Pool Remodel Cost Secrets: What Your Contractor Won’t Tell You

Renovating your pool involves more than just the quoted price. With costs ranging from $5,000 to $100,000, understanding the hidden financial factors can save you thousands. Recent data shows that 68% of homeowners exceed their initial pool renovation budget by 15-30%. I discovered this firsthand when my simple resurfacing project ballooned into a complete system overhaul. This guide reveals the economic realities behind pool remodeling that most contractors won’t discuss, helping you make informed decisions and avoid costly surprises.

Table of Contents

-

Understanding True Pool Renovation Costs

-

Strategic Phasing of Pool Renovations

-

Technology Integration Cost-Benefit Analysis

-

Material Selection Economics

-

Creative Funding Approaches for Pool Renovation

-

Psychological Aspects of Pool Renovation Decisions

-

Contractor Selection Science

-

Post-Renovation Value Maximization

Understanding True Pool Renovation Costs

Pool remodeling expenses extend far beyond the initial quote. Most homeowners focus only on visible costs while overlooking hidden expenses that typically account for 30-40% of the final bill. These unseen costs include permit fees, equipment upgrades, landscaping restoration, and utility adjustments.

Permit fees vary significantly by location, with coastal and high-regulation areas charging 2-3 times more than inland regions, often requiring multiple departmental approvals. This can add thousands to your project before work even begins.

Equipment compatibility issues frequently arise during renovations, as new technology may not integrate with existing systems without additional adapters or complete replacements. I’ve seen simple pump upgrades turn into full plumbing overhauls because the new equipment wouldn’t connect to decades-old pipes.

According to a comprehensive industry survey, pool renovation costs typically range from $5,000 to $100,000, with the average homeowner spending between $10,000 to $60,000 depending on the scope of work and materials selected.

By understanding these hidden factors, you can develop a more accurate budget and avoid mid-project financial stress.

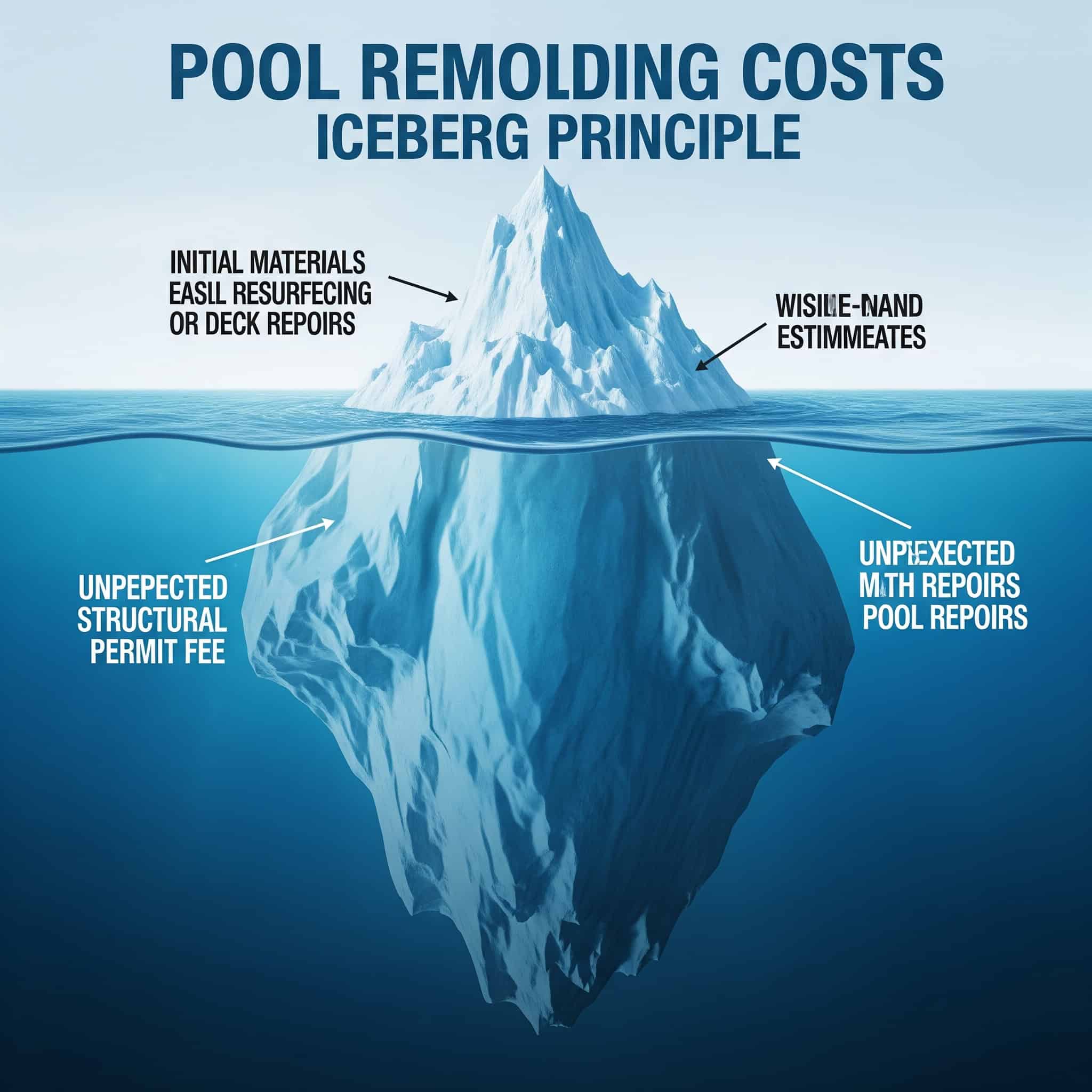

The Cost Iceberg Principle

Visible costs represent only a fraction of your total pool remodeling budget. The unseen expenses—permit fees, equipment upgrades, landscaping restoration, and utility adjustments—often comprise 30-40% of the final bill.

Regulatory compliance costs have increased 25-35% in the past five years due to stricter safety and environmental standards. This means that even if you’re doing a simple pool remodel, you might need to upgrade safety features to meet current codes.

Electrical upgrades are required in 70% of pool renovations over 10 years old to meet current code requirements, adding $1,200-$3,500 to project costs. These aren’t optional extras—they’re mandatory changes that contractors often don’t mention until work is underway.

Soil stabilization and drainage modifications become necessary in approximately 40% of deep renovations, particularly in areas with clay soils or high water tables. This can add thousands to your project cost when the ground beneath your pool isn’t as stable as expected.

The Park District of Oak Park recently completed a $3 million renovation of their diving well at Rehm Pool, converting a 16-foot deep area that accommodated just four people into a 3.5-foot deep space with capacity for over 30 people.

Preparing for these hidden costs helps prevent budget overruns and ensures you have sufficient funds to complete your project as envisioned.

|

Hidden Cost Category |

Typical Percentage of Total Budget |

Common Overlooked Expenses |

|---|---|---|

|

Regulatory Compliance |

5-10% |

Permit fees, inspection costs, code upgrades |

|

Equipment Compatibility |

10-15% |

Adapters, system replacements, rewiring |

|

Site Restoration |

8-12% |

Landscaping repair, deck restoration, drainage fixes |

|

Utility Adjustments |

7-10% |

Electrical panel upgrades, gas line modifications, water line extensions |

|

Waste Disposal |

3-8% |

Debris removal, hazardous material handling, recycling fees |

Demolition Disposal Economics

Removal and disposal of old pool materials represent a significant yet frequently overlooked expense. Concrete debris from an average pool can weigh 15-20 tons, with disposal costs ranging from $50-$150 per ton depending on your location.

Concrete disposal costs have risen 15-20% in urban areas due to landfill capacity limitations and increased environmental regulations. This means getting rid of your old pool surface costs more every year.

Specialized pool material disposal (fiberglass, vinyl liners) requires separation and specific handling procedures that add $200-$500 to standard disposal costs. These materials can’t just go to the regular landfill.

Recycling concrete debris can reduce disposal costs by 30-50% while providing environmental benefits, though it requires contractor coordination with specialized recycling facilities.

When planning your pool remodel, it’s important to consider where all that concrete will go. Many homeowners are surprised by the concrete disposal challenges that come with major pool renovations, especially when dealing with older structures.

