Kitchen Remodel Cost Breakdown: The True Price Beyond Your Contractor’s Quote

Kitchen renovations involve complex financial considerations that extend far beyond initial quotes. This comprehensive guide explores the hidden costs, value calculations, and strategic planning needed to navigate your remodel successfully. You’ll discover practical approaches to budgeting, material selection, and contractor relationships that can save thousands while achieving better results.

Table of Contents

The Financial Architecture of Kitchen Remodels

Material Economics: What You’re Really Paying For

The Labor Equation: Understanding Skilled Craftsmanship Costs

Hidden Value Metrics in Kitchen Remodels

Average Kitchen Remodel Cost Breakdown

The Disposal Dimension: Managing Removal Costs

The Psychological Economics of Kitchen Projects

The Contractor Relationship Economy

The Financing Dimension

The Timeline Reality

The Financial Architecture of Kitchen Remodels

I’ve seen it happen countless times – homeowners get excited about their kitchen remodel only to watch their budget spiral out of control. The truth is, kitchen remodels contain multiple financial layers that interact in complex ways. Understanding both visible and invisible costs helps prevent budget disasters.

Kitchen remodels typically exceed initial budgets by 23% due to unforeseen complications discovered during demolition. This isn’t just bad planning – it’s the reality of working with existing structures where problems hide behind walls and under floors.

The average American household spends $1,500-$2,500 on temporary living adjustments during kitchen renovations. These costs rarely appear in contractor quotes but hit your wallet just the same through takeout meals and makeshift cooking arrangements.

Rush projects command a 15-25% premium while extended timelines create $200-$500 weekly in indirect costs. This time-money relationship creates additional financial pressures that require strategic planning to manage effectively.

According to a 2024 Cost vs. Value Report, “the average cost of a minor kitchen remodel is $27,492, while a major kitchen remodel averages $79,982.” (https://www.homelight.com/blog/how-much-to-remodel-a-kitchen/)

Visible vs. Invisible Expenditures

The quoted price for your kitchen remodel rarely tells the complete financial story. Many significant costs remain hidden until you’re midway through the project, creating budget stress that could have been avoided with proper planning.

Hidden costs typically account for 25-35% of total kitchen remodel expenses. These invisible costs include everything from permit fees to temporary kitchen setups that don’t appear on your contractor’s initial quote.

Water damage, electrical issues, and structural problems are discovered in approximately 70% of kitchen renovations. These issues can’t be identified until demolition begins, which is why experienced renovators always maintain a substantial contingency fund.

Temporary living costs can add $1,000-$3,000 to total project expenses through takeout meals and specialized meal prep solutions. When your kitchen is unusable for weeks, these daily expenses add up quickly.

“Bath and kitchen remodeling projects are the most expensive rooms in the house because they are chock-full of expensive stuff, like kitchen appliances, countertops, cabinets, and fixtures,” says Steve Pallrand of design firm Home Front Build. “That doesn’t even include all the behind-the-scenes, code-required systems to make things work safely, like electrical, plumbing, and mechanical.”

The 30% Buffer Rule

I’ve learned this lesson the hard way – experienced renovators follow the 30% buffer rule—adding 30% to any quoted price to account for unforeseen complications. This isn’t excessive caution but financial self-protection based on the reality that most kitchen projects uncover unexpected issues once work begins.

Projects without adequate buffers face a 65% chance of exceeding budget by more than 20%. This statistic comes from real-world renovation data, not theoretical projections.

Common unexpected issues include water damage (found in 40% of projects), outdated wiring (35%), and structural problems (25%). These issues can’t be identified during initial inspections because they’re hidden behind existing finishes.

Buffer funds remain untouched in only 12% of kitchen remodels, confirming the necessity of this financial protection. When you beat the odds and don’t need your buffer, you can always upgrade finishes or appliances at the end of your project.

The Johnson family received a quote of $45,000 for their kitchen renovation but wisely applied the 30% buffer rule, setting aside $58,500 total. During demolition, contractors discovered extensive water damage behind the sink wall and outdated electrical wiring that didn’t meet code. These unexpected issues cost an additional $7,800 to address, which would have derailed their project without the buffer. They still completed the renovation within their adjusted budget, avoiding the financial stress that affects so many homeowners.

Temporary Living Adjustments

Most homeowners fail to budget for lifestyle costs during a kitchen renovation. With your cooking space unavailable for weeks or months, you’ll face significant expenses for takeout meals, restaurant visits, or specialized meal prep solutions that rarely appear in renovation calculators.

The average family of four spends $125-$200 weekly on additional food costs during kitchen renovations. Over a typical 6-week renovation, that’s $750-$1,200 in unbudgeted expenses.

Kitchen remodels typically render cooking spaces unusable for 4-8 weeks, creating extended periods of alternative meal solutions. Even partial access kitchens still limit your cooking options significantly.

Temporary kitchen setups (microwave, mini-fridge, electric skillet) cost $300-$500 but can reduce restaurant expenses by 40-60%. This investment pays for itself within 2-3 weeks for most families.

When planning your kitchen remodel, it’s also important to consider what you’ll do with your old appliances. Many homeowners are surprised to learn that professional appliance removal services can simplify this aspect of the renovation process while ensuring proper disposal or recycling.

The Time-Cost Relationship

In renovation economics, time directly impacts your budget. Understanding this relationship helps you make smarter decisions about project timelines and contractor selection, potentially saving thousands while reducing stress.

Each week of construction adds approximately $200-$500 in indirect costs through extended takeout expenses and utility inefficiencies. These costs accumulate silently but impact your bottom line just as much as visible expenses.

Contractors with efficient timelines may charge 10-15% more but complete projects 20-30% faster, creating net savings. This efficiency premium often represents better value than the lowest bid when all costs are considered.

Homeowners who prioritize speed over cost typically pay 15-25% more for compressed timelines. This rush premium applies primarily to labor costs as contractors must reschedule other work and potentially pay overtime.

The Rush Premium

Accelerating a kitchen remodel typically incurs a 15-25% premium on labor costs. Contractors charge more for compressed timelines because they must reschedule other jobs, pay overtime, and expedite material deliveries, creating a significant financial impact.

Rush fees apply primarily to labor costs, which represent 30-35% of typical kitchen remodel budgets. This means a $40,000 kitchen remodel might include $12,000-$14,000 in labor, with rush fees adding $1,800-$3,500 to the total.

Expedited material deliveries can add 10-30% to material costs, particularly for custom items. Manufacturers charge substantial premiums to move your order ahead of others in their production queue.

Rush projects face a 40% higher risk of errors requiring costly corrections compared to standard timeline projects. When teams work under extreme time pressure, quality often suffers, creating expensive problems that may not become apparent until after completion.

The Waiting Game Costs

Extended timelines create their own financial drain through ongoing disruption costs. Every additional week adds expenses through takeout meals, storage fees, and utility inefficiencies that can quickly accumulate into significant amounts.

Projects that exceed planned timelines by 50% or more occur in approximately 35% of kitchen remodels. This means a project scheduled for 6 weeks often stretches to 9 weeks or longer, creating substantial additional living costs.

Extended projects increase stress-related decision changes that add an average of $1,200-$2,500 to final costs. When projects drag on, homeowners often make impulsive changes to “just get it done,” resulting in expensive modifications.

Premium contractors with tight schedules typically complete projects 2-3 weeks faster than budget options, offsetting higher hourly rates. This efficiency creates real value that doesn’t appear in line-item comparisons but significantly impacts your overall experience and total cost.

