use to identify turbulence zones and dead air pockets. This step separates successful DIY paint booth builders from those who struggle with inconsistent results. Smoke testing shows you exactly where your ventilation system is working and where it’s failing.

Position extraction vents based on molecular weight data for your specific solvents rather than generic ventilation guidelines. Generic advice doesn’t account for the specific chemistry of your paint system. Each solvent behaves differently, and your extraction points need to match those behaviors.

Electrostatic Discharge Prevention

Paint particles become electrically charged during spraying, and improper grounding can cause finish defects or safety hazards that most DIYers never consider. Static buildup affects particle distribution and can create dangerous conditions with flammable vapors. Your DIY paint booth needs proper electrical grounding to prevent both safety issues and finish problems.

Conductive flooring or grounding mats provide continuous electrical paths that prevent static charge accumulation. Static electricity builds up naturally during paint spraying, and without proper grounding, you’re setting yourself up for problems. The electrical charge affects how paint particles behave in the air and how they land on your project.

Anti-static spray gun accessories and proper humidity levels (40-60%) reduce charge generation during application. Maintaining proper humidity in your booth isn’t just about comfort – it’s about controlling the electrical environment that affects paint application.

Ground all metal surfaces with copper wire connections to create equipotential bonding throughout the booth. Recent automotive restoration projects highlight the importance of proper grounding, as shown in “DIY Paint And Body At Home: Restoring A 1964 Pontiac LeMans” where painters work without fancy equipment but must still address static electricity concerns in barn environments.

Contamination Source Mapping

Professional-grade results require identifying and eliminating microscopic contamination sources that aren’t visible during construction. Common booth materials release particles that embed in wet paint, creating orange peel or fisheye defects. Your DIY spray booth needs systematic contamination control to achieve professional results.

Fabric and material off-gassing from plastic sheeting and foam filters releases particles that contaminate wet paint surfaces. These materials continue releasing microscopic particles for weeks after installation, creating ongoing contamination issues that affect every paint job.

Pressurization cascade design creates positive pressure zones that prevent outside contamination while managing overspray containment. Strategic air pressure differentials maintain clean air flow patterns without compromising ventilation efficiency. Similar to how garage cleanout experts identify hidden contamination sources in cluttered spaces, paint booth builders must systematically eliminate particle sources that compromise finish quality.

Fabric and Material Off-Gassing

Common booth materials release particles that embed in wet paint, creating orange peel or fisheye defects. Material selection requires understanding which products continue releasing contaminants after installation. Your DIY paint booth materials are either helping or hurting your finish quality.

Plastic sheeting and foam filters continue releasing microscopic particles for weeks after installation. That cheap plastic drop cloth might seem adequate, but it’s actively contaminating your paint environment. Material off-gassing creates contamination that embeds in wet paint, causing visible surface defects.

Pre-conditioning booth materials through extended ventilation cycles reduces initial contamination levels. A typical DIY booth using standard plastic drop cloths and basic HVAC filters can contaminate paint surfaces for up to 30 days after construction. Pre-conditioning involves running ventilation systems for 48-72 hours before first use, allowing volatile compounds to outgas from materials. This process reduces contamination by approximately 80% compared to immediate use after construction.

Pressurization Cascade Design

Creating positive pressure zones prevents outside contamination while managing overspray containment through strategic air pressure differentials. This approach maintains clean airflow without compromising safety or efficiency. Your booth needs controlled pressure zones to work properly.

Positive pressure zones create barriers against outside contamination while maintaining controlled airflow patterns. The pressure differential keeps dirty air from entering your clean paint environment. Strategic air pressure differentials manage overspray containment without creating turbulence that affects spray patterns.

Cascade pressure design maintains clean air supply while ensuring adequate exhaust for safety compliance. You need both clean air coming in and contaminated air going out, balanced properly to maintain the right pressure zones.

| Pressure Zone | Differential (Pa) | Function | Airflow Direction |

|---|---|---|---|

| Clean Air Supply | +15 to +20 | Contamination prevention | Inward |

| Work Area | +5 to +10 | Spray zone control | Neutral |

| Exhaust Zone | -5 to -10 | Overspray capture | Outward |

| Transition Areas | +2 to +5 | Gradient management | Controlled |

The Modular Transformation System

Advanced DIY enthusiasts create convertible spaces that serve multiple purposes while maintaining paint booth functionality when needed. Rather than permanent structures, these systems transform ordinary rooms into professional-grade paint environments within minutes through strategic design and equipment placement. Building a paint booth doesn’t mean sacrificing your entire garage to a single purpose.