Timing your project during off-peak seasons when disposal services offer lower rates can result in substantial savings.

Water Replacement Calculations

Refilling your pool after renovation incurs both direct water costs and potential tiered pricing penalties from utilities. A typical 20,000-gallon pool refill can cost $60-$300, with prices doubling in drought-prone regions.

Municipal water rates follow tiered pricing structures in 65% of U.S. markets, with high-volume usage tiers costing 2-3 times more than base rates. This means filling your pool might push you into a higher pricing bracket for your entire water bill.

Water delivery services typically charge $0.01-$0.03 per gallon plus delivery fees, but offer scheduling flexibility and avoid utility surcharges. For many homeowners, this option actually saves money despite seeming more expensive upfront.

Water conservation credits are available in many drought-prone regions when replacing pools with more efficient designs, potentially offsetting 10-15% of water costs.

When I renovated my backyard pool last year, the water refill cost caught me completely off guard. Living in Southern California during a drought period, our municipal water provider charged triple rates for “excessive use” during the month I refilled my 25,000-gallon pool. The water bill alone came to $475, nearly $300 more than I had budgeted. Had I known about this beforehand, I could have scheduled the renovation completion for our rainy season or arranged for a water delivery service that offered fixed-rate pricing regardless of local drought conditions.

You can minimize these costs by scheduling your refill during non-drought months and considering water delivery services that offer bulk pricing.

Return on Investment Analysis

Pool remodeling should be viewed as a financial investment with quantifiable returns. Different renovation choices yield varying ROI percentages, with energy efficiency upgrades typically offering the highest long-term financial benefit.

Energy efficiency upgrades deliver an average 115-140% ROI over a 5-year period through reduced operational costs. This makes them one of the smartest investments in any pool remodel.

Safety feature improvements (fencing, covers, non-slip surfaces) provide both liability reduction and insurance premium savings of 5-15% annually. Many homeowners don’t realize these safety upgrades can actually pay for themselves through insurance discounts.

Automation systems show increasing ROI as utility rates rise, with current calculations showing 85-110% returns over system lifespan. The more energy costs increase, the more valuable these systems become.

According to HomeGuide, a well-maintained and updated pool can increase home value by 5-7%, making it a worthwhile investment for homeowners planning to sell in the future.

Understanding the financial impact of each renovation decision helps prioritize improvements that deliver the greatest value for your specific situation and budget.

Property Valuation Impact

A professionally remodeled pool adds 5-8% to home value in warm climates but only 2-4% in seasonal regions. To maximize your investment return, focus on modernizing features that appeal to the broadest market segment—salt systems over chlorine, energy-efficient pumps, and neutral finishes.

Homes with updated pools sell 20-30% faster than those with dated pool features, particularly in competitive real estate markets. This means your pool remodel might help your home sell months faster when it’s time to move.

Neutral finishes (whites, light blues, grays) appeal to 75-85% of potential buyers, while bold colors or patterns limit appeal to 15-25% of the market. That bright red pool bottom might look amazing to you but will significantly reduce your buyer pool.

Salt chlorination systems increase property appeal to 65% of buyers compared to traditional chlorine systems at 35%, according to recent real estate surveys. This single upgrade can dramatically increase your pool’s contribution to property value.

Energy Consumption Metrics

Outdated pool equipment can consume 3-4 times more energy than modern alternatives. Calculate your energy consumption baseline before remodeling, then project savings from each potential upgrade.

Variable-speed pumps operate at different RPMs based on needed flow rates, consuming as little as 100 watts at low speeds compared to 2,000+ watts for single-speed models. This dramatic difference explains why they’re now mandated in many regions.

LED lighting reduces electricity consumption from 300-500 watts to 30-50 watts while providing 15,000+ hours of operation versus 1,000-2,000 for incandescent options. The energy savings alone justify the upgrade, with the extended lifespan being a bonus.

Automated chemical controllers reduce chemical usage by 30-40% through precision dosing while maintaining more consistent water quality parameters. This means better water quality with less effort and lower chemical costs.

A variable-speed pump alone can reduce energy costs by 70-80%, paying for itself within 2-3 years. After that, it’s putting money back in your pocket every month.

Maintenance Cost Trajectory

Each remodeling decision creates a maintenance cost trajectory that extends for years. Premium surfaces like pebble finishes cost 40-60% more upfront but require resurfacing half as often as plaster.

Traditional plaster surfaces require acid washing every 3-5 years ($350-$650) and complete resurfacing every 7-10 years ($3,500-$7,000). These recurring costs add up quickly over the life of your pool.

Quartz and pebble aggregate finishes extend resurfacing intervals to 15-20 years, though initial costs run 40-60% higher than standard plaster. The longer lifespan often makes them more economical despite the higher upfront cost.

Chemical maintenance costs vary by surface type, with porous materials requiring 15-25% more chemicals annually than non-porous alternatives. This hidden cost can add hundreds to your annual pool maintenance budget.

Document all maintenance requirements and projected schedules to calculate the true lifetime cost of each material option. This comprehensive approach often reveals that the “budget” option actually costs more over time.

Strategic Phasing of Pool Renovations

Rather than approaching pool remodeling as a single project, strategic phasing allows for budget control while maximizing functionality throughout the renovation process. This approach can reduce overall costs by 15-25% by avoiding rush charges, capitalizing on material price fluctuations, and maintaining partial pool use during extended renovations.

Multi-phase renovations allow for budget distribution across multiple tax years, potentially creating tax advantages for certain improvement categories. This can be especially beneficial for high-cost renovations.

Phased approaches reduce contractor rush fees and premium charges that typically add 10-20% to expedited projects. When contractors know they have more time to complete work, they often provide better pricing.

I’ve found that breaking my pool renovation into three phases—hydraulics first, then equipment upgrades, and finally cosmetic improvements—allowed me to spread the cost over 18 months while keeping the pool usable for most of that time. This approach also gave me time to research each phase thoroughly before committing.

Hydraulic System Prioritization

The circulatory system of your pool—plumbing, pumps, filters, and skimmers—forms the foundation of all other renovations. Prioritizing these components first prevents costly rework and creates a robust platform for future aesthetic upgrades.

Plumbing infrastructure typically accounts for 15-25% of total renovation costs but influences 70-80% of system performance and efficiency. This makes it the most important system to get right, even though it’s completely invisible once the renovation is complete.

Undersized hydraulic systems cause 40-50% of premature equipment failures due to increased pressure and operational strain. Many pool owners replace pumps and heaters repeatedly without addressing the underlying hydraulic issues causing the failures.

Modern hydraulic designs incorporate velocity-reducing features that minimize turbulence, reducing energy requirements by 20-30% compared to traditional layouts. These design improvements can significantly reduce operating costs for the life of your pool.

Addressing hydraulic issues early ensures the long-term success of your renovation and prevents the frustration of equipment failures shortly after your beautiful new pool is complete.

Pressure Testing Protocols

Before committing to any renovation, conduct comprehensive pressure testing of existing plumbing. This $200-$400 diagnostic can identify leaks losing 1,000+ gallons monthly, preventing post-renovation surprises.

Static pressure testing identifies leaks by pressurizing closed plumbing systems to 15-20 PSI and monitoring pressure loss over 24-48 hours. This simple test can reveal hidden leaks that might otherwise go undetected until after your renovation is complete.

Dynamic pressure testing measures flow rates and pressure differentials during operation, identifying restrictions and efficiency losses not visible during static tests. This helps identify crushed pipes, internal obstructions, and other flow problems.

Hydrostatic testing of the pool shell detects structural leaks by maintaining water levels and measuring water loss rates under controlled conditions. This is particularly important for older pools where structural integrity might be compromised.

Request documentation of all test results and incorporate repair costs into your initial budget rather than as change orders. Having this information upfront prevents the all-too-common scenario of discovering major plumbing issues halfway through your pool remodel.

Plumbing Diameter Economics

Increasing pipe diameter by just 1/2 inch during renovation reduces friction loss by approximately 50%, lowering long-term energy costs. While this upgrade adds $500-$1,500 to initial plumbing costs, it yields lifetime savings of $2,000-$5,000 through reduced pump requirements and improved circulation efficiency.