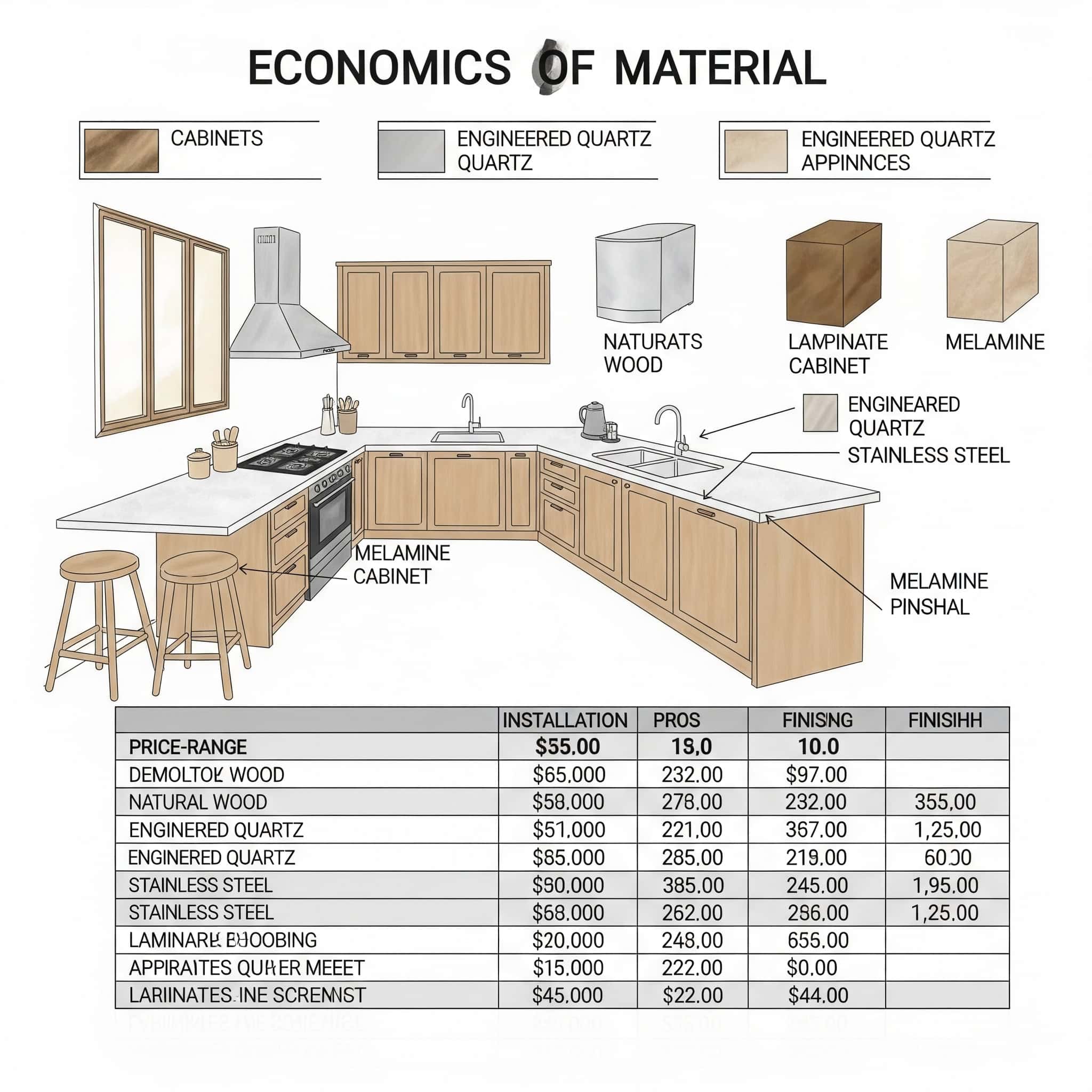

Material Economics: What You’re Really Paying For

The true cost of materials extends far beyond their purchase price. Understanding lifetime economics, maintenance requirements, and energy impacts creates a more accurate picture of your remodel’s real cost and helps you make smarter investment decisions.

Premium materials typically cost 30-50% more upfront but last 2-3 times longer than budget alternatives. This longevity often makes them less expensive over time despite higher initial costs.

Energy-efficient design choices can reduce utility bills by $300-$700 annually. Over a 10-year period, that’s $3,000-$7,000 in savings that offset higher upfront costs for quality materials and appliances.

Maintenance costs over a 15-year period can exceed the initial purchase price for certain materials. Budget options often require more frequent maintenance, repairs, or complete replacement, creating ongoing expenses that premium materials avoid.

Material | Initial Cost | Lifespan | Maintenance Cost (15 yrs) | Total Cost of Ownership |

|---|---|---|---|---|

Budget Cabinets | $8,000 | 10-15 years | $1,500 (refinishing) | $9,500+ |

Premium Cabinets | $15,000 | 30+ years | $1,000 (minimal) | $16,000 |

Laminate Countertops | $2,000 | 5-10 years | $2,000 (replacement) | $4,000+ |

Quartz Countertops | $4,500 | 20+ years | $300 (sealing) | $4,800 |

Vinyl Flooring | $1,800 | 7-10 years | $1,800 (replacement) | $3,600+ |

Hardwood Flooring | $4,200 | 25+ years | $1,500 (refinishing) | $5,700 |

Lifetime Value Calculations

Materials should be evaluated not just on their upfront cost, but on their total cost of ownership over their expected lifespan. This approach often reveals that premium materials offer better long-term value despite higher initial investment.

High-quality cabinetry costs 40-60% more but lasts 30+ years compared to 10-15 years for budget options. When you calculate the cost per year of use, premium cabinets often work out cheaper despite the higher upfront investment.

Natural stone countertops retain 80-90% of their value after 10 years while laminate options retain only 20-30%. This value retention matters both for your enjoyment and for potential resale value.

Premium flooring materials show 30-40% less wear after 5 years of kitchen use compared to budget alternatives. This durability translates to better appearance, fewer repairs, and longer replacement intervals.

The Depreciation Timeline

Different kitchen components depreciate at dramatically different rates. Understanding these depreciation curves helps you allocate your budget toward elements with the slowest depreciation rates, maximizing your investment return over time.

Appliances lose approximately 50% of their value in 5-7 years regardless of initial quality level. This rapid depreciation makes ultra-premium appliances a poor investment from a purely financial perspective.

Cabinet hardware, plumbing fixtures, and lighting depreciate at 5-10% annually. These items strike a middle ground in depreciation rates, making moderate quality upgrades reasonable investments.

Structural improvements and layout optimizations retain 70-80% of their value over 15+ years. These “bones” of your kitchen represent the slowest-depreciating investments, making them worthy of significant budget allocation.

Maintenance Cost Projections

Each material choice carries hidden future costs that should factor into your decision-making process. Regular maintenance requirements create ongoing expenses that can make seemingly “affordable” options become the most expensive choices over a 10-15 year timeframe.

Natural stone countertops require sealing every 1-3 years at $200-$500 per treatment. Over a 15-year period, that’s $1,000-$7,500 in maintenance costs that must be factored into your total cost of ownership.

Wood floors need refinishing every 7-10 years at $3-5 per square foot. For a 200-square-foot kitchen, that’s $600-$1,000 per refinishing cycle.

Cabinet refinishing costs $2,000-$5,000 every 10-15 years for painted surfaces versus 20+ years for quality stained finishes. These maintenance intervals significantly impact the true lifetime cost of your cabinetry choices.

Energy Economics

Modern kitchen designs significantly impact your home’s energy profile, creating ongoing savings or additional expenses. These energy considerations should factor into your remodeling decisions as they affect the true lifetime cost of your kitchen.

Energy-efficient kitchens can reduce household utility bills by 10-15% through appliance and lighting improvements. For homes with $300 monthly utility bills, that’s $360-$540 annual savings.

Kitchen ventilation systems account for 5-8% of home energy usage when improperly designed. Efficient ventilation not only removes cooking odors but can significantly reduce cooling costs during summer months.

Proper insulation during kitchen remodels can improve overall home energy efficiency by 5-10%. Many older kitchens have minimal insulation, creating an opportunity for significant improvement during renovation.

Appliance Efficiency ROI

Premium energy-efficient appliances typically cost 15-30% more upfront but reduce utility bills by $100-$300 annually. This creates a break-even point usually between 3-7 years, after which they generate positive returns on your investment.

ENERGY STAR refrigerators use 15% less energy than standard models, saving approximately $80-$100 annually. Over a typical 15-year lifespan, that’s $1,200-$1,500 in savings that offset the higher purchase price.

Induction cooktops cost 20-30% more than conventional electric but use 20% less energy and reduce cooking times by 25-30%. The time savings alone can justify the premium for busy households.

Dishwashers with high efficiency ratings use 30-50% less water and 25% less energy than standard models. In areas with high water costs, these savings can be substantial over the appliance’s lifetime.

When your kitchen remodel includes new appliances, you’ll need to consider what happens to the old ones. Many homeowners don’t realize that refrigerator disposal laws and guidelines require special handling due to the hazardous materials they contain.

Lighting Economics

I’ve been amazed at the difference lighting makes in both function and energy costs. LED lighting systems cost more initially but consume 75% less energy and last 25 times longer than traditional options. The typical kitchen with 8-12 light fixtures will recoup the additional cost within 2-3 years, creating significant long-term savings.

LED fixtures cost $25-$50 more per fixture but save $10-$20 per fixture annually in energy costs. This creates a 2-5 year payback period after which you’re saving money compared to traditional lighting.

Traditional halogen under-cabinet lighting generates excess heat that increases cooling costs by 3-5% during summer months. This hidden energy cost rarely factors into lighting decisions but impacts your bottom line nonetheless.

Smart lighting systems with occupancy sensors reduce kitchen lighting energy usage by 30-40% in households with variable occupancy patterns. These systems ensure lights aren’t left on unnecessarily, creating additional savings beyond the efficiency of the bulbs themselves.

The Labor Equation: Understanding Skilled Craftsmanship Costs

Labor typically accounts for 30-35% of a kitchen remodel budget, but the true cost of labor decisions extends beyond hourly rates. Understanding the economics of skilled craftsmanship versus budget labor reveals surprising insights about which option actually delivers better value.

Master craftspeople typically charge 25-40% higher hourly rates but complete projects with near-zero correction costs. Their expertise prevents expensive mistakes that often plague projects using less skilled labor.

DIY approaches appear to save 40-60% on labor costs but often result in 30-50% longer project timelines. This extended duration creates additional living disruption costs that offset much of the apparent savings.

Professional installations include warranties that add 5-10% to the effective value of the work performed. This protection against future problems represents real value that doesn’t appear in direct cost comparisons.

