DIY Outdoor Fireplace Secrets That Transform Your Backyard Into a Year-Round Paradise

Building a DIY outdoor fireplace represents one of the most rewarding projects you can tackle, especially when professional installations typically cost between $3,000 and $20,000 according to Farrell’s Landscaping. I’ve discovered that understanding the critical success factors most guides completely overlook helps you create an outdoor stone fireplace that performs beautifully for decades while avoiding costly mistakes that plague amateur builds.

When planning your DIY outdoor fireplace project, proper construction debris removal becomes essential for maintaining a clean and safe work environment throughout the build process.

Table of Contents

- The Foundation Game-Changer: Site Analysis and Environmental Integration

- Material Selection That Actually Matters for Long-Term Performance

- Advanced Construction Techniques That Prevent Costly Failures

- Post-Construction Optimization for Maximum Enjoyment

- Construction Sequencing That Saves Time and Money

- Seamless Landscape Integration Strategies

- Troubleshooting Common Performance Issues

TL;DR

- Site analysis and microclimate assessment determine 80% of your fireplace’s long-term success before you even break ground

- Material compatibility and thermal expansion planning prevent expensive cracking and structural failures

- Professional-grade construction techniques are achievable for DIYers and dramatically improve durability

- Water management systems protect your investment better than any other single factor

- Performance tuning after construction maximizes heat output and minimizes smoke issues

- Strategic construction sequencing prevents rework and material waste

- Proper landscape integration creates cohesive outdoor living spaces rather than isolated fire features

The Foundation Game-Changer: Site Analysis and Environmental Integration

Most DIY guides jump straight into construction without addressing the critical pre-build phase that determines whether your DIY outdoor fireplace becomes a beloved gathering spot or an expensive mistake. I’ve learned that understanding your specific environment, local regulations, and natural elements creates the foundation for a fireplace that works with your landscape instead of fighting against it.

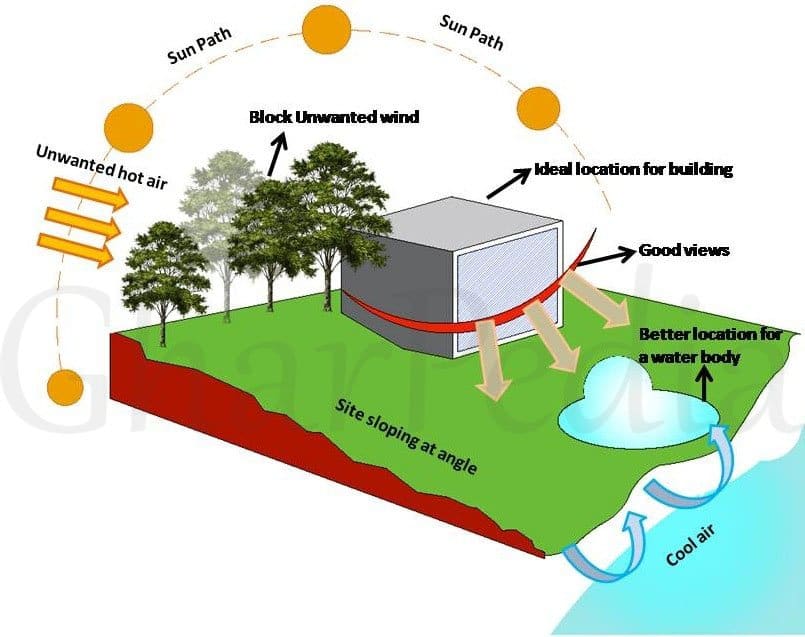

Site analysis involves mapping wind patterns, assessing soil composition, and understanding seasonal weather changes that affect fireplace performance and safety. This comprehensive approach prevents the most common and costly DIY fireplace failures when building an outdoor fireplace.

Environmental integration requires evaluating existing structures, vegetation, and microclimates to optimize placement for both functionality and aesthetic appeal. I’ve seen too many projects fail because builders ignored these fundamental considerations.

Proper pre-construction planning addresses regulatory requirements, utility locations, and neighbor relations before they become expensive problems. The time you invest in this phase pays dividends throughout the entire project.

Understanding Your Backyard’s Hidden Weather Patterns

Your DIY outdoor fireplace’s performance depends heavily on how air moves through your specific yard space and how seasonal changes affect smoke dispersion and heat distribution. Creating a comprehensive understanding of these patterns through systematic observation and documentation ensures optimal placement and design decisions that work year-round.

Microclimate assessment involves tracking temperature variations, humidity levels, and wind patterns across different areas of your property throughout the seasons. I recommend spending at least two weeks documenting these patterns before finalizing your fireplace location.