Space-time optimization maximizes utility from limited space through rapid deployment systems that don’t require permanent modifications. Most of us don’t have dedicated paint booth space, so we need systems that work when we need them and disappear when we don’t.

Modular systems provide professional-grade functionality while preserving workshop versatility for other projects and activities. Your garage can be a paint booth on Saturday and a woodworking shop on Sunday with the right modular approach.

Space-Time Optimization

Maximizing utility from limited space by designing systems that transform ordinary rooms into professional-grade paint environments within minutes. These systems provide full functionality without permanent modifications that limit space usage. Your DIY paint booth should enhance your workshop, not take it over completely.

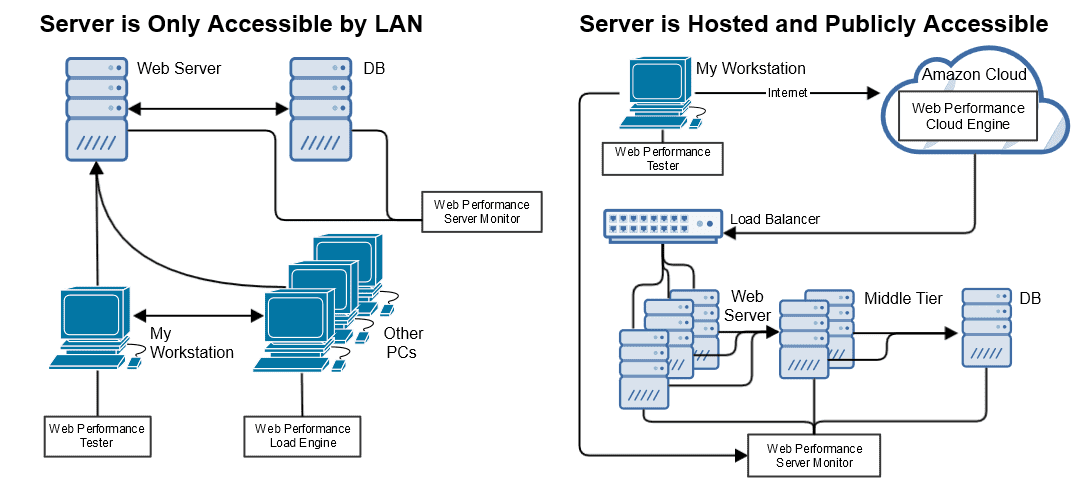

Rapid deployment ventilation connects to existing HVAC or window openings without permanent structural modifications. You can achieve professional ventilation without cutting holes in walls or installing permanent ductwork. The key is designing connections that work with your existing infrastructure.

Collapsible containment walls provide professional-grade isolation while folding away when not needed. Equipment integration stations house compressors, lighting, and electrical systems in mobile configurations that serve multiple workshop functions.

Typical DIY booth construction using PVC pipe requires 12 pieces of 10-foot 3/4″ PVC pipe cut to 7-foot lengths, as documented in successful DIY booth builds, providing adequate headroom for painters up to 5’6″ while maintaining structural integrity. This paint booth DIY approach gives you professional capability without permanent installation.

Rapid Deployment Ventilation

Portable ventilation systems connect to existing HVAC or window openings, providing professional-grade air exchange without permanent modifications. These systems deliver required air changes per hour while maintaining installation flexibility. Your DIY paint booth ventilation doesn’t require major construction projects.

Calculate space volume and required air changes per hour (minimum 4 ACH) to determine proper fan sizing and ductwork requirements. The math is straightforward: measure your booth volume, multiply by 4, then divide by 60 to get your required CFM. This calculation determines what size fans you need for safe operation.

Variable-speed inline fans rated for paint vapor exposure provide adjustable airflow based on project requirements. You need fans specifically rated for paint vapors – regular HVAC fans aren’t designed for this environment and can create safety hazards.