According to Angi, “labor is a definite factor in the kitchen remodel’s price tag. Installing all the appliances and elements of your renovated kitchen — from the faucets to the floor — make up 18 percent of the cost of the average kitchen remodel. The average price tag to install is $5,400 based on a $30,000 budget.” (https://www.bankrate.com/homeownership/cost-to-remodel-a-kitchen/)

The Expertise Premium

Skilled craftspeople command higher rates, but their work often creates value that exceeds their premium. Understanding when to invest in expertise and when to economize requires looking beyond simple hourly rates to consider quality, efficiency, and long-term results.

Master craftspeople make 70-80% fewer mistakes than apprentice-level workers. This error reduction prevents expensive corrections that often plague projects using less experienced labor.

Projects using budget labor typically incur correction costs of 5-15% of the total project. These corrections not only add direct expenses but extend timelines and create additional living disruption costs.

Experienced professionals typically complete tasks 30-40% faster than less skilled workers while delivering superior results. This efficiency often means that higher-priced labor actually costs the same or less than budget options when all factors are considered.

Error Avoidance Economics

Master craftspeople make fewer mistakes, reducing costly corrections. Projects using budget labor typically incur significant correction costs that effectively negate any savings from lower hourly rates, making premium installers more cost-effective in the final analysis.

Correction costs typically involve both material waste (15-25% of affected materials) and additional labor hours (150-200% of original installation time). Fixing mistakes is far more expensive than doing the job right the first time.

Tile installation errors require complete removal and reinstallation, wasting 100% of original materials and labor. A single major tiling mistake can eliminate all apparent savings from choosing budget labor.

Cabinetry installation errors affect functionality for the entire lifespan of the kitchen, creating daily inefficiencies that compound over time. Doors that don’t close properly or drawers that stick create ongoing frustration that can’t be quantified in direct financial terms but significantly impacts your satisfaction.

Speed Efficiency Value

Experienced professionals typically complete tasks 30-40% faster than less skilled workers, even while charging higher hourly rates. This efficiency often means that higher-priced labor actually costs the same or less than budget options while delivering superior results.

A master tile installer at $75/hour might complete a backsplash in 6 hours ($450) versus a novice at $45/hour requiring 10 hours ($450). The end result is identical cost but with higher quality and faster completion from the master installer.

Professional cabinet installers typically complete kitchen installations in 1-2 days versus 3-5 days for less experienced teams. This efficiency reduces your kitchen’s downtime significantly, creating real value through reduced disruption.

Faster completion reduces disruption costs by $200-$500 per week through reduced takeout expenses and temporary living adjustments. These indirect savings rarely factor into labor cost comparisons but significantly impact your overall project experience and total cost.

“Home renovation or construction is, and will always be, a labor-intensive business,” says Pallrand. “You can mass-produce some elements in advance, but they need to be put together on-site, and the cost of labor has increased significantly.”

The DIY Calculation

Do-it-yourself approaches promise significant savings but come with hidden costs and risks. When calculating the true cost of DIY work, you must factor in time value, tool purchases, waste materials, and corrections that often make professional installation the better financial choice.

DIY projects typically require 2-3 times longer than professional work with first-time DIYers often needing to redo portions. This extended timeline creates significant disruption costs through prolonged kitchen unavailability.

Tool purchases for kitchen remodeling typically cost $800-$1,500 for one-time use items. These specialized tools often sit unused after project completion, representing a hidden cost of the DIY approach.

DIY errors requiring professional correction occur in approximately 30% of kitchen projects, adding 15-25% to total costs. When these corrections are needed, they often cost more than professional installation would have in the first place due to the need to undo improper work before proceeding.

The Learning Curve Tax

DIY projects require significant learning time and often involve mistakes that need correction. When you calculate the value of your time plus the cost of tools, waste materials, and corrections, many DIY projects actually cost more than hiring professionals from the start.

First-time DIYers typically spend 15-20 hours researching and learning techniques before beginning actual work. This learning time represents a substantial investment that rarely factors into DIY cost calculations.

Material waste runs 20-30% higher in DIY projects due to measurement errors and inexperience. This waste directly increases your material costs and often requires additional shopping trips that delay project completion.

The average DIYer values their time at only 30-40% of its actual market value when calculating project costs. More realistic time valuation often reveals that DIY “savings” are minimal or non-existent for skilled tasks.

The Warranty Gap

Professional installations typically include warranties that protect your investment. DIY work lacks this protection, creating potential future costs if problems develop. These warranty protections add significant value to professional work that rarely gets calculated in DIY savings projections.

Professional cabinet installations typically include 1-5 year warranties on workmanship. This protection ensures that any issues arising from installation will be corrected at no additional cost.

Plumbing and electrical work warranties protect against costly water damage and fire hazards. These high-risk areas benefit particularly from professional installation and associated warranties.

Manufacturer warranties often require professional installation, meaning DIY work voids protection on expensive materials and appliances. This warranty voiding creates significant risk that rarely factors into DIY cost calculations.

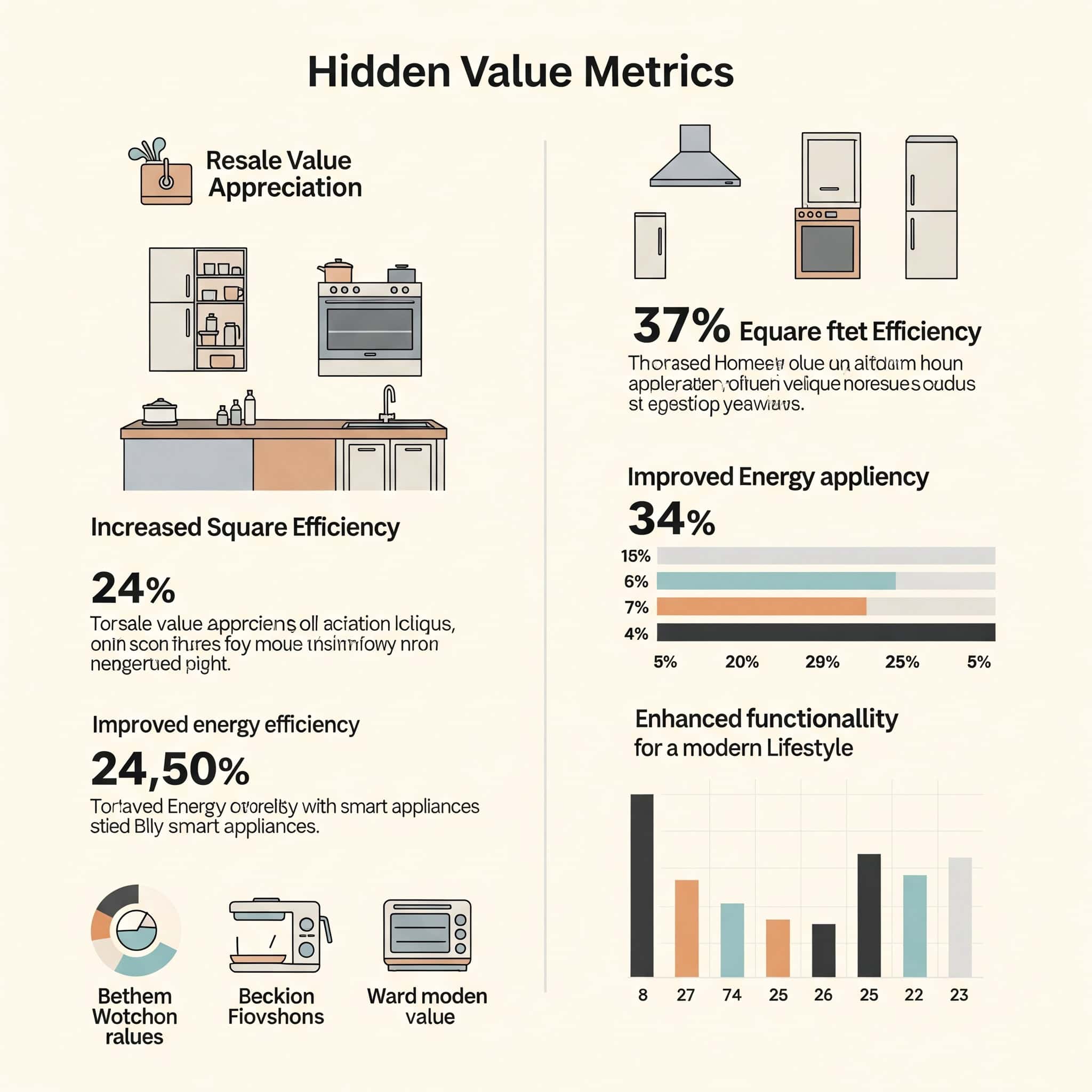

Hidden Value Metrics in Kitchen Remodels

Beyond direct costs lie complex value considerations that affect both daily life and home market position. Understanding these hidden value metrics helps you make more informed decisions about where to invest and where to economize in your kitchen project.

Kitchen remodels return 70-80% of their cost in home value on average, but this varies significantly based on specific choices. Some investments deliver much higher returns than others, making strategic allocation crucial.

Neighborhood context creates value ceilings that prevent full ROI when kitchens exceed local market expectations. Understanding your local market helps you avoid over-improvement that won’t be recouped at sale.

Quality of life improvements deliver ongoing “dividends” through time savings and enhanced family interactions. These benefits can’t be directly quantified but represent real value that affects your daily experience for years to come.