Friction loss in plumbing follows an exponential rather than linear relationship to diameter, with 2″ pipes experiencing approximately 75% less friction than 1.5″ pipes at equal flow rates. This dramatic difference explains why larger pipes save so much energy.

Return line positioning affects circulation efficiency by 15-25%, with strategic placement creating complete water turnover with less energy input. Many older pools have poorly positioned returns that create dead spots and require higher pump speeds to achieve proper circulation.

Modern plumbing materials like PVC Schedule 40 maintain interior smoothness for decades, while older materials develop internal roughness that increases friction by 10-30% over time. This progressive deterioration explains why many older pools become increasingly expensive to operate.

Seasonal Timing Strategies

The timing of your pool renovation significantly impacts costs, with price variations of 15-30% based solely on season and contractor availability. Understanding regional contractor cycles and material price fluctuations allows for strategic scheduling that maximizes your renovation budget.

Construction material prices follow predictable annual cycles, with concrete costs typically lowest in winter months and highest during summer construction peaks. This seasonal variation can save thousands on large renovation projects.

Labor availability fluctuates seasonally, with skilled pool technicians commanding 20-30% premium rates during peak season. The same crew that might be eager for work in October could be booked solid with a waiting list by April.

Permit processing times vary seasonally, with off-season applications typically processed 30-50% faster than during construction peaks. This can shave weeks or even months off your project timeline.

Fall is actually the ideal time for pool installation projects. As Greg Povlow, owner of Ross Services notes, “People often assume a pool remodel means tearing everything out, but that’s rarely the case. Sometimes, just updating the surface or replacing old coping can transform a pool’s look and function.”

Contractor Off-Season Leverage

Pool contractors in northern regions experience demand drops of 40-60% during fall and winter months, creating negotiation opportunities for savvy homeowners.

Contractor overhead costs remain relatively constant year-round, creating financial pressure during low-demand periods that increases willingness to negotiate. This economic reality gives off-season customers significant leverage.

Material storage capabilities vary between contractors, affecting their ability to purchase during price dips and maintain price guarantees for delayed projects. Contractors with warehouse facilities can often lock in better pricing than those who purchase materials as needed.

Labor retention strategies drive off-season pricing, with established companies often offering lower off-season rates to maintain their skilled workforce. They’d rather keep their best workers busy at lower margins than lose them to competitors.

My neighbor Tom saved nearly 30% on his pool renovation by strategically timing his project. He obtained quotes from three contractors during the summer peak season, but specified that work would begin in October. The winning contractor offered a 15% discount on labor, extended payment terms that allowed Tom to split payments across two tax years, and agreed to purchase and store key materials during summer sales. By the time the renovation was complete in November, Tom had saved over $8,000 compared to identical work performed during the summer months, and his pool was ready well before the following swim season.

Schedule consultations in peak season but negotiate contracts for off-season work, requesting price guarantees and extended payment terms in exchange for providing winter employment.

Material Price Cycle Analysis

Pool renovation materials follow predictable price cycles influenced by manufacturing schedules and shipping costs. For example, tile prices often drop 10-15% in late fall as manufacturers clear inventory.

Imported materials (particularly tile and stone) follow shipping container pricing cycles, with costs typically lowest when shipping volume decreases in September-November. This seasonal pattern affects everything from imported tile to stone coping.

Domestic material production follows seasonal construction demand, with manufacturers offering incentives during production lulls to maintain factory utilization. These incentives often translate to dealer discounts during slower seasons.

Storage considerations affect early purchasing viability, with moisture-sensitive materials requiring climate-controlled environments to prevent degradation. Make sure your contractor has appropriate storage facilities before purchasing materials significantly in advance of installation.

Track material prices for 3-6 months before your project and purchase high-cost, non-perishable items like tile and coping stones during price dips, even if installation occurs months later. This strategy alone can save 10-15% on material costs.

Technology Integration Cost-Benefit Analysis

Modern pool renovations increasingly incorporate automation, smart technology, and energy-efficient systems. While these technologies add upfront costs ranging from $2,000 to $15,000, they can reduce operating expenses by 30-60% while extending equipment lifespan.

Integration complexity varies significantly between closed and open-protocol systems, affecting both initial costs and long-term flexibility. Closed systems are often easier to install but limit future expansion options.

Technological obsolescence rates differ between mechanical and digital components, with mechanical systems typically maintaining functionality 2-3 times longer than digital interfaces. This difference should influence how you allocate your technology budget.

I’ve found that focusing on core mechanical upgrades first—variable speed pumps, efficient filters, and LED lighting—provides the best return on investment. These components deliver immediate energy savings while creating the foundation for more advanced automation later.

Understanding the cost-benefit relationship of each technology allows for targeted investments with measurable returns.

Automation System Scalability

Pool automation systems range from basic timer upgrades to comprehensive home integration platforms. The scalable nature of these systems allows for strategic implementation that aligns with renovation budgets while providing infrastructure for future expansion.

Communication protocols determine system compatibility, with proprietary systems offering streamlined setup but limited expansion options compared to open-protocol alternatives. This choice significantly impacts your future flexibility.

Processing capacity requirements increase exponentially with system complexity, necessitating more robust controllers for comprehensive automation. Underpowered controllers often become bottlenecks as systems expand.

Power management considerations become critical in fully automated systems, with surge protection and stable power delivery affecting system reliability and longevity. Many automation failures trace back to inadequate power protection.

Starting with core automation components and expanding over time maximizes both functionality and budget efficiency. This approach allows you to spread costs while gaining experience with each level of automation before advancing to more complex systems.

|

Automation Level |

Initial Cost |

Monthly Savings |

Breakeven Period |

Key Components |

|---|---|---|---|---|

|

Basic |

$800-$1,500 |

$30-$50 |

2-4 years |

Digital timers, basic remote control |

|

Intermediate |

$2,000-$4,000 |

$60-$100 |

2-3 years |

Variable speed control, smartphone app, basic chemical monitoring |

|

Advanced |

$5,000-$8,000 |

$100-$180 |

3-5 years |

Home integration, complete chemical automation, multi-device control |

|

Premium |

$10,000-$15,000 |

$150-$250 |

4-6 years |

AI optimization, predictive maintenance, complete home ecosystem integration |

Control System Architecture Planning

Design your automation infrastructure with expansion capability by selecting systems with modular architecture. Initial investment in a robust control panel ($800-$1,500) with expansion capacity allows for phased addition of features without replacement costs.

Relay capacity determines the number of devices a control system can manage, with base models typically supporting 4-8 devices while expandable systems accommodate 20+ connections. This capacity limit is often overlooked until homeowners try to add features later.

Communication bandwidth affects response time and reliability, particularly in wireless systems where signal strength and interference impact performance. Systems with dedicated communication channels typically outperform those that share bandwidth with home WiFi.

Software update policies vary significantly between manufacturers, with some providing lifetime updates while others charge subscription fees for continued support. This ongoing cost should factor into your decision-making process.

Request open-protocol systems that can integrate with multiple manufacturers’ equipment to prevent vendor lock-in. This approach preserves your freedom to select the best components regardless of brand, often resulting in better performance and value.

Remote Monitoring ROI

Remote monitoring systems ($500-$2,000) provide real-time data on water chemistry, temperature, and equipment performance. These systems reduce chemical costs by 15-25% through precision dosing while extending equipment life by identifying problems before failure occurs.

Sensor accuracy degrades over time, with most chemical sensors requiring recalibration every 3-6 months and replacement every 1-2 years to maintain precision. This maintenance requirement represents an ongoing cost that should factor into your ROI calculations.

Data storage architectures vary between cloud-based and local systems, affecting both accessibility during internet outages and long-term data retention. Cloud systems offer better accessibility but may involve subscription fees.

Alert threshold customization capabilities determine system effectiveness, with advanced systems allowing for seasonal parameter adjustments and trend-based notifications. This adaptability significantly improves system value by reducing false alarms while catching real problems.

Calculate your chemical and service call expenses for the past two years to establish your baseline for ROI projections. This personalized approach provides much more accurate savings estimates than generic manufacturer claims.