Quick-connect ductwork using standard HVAC fittings enables rapid setup and breakdown without specialized tools. Standard fittings mean you can source parts locally and make modifications easily.

Rapid Deployment Checklist:

- ☐ Calculate booth volume (L x W x H)

- ☐ Determine required CFM (Volume x 4 ACH ÷ 60)

- ☐ Select explosion-proof fans rated for paint vapors

- ☐ Install quick-connect ductwork fittings

- ☐ Test airflow patterns with smoke pencils

- ☐ Verify negative pressure at exhaust points

- ☐ Document baseline performance measurements

Collapsible Containment Walls

Professional-grade containment that folds away when not in use, utilizing tensioned fabric systems and modular framework. These walls provide complete isolation during painting while disappearing when you need full workshop access. Your cheap paint booth can still have professional containment capabilities.

Ceiling-mounted track systems along booth perimeter support fabric panels without floor-based framework that limits movement. Tracks mounted to ceiling joists provide solid support while keeping the floor clear for equipment and movement.

Weighted bottom rails and corner connection systems using industrial fasteners create secure containment without permanent installation. The weight keeps fabric panels taut while corner connections maintain booth integrity during operation.

Fire-retardant, anti-static fabrics rated for solvent exposure ensure safety compliance while maintaining flexibility. A 20×20 foot garage can accommodate a 12×16 foot collapsible booth that stores in a 4×6 foot corner when not in use. The system uses ceiling-mounted tracks with weighted curtain panels that deploy in under 15 minutes. Total material cost typically ranges from $800-1200, compared to $3000-5000 for permanent booth construction.

Equipment Integration Stations

Pre-wired utility stations house compressors, lighting, and electrical systems in mobile configurations. These stations provide professional capabilities while serving multiple workshop functions beyond paint booth operation. Your equipment should work for multiple purposes, not just painting.

Mobile utility stations consolidate electrical, compressed air, and lighting systems in wheeled configurations. Everything you need for paint booth operation can be contained in mobile units that serve other workshop functions when you’re not painting.

Pre-wired connections enable rapid booth setup while providing workshop utility for other projects. Integrated storage systems keep booth-specific equipment organized and readily accessible.

Multi-Function Design Philosophy

Creating paint booth systems that enhance rather than limit your workshop’s versatility. These designs provide specialized painting capabilities while improving general workshop functionality through dual-purpose components and convertible systems. Building a paint booth should make your entire workshop better, not just add painting capability.

Dual-purpose lighting systems provide color-accurate painting illumination while serving as general workshop lighting with adjustable color temperatures. Convertible flooring solutions protect concrete during painting while providing comfortable workshop surfaces for other activities.

The growing trend toward portable solutions is evident in recent innovations such as the “VEVOR 6x3x2.5m Inflatable Paint Booth” which starts at $1,058.99 and demonstrates how mobile booth technology is making professional-grade painting accessible to more DIY enthusiasts.

Dual-Purpose Lighting Systems

LED arrays provide color-accurate painting illumination while serving as general workshop lighting with different color temperature settings. These systems eliminate the need for separate lighting installations while improving both painting and general work conditions. Your lighting investment should serve multiple purposes.

LED arrays with adjustable color temperature provide accurate color rendering for paint work and comfortable illumination for general tasks. Color accuracy is critical for paint matching, but you also need good general workshop lighting for other projects.

Programmable lighting zones enable different illumination patterns for painting versus general workshop activities. Energy-efficient operation reduces electrical costs while providing superior light quality compared to traditional workshop lighting.

Convertible Flooring Solutions

Flooring systems protect concrete during painting while providing comfortable workshop surfaces for other activities. These solutions handle paint cleanup requirements while improving general workshop comfort and functionality. Your floor protection should enhance your workspace, not just protect it.