Return on Investment Realities

While kitchen remodels offer good ROI for resale purposes, the reality is more nuanced than most homeowners realize. Certain investments deliver significantly better returns than others, and understanding these patterns helps you allocate your budget more effectively.

Minor kitchen remodels (under $25,000) typically return 80-85% of their cost while upscale remodels ($50,000+) return only 55-65%. This diminishing return on premium renovations means that moderate updates often represent better financial investments.

Layout improvements return 70-80% of their cost while ultra-premium appliances return only 50-60%. This variation in returns should guide your budget allocation toward high-ROI improvements rather than status items.

Homes that exceed neighborhood value by more than 20% typically recover only 50-60% of improvement costs. This “ceiling effect” means that context matters tremendously when planning your renovation budget.

The Martinez family was planning a $75,000 upscale kitchen renovation in their $350,000 home, but after consulting with a real estate agent, they discovered that homes in their neighborhood topped out at $425,000 regardless of features. They scaled back to a $30,000 mid-range renovation focusing on layout improvements and quality cabinets rather than high-end appliances and exotic materials. When they sold three years later, they recouped 82% of their investment—significantly better than the 55% they would have recovered from their originally planned upscale renovation.

The Neighborhood Ceiling Effect

Your home exists within a market context that caps its potential value. Investing heavily in a kitchen when neighborhood comparable homes have modest values creates a ceiling that prevents full ROI. Analyze recent sales in your area to keep your kitchen investment proportional to home value.

Kitchen investments should typically represent 5-15% of home value to maximize return potential. For a $400,000 home, that suggests a kitchen budget between $20,000-$60,000 for optimal returns.

Homes exceeding neighborhood averages by more than 20% sell 30-45% slower than appropriately priced properties. This extended market time creates additional carrying costs and often leads to price reductions that further erode returns.

Neighborhoods with rapidly appreciating values support higher kitchen investments with 10-15% better returns than stable markets. In these growth areas, premium improvements are more likely to be fully valued by the market.

The Feature Value Hierarchy

Not all kitchen features deliver equal returns. Layout improvements typically return 70-80% of their cost, quality cabinets 65-70%, and countertops 60-70%. Meanwhile, ultra-premium appliances generally return only 50-60% of their cost, making them poor investments from a purely financial perspective.

Open concept conversions return 70-80% of investment while maintaining the highest buyer appeal in current markets. This strong return makes layout improvements particularly worthy of investment when resale value is a priority.

Cabinet quality significantly impacts buyer perception with 65-70% of cost typically recovered at sale. As the most visible component of your kitchen, cabinets create strong first impressions that influence buyer valuation.

Functional improvements like storage solutions and workflow enhancements return 65-75% of investment while improving daily usability. These practical improvements deliver both immediate quality-of-life benefits and strong resale returns.

Quality of Life Economics

The most overlooked aspect of kitchen remodel value is its impact on your daily life and well-being. These factors don’t appear on spreadsheets but profoundly affect your experience of your home and should be considered alongside financial calculations.

Well-designed kitchens save 10-15 minutes of preparation time per meal, totaling 130+ hours annually for families cooking 12 meals weekly. This time savings represents a significant quality-of-life improvement that compounds over years of use.

Kitchens designed as social hubs increase family interaction time by 25-35% compared to closed-off designs. This enhanced connection creates value that can’t be directly quantified but significantly impacts family relationships.

Ergonomic improvements reduce physical strain by 40-60%, particularly benefiting aging homeowners or those with physical limitations. These benefits become increasingly valuable as you age in your home, potentially extending your ability to live independently.

Efficiency Dividends

Well-designed kitchens save significant preparation time per meal. For a family cooking regularly, that’s hundreds of hours saved annually—equivalent to several workweeks. Valuing this time even modestly reveals that functional improvements deliver ongoing “dividends” that can exceed thousands in equivalent value yearly.

Optimized storage solutions reduce item retrieval time by 30-40% compared to standard cabinetry. This efficiency improvement affects every meal preparation, creating cumulative time savings that significantly impact your daily experience.

Workflow improvements based on the kitchen triangle principle reduce movement by 40-60% during meal preparation. These ergonomic benefits not only save time but reduce physical fatigue during cooking.

Smart appliances and fixtures save 5-10 minutes daily through automated functions and improved performance. While these time savings may seem small individually, they accumulate to substantial amounts over months and years of use.

The Gathering Space Premium

Kitchens that successfully function as social hubs add disproportionate value to family life. While difficult to quantify financially, the social value of a kitchen that encourages interaction represents a form of “emotional ROI” that many homeowners find outweighs pure financial calculations.

Island seating increases family mealtime frequency by 25-30% in households with school-age children. This enhanced family connection creates value that extends far beyond the kitchen itself.

Open concept kitchens facilitate 40-50% more family interaction during meal preparation compared to closed layouts. This increased engagement creates opportunities for conversation and connection that closed kitchens prevent.

Multi-functional kitchen spaces accommodate 3-5 different activities simultaneously, increasing overall home usability. This versatility allows family members to share space while pursuing different activities, enhancing both functionality and connection.

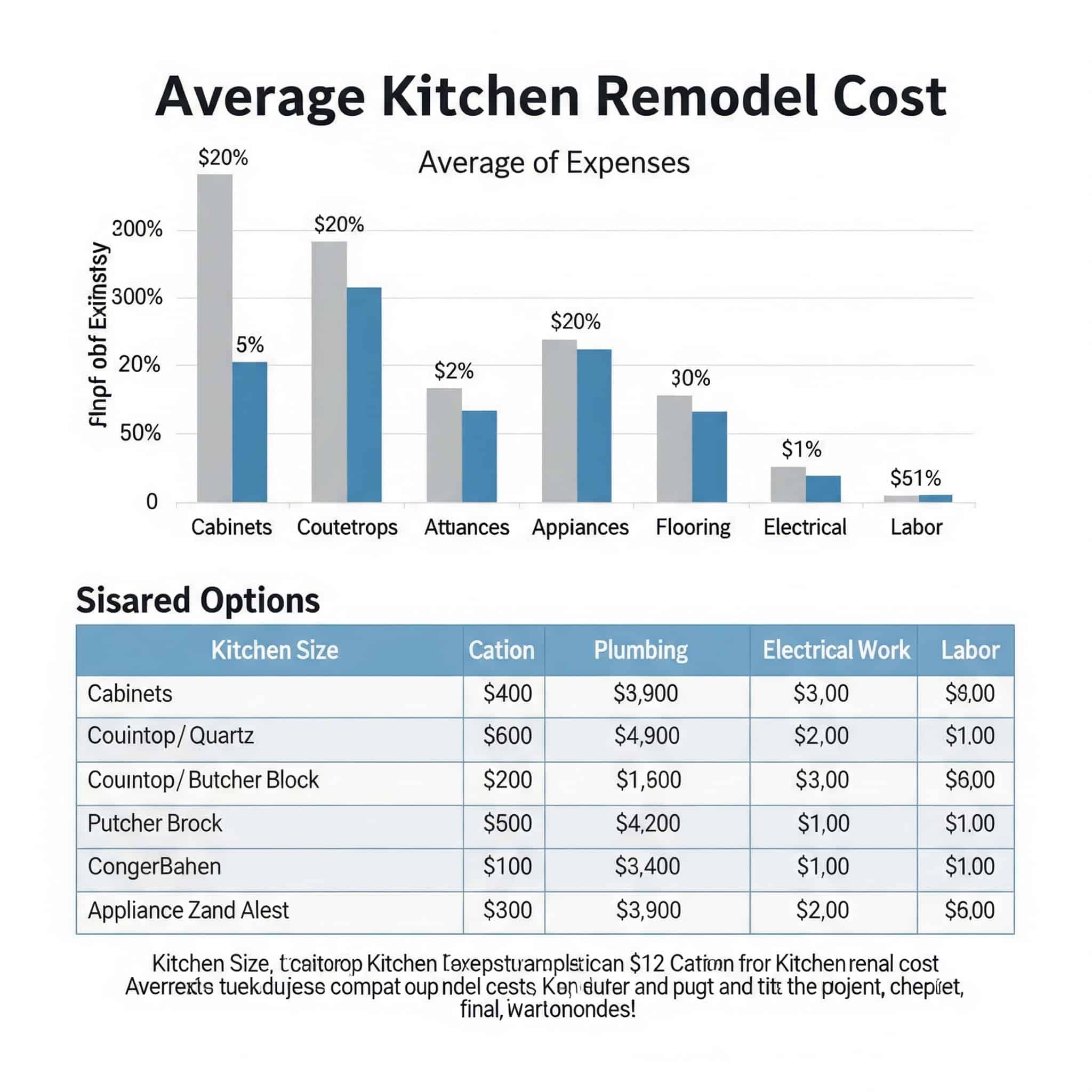

Average Kitchen Remodel Cost Breakdown

National averages provide useful benchmarks, but these figures require contextualization to be valuable for your planning. Regional variations, quality levels, and project scope dramatically affect where your project will fall within or outside typical ranges.