Wind pattern analysis requires documenting prevailing winds, seasonal changes, and how existing structures create wind shadows or acceleration zones. These patterns directly impact where smoke goes and how effectively your fireplace heats seating areas.

Heat distribution planning considers how thermal currents will interact with seating areas, structures, and landscaping to create comfortable outdoor spaces. Most neighborhoods require outdoor fireplaces to be at least 10 to 20 feet away from any buildings, trees, and fences according to Farrell’s Landscaping, making proper site analysis crucial for compliance and safety.

Creating Your Personal Wind Map

Developing a year-round wind diary using simple observation tools helps identify optimal fireplace placement that minimizes smoke issues and maximizes warmth distribution to seating areas. This systematic approach prevents the frustration of discovering wind problems after construction is complete and should be incorporated into your outdoor fireplace plans.

Wind mapping techniques include using ribbon flags, smoke pencils, and weather tracking apps to document wind direction and intensity at different times and seasons. I’ve found that morning patterns often differ dramatically from evening conditions.

Documentation methods involve creating seasonal wind roses and noting how weather fronts, temperature changes, and daily heating cycles affect local air movement patterns. Create a simple wind mapping system by placing colored ribbons at different heights (3 feet, 6 feet, and 10 feet) around your proposed fireplace location. Document wind direction and intensity twice daily for two weeks during different seasons. This reveals how morning thermal currents differ from evening patterns and helps identify the optimal fireplace orientation for consistent smoke evacuation.

Managing Heat Islands and Thermal Zones

Understanding how your fireplace will interact with existing structures, paved areas, and vegetation helps create comfortable microzones rather than problematic hot spots. This planning prevents uncomfortable seating areas and potential damage to nearby plants or structures.

Heat island analysis involves mapping existing thermal zones created by pavement, buildings, and sun exposure patterns throughout your property. These existing conditions significantly influence how your fireplace heat will behave.

Thermal zone planning considers how radiant heat from your fireplace will interact with these existing conditions to create optimal comfort areas for different activities and seasons. I’ve seen fireplaces that work beautifully in winter become unbearable in summer because builders ignored existing heat patterns.

Navigating the Regulatory Maze Beyond Basic Building Permits

Building codes represent just the starting point for regulatory compliance when learning how to build an outdoor fireplace. Understanding HOA restrictions, insurance implications, and neighbor relations prevents costly mistakes and legal complications that can shut down your project or create ongoing problems after completion.

Regulatory navigation involves researching multiple layers of restrictions including municipal codes, HOA covenants, and insurance requirements that may conflict with each other. I’ve encountered situations where municipal codes allow something that HOA rules prohibit.

Documentation requirements extend beyond basic permits to include detailed construction plans, safety protocols, and ongoing maintenance commitments. The paperwork might seem overwhelming, but it protects you legally and financially.

Proactive communication strategies help address potential conflicts before they become legal or insurance issues. I always recommend talking to neighbors early in the planning process.

| Regulatory Checkpoint | Timeline | Key Considerations | Potential Costs |

|---|---|---|---|

| Municipal Building Permit | 2-4 weeks | Height restrictions, setback requirements, fuel type limitations | $150-$500 |

| HOA Approval | 1-6 weeks | Architectural guidelines, neighbor notification, design review | $0-$200 |

| Insurance Notification | 1 week | Coverage verification, premium adjustments, safety requirements | $0-$300 annually |

| Utility Marking | 48-72 hours | Underground line identification, easement restrictions | Free |

| Fire Department Review | 1-2 weeks | Access requirements, water source proximity, safety protocols | $0-$150 |

Protecting Yourself Through Smart Documentation

Proactively documenting your build process and safety measures protects you legally and potentially reduces insurance premiums through demonstrated fire safety practices. This documentation becomes valuable if questions arise about construction quality or safety compliance.

Documentation protocols include photographing each construction phase, maintaining material receipts, and recording safety measure implementations. I keep a detailed project journal that includes weather conditions, material delivery dates, and any issues encountered.

Insurance optimization involves communicating with your provider about fire safety features and potentially qualifying for premium reductions through demonstrated risk mitigation. Some insurers offer discounts for properly built and maintained outdoor fire features.

Underground Utility Investigation That Goes Beyond the Basics

Moving beyond the basic “call before you dig” service to understand underground utility patterns, easements, and future access needs prevents location conflicts that could impact your fireplace placement or create expensive relocation requirements.

Utility investigation involves mapping not just current utility locations but also easements, future expansion plans, and access requirements for maintenance. I’ve seen projects delayed for months because builders discovered utility conflicts after starting excavation.