Energy Efficiency Upgrade Hierarchy

Energy-related upgrades offer varying payback periods, from immediate returns to multi-year investments. Prioritizing these improvements based on your specific usage patterns maximizes financial benefits while meeting environmental goals.

Energy consumption distribution in typical pools allocates 70-80% to pumping, 15-20% to heating, and 5-10% to lighting and auxiliary systems. This breakdown should guide your upgrade priorities, with pumping typically offering the greatest savings potential.

Operational scheduling optimization can reduce energy consumption by 30-40% without equipment changes by aligning run times with utility rate structures. This zero-cost improvement often delivers substantial savings before any equipment is replaced.

System integration efficiency multiplies individual component benefits, with properly matched equipment delivering 10-15% greater efficiency than the same components operating independently. This synergistic effect explains why comprehensive upgrades often outperform piecemeal improvements.

According to All Seal Exterior, pump or filter upgrades during pool renovations typically cost between $500 and $1,500, making them one of the most cost-effective improvements with significant long-term energy savings potential.

Creating an upgrade hierarchy based on ROI helps allocate your renovation budget for maximum impact. For most pools, this means prioritizing variable speed pumps, followed by LED lighting, then heating system improvements.

Pump Efficiency Calculations

Variable-speed pumps represent the highest ROI energy upgrade, reducing electricity consumption by 70-90% compared to single-speed alternatives. While installation costs $800-$1,500 more than standard pumps, annual savings of $300-$1,200 create payback periods of 1-3 years.

Flow rate requirements vary by function, with filtration requiring only 25-30% of the flow needed for features like waterfalls or spa jets. This operational flexibility is what makes variable speed pumps so efficient—they can run at lower speeds for routine filtration.

Motor efficiency ratings (Total Efficiency Factor) provide standardized comparison metrics, with higher TEF numbers indicating greater efficiency across operating ranges. This standardized measure helps compare different models objectively.

Hydraulic matching between pump output and system requirements determines actual efficiency, with oversized pumps consuming 20-40% more energy than properly sized alternatives. Many pool owners mistakenly believe bigger is better when it comes to pumps.

Many homeowners don’t realize that their old pool pumps are energy hogs. When planning your pool remodel, consider appliance recycling options for your old equipment, which can help offset some costs while ensuring proper disposal of these items.

Request electricity usage data in gallons pumped per kilowatt-hour to make accurate comparisons between models. This metric provides a much more useful comparison than horsepower or other traditional measures.

Heating System Comparison Metrics

Heating options (gas, electric, solar) offer dramatically different operating costs despite similar purchase prices. Solar heating systems cost 50-100% more initially ($5,000-$10,000) but reduce operating costs by 80-95%, with payback periods of 3-7 years depending on climate and usage patterns.

BTU delivery rates determine heating speed, with gas heaters providing 200,000-400,000 BTU/hour compared to heat pumps at 50,000-125,000 BTU/hour and solar at 10,000-50,000 BTU/hour. This speed difference is crucial for pools that need rapid heating.

Coefficient of Performance (COP) measures heat pump efficiency, with modern units achieving 5.0-7.0 COP in optimal conditions versus 0.8-0.95 for gas heaters. This dramatic efficiency difference explains why heat pumps cost so much less to operate despite slower heating.

Temperature rise capabilities vary by technology, with gas heaters capable of 1-3°F per hour regardless of ambient conditions while heat pumps and solar systems slow significantly in suboptimal weather. This performance difference makes gas heaters better for occasional use while heat pumps excel for maintained temperatures.

Calculate your specific break-even point by analyzing your historical heating costs and projected usage. This personalized approach accounts for your unique climate, usage patterns, and utility rates.

Lighting Efficiency Standards

LED lighting upgrades reduce underwater lighting electricity consumption by 80% while extending bulb life 5-10 times compared to traditional options. Though LEDs cost $50-$100 more per fixture, their 15,000+ hour lifespan eliminates multiple replacement cycles.

Lumen output per watt has increased dramatically in LED technology, with current fixtures producing 75-100 lumens per watt versus 10-15 for incandescent options. This efficiency improvement explains the dramatic energy savings.

Color rendering index (CRI) affects water appearance, with higher CRI values (90+) providing more natural color representation than lower-rated alternatives. This quality difference is particularly noticeable in clear water.

Driver technology determines dimming capability and longevity, with constant-current drivers offering superior performance to voltage-regulated alternatives in underwater applications. This technical distinction significantly impacts both light quality and fixture lifespan.

Consider color-changing LED options that provide both aesthetic flexibility and energy efficiency. These versatile fixtures allow you to change your pool’s appearance for different occasions while still delivering excellent energy performance.

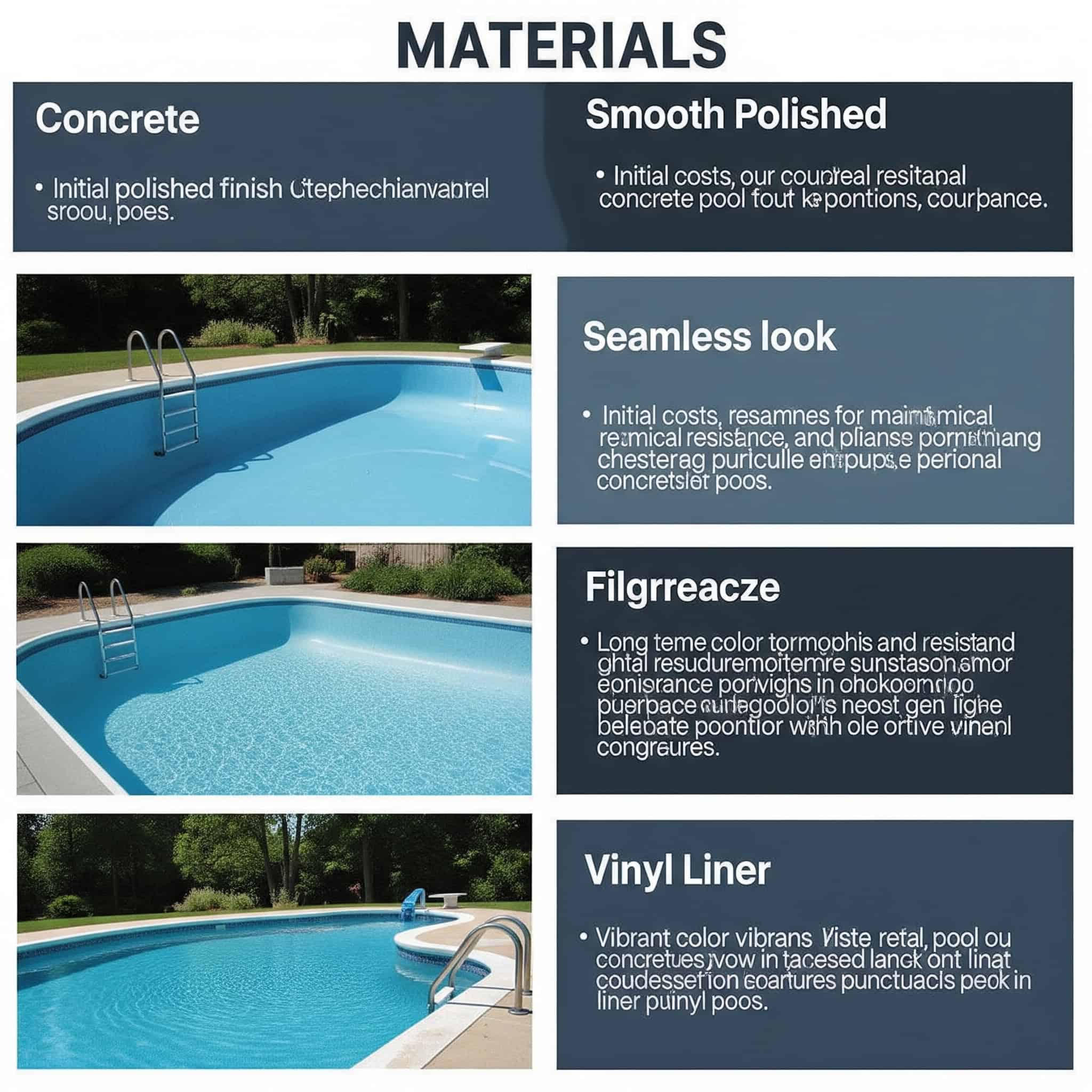

Material Selection Economics

The materials selected for your pool renovation dramatically impact both initial costs and long-term maintenance requirements. Understanding the complete lifecycle costs of each material option—from installation through maintenance to eventual replacement—provides a framework for making economically sound decisions that align with aesthetic preferences and usage patterns.