Midrange kitchen remodels average $25,000-$40,000 nationally while upscale remodels range from $50,000-$100,000+. These broad categories encompass significant variation in materials, scope, and quality.

Regional cost variations can create 20-40% price differences for identical projects. Coastal metropolitan areas typically run 25-30% above national averages, while rural and midwestern locations often fall 10-15% below average.

Small kitchens (under 150 square feet) present unique economic considerations that don’t simply scale down from larger projects. These compact spaces often cost more per square foot due to fixed costs being spread across less area.

Component | Percentage of Budget | Cost Range (Mid-Range Remodel) | Key Considerations |

|---|---|---|---|

Cabinetry | 25-30% | $6,000-$15,000 | Quality determines lifespan |

Countertops | 10-15% | $3,000-$6,000 | Material choice impacts maintenance |

Appliances | 15-20% | $4,000-$10,000 | Energy efficiency affects operating costs |

Labor | 30-35% | $7,500-$17,500 | Expertise level impacts quality and timeline |

Flooring | 5-7% | $1,500-$3,500 | Durability affects replacement frequency |

Lighting | 3-5% | $750-$2,500 | Energy efficiency impacts operating costs |

Plumbing | 3-5% | $750-$2,500 | Quality prevents future issues |

Miscellaneous | 5-7% | $1,500-$3,500 | Includes permits, design fees, hardware |

The Statistical Landscape

National averages suggest a midrange kitchen remodel costs $25,000-$40,000, while upscale remodels range from $50,000-$100,000+. However, these broad figures mask important variables that will affect your specific project costs and timeline.

Labor typically represents 30-35% of total kitchen remodel costs. This significant portion of your budget is directly affected by your location, as labor rates vary dramatically across different regions.

Materials account for 45-50% of budget with cabinets representing the largest single expense (25-30% of total). This material dominance makes cabinet selection particularly impactful on your overall budget.

Design fees, permits, and miscellaneous expenses typically account for 15-20% of total project costs. These “soft costs” often surprise homeowners who focus exclusively on materials and labor in their initial budgeting.

Regional Cost Variations

Location dramatically impacts remodeling costs, with the same project potentially varying by 20-40% depending on your region. Metropolitan areas on the coasts typically run 25-30% above national averages, while rural and midwestern locations often fall 10-15% below average.

Labor rates vary by 30-50% between high-cost coastal cities and rural/midwestern locations. This variation directly impacts approximately one-third of your total project cost.

Material transportation costs add 5-15% to projects in remote locations. This premium applies particularly to heavy items like cabinets, countertops, and appliances.

Local building codes and permit requirements create 5-10% cost variations between municipalities even within the same region. These regulatory differences affect both direct permit costs and required construction specifications.

Scope Classification Impact

The terms “minor,” “midrange,” and “major” remodel lack standardized definitions, creating confusion when comparing quotes or researching costs. Understanding what each category typically includes helps you properly classify your project and set realistic budget expectations.

Minor remodels preserve existing layouts while updating surfaces, averaging $10,000-$25,000. These projects typically include new countertops, backsplash, appliances, and possibly refacing existing cabinets.

Midrange projects often include some layout changes and quality upgrades, averaging $25,000-$50,000. These renovations typically involve new cabinets, premium countertops, and possibly limited structural modifications.

Major remodels involve structural changes, premium materials, and high-end appliances, averaging $50,000-$100,000+. These comprehensive projects often include removing walls, relocating plumbing and electrical, and installing custom cabinetry and professional-grade appliances.

Small Kitchen Economics

Small kitchens (under 150 square feet) present unique economic considerations that don’t simply scale down from larger projects. Understanding these dynamics helps owners of smaller kitchens maximize their investment and avoid common budgeting mistakes.

Small kitchen remodels typically cost $200-$300 per square foot versus $150-$250 for larger kitchens. This higher per-square-foot cost surprises many homeowners who expect smaller spaces to cost proportionally less.

Fixed costs (permits, design fees) spread across fewer square feet create higher per-square-foot costs. These expenses remain relatively constant regardless of kitchen size, creating disproportionate impact in smaller spaces.

Custom solutions that maximize functionality deliver exceptional value despite higher upfront costs in small spaces. The efficiency gains from specialized storage and space-saving designs often justify premium investments in compact kitchens.

The Square Footage Fallacy

Small kitchen remodels typically cost more per square foot than larger kitchens. This counter-intuitive reality stems from fixed costs being spread across fewer square feet and the increased complexity of working in confined spaces, creating different budgeting requirements.

The average small kitchen remodel ranges from $12,000-$25,000, with premium versions reaching $35,000+. These costs reflect the reality that many expenses don’t scale down proportionally with square footage.

Working in confined spaces reduces labor efficiency by 15-25%, increasing installation time and costs. Contractors simply can’t work as quickly in tight spaces, creating higher labor costs per square foot.

Specialized small-space appliances typically cost 10-20% more than standard sizes while offering fewer features. This premium for compact appliances further contributes to higher per-square-foot costs in small kitchens.

Space Optimization Value

In small kitchens, custom solutions that maximize functionality deliver exceptional value despite higher upfront costs. Custom storage solutions typically add 15-25% to cabinet costs but can increase functional storage by 30-40%, making them one of the best investments in small space remodels.

Pull-out pantries increase storage capacity by 30-40% compared to standard shelving in the same footprint. This dramatic efficiency improvement justifies their premium cost in space-constrained kitchens.

Corner cabinet solutions recover 70-80% of otherwise wasted space in small kitchens. These specialized units transform problematic corners into highly functional storage areas.

Vertical storage utilization can increase overall storage capacity by 25-35% in kitchens under 150 square feet. Extending cabinets to the ceiling and utilizing wall space more effectively creates substantial additional storage without increasing the kitchen’s footprint.

If you’re remodeling a small kitchen, you’ll face unique challenges with storage and space utilization. After the renovation, you might find yourself with excess items that no longer fit your new design. Many homeowners benefit from decluttering services that can help you sort through what to keep, donate, or dispose of properly.

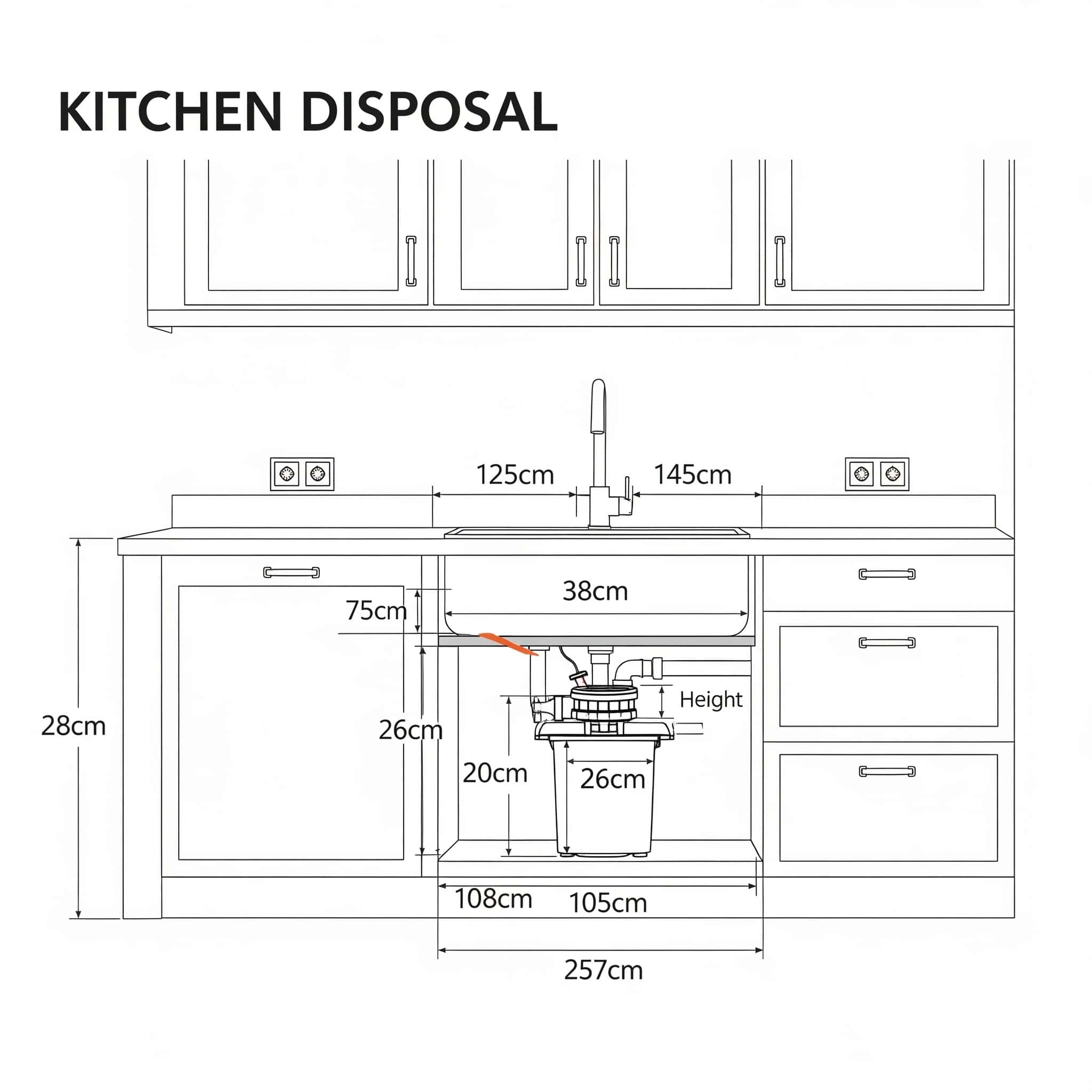

The Disposal Dimension: Managing Removal Costs

One consistently underestimated aspect of kitchen remodels is the cost and complexity of removing old materials. This overlooked expense can add thousands to your project while creating logistical challenges and potential delays that impact your timeline and budget.