Advanced planning considers how utility locations affect foundation depth, drainage systems, and potential conflicts with fireplace components such as gas lines or electrical connections. This foresight prevents expensive redesigns during construction.

Building Positive Neighbor Relationships

Developing a diplomatic approach to discussing your project with neighbors addresses smoke concerns proactively and potentially creates shared enjoyment opportunities. This communication prevents complaints and builds community support for your project.

Communication strategies include presenting your project plans, addressing potential concerns about smoke and noise, and inviting input on design elements that affect shared views. I’ve found that neighbors appreciate being informed and consulted rather than surprised.

Relationship building involves considering how your fireplace can enhance neighborhood gatherings and potentially create shared outdoor entertainment opportunities. Some of my most successful projects have become community gathering spots that strengthen neighborhood bonds.

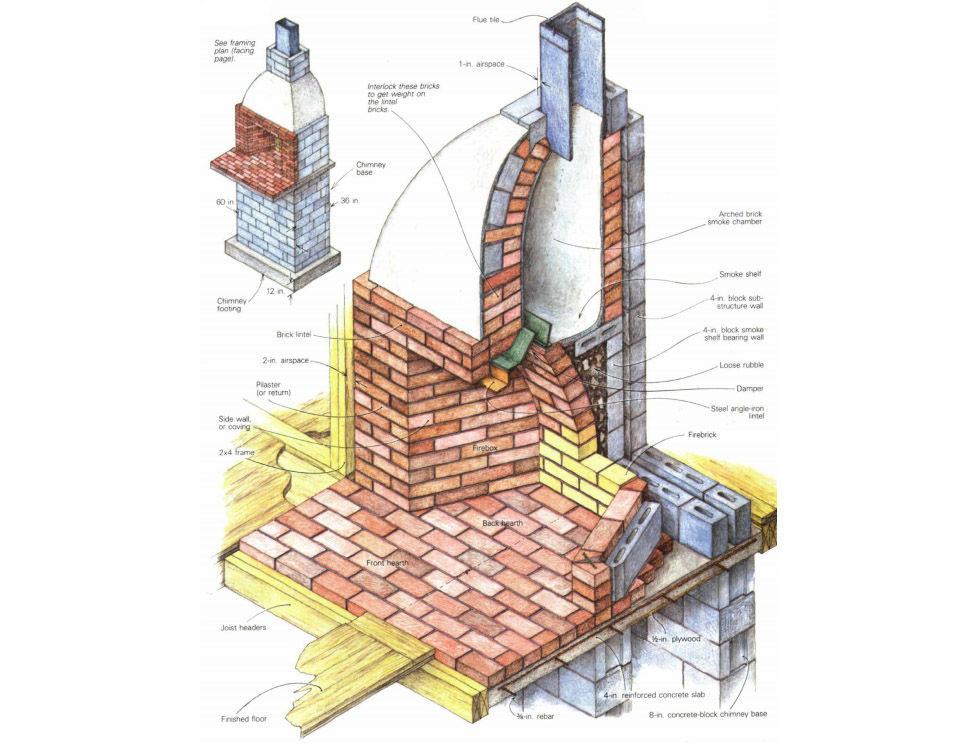

Soil Engineering That Prevents Structural Failures

The ground beneath your fireplace determines structural integrity and longevity more than any other single factor when building outdoor fireplace structures. Understanding soil behavior prevents settling, cracking, and water damage issues that can require expensive reconstruction or complete rebuilding.

Soil composition analysis involves testing for clay content, drainage characteristics, and load-bearing capacity to determine appropriate foundation design. I recommend professional soil testing for any fireplace project, as the cost is minimal compared to potential foundation problems.

Drainage engineering requires understanding how water moves through your specific soil type and designing systems that prevent water accumulation around foundation elements. Poor drainage causes more fireplace failures than any other factor.

Foundation strategies must account for seasonal soil movement, freeze-thaw cycles, and long-term settling patterns specific to your soil conditions. Different soil types require completely different approaches to foundation design and construction.

Adapting Foundation Strategies to Your Soil Type

Clay and sandy soils require completely different foundation approaches, with clay needing specialized drainage solutions and sandy soils requiring different stabilization techniques. Mixed soils demand hybrid approaches that address multiple soil behavior patterns.

Clay soil strategies involve creating drainage systems that prevent water accumulation and designing foundations that accommodate seasonal expansion and contraction cycles. Clay soils can move significantly with moisture changes, requiring flexible foundation designs.

Sandy soil approaches focus on achieving adequate load distribution and preventing settling through proper compaction and base preparation techniques. Sandy soils drain well but may not provide adequate bearing capacity without proper preparation.