Material compatibility factors significantly impact system longevity, with chemical interactions between incompatible materials accelerating deterioration. This often-overlooked factor can dramatically reduce the lifespan of otherwise quality materials.

Regional climate considerations affect material performance differently, requiring location-specific analysis rather than general recommendations. Materials that perform beautifully in dry climates may deteriorate rapidly in humid regions.

I’ve found that focusing on material durability rather than initial cost almost always delivers better long-term value. The premium materials I selected for my pool renovation five years ago still look new, while my neighbor’s budget-friendly choices are already showing significant wear.

Surface Material Lifecycle Analysis

Pool interior surfaces vary dramatically in cost, appearance, durability, and maintenance requirements. Analyzing the complete lifecycle of each option reveals that premium materials often provide better long-term value despite higher initial costs.

Alkalinity buffering capacity varies between surface materials, with quartz and pebble finishes providing 30-50% greater resistance to pH fluctuations than plaster. This chemical stability translates to easier maintenance and longer surface life.

Ultraviolet degradation affects color stability, with premium pigments maintaining appearance 3-4 times longer than standard colorants under identical conditions. This performance difference explains why some pools fade within years while others maintain vibrant colors for decades.

Compression strength differences between surface options affect crack resistance, with fiber-reinforced materials offering 25-40% greater structural integrity than non-reinforced alternatives. This improved strength significantly reduces the likelihood of structural cracking.

During my pool renovation consultation, I was initially shocked at the $12,000 price difference between standard plaster and a premium pebble finish. However, the contractor provided a 20-year lifecycle cost comparison that completely changed my perspective. The analysis showed that while plaster would require full resurfacing three times over 20 years at a total cost of approximately $21,000 (including initial installation), the pebble finish would need just one minor touch-up around year 15 at a total 20-year cost of $18,500. Factor in reduced chemical costs and fewer maintenance closures, and the premium material actually saved money over the long term while providing a superior appearance and swimming experience.

This analysis helps you select surfaces that balance immediate budget constraints with long-term performance.

Chemical Compatibility Factors

Different surface materials react uniquely to water chemistry fluctuations, with significant cost implications. Plaster surfaces deteriorate rapidly with pH variations, while quartz aggregates offer 40-60% more chemical resistance.

Calcium saturation requirements vary by surface type, with plaster requiring calcium hardness of 200-400 ppm while fiberglass tolerates 80-150 ppm without damage. This difference significantly impacts chemical management complexity.

Acid washing frequency requirements differ dramatically, with plaster needing treatment every 3-5 years while pebble surfaces may go 10-15 years between treatments. These maintenance differences translate directly to long-term cost variations.

Salt system compatibility varies by surface composition, with some plaster blends experiencing 15-25% faster deterioration when exposed to salt chlorination. This compatibility issue can dramatically reduce surface lifespan if not properly addressed.

Document the specific chemical sensitivity of each material option and calculate the cost of maintaining optimal chemistry based on your historical maintenance patterns. This personalized approach provides much more accurate lifecycle cost projections than generic estimates.

Texture Degradation Timeline

Surface textures evolve differently over time, affecting both aesthetics and functionality. Smooth plaster becomes increasingly rough as it ages, while pebble finishes maintain consistent texture throughout their lifespan.

Microscopic porosity increases over time in cementitious surfaces, creating additional surface area that harbors algae and consumes 15-30% more chemicals annually. This progressive deterioration explains why older pools often require more chemicals despite consistent usage.

Abrasion resistance varies significantly, with exposed aggregate finishes losing less than 1mm thickness over 10 years compared to 3-5mm for plaster under identical use conditions. This wear resistance directly impacts surface longevity.

Surface profile changes affect water flow characteristics, with roughening surfaces creating turbulence that reduces circulation efficiency by 5-15% over the material’s lifespan. This efficiency loss translates to higher pumping costs as surfaces age.

This degradation affects not only appearance but also maintenance costs, as rough surfaces require more aggressive cleaning and higher chemical usage. Understanding these progression patterns helps project true lifetime costs for different surface options.

Decking Material Economic Analysis

Pool deck materials represent 20-35% of renovation costs while significantly impacting safety, comfort, and maintenance requirements. The economic analysis must consider not only installation costs but also heat reflection, slip resistance degradation, and repair accessibility.

Load-bearing capacity requirements vary by installation type, with elevated decks requiring materials capable of supporting 100+ pounds per square foot. This structural requirement can eliminate some material options for certain applications.

Freeze-thaw cycle resistance determines longevity in seasonal climates, with some materials experiencing 3-5% annual deterioration while others remain stable for decades. This climate sensitivity explains why certain materials perform well in some regions but fail rapidly in others.

Water permeability affects both drainage requirements and surrounding landscape health, with permeable options reducing runoff by 70-90% compared to solid surfaces. This environmental factor is increasingly important in areas with stormwater management regulations.

These factors contribute to both the immediate and long-term value of your decking investment, often making premium materials more economical over their complete lifecycle despite higher initial costs.

Temperature Management Costs

Deck surface temperatures can vary by 30-40°F between materials, with darker surfaces reaching unsafe temperatures above 140°F in direct sunlight. This heat absorption affects both usability and pool water temperature, potentially increasing cooling costs in warm climates.

Solar reflectance index (SRI) quantifies heat reflection, with high-SRI materials (50+) remaining 20-30°F cooler than low-SRI alternatives (0-25) under identical conditions. This measurable difference directly impacts comfort and usability.

Thermal mass characteristics determine heat retention duration, with dense materials radiating stored heat for 4-6 hours after sunset. This heat retention can be either beneficial or problematic depending on your climate and usage patterns.

Edge treatment options affect heat transfer to bare feet, with bullnose and rounded edges reducing contact discomfort by 30-40% compared to sharp transitions. This design detail significantly impacts comfort without affecting material performance.

When selecting deck materials for your pool renovation, temperature management is crucial for comfort. After completing your pool area, consider backyard cleaning services to remove construction debris and prepare the space for immediate enjoyment.

Consider the thermal properties of materials alongside their aesthetic appeal to avoid operational cost surprises and ensure your deck remains comfortable throughout the swimming season.

Repair Accessibility Value

Modular decking materials like pavers cost 15-25% more than poured concrete initially but offer significant savings when underground repairs become necessary.

Selective removal capabilities vary dramatically, with modular systems allowing access to 2-3 square foot areas while monolithic surfaces require breaking out sections of 15-25 square feet. This difference dramatically affects repair costs and disruption.

Replacement material matching becomes increasingly difficult with age, with poured surfaces showing visible patches while modular systems allow individual piece replacement. This aesthetic consideration becomes increasingly important as materials age and production batches change.

Structural integrity after repairs differs significantly, with segmented systems maintaining 95-100% of original strength while repaired monolithic surfaces typically achieve 70-85%. This strength difference affects long-term durability after repairs.

Calculate the replacement area required for potential plumbing repairs under different decking options to quantify this often-overlooked value factor. This analysis often reveals that modular materials deliver better lifetime value despite higher initial costs.

Lifecycle Maintenance Scheduling

Each decking material requires specific maintenance on predictable schedules. Wooden decks need sealing every 1-2 years at $1-$3 per square foot, while concrete requires resurfacing every 5-7 years at $3-$7 per square foot.

Cleaning requirement frequency varies by material porosity, with non-porous surfaces requiring 50-70% less frequent deep cleaning than porous alternatives. This maintenance difference translates directly to time and money saved over the material’s lifespan.

Sealer longevity differs dramatically by formulation and exposure, with acrylic sealers lasting 1-3 years while silicone-based products maintain effectiveness for 5-7 years. This performance difference significantly impacts maintenance frequency and lifetime costs.