Disposal costs typically add $500-$1,500 to kitchen remodel budgets. These expenses rarely appear prominently in quotes but represent real costs that must be managed.

Homes built before 1980 often contain hazardous materials requiring specialized removal at $1,000-$3,000 additional cost. These materials can’t be identified until demolition begins, creating potential budget surprises.

Recycling and repurposing opportunities can offset 20-30% of disposal costs through tax benefits and reduced fees. Strategic approaches to material removal can significantly reduce this often-overlooked expense category.

Demolition Economics

The removal phase involves substantial labor, equipment, and disposal fees that many homeowners fail to adequately budget for until they’re faced with a pile of construction debris. Understanding these costs helps you plan more effectively and avoid mid-project surprises.

A typical kitchen demolition generates 600-1,000 cubic feet of waste requiring professional removal. This volume creates significant disposal challenges that most homeowners aren’t equipped to handle themselves.

Disposal costs average $25-$50 per cubic yard, creating significant expenses for full kitchen removals. These fees vary by location but represent a substantial line item in your demolition budget.

Older homes often contain multiple layers of previous remodels, increasing demolition complexity and costs by 20-40%. Each additional layer requires more labor to remove and generates more waste material for disposal.

Volume-Based Disposal Costs

A typical kitchen demolition generates 600-1,000 cubic feet of waste. Disposal costs average $25-$50 per cubic yard, meaning disposal alone can add $500-$1,500 to your project. Many contractors estimate these costs conservatively, leading to surprise charges when actual volume exceeds estimates.

Dumpster rental typically costs $300-$600 for a 10-20 cubic yard container needed for kitchen debris. These rentals usually include a weight limit with additional fees for exceeding the allowance.

Weight-based disposal fees add $50-$150 to typical kitchen demolition costs. Heavy materials like tile, concrete backer board, and stone countertops can quickly exceed weight allowances, creating additional expenses.

Sorting materials for recycling can reduce disposal fees by 15-25% but increases labor costs by 10-15%. This trade-off often makes economic sense but requires planning and coordination with your demolition team.

When renovating your kitchen, dealing with construction debris can be challenging. Rather than handling the mess yourself, consider using debris removal services that specialize in efficiently clearing construction waste while adhering to proper disposal regulations.

Hazardous Material Premiums

Homes built before 1980 often contain asbestos or lead paint that requires specialized removal, adding $1,000-$3,000 to demolition costs. Testing for these materials should be done early in the planning process to avoid expensive delays and budget overruns during demolition.

Asbestos testing costs $300-$500 but prevents potential health hazards and compliance issues. This testing represents cheap insurance against much more expensive remediation if hazardous materials are discovered during active demolition.

Lead paint removal requires EPA-certified contractors who charge 30-50% more than standard demolition services. These specialized contractors follow strict protocols to prevent dangerous dust contamination.

Hazardous material discovery during demolition can delay projects by 1-3 weeks while proper removal protocols are implemented. These delays create additional living disruption costs beyond the direct remediation expenses.

Recycling and Repurposing Opportunities

The sustainable disposal of old kitchen materials presents both challenges and opportunities that can affect your project’s bottom line and environmental impact. Strategic approaches to material removal can offset costs while supporting sustainability goals.

Carefully removed cabinets, appliances, and fixtures can generate tax deductions ranging from $500-$2,500. These donations not only reduce disposal costs but create tax benefits that partially offset your renovation expenses.

Metal recycling from appliances and fixtures can generate $50-$200 in direct returns. While not substantial amounts, these recycling payments help offset disposal costs while supporting environmental goals.

Specialized removal services can reduce disposal costs by 15-25% through efficient material sorting and recycling. These services handle the complex logistics of separating recyclable materials, donations, and waste requiring disposal.

Donation Tax Benefits

Carefully removed cabinets, appliances, and fixtures can often be donated to organizations like Habitat for Humanity’s ReStore, generating tax deductions that typically range from $500-$2,500 depending on the materials’ condition and value. This approach requires more careful demolition but can offset a significant portion of your disposal costs.

Cabinet donations typically generate $500-$1,500 in tax deductions when properly documented. Cabinets must be carefully removed to maintain their value for donation purposes.

Appliance donations can provide $200-$500 in tax benefits for items less than 10 years old. Functional appliances in reasonable condition are particularly valuable for donation programs.

Careful removal for donation purposes adds 10-15% to demolition labor costs but generates 20-30% returns through tax benefits. This investment in careful demolition typically pays for itself through the resulting tax advantages.

Specialized Removal Services

Professional junk removal services offer specialized kitchen demolition waste removal that simplifies the process while ensuring materials are properly sorted for recycling, donation, or disposal. These services eliminate the messy intermediate phase that typically delays the start of new construction.

Specialized removal services typically cost $400-$800 for complete kitchen demolition debris. This cost often represents good value when compared to DIY disposal efforts that consume significant time and create logistical challenges.

Professional services properly handle materials like metal appliances, wood cabinetry, and recyclable components. This proper sorting ensures maximum recycling and minimum landfill impact.

Jiffy Junk’s “White Glove Treatment” leaves spaces broom-clean, eliminating delays between demolition and construction phases. This clean transition allows construction to begin immediately after demolition, potentially shortening your overall project timeline.

The Psychological Economics of Kitchen Projects

Beyond dollars and cents, kitchen renovations carry significant psychological costs and benefits. Understanding these mental and emotional factors helps create a more complete picture of what you’re truly investing and how to protect your wellbeing throughout the process.

The average kitchen remodel requires 300-400 individual decisions, creating substantial cognitive load. This decision fatigue represents a real but often unacknowledged cost of renovation projects.

Kitchen renovations place significant stress on relationships, with 35% of couples reporting serious conflict. These interpersonal tensions constitute a real project cost that deserves planning and mitigation strategies.

Strategic decision-making approaches can reduce mental strain by 40-60% while improving outcomes. Implementing structured decision processes helps protect both your relationships and your project results.

Decision Fatigue Impact

The average kitchen remodel requires hundreds of individual decisions, creating a psychological burden that impacts both your project and personal life. This cognitive load represents an unquantified cost that smart renovators actively manage through strategic planning.

Decision fatigue leads to poorer choices in later project phases, increasing the risk of expensive changes. As your mental energy depletes, your decision quality deteriorates, potentially leading to choices you’ll later regret.

Each decision requires evaluating an average of 5-7 options, creating overwhelming complexity. This evaluation process consumes significant mental energy across hundreds of decisions.

Strategic decision frameworks can reduce total decisions by 30-40% while improving overall coherence. These structured approaches not only save mental energy but typically produce better results.

The Williams family approached their kitchen remodel by creating a decision hierarchy. They first established their overall style direction (modern farmhouse) and color palette (white, navy, and natural wood tones). With these foundational decisions made, they eliminated thousands of options that didn’t fit their aesthetic. For each subsequent decision, from cabinet styles to hardware finishes, they could quickly eliminate options that didn’t align with their established direction. This approach reduced their decision-making time by approximately 60% while creating a more cohesive final design than friends who made each selection in isolation.

Choice Architecture Planning

Structuring decisions hierarchically reduces mental strain and improves outcomes. Establish foundational choices before addressing specific selections. This methodical approach prevents the common scenario where exhausted homeowners make increasingly poor decisions in later project phases.

Establishing style direction first eliminates 60-70% of potential options for subsequent decisions. This dramatic reduction in choices prevents the overwhelming complexity that leads to decision paralysis.

Decision hierarchies reduce the average decision time from 45-60 minutes to 15-20 minutes. This efficiency not only saves time but preserves mental energy for more important decisions.

Structured decision processes reduce expensive mid-project changes by 40-60%. By creating more coherent initial selections, these approaches prevent the regret and second-guessing that often lead to costly modifications.

Decision Bundling Strategies

Group similar choices to preserve mental energy and create cohesive results. Rather than selecting each element in isolation, create decision packages. This approach typically reduces decision time significantly while producing more harmonious design outcomes and fewer expensive mid-project changes.

Decision bundling reduces total decision points by 40-60% compared to item-by-item selection. This consolidation preserves mental energy while improving design coherence.

Bundled decisions show 30-40% greater style consistency than individually made selections. This improved coherence creates more professional-looking results without requiring design expertise.

Pre-selected designer packages eliminate 70-80% of decisions while ensuring professional-level coherence. These curated collections offer significant advantages for homeowners who find the multitude of choices overwhelming.