Interlocking rubber tiles with removable top layers provide paint protection while offering comfortable standing surfaces. Peel-away protective films enable temporary paint protection without permanent floor modifications. Integrated drainage systems handle both paint cleanup and general workshop water management needs.

| Flooring Solution | Initial Cost | Durability | Paint Protection | Comfort Rating |

|---|---|---|---|---|

| Interlocking Rubber Tiles | $3-5/sq ft | 10+ years | Excellent | High |

| Peel-Away Films | $0.50-1/sq ft | Single use | Good | Medium |

| Plastic Drop Cloths | $0.10-0.25/sq ft | Single use | Fair | Low |

| Epoxy Coating | $2-4/sq ft | 5-7 years | Excellent | High |

The Waste Stream Integration Approach

Professional paint booth operation generates multiple waste streams that require systematic management, turning waste handling into opportunities for cost recovery and environmental responsibility. Building waste recovery systems directly into booth design creates ongoing value rather than treating disposal as an afterthought. Your DIY spray booth can actually pay for itself through smart waste management.

Circular economy design integrates waste recovery and reuse systems directly into booth operation rather than treating waste as disposal problem. Resource recovery networks connect DIY operations with local waste streams and recovery opportunities for mutual benefit.

Effective waste management parallels the systematic approach used in scrap metal removal where valuable materials are identified and processed for recovery rather than simply discarded. Your paint waste contains recoverable value if you know how to capture it.

Circular Economy Design

Building waste recovery and reuse systems directly into your booth design rather than treating waste as an afterthought. These systems capture value from waste streams while reducing disposal costs and environmental impact. Your DIY paint booth becomes a resource recovery system instead of just a consumption center.

Overspray recovery systems capture and process overspray for reuse in primer applications or non-critical projects. Solvent reclamation integration provides on-site recovery that reduces disposal costs while supplying cleaning materials. Filter media lifecycle management minimizes ongoing operational costs through systematic replacement and recycling protocols.

Professional booth operations require replacement of 3200 cubic feet of air per minute in a 20x20x8 foot space, as noted in professional painter discussions, highlighting the importance of efficient waste stream management in confined spaces.

Overspray Recovery Systems

Capturing and processing overspray for reuse in primer applications or non-critical painting projects. These systems turn waste into usable materials while reducing both disposal costs and material purchasing requirements. Every paint particle that doesn’t hit your project can still have value.

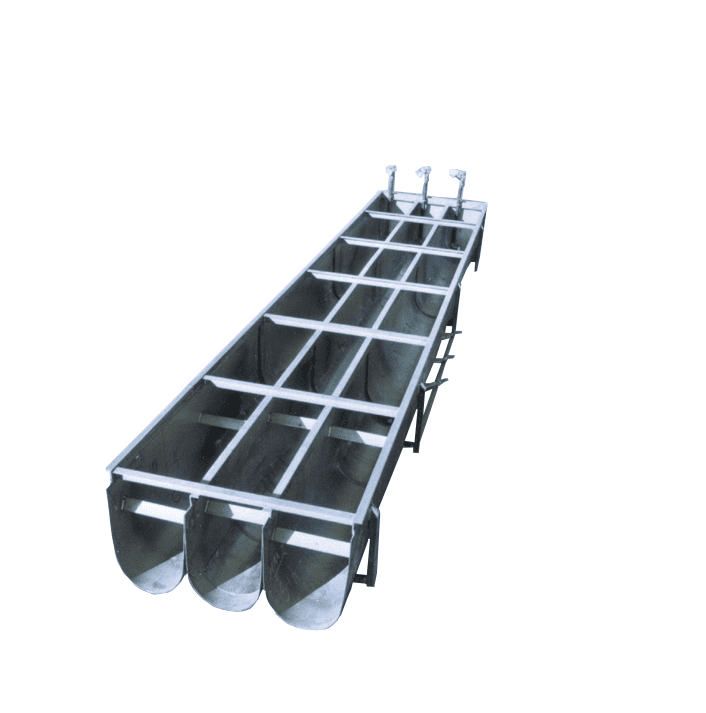

Collection troughs below spray zones capture overspray before it becomes contaminated waste. Positioning these troughs strategically means you’re collecting relatively clean overspray that can be processed for reuse. Filtration systems separate usable paint from debris, enabling quality control for reuse applications.

Storage and testing protocols ensure recovered materials meet quality standards for intended reuse applications. You need systematic approaches to determine what recovered paint is suitable for different applications.