Color restoration options vary in complexity and cost, with some materials offering simple reapplication processes while others require complete removal and replacement of surface layers. This restoration difference becomes increasingly important as materials age.

Document these requirements and associated costs to create an accurate lifetime ownership cost comparison. This comprehensive approach often reveals that materials with higher initial costs but lower maintenance requirements deliver better long-term value.

Creative Funding Approaches for Pool Renovation

Beyond traditional home equity loans, today’s pool owners can access innovative financing mechanisms specifically designed for aquatic renovations. These specialized options often feature more favorable terms than general home improvement loans, with interest rates typically 1-2% lower when the renovation includes energy-efficient upgrades.

Loan-to-value ratio requirements vary significantly between financing types, affecting both approval likelihood and interest rate offerings. Specialized pool loans often offer more flexible LTV requirements than traditional financing.

Term structure options impact monthly payment amounts and total interest paid, with specialized pool loans offering flexible terms not available through standard financing. These customized terms can better align with your financial situation and goals.

I was surprised to discover that my local utility company offered a special financing program for energy-efficient pool equipment with rates 2.5% lower than my bank’s home equity line. This program covered my variable-speed pump, LED lighting, and automation system—about 40% of my total renovation cost.

Understanding all available funding options helps maximize your renovation budget and often reduces total project cost through lower interest expenses.

Tax Advantage Maximization

Various tax incentives exist for specific types of pool renovations, particularly those involving energy efficiency, safety improvements, or medical necessity modifications. Identifying and documenting these potential tax benefits can offset 5-15% of your total project cost.

Documentation requirements for tax benefits include specific certification standards that must be met before project completion. These requirements often involve particular forms or certifications that must be obtained during the renovation process.

Timing considerations affect tax benefit eligibility, with some incentives requiring completion within specific calendar years. This timing factor can influence when you schedule certain aspects of your renovation.

Stacking multiple incentive programs requires careful planning to ensure compliance with potentially conflicting requirements. Some programs specifically allow combination with other incentives while others prohibit it.

Consulting with a tax professional before finalizing your renovation plan ensures you incorporate eligible components and maintain proper documentation throughout the project.

Energy Efficiency Tax Credits

Federal and state tax programs reward energy-conscious pool upgrades, with credits available for high-efficiency pumps, solar heating, and automated covers. These incentives typically cover 10-30% of qualifying equipment costs up to predetermined caps.

Certification requirements vary by program, with some requiring Energy Star ratings while others use specific efficiency metrics like Total Efficiency Factor (TEF). Understanding these specific requirements ensures your equipment qualifies for available incentives.

Documentation standards include manufacturer certification forms, detailed invoices separating eligible components, and proof of installation completion dates. Maintaining these records is essential for claiming available credits.

Carryover provisions allow unused credits to be applied to future tax years in many programs, affecting project timing decisions for maximum benefit. This flexibility can be particularly valuable for larger renovations with substantial eligible components.

Consult with a tax professional before finalizing your renovation plan to ensure your design incorporates credit-eligible components. This proactive approach maximizes available incentives while ensuring compliance with all program requirements.

Medical Necessity Documentation

Pool renovations that address specific health conditions may qualify as tax-deductible medical expenses when properly documented. Accessibility features, therapeutic modifications, and certain heating systems can meet IRS requirements if prescribed by healthcare providers.

Prescription requirements include specific language connecting the renovation to treatment of diagnosed medical conditions rather than general wellness benefits. This medical necessity documentation is essential for qualifying expenses.

Reasonable cost standards apply to medical deductions, requiring demonstration that modifications don’t exceed necessary expenditures for therapeutic benefit. This standard prevents claiming luxury features as medical necessities.

Primary purpose tests must be satisfied, documenting that medical necessity rather than general improvement motivated specific renovation components. This distinction is crucial for IRS compliance.

Maintain thorough documentation including medical recommendations, before/after functionality assessments, and how modifications address specific health needs. This comprehensive documentation supports your deduction claims if questioned.

Contractor Financing Evaluation

Many pool renovation companies offer in-house financing options that appear convenient but often contain hidden costs and restrictive terms. Understanding how to evaluate these offers against third-party alternatives can save thousands over the life of your loan.

Fee structure transparency varies dramatically between financing providers, with some burying significant charges in complex contract language. These hidden fees can substantially increase your effective interest rate.

Credit reporting practices differ between in-house and traditional financing, affecting both approval standards and impact on credit profiles. Some contractor financing doesn’t report positive payment history, missing an opportunity to build your credit.

Lien positioning affects property sale flexibility, with some financing methods creating complications during property transfers. This consideration becomes particularly important if you might sell your home before the loan is fully repaid.

Carefully review all financing terms before committing to contractor-provided options. This diligent approach often reveals that third-party financing offers better terms despite seeming less convenient.

Interest Rate Structure Analysis

Contractor financing frequently employs promotional rates that escalate significantly after introductory periods. These “teaser rates” typically jump 5-10% after 6-12 months, dramatically increasing your effective project cost.

Compound interest calculation methods vary between financing options, with some applying interest to previously accrued interest in ways that accelerate total costs. This compounding approach can substantially increase your total repayment amount.

Rate adjustment triggers include both time-based changes and external index movements, creating variable cost projections under different economic scenarios. Understanding these triggers helps project true financing costs under various conditions.

Default rate provisions often impose severe penalties, with some financing agreements increasing rates by 10-15% after single missed payments. These punitive terms can create financial hardship if payment difficulties arise.

Calculate the complete interest expense across the full repayment term rather than focusing solely on initial payment amounts. This comprehensive analysis often reveals that seemingly attractive financing offers actually cost significantly more over their full term.

Prepayment Penalty Identification

Hidden prepayment penalties in contractor financing agreements can trap homeowners who later wish to refinance or pay off their renovation loans early. These penalties typically range from 2-5% of the remaining balance or disguise themselves as “administrative fees.”

Penalty calculation methods vary widely, with some based on remaining principal while others incorporate projected interest over specific time periods. This calculation difference can significantly impact the cost of early repayment.

Declining balance structures reduce penalties over time in some agreements while others maintain fixed percentages regardless of loan age. Understanding this structure helps determine optimal repayment timing if early payoff becomes possible.

Exemption clauses may exist for specific prepayment scenarios like home sales or refinancing, but typically require specific documentation to invoke. These exemptions can provide valuable flexibility if properly understood and documented.

Request explicit written confirmation regarding prepayment terms before signing any financing agreement. This documentation protects your future financial flexibility and prevents unexpected penalties.

Psychological Aspects of Pool Renovation Decisions

The emotional dimensions of pool remodeling significantly influence budgeting decisions and satisfaction outcomes. Understanding the psychological factors at play helps homeowners make financially sound choices while still achieving the emotional benefits that motivated their renovation.

Decision fatigue impacts choice quality as renovation processes progress, with later decisions showing measurably less optimal outcomes. This cognitive limitation explains why many homeowners make poorer choices toward the end of their renovation planning.

Anchoring effects cause initial price exposures to disproportionately influence perceived value throughout the project. This psychological phenomenon explains why initial quotes so strongly influence budget expectations.

Have you considered how your emotional connection to your pool area might be influencing your renovation decisions? I found that separating my practical needs from my emotional wants helped me prioritize spending on features that delivered the greatest long-term satisfaction.

Recognizing these psychological influences helps balance emotional desires with practical constraints, leading to renovation decisions that provide lasting satisfaction without unnecessary financial strain.

Expectation Management Framework

Unrealistic expectations represent the primary source of dissatisfaction with pool renovations, with 65% of homeowner disappointment stemming from misaligned expectations rather than actual project deficiencies. Developing a structured approach to expectation setting improves both decision-making and ultimate satisfaction with your renovation results.

Confirmation bias leads homeowners to selectively notice information that supports their existing beliefs about renovation outcomes while overlooking contradictory evidence. This cognitive bias often reinforces unrealistic expectations despite clear evidence to the contrary.

Optimism bias consistently causes underestimation of timeline and complexity factors by 20-40% compared to statistical averages. This psychological tendency explains why so many homeowners are surprised by delays and complications despite contractor warnings.

Reference point dependency affects satisfaction levels, with outcomes judged relative to expectations rather than objective quality standards. This psychological phenomenon explains why identical renovations can generate dramatically different satisfaction levels based solely on pre-project expectations.