The Relationship Cost

Kitchen renovations place significant stress on relationships, with many couples reporting serious conflict during major remodels. These interpersonal tensions constitute a real project cost that deserves planning and mitigation strategies to protect both your relationships and your project outcomes.

35% of couples report serious conflict during kitchen renovations. This statistic highlights the relationship strain that often accompanies major home projects.

Relationship stress increases project costs by 10-15% through impulsive changes and compromise solutions. Emotional decisions rarely represent good value and often create additional expenses.

Clear decision protocols established before beginning prevent costly conflicts and delays. These communication systems protect both your budget and your relationships throughout the renovation process.

Communication Infrastructure

Establishing clear decision protocols before beginning prevents costly conflicts. Determine in advance who has final say in which areas, how disagreements will be resolved, and what approval process contractors must follow for changes. These systems prevent arguments and accelerate decision-making.

Couples with established decision protocols report 60% fewer arguments during renovations. This reduction in conflict creates a more positive renovation experience while preventing stress-induced poor decisions.

Clear communication systems reduce decision time by 3-5 days compared to ad-hoc approaches. This efficiency prevents the delays that often occur when couples struggle to reach consensus.

Written approval requirements prevent unauthorized changes that create relationship conflict and budget overruns. These formal systems ensure that both partners remain informed and involved throughout the process.

Expectation Management Techniques

Misaligned expectations cause both relationship strain and budget overruns. Create a shared vision document that explicitly addresses priorities, must-haves, nice-to-haves, and absolute no’s. This alignment process takes time but saves countless arguments and prevents impulsive decisions.

Expectation alignment processes typically take 3-5 hours but save an average of $1,500-$3,000 in unnecessary expenses. This upfront investment pays significant dividends throughout your project.

Couples with aligned expectations report 70% higher satisfaction with final results. This improved satisfaction stems from having a shared vision that guides all project decisions.

Prioritized requirement lists prevent budget allocation conflicts that occur in 40-50% of kitchen projects. These lists create clear guidelines for where to invest and where to economize when budget constraints arise.

The Contractor Relationship Economy

Your relationship with renovation professionals represents a complex economic ecosystem beyond the numbers on a contract. Understanding the unwritten rules and invisible incentives in this relationship directly impacts your project’s success and final cost.

Effective contractor communication directly correlates with both budget adherence and satisfaction. This skill represents a form of currency that can be more valuable than actual dollars in achieving your desired outcome.

Contractors operate within economic incentive systems that aren’t always transparent to homeowners. Understanding these motivations allows you to align interests more effectively.

Understanding these dynamics allows you to align interests more effectively and achieve better results. Strategic approaches to contractor relationships typically yield better outcomes for the same budget.

The Communication Premium

Effective contractor communication directly correlates with both budget adherence and satisfaction. This skill represents a form of currency that can be more valuable than actual dollars in achieving your desired outcome and preventing expensive misunderstandings.

Projects with documented communication protocols show 25-35% fewer change orders. These formal systems prevent the miscommunications that often lead to expensive modifications.

Written records prevent disputes that occur in approximately 30% of kitchen remodels. This documentation protects both you and your contractor from misunderstandings about what was agreed upon.

Clear communication reduces project delays by 15-20% through improved coordination. When expectations and timelines are clearly communicated, work proceeds more efficiently with fewer interruptions.

Documentation Discipline

Written records dramatically improve project outcomes and prevent disputes. Maintain a dedicated project email account for all contractor communications, confirm verbal discussions in writing, and photograph progress daily. This documentation system requires minimal time but prevents significant miscommunication costs.

Documentation systems typically require 10-15 minutes daily but prevent an average of $2,000-$5,000 in miscommunication costs. This small time investment creates substantial protection against expensive misunderstandings.

Daily progress photos create accountability that improves workmanship quality by 15-20%. When contractors know their work is being documented, they typically deliver higher quality results.

Written confirmation of verbal discussions prevents the “he said/she said” conflicts that occur in 25-30% of projects. This simple practice eliminates most disputes about what was agreed upon in conversations.

Decision Timing Economics

Late decisions and changes cost exponentially more as projects progress. Changes requested during planning typically add minimal costs, while those during construction add significant premiums. Establishing a front-loaded decision calendar that resolves most choices before construction begins saves substantial money.

Changes requested during planning typically add 1-3% to costs versus 15-25% during late construction. This dramatic cost difference makes early decision-making crucial for budget control.

Front-loaded decision calendars that resolve 90% of choices before construction begins save 8-12% on total project costs. This planning approach prevents the expensive mid-project changes that plague many renovations.

Each week of delay in critical path decisions typically adds $300-$500 to project costs through extended timelines. These delay costs accumulate quickly, making prompt decision-making financially important.

The Hidden Incentive Structure

Contractors operate within economic incentive systems that aren’t always transparent to homeowners. Understanding these motivations allows you to align interests more effectively and achieve better results for the same budget through strategic planning and communication.

Contractor profit margins typically range from 15-25% but vary significantly based on project type and timing. Understanding these margins helps you identify where flexibility might yield better pricing.

Schedule flexibility can be traded for cost savings of 5-10% as contractors optimize crew assignments. This flexibility allows contractors to fill gaps in their schedule, creating mutual benefits.

Understanding the quality-speed-cost triangle helps set realistic expectations that prevent disappointment. Recognizing that you can’t optimize all three factors simultaneously leads to more successful project outcomes.

The Quality Triangle Reality

The old adage “good, fast, cheap—pick two” reflects a fundamental reality of construction economics. Attempting to optimize all three creates inherent contradictions that lead to disappointment and conflict. Explicitly prioritizing two factors while accepting limitations on the third creates more successful partnerships.

Projects prioritizing quality and speed typically cost 15-25% more than standard projects. This premium reflects the additional resources required to deliver both attributes simultaneously.

Projects prioritizing economy and quality typically take 20-30% longer to complete. This extended timeline allows contractors to work more efficiently and schedule work during optimal periods.

Projects attempting to optimize all three factors report 40-50% higher dissatisfaction rates. This dissatisfaction stems from the inevitable compromises required when trying to achieve inherently conflicting goals.

Scheduling Currency

Contractor schedules represent a form of currency that can be traded for other benefits. Flexibility with timing typically yields cost savings as contractors can optimize their crew assignments. Conversely, demanding specific tight timeframes creates premium costs that rarely appear as line items but get embedded in overall pricing.

Accepting a start date 4-6 weeks later than desired typically yields 5-10% cost savings. This flexibility allows contractors to schedule your project during periods that would otherwise be underutilized.

Rush scheduling increases costs by 10-15% through overtime and crew reassignments. These premiums reflect the real costs contractors incur when rearranging their schedules to accommodate urgent projects.

Contractors typically maintain 15-20% schedule buffer that can be negotiated for price concessions. Understanding this buffer allows you to request modest timeline adjustments without triggering premium pricing.

The Financing Dimension

How you pay for your kitchen remodel dramatically affects its true cost. Understanding the full range of payment options and their long-term implications reveals opportunities to optimize your investment and potentially save thousands over the life of your project.

Financing choices can impact total project cost by 10-20% through interest rates and tax implications. These financial considerations often receive less attention than material selections but can have equal or greater impact on your bottom line.

Alternative financing approaches offer advantages in specific situations that can significantly reduce total costs. Strategic use of credit promotions, manufacturer financing, and other options can create substantial savings.

Tax considerations can substantially impact the effective cost of your remodel but rarely enter initial budgeting discussions. Understanding potential tax benefits helps you structure your project to maximize deductions where legally possible.

Beyond Home Equity

While home equity loans and lines of credit remain popular renovation funding sources, alternative financing approaches offer advantages in specific situations. Strategic use of credit promotions, manufacturer financing, and other options can significantly reduce your total project cost.

Home equity loans typically offer interest rates 2-4% lower than personal loans but involve closing costs of $500-$1,000. These closing costs must be factored into your total financing expense calculations.

Manufacturer financing programs often provide 0-3% financing for 12-36 months on purchases over specific thresholds. These programs can create significant savings compared to traditional financing options.

Strategic credit card promotions can fund portions of your project at effectively negative interest rates when combined with signup bonuses. This approach requires careful management but can create substantial savings when executed properly.

A recent survey found that “to finance remodel projects, the National Association of Realtors said 54% used a home-equity loan, 29% saved up for it and 10% put some remodeling or renovation costs on credit cards” according to WTOP News.

Strategic Credit Utilization

Strategic use of credit card promotions can fund portions of your project at effectively negative interest rates. Major purchases timed with new card bonuses combined with 0% introductory periods create immediate returns if paid off during the promotional window. This approach works best for equipment purchases rather than labor costs.

New credit card bonuses worth $500-$1,000 effectively discount major purchases when meeting spending requirements. These bonuses can create substantial savings when timed with significant renovation expenses.

Zero-interest promotional periods typically run 12-18 months, providing interest-free financing. This interest-free period creates significant savings compared to traditional financing options.

This strategy works best for discrete purchases like appliances rather than ongoing construction costs. The defined payment amount makes budgeting for repayment more straightforward than financing variable construction expenses.