Solvent Reclamation Integration

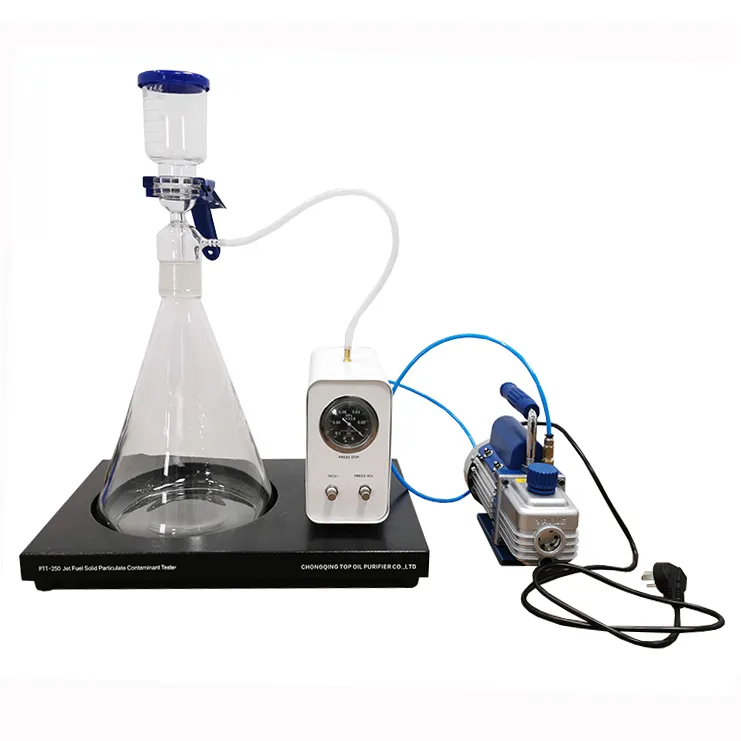

On-site solvent recovery reduces disposal costs while providing cleaning materials for ongoing projects. Reclamation systems pay for themselves through reduced purchasing and disposal expenses while improving workshop sustainability. Your cheap paint booth can include expensive solvent recovery technology.

Distillation systems recover clean solvents from contaminated cleaning materials. Recovered solvents provide ongoing cleaning supplies while reducing hazardous waste disposal requirements. Cost analysis typically shows payback periods under two years for active painting operations.

A typical DIY operation using 5 gallons of solvent monthly can recover 60-70% through simple distillation. Initial equipment cost of $1,200-1,800 pays for itself within 18-24 months through reduced solvent purchases ($40-60/gallon) and disposal fees ($8-12/gallon). Annual savings typically range from $800-1,500 for active painters.

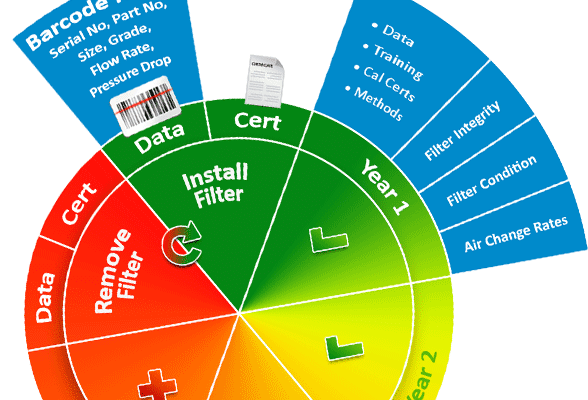

Filter Media Lifecycle Management

Systematic approach to filter replacement, cleaning, and disposal that minimizes ongoing operational costs. Proper lifecycle management extends filter life while maintaining booth performance and reducing waste generation. Your filters are consumables, but smart management reduces consumption.

Filter rotation schedules based on actual usage rather than time intervals optimize replacement timing and costs. Washable pre-filters extend primary filter life by capturing larger particles before they reach expensive final filters.

Performance tracking identifies optimal replacement timing while establishing relationships with recycling services reduces disposal costs. You need data-driven decisions about when to replace filters, not guesswork based on calendar dates.

Filter Management Schedule:

- ☐ Daily: Visual inspection for obvious contamination

- ☐ Weekly: Pressure differential measurement across filters

- ☐ Monthly: Pre-filter cleaning and rotation

- ☐ Quarterly: Primary filter replacement assessment

- ☐ Annually: Complete system filter audit and replacement

Resource Recovery Networks

Connecting your DIY operation with local waste streams and recovery opportunities creates mutual benefits while reducing individual costs. These networks provide access to materials and services that improve both efficiency and sustainability. Your paint booth operation can become part of a larger resource sharing ecosystem.