Visualization Technique Implementation

Professional renderings cost $500-$1,500 but dramatically reduce expectation misalignment by providing realistic previews of finished results. These visualizations help identify preference discrepancies before construction begins and serve as reference documents when evaluating the completed project.

Rendering accuracy varies significantly between providers, with photorealistic techniques achieving 85-95% visual fidelity while conceptual approaches may represent only 60-70% of actual appearance. This quality difference significantly impacts expectation management effectiveness.

Material representation limitations affect expectation setting, with certain finishes (particularly water-reactive surfaces) showing significant differences between digital and physical appearance. Understanding these limitations helps interpret visualizations appropriately.

Perspective selection influences perception, with renderings from multiple viewpoints providing more comprehensive understanding than single-angle representations. This multi-perspective approach creates more accurate expectations of how the completed project will look from different vantage points.

Request both daytime and nighttime renderings to understand how lighting impacts appearance. This dual visualization approach prevents disappointment with evening appearance, a common issue when only daytime renderings are provided.

Decision Fatigue Mitigation

The average pool renovation requires over 50 distinct material, equipment, and design decisions. This volume creates decision fatigue that often leads to poor choices in later project phases.

Cognitive resource depletion follows predictable patterns, with decision quality declining approximately 5% with each major choice made in succession without breaks. This progressive deterioration explains why later decisions often produce less satisfactory results.

Decision interdependency mapping identifies choice sequences that minimize rework and regret by addressing foundational decisions before dependent options. This structured approach prevents cascading changes when later decisions necessitate revising earlier ones.

Choice architecture structuring reduces decision complexity by eliminating incompatible options early in the process rather than evaluating all possibilities simultaneously. This streamlined approach preserves cognitive resources for truly important decisions.

Combat this phenomenon by grouping decisions into priority tiers and scheduling decision-making sessions during peak mental energy periods, typically early in the day. This strategic approach maintains decision quality throughout the renovation planning process.

Renovation Regret Prevention

Post-renovation regret commonly centers on features homeowners wish they had included rather than elements they chose to implement. Understanding common regret patterns helps prioritize investments that maximize long-term satisfaction.

Temporal discounting causes undervaluation of future benefits compared to immediate costs, leading to regretted economizing on long-term features. This psychological tendency explains why many homeowners later wish they had invested in higher-quality materials or more comprehensive features.

Feature utilization studies show significant disparities between anticipated and actual usage patterns, with some highly desired features seeing minimal actual use. This usage disconnect explains why expensive features sometimes deliver disappointing value.

Adaptation rate variations affect satisfaction duration, with some features providing sustained enjoyment while others quickly become normalized and unnoticed. Understanding these adaptation differences helps prioritize investments in features that provide lasting satisfaction.

Addressing potential regret factors during planning prevents disappointment after project completion. This proactive approach focuses investment on features that consistently deliver high satisfaction while avoiding those that typically generate regret.

Future-Proofing Infrastructure

Installing conduit for future electrical needs and plumbing access points for potential water features adds minimal cost during renovation ($300-$800) but saves thousands if additions become desirable later.

Conduit sizing requirements should exceed current needs by 30-50% to accommodate future technology with potentially larger wiring requirements. This excess capacity ensures future compatibility without knowing specific future needs.

Access point positioning requires strategic planning based on likely future feature locations, with incorrect placement reducing or eliminating future value. This positioning consideration requires thoughtful analysis of potential future additions.

Documentation standards for hidden infrastructure determine future usability, with comprehensive mapping and material specifications essential for maximizing long-term value. Without proper documentation, future contractors may be unable to locate or utilize installed infrastructure.

Identify likely future upgrades based on family evolution patterns and incorporate necessary infrastructure even if the features themselves are deferred. This forward-thinking approach preserves future options at minimal current cost.

Usage Pattern Alignment

Renovation plans often reflect aspirational rather than actual usage patterns, leading to expensive features that go unused. Document your family’s pool usage over several weeks before finalizing plans, noting time of day, activities performed, and features utilized.

Activity zoning analysis identifies spatial usage patterns that may not be consciously recognized but significantly impact satisfaction with renovation outcomes. This objective analysis often reveals usage patterns that differ from perceived ones.

Temporal distribution mapping reveals usage concentration during specific dayparts, informing lighting, heating, and convenience feature decisions. Understanding when you actually use your pool helps prioritize features that enhance that specific usage.

User preference variation within households often goes unaddressed, with renovation plans frequently reflecting primary decision-maker preferences rather than composite family needs. Considering all users’ preferences typically produces higher overall satisfaction.

This data-driven approach prevents investing in rarely-used features while highlighting high-value improvements aligned with established patterns. The resulting renovation better serves your family’s actual needs rather than idealized usage scenarios.

Contractor Selection Science

The process of selecting a pool renovation contractor involves more than comparing quotes and reviewing portfolios. Understanding the business models, specialization advantages, and communication frameworks of different contractor types enables homeowners to identify the optimal partner for their specific project requirements.

Business model variations significantly impact project management approaches, with different compensation structures creating distinct incentive alignments. These structural differences explain why seemingly similar contractors can deliver dramatically different experiences.

Communication protocol effectiveness varies dramatically between contractors, affecting both satisfaction and outcome quality regardless of technical capability. This communication factor often determines overall project satisfaction more than technical skill.

When I interviewed contractors for my pool renovation, I was surprised by how differently they approached the project. Some focused exclusively on aesthetic improvements while others immediately identified hydraulic issues that would compromise any cosmetic upgrades. This difference in approach revealed their varying expertise and priorities.

This systematic approach improves both renovation outcomes and project experience by matching contractor strengths with your specific project requirements.

Specialization Value Assessment

Contractors with specialized focus on specific renovation types typically deliver superior results at 5-15% lower costs than general pool builders who occasionally handle renovations. This specialization advantage stems from established supplier relationships, refined processes, and deeper experience with renovation-specific challenges.

Process refinement metrics reveal efficiency differences, with specialized contractors typically completing similar projects 20-30% faster than generalists. This time efficiency translates to both cost savings and reduced disruption.

Problem resolution capabilities differ significantly, with specialists demonstrating 40-60% faster diagnosis and solution implementation for common renovation challenges. This troubleshooting advantage prevents the delays and cost overruns that often plague complex renovations.

Material wastage rates show measurable differences, with specialists typically utilizing 5-10% less material through optimized estimation and application techniques. This efficiency difference directly impacts project costs.

Finding specialized contractors for your pool renovation is similar to choosing between service companies in any field – expertise and specialization often deliver better results than working with generalists who handle many different project types.

Identifying truly specialized renovation contractors improves both quality and value by leveraging their focused expertise and established processes.

Equipment Sourcing Transparency

Specialized renovation contractors typically maintain relationships with multiple equipment suppliers, offering broader selection and often 10-20% better pricing than general contractors with limited supplier networks.

Volume purchasing discounts vary significantly between contractors, with high-volume specialists often receiving 15-25% better pricing than occasional buyers. These purchasing advantages can translate directly to customer savings.

Warranty registration practices affect long-term protection, with some contractors failing to properly document manufacturer warranties while others provide supplemental coverage. This documentation difference significantly impacts equipment protection.

Compatibility verification processes differ in thoroughness, with specialists typically performing more comprehensive integration testing before finalizing equipment selections. This verification process prevents compatibility issues that often plague complex systems.

Request disclosure of markup percentages on equipment and explore the possibility of direct purchasing for major components to eliminate markup entirely. This transparency creates both cost savings and accountability throughout the equipment selection process.

Renovation-Specific Problem Anticipation

Experienced renovation specialists develop pattern recognition for hidden issues common in pool updates. This anticipatory knowledge helps identify potential problems before demolition begins, reducing change orders by 30-50% compared to general contractors.

Diagnostic technology utilization varies widely, with specialists employing advanced tools like thermal imaging and sonar leak detection that generalists may lack. These diagnostic capabilities identify hidden issues before they become expensive surprises.

Historical data application differentiates contractors, with experienced specialists drawing on documented patterns from hundreds of similar projects to anticipate issues. This pattern recognition allows for proactive problem-solving rather than reactive fixes.