Manufacturer Financing Leverage

Appliance and cabinet manufacturers frequently offer promotional financing that beats traditional loan rates. These programs typically provide 0-3% financing for 12-36 months on purchases over specific thresholds. Timing your project to coincide with these promotional periods can reduce financing costs significantly.

Major cabinet manufacturers offer 0% financing promotions typically in April-May and October-November. Timing your cabinet purchase to coincide with these promotional periods can save hundreds or thousands in interest costs.

Appliance package purchases over $5,000 frequently qualify for special financing rates 3-5% below market. These packages often represent better value than purchasing appliances individually, both in product cost and financing terms.

Manufacturer financing typically requires less documentation than bank loans, with approval in 24-48 hours. This streamlined process creates convenience benefits beyond the favorable interest rates.

Tax Consideration Strategies

The tax implications of your kitchen remodel can substantially impact its effective cost, yet these factors rarely enter into initial budgeting discussions. Understanding potential tax benefits helps you structure your project to maximize deductions where legally possible.

Home improvements that qualify as medical necessities may be tax-deductible with proper documentation. These deductions can significantly reduce the effective cost of accessibility-focused renovations.

Business use portions of kitchen remodels may qualify for depreciation or direct expense deductions. For home-based businesses, these deductions can create substantial tax savings.

Energy efficiency improvements may qualify for tax credits that reduce project costs by 10-30%. These credits directly reduce your tax liability rather than simply reducing taxable income, creating more valuable benefits.

Medical Necessity Documentation

Kitchen modifications for medical reasons may qualify as tax-deductible expenses. Features like lowered countertops, specialized storage, or accessibility improvements can potentially be deducted if properly documented as medical necessities. This approach requires physician documentation but can effectively reduce costs.

Medical necessity deductions can effectively reduce costs by your tax bracket percentage (22-37% for most homeowners). This reduction applies to the portion of your renovation that serves legitimate medical purposes.

Qualifying improvements must be prescribed by a physician and primarily serve medical purposes. This documentation requirement creates additional paperwork but protects the legitimacy of your deductions.

Partial deductions may apply to dual-purpose modifications that serve both medical and general household functions. These partial deductions still create valuable tax benefits while acknowledging the mixed-use reality of many improvements.

After your kitchen renovation is complete, you’ll likely have old appliances and cabinets to dispose of. Consider exploring appliance disposal options for your refurbished kitchen that prioritize recycling and donation over landfill disposal.

Home Office Allocation

If your kitchen legitimately serves your home business, a portion of the remodel may qualify for business expense treatment. This strategy requires careful documentation and reasonable allocation, but can transform a portion of your project from a personal expense to a business deduction with significant tax advantages.

Business use portions typically range from 10-20% for kitchen spaces with legitimate dual use. This allocation must reflect actual business usage rather than aspirational estimates.

Depreciation deductions spread the business portion of costs over 27.5 years for residential property. While this extended timeline reduces the immediate benefit, it creates tax advantages that persist for decades.

Direct expense treatment may apply to portions that exclusively serve business functions. These expenses can potentially be deducted immediately rather than depreciated, creating more valuable short-term tax benefits.

The Timeline Reality

Kitchen renovation timelines rarely unfold as initially projected, creating cascading financial effects beyond simple delay costs. Understanding the true temporal economics of your project helps you make more realistic plans and avoid expensive accommodations due to schedule overruns.

Kitchen projects follow dependency chains where delays in one phase impact all subsequent steps. Understanding these dependencies helps you identify critical path items that require special attention.

Strategic scheduling aligned with industry cycles can yield 10-15% savings. Timing your project to coincide with seasonal slowdowns typically secures better pricing and more attentive service.

Building buffer zones into project timelines prevents expensive cascade failures. These strategic time reserves cost nothing upfront but save significantly in rush fees and stress-induced changes.

The Scheduling Cascade

Kitchen projects follow dependency chains where delays in one phase impact all subsequent steps, creating compounding timeline effects. Identifying critical path items and building appropriate buffers helps prevent expensive rush charges and quality compromises.

The average kitchen remodel involves 15-20 sequential steps with complex dependencies. Understanding these relationships helps you anticipate potential delay points and plan accordingly.

Critical path delays extend overall timelines on a 1:1 basis while non-critical delays may have zero impact. Distinguishing between these delay types helps you focus attention on truly important schedule items.

Custom cabinets, specialty materials, and structural modifications represent critical path items with 4-12 week lead times. These long-lead items require early decisions and careful tracking to prevent cascading delays.

Critical Path Identification

Identifying the true critical path of your project reveals which delays actually impact completion and which don’t. Building a schedule that accounts for these realities rather than optimistic scenarios prevents expensive rush charges and quality compromises when inevitable delays occur.

Cabinet delivery typically represents the primary critical path item, with 4-8 week lead times. This extended manufacturing period means cabinet decisions must be finalized early to prevent project delays.

Permit approvals create critical path dependencies with highly variable timelines (1-6 weeks in most jurisdictions). This variability requires building appropriate buffers into your schedule to accommodate potential delays.

Non-critical path items can be rescheduled without timeline impacts if properly identified and managed. Understanding which elements offer scheduling flexibility helps you adapt to inevitable changes without extending your overall timeline.

Buffer Zone Implementation

Building strategic time buffers into your schedule prevents expensive cascade failures. Experienced renovators add 25% to estimated timeframes and avoid scheduling critical events within 30 days of projected completion. This buffer approach costs nothing upfront but saves significantly in rush fees and stress-induced changes.

Projects without adequate buffers face an 80% chance of timeline overruns. This statistic reflects the reality that unexpected issues arise in nearly all renovation projects.

Each week of buffer typically prevents $400-$800 in rush charges and expediting fees. These potential savings make time buffers one of the most cost-effective planning strategies available.

Buffer zones averaging 25% of projected timeline prevent approximately $1,200-$3,000 in rush fees and temporary accommodations. This protection costs nothing upfront but creates significant financial benefits when inevitable delays occur.

Seasonal Strategic Planning

The timing of your kitchen remodel within the annual construction cycle significantly impacts both cost and timeline. Planning your project during industry low seasons typically yields substantial savings through reduced labor rates and material promotions.

Counter-cyclical planning typically yields 10-15% savings through reduced labor rates and material promotions. These savings apply across multiple budget categories, creating substantial total impact.

January-February and September-October represent optimal starting periods in most regions. These shoulder seasons typically offer the best combination of contractor availability and favorable pricing.

Material purchases aligned with industry cycles can save 15-25% compared to random timing. Understanding these cycles helps you capture promotional pricing that can significantly reduce your total project cost.

Counter-Cyclical Advantages

Planning your project during industry low seasons yields significant savings through reduced labor rates and material promotions. In most regions, kitchen remodels starting in January-February or September-October secure better contractor availability, more attentive service, and lower pricing than peak season projects.

Contractors typically discount rates by 5-15% during slow seasons to maintain crew employment. These discounts rarely appear as line-item reductions but manifest as more competitive overall pricing.

Permit processing times decrease by 20-30% during off-peak construction periods. This efficiency can shave weeks off your project timeline while reducing the uncertainty associated with permit approvals.

Vendor attention and service quality typically improves by 15-25% during slower business cycles. This enhanced service often translates to fewer errors, better communication, and more attentive project management.

Material Timing Optimization

Aligning purchases with industry cycles captures significant discounts. Appliance purchases timed to model year transitions can save 15-25% as retailers clear old inventory. Similarly, cabinet and countertop material purchases during manufacturer promotional periods yield substantial savings compared to random timing.

Appliance model transitions typically occur in September-October with clearance discounts of 15-25%. These discounts apply to perfectly good models being replaced by marginally updated versions.

Cabinet manufacturers offer promotional pricing in January and July in most markets, saving 10-20%. These semi-annual promotions create predictable savings opportunities for informed consumers.

Countertop fabricators offer discounts of 10-15% during seasonal slowdowns (typically January-February). These discounts help fabricators maintain steady workflow during traditionally slow periods.

Final Thoughts: Making Informed Kitchen Remodel Decisions

Kitchen remodeling involves complex financial considerations beyond basic material and labor costs. By understanding the true economics of your project—from hidden costs and material longevity to contractor relationships and disposal challenges—you can make more informed decisions that maximize value while minimizing stress. Remember that proper planning, realistic budgeting with appropriate buffers, and strategic timing can significantly impact your final results and satisfaction.

Successful kitchen remodels balance financial considerations with quality of life improvements. The best renovations create spaces that enhance your daily experience while respecting your budget constraints.

The 30% buffer rule protects against budget disasters while allowing for appropriate quality investments. This financial self-protection strategy prevents the stress and compromises that plague under-budgeted projects.

Professional waste removal services like Jiffy Junk can simplify the demolition phase while ensuring responsible disposal of your old kitchen materials. These specialized services create value through convenience, proper material handling, and environmental responsibility.

When your kitchen remodel reaches the demolition phase, consider how you’ll handle the significant amount of waste generated. Jiffy Junk specializes in responsible removal of kitchen demolition debris, ensuring materials are properly sorted for recycling, donation, or disposal. Their “White Glove Treatment” leaves your space broom-clean and ready for construction to begin without delays. Contact Jiffy Junk today to discuss how they can help make the disposal dimension of your kitchen remodel stress-free and environmentally responsible.