Community paint exchange programs enable sharing resources with local contractors and DIY enthusiasts. Construction debris partnerships provide painting services in exchange for materials and workspace access.

Building networks mirrors the community approach seen in furniture donation programs where resources are shared to benefit multiple parties while reducing waste.

Community Paint Exchange Programs

Partnering with local contractors and DIY enthusiasts to share resources and reduce individual waste streams. These programs create access to materials while providing outlets for excess supplies and recovered materials. Your leftover paint becomes someone else’s perfect color match.

Local contractor partnerships provide access to bulk materials while offering outlets for recovered paints and solvents. DIY community networks enable sharing specialized equipment and materials that individual users need infrequently.

Exchange programs reduce individual purchasing costs while providing disposal alternatives for partially used materials. Why throw away half a gallon of expensive paint when someone else needs exactly that color?

Construction Debris Partnerships

Collaborating with renovation projects to provide painting services in exchange for materials and workspace access. These partnerships create win-win situations while providing real-world experience with different project types. Your painting skills become currency for materials and space access.

Renovation project partnerships provide access to practice materials and workspace in exchange for painting services. Construction debris streams often include reusable materials suitable for booth construction and maintenance.

Service exchange arrangements provide experience with different paint systems while reducing material costs. You get practice with various projects while contractors get quality painting work.

The Performance Validation Framework

Most DIY paint booths never undergo performance testing, leading to inconsistent results and potential safety issues that only become apparent after significant time and material investment. Establishing measurable performance standards ensures your booth meets professional specifications through systematic testing and documentation. Your DIY spray booths need validation just as much as commercial installations.

Empirical testing protocols establish measurable performance standards that verify DIY booth performance against professional specifications. Documentation and monitoring systems track booth performance over time to identify degradation and optimization opportunities.

Empirical Testing Protocols

Establishing measurable performance standards ensures your DIY booth meets professional specifications. Testing protocols provide objective data about booth performance rather than relying on subjective assessments or assumptions about functionality. You need hard data, not guesswork, about how your booth performs.

Airflow visualization and measurement verify that booth airflow patterns match design specifications using quantifiable data. Contamination level assessment quantifies booth cleanliness using standardized testing methods rather than visual inspection. Safety parameter monitoring provides continuous tracking of explosive vapor concentrations and air quality parameters.

Airflow Visualization and Measurement

Using smoke testing and anemometer readings to verify that your booth’s airflow patterns match design specifications. Visual and quantitative testing reveals actual performance versus theoretical calculations, enabling adjustments for optimal operation. Your booth’s airflow patterns determine everything from safety to finish quality.

Grid pattern measurement points provide systematic data collection across booth cross-sections for comprehensive airflow analysis. Smoke pencil mapping reveals turbulence zones and dead air pockets that aren’t apparent from velocity measurements alone.

Baseline measurement documentation enables ongoing performance comparison and degradation detection over time. You need reference data to know when your booth performance is declining.

Airflow Testing Protocol:

- ☐ Establish 3×3 measurement grid at booth entrance

- ☐ Record velocity at each point using calibrated anemometer

- ☐ Document smoke pencil flow patterns at 5 heights

- ☐ Identify and mark turbulence zones

- ☐ Calculate average airflow and uniformity coefficient

- ☐ Compare results to design specifications

- ☐ Schedule quarterly re-testing

Contamination Level Assessment

Quantifying the cleanliness of your booth environment using standardized testing methods. Objective contamination measurement prevents finish quality issues while establishing performance benchmarks for ongoing operation. Contamination control separates professional results from amateur finishes.

Particle counters measure airborne contamination levels using industry-standard metrics for booth cleanliness assessment. Adhesion testing on sample panels provides objective finish quality data that correlates with contamination levels.

Defect rate tracking over time identifies system degradation patterns and maintenance requirements. You need systematic data collection to understand how contamination affects your specific booth setup.