Contingency planning approaches reveal expertise differences, with specialists developing specific response protocols for common renovation surprises rather than generic allowances. These targeted contingency plans typically resolve issues more efficiently than generalized approaches.

Ask prospective contractors to outline the typical hidden issues they encounter and their standard protocols for addressing each. This discussion reveals their renovation-specific expertise while helping you prepare for potential complications.

Contract Structure Optimization

Pool renovation contracts vary significantly in structure, detail level, and homeowner protections. Understanding contract models allows for negotiation of terms that balance risk appropriately while incentivizing quality and efficiency.

Specification detail levels correlate strongly with outcome satisfaction, with comprehensive contracts containing 3-5 times more detail than problematic agreements. This specification detail prevents misunderstandings and ensures clear expectations.

Dispute resolution mechanisms vary in effectiveness, with clearly defined escalation procedures reducing resolution time by 50-70% compared to vague provisions. These structured processes prevent minor disagreements from becoming major conflicts.

Risk allocation balance affects both pricing and contractor behavior, with one-sided agreements often resulting in defensive work practices that reduce quality. Balanced contracts typically produce better outcomes for both parties.

Optimizing your contract structure before work begins prevents disputes and ensures clear expectations for all parties. This proactive approach significantly improves both the renovation process and final results.

Payment Schedule Engineering

Standard payment schedules often front-load contractor compensation, reducing leverage as the project progresses. Restructure payment milestones to maintain 30-40% of total payment until final completion, with clearly defined criteria for what constitutes “completion.”

Milestone definition specificity determines payment trigger clarity, with objective completion criteria preventing disagreements about stage completion. These clear definitions prevent payment disputes during the project.

Retention percentage effectiveness follows a curve rather than linear relationship, with amounts below 5% providing insufficient motivation while amounts above 10% potentially creating adversarial relationships. This balanced approach maintains contractor motivation without creating financial hardship.

Release condition documentation requirements affect both parties’ rights, with clearly defined testing protocols and acceptance standards preventing disputes during project finalization. These objective standards ensure quality completion before final payment.

Include retention clauses that withhold 5-10% of the final payment for 30-60 days after completion to ensure all systems function properly. This retention period provides protection against latent defects that might not be immediately apparent.

Change Order Protocol Development

Change orders drive cost overruns in 70% of pool renovations, with prices for changes typically 30-50% higher than identical work included in the original contract.

Pricing formula transparency varies dramatically between contractors, with some providing detailed cost breakdowns while others offer only lump-sum figures for changes. This transparency difference significantly impacts change order fairness.

Schedule impact documentation requirements affect project timeline protection, with comprehensive protocols requiring both duration and sequence effect analysis. This impact documentation prevents schedule manipulation through change orders.

Approval hierarchy definition prevents unauthorized changes, with clear designation of which representatives can authorize modifications at various cost thresholds. This authority structure prevents unexpected changes and associated costs.

Establish a detailed change order protocol that requires written approval, transparent pricing calculations, and schedule impact assessments before any deviation from original specifications. This structured approach prevents the change order escalation that plagues many renovations.

Post-Renovation Value Maximization

The period immediately following pool renovation presents unique opportunities to maximize return on investment through proper commissioning, documentation, and maintenance program establishment. These critical activities are frequently overlooked but significantly impact both the lifespan of renovated components and the property value enhancement achieved.

Value retention curves differ dramatically based on post-renovation practices, with proper commissioning and documentation increasing value retention by 15-25% over five years. This performance difference explains why some renovations maintain value while others deteriorate rapidly.

Warranty validation requirements often include specific maintenance documentation, with improper procedures potentially voiding manufacturer protections. This documentation requirement makes proper post-renovation procedures essential for warranty protection.

I was surprised by how much difference proper startup procedures made for my renovated pool. The contractor who took time to properly balance chemistry, calibrate equipment, and document baseline performance delivered a system that has operated flawlessly for years, while my neighbor’s similarly renovated pool has required multiple service calls due to improper commissioning.

Proper post-renovation procedures protect and extend your investment, ensuring maximum value from your renovation expenditure.

Professional Commissioning Processes

Proper system commissioning extends equipment life by 25-40% while ensuring optimal efficiency from the start. This systematic approach to initializing renovated systems goes far beyond the basic startup procedures typically performed by contractors.

Calibration sequence optimization affects both immediate performance and long-term efficiency, with proper procedures reducing energy consumption by 10-15% compared to standard startups. This efficiency difference begins immediately and continues throughout equipment life.

Component interaction verification identifies potential conflicts between systems that may not manifest immediately but could cause premature failures. This proactive identification prevents cascading failures that often occur weeks or months after renovation completion.

Performance baseline establishment creates reference points for future maintenance, with comprehensive documentation enabling early identification of declining efficiency. These baselines allow for preventive maintenance before noticeable problems develop.

Professional commissioning establishes proper operation parameters for all new systems and documents baseline performance metrics. This comprehensive approach ensures your renovation delivers maximum performance and longevity from the start.

Baseline Performance Documentation

Establishing performance baselines during commissioning creates reference points for future maintenance and troubleshooting. Document flow rates, pressure readings, chemical consumption rates, and energy usage during the first month of operation.

Measurement standardization protocols ensure consistent data collection, with specific test conditions documented to enable valid future comparisons. This standardization makes baseline data truly useful for future reference.

Sensor placement affects reading accuracy, with proper positioning capturing representative data while improper locations may provide misleading information. This positioning consideration significantly impacts data reliability.

Documentation format standardization improves long-term usability, with structured data collection templates facilitating trend analysis across extended time periods. This structured approach makes information accessible and useful years after collection.

These baselines allow for early identification of declining performance long before noticeable problems develop. This early detection capability often prevents minor issues from becoming major failures.

Water Chemistry Stabilization

New pool surfaces and equipment require specialized chemical balancing during the critical break-in period. Improper initial chemistry management causes surface deterioration that reduces material lifespan by 20-30%.

Curing process chemistry requirements differ significantly from normal operation parameters, with specific pH, alkalinity, and calcium hardness targets for different surface materials. These specialized requirements protect new surfaces during their vulnerable curing period.

Adjustment rate limitations prevent shock to new surfaces, with gradual changes of no more than 0.2 pH units or 20 ppm alkalinity per day during stabilization. This gradual approach prevents chemical damage to uncured surfaces.

Testing frequency requirements increase during stabilization, with daily testing recommended for the first week followed by every-other-day for three weeks before transitioning to normal schedules. This intensive monitoring ensures optimal conditions during the critical curing period.

Implement a 30-day stabilization protocol with more frequent testing and gradual chemical adjustments rather than large corrections. This methodical approach protects your investment during its most vulnerable period.

Documentation Package Development

Comprehensive documentation of your renovation enhances both maintenance effectiveness and property value. This portfolio of information serves multiple purposes from warranty enforcement to eventual resale value justification.

Warranty documentation hierarchies organize coverage by component, duration, and responsible party to facilitate future claims. This organized approach prevents warranty confusion when issues arise.

Maintenance requirement consolidation from multiple manufacturers creates comprehensive protocols that prevent conflicting procedures. This consolidated approach prevents maintenance practices that might void warranties or damage components.

Photographic documentation standards affect future usefulness, with specific perspectives and reference markers improving diagnostic value. These visual records provide invaluable reference when troubleshooting future issues.

Creating thorough documentation immediately after renovation completion ensures no critical information is lost over time. This comprehensive approach preserves valuable information that might otherwise be forgotten or lost.

Digital Record Organization

Create a digital archive containing all warranties, equipment specifications, contractor information, and maintenance requirements. This centralized resource simplifies future service needs and transfers seamlessly to new owners if the property is sold.

File format standardization affects long-term accessibility, with PDF/A format providing greater future compatibility than proprietary formats. This format consideration ensures documents remain accessible as technology evolves.

Redundant storage implementation protects against data loss, with cloud-based systems offering protection from local disasters or device failures. This redundancy ensures critical information remains available when needed.

Indexing methodology determines retrieval efficiency, with consistent naming conventions and metadata tagging improving searchability. This organizational structure makes information easily accessible years after collection.