Safety Parameter Monitoring

Continuous monitoring of explosive vapor concentrations and air quality parameters affects both safety and finish quality. Real-time monitoring prevents dangerous conditions while optimizing booth performance for consistent results. Safety monitoring isn’t optional – it’s essential for both protection and performance.

Vapor concentration monitoring prevents explosive atmosphere development while ensuring adequate ventilation for finish quality. Air quality parameter tracking identifies trends that affect both safety compliance and paint application results.

Automated monitoring systems provide continuous safety oversight without requiring constant manual attention. Modern sensors can alert you to problems before they become dangerous or affect your paint job.

Safety Monitoring Checklist:

- ☐ Install LEL (Lower Explosive Limit) monitors

- ☐ Set alarm thresholds at 10% LEL

- ☐ Calibrate sensors monthly

- ☐ Log vapor concentration readings

- ☐ Test emergency ventilation systems

- ☐ Verify grounding connections

- ☐ Review safety protocols quarterly

The Regulatory Navigation Maze

Building codes, fire safety regulations, and environmental compliance create a complex web of requirements that vary dramatically by location, yet most DIY builders discover these constraints only after construction begins. Strategic planning helps navigate regulatory frameworks while maintaining safety and functionality. Your paint booth DIY project needs to comply with regulations you probably don’t know exist.

Permit pathway optimization provides strategic approaches to working within regulatory frameworks while maintaining booth functionality. Understanding regulatory triggers helps design systems that minimize bureaucratic obstacles without compromising performance.

Permit Pathway Optimization

Strategic approaches to working within or around regulatory frameworks while maintaining safety and functionality. Understanding regulatory definitions and thresholds enables booth design that achieves professional results without triggering complex permit requirements. Smart design choices can keep you out of regulatory trouble while maintaining functionality.

Fire Marshal compliance strategies focus on understanding classification definitions that trigger different regulatory requirements. Insurance liability considerations address coverage exclusions that affect both residential and business painting operations. Environmental discharge permits may be required for certain solvent volumes even in residential settings.

Fire Marshal Compliance Strategies

Understanding how paint booth classifications trigger different regulatory requirements and designing systems that minimize bureaucratic obstacles. Strategic design choices can maintain functionality while avoiding complex commercial regulations. The difference between a “spray booth” and “spray area” can determine your entire regulatory burden.

Local fire code definitions distinguish between “spray booth” and “spray area” classifications with different regulatory requirements. Booth dimension design can stay below commercial classification thresholds while maintaining adequate workspace.

Documentation preparation for ventilation calculations and fire suppression systems demonstrates compliance even for exempt installations. Having proper documentation ready shows regulatory officials that you understand the requirements and take safety seriously.

Insurance Liability Considerations

Homeowner’s and business insurance policies often exclude coverage for painting operations, requiring specific documentation and safety measures. Understanding coverage limitations prevents expensive surprises while ensuring adequate protection. Your insurance company needs to know about your painting activities before you have a claim.

Policy exclusions for painting operations require specific documentation and safety measures for coverage maintenance. Business insurance requirements differ significantly from residential coverage for painting activities.

Safety documentation and compliance records support insurance claims and demonstrate risk management practices. Building a paint booth without considering insurance implications can leave you financially exposed.

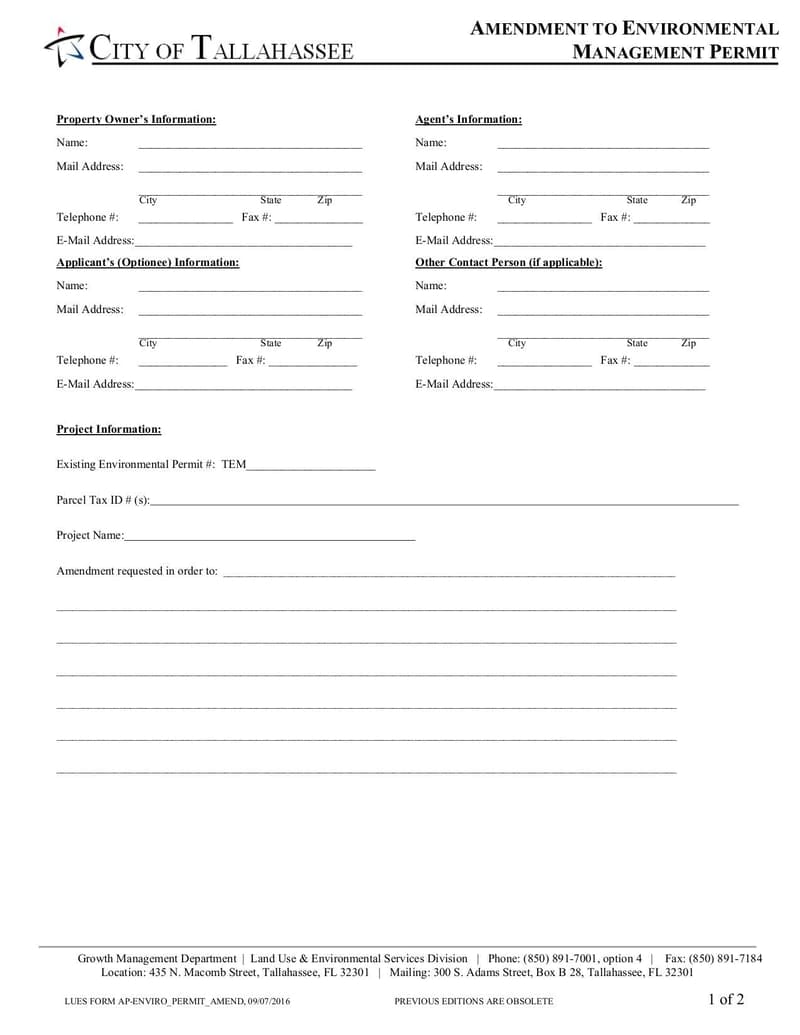

Environmental Discharge Permits

Air quality regulations may require permits for certain solvent volumes, even in residential settings. Understanding discharge thresholds and monitoring requirements prevents regulatory violations while maintaining operational flexibility. Environmental regulations apply to DIY operations more than most people realize.

Annual solvent usage projections determine permit requirements under local air quality management regulations. Emission control documentation and efficiency ratings support permit applications and compliance monitoring.

Discharge monitoring procedures ensure ongoing compliance with environmental regulations. You need systems to track and document your environmental impact, even for hobby-level operations.

How Jiffy Junk Supports Advanced DIY Paint Booth Operations

Your sophisticated paint booth system generates unique waste management challenges that extend beyond typical household disposal needs. Professional-grade operations produce contaminated materials, expired chemicals, and specialized equipment requiring knowledgeable handling.

We understand the complex waste streams from serious DIY paint operations. Our team recognizes contaminated filters, obsolete spray equipment, and materials requiring special handling protocols – ensuring proper disposal while preserving valuable components.

When upgrading booth systems or transitioning between projects, accumulated specialized materials can overwhelm workspace efficiency. Our systematic sorting and removal maintains the precise environmental controls your advanced paint booth demands.

Ready to optimize your paint booth workspace? Contact Jiffy Junk today for professional waste management that keeps your operation running at peak performance.

Final Thoughts

Advanced DIY paint booth construction requires understanding systems that most builders never consider. Atmospheric chemistry management, modular transformation capabilities, and waste stream integration separate professional-quality results from basic spray booth construction.

Performance validation through empirical testing ensures your investment delivers consistent results while regulatory navigation prevents costly compliance issues. These advanced concepts transform DIY paint booth construction from simple ventilation projects into sophisticated micro-environment engineering.

Success depends on systematic implementation of these principles rather than hoping basic construction will deliver professional results. Your paint booth becomes a precision instrument when you understand and control the invisible factors that determine finish quality.

Advanced DIY paint booth systems require understanding atmospheric chemistry, contamination control, and performance validation beyond basic construction. Modular transformation and waste stream integration create professional capabilities while maintaining workshop versatility and cost efficiency. Regulatory compliance and systematic testing protocols ensure safe operation while delivering consistent professional-quality results.

A professional validation test on a 12×16 foot DIY booth revealed that 40% of amateur installations failed to meet the minimum 100 feet per minute face velocity standard. Proper testing identified dead zones where airspeeds dropped below 50 FPM, creating safety hazards and finish defects. Repositioning intake fans and adding corner deflectors increased uniformity by 75% and eliminated contamination issues.