Material Selection That Actually Matters for Long-Term Performance

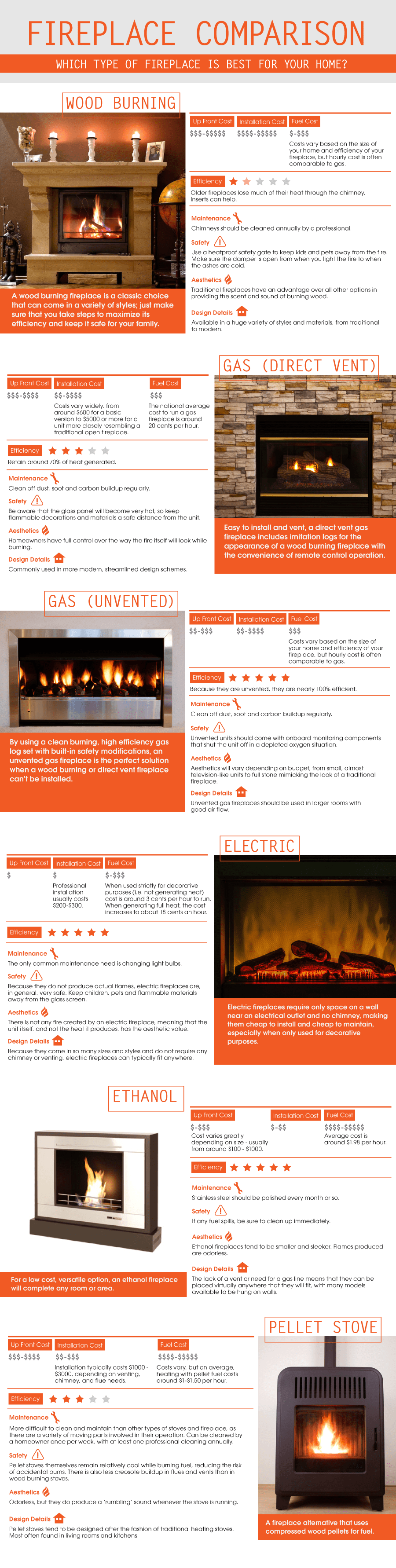

Moving beyond aesthetic choices to understand how different materials perform under thermal stress, weather exposure, and maintenance demands creates a stone outdoor fireplace that maintains its beauty and functionality for decades. This performance-focused approach prevents expensive material failures and reduces long-term maintenance requirements, whether you’re building from scratch or using DIY outdoor fireplace kits to create your outdoor stone fireplace.

For those considering alternative approaches, understanding concrete disposal methods becomes important when removing old hardscaping to make way for your new fireplace foundation.

Performance-based material selection involves evaluating thermal expansion rates, weather resistance, and maintenance requirements rather than focusing solely on appearance. I’ve seen beautiful fireplaces fail within years because builders chose materials based on looks alone.

Long-term cost analysis considers not just initial material costs but also replacement frequency, maintenance requirements, and performance degradation over time. The cheapest materials often become the most expensive over the fireplace’s lifetime.

Material compatibility ensures all components work together harmoniously under thermal stress and weather exposure without creating failure points. Incompatible materials create stress concentrations that lead to cracking and structural problems.

The Science Behind Stone Selection

Different stones behave dramatically differently under heat cycles, with some expanding and contracting at rates that cause cracking while others maintain stability through thousands of heating cycles. Understanding thermal expansion, porosity, and local availability creates a stone outdoor fireplace that performs beautifully long-term while supporting local suppliers. This knowledge is crucial for any DIY outdoor fireplace project success.

Stone performance characteristics include thermal expansion rates, porosity levels, and freeze-thaw resistance that determine long-term durability under fireplace conditions. I always test stone samples by heating them with a torch and cooling them rapidly to observe their behavior.

Local sourcing strategies involve building relationships with quarries and suppliers to access better materials at lower costs while reducing environmental impact. Local stones often perform better because they’re adapted to your climate conditions.

Material testing methods help evaluate stone samples for thermal performance, weather resistance, and compatibility with other fireplace components. Normal bricks cannot withstand the high temperatures inside a fireplace and will crack much easier, potentially causing structural collapse according to Farrell’s Landscaping, making proper material selection critical for safety and longevity.

Building Relationships with Local Stone Suppliers

Developing relationships with local quarries and stone suppliers provides access to better materials at lower costs while supporting local businesses and reducing transportation environmental impact. These relationships often provide access to premium materials and expert advice that can elevate your DIY outdoor fireplace project.

Supplier relationship building involves visiting quarries, understanding their inventory cycles, and establishing ongoing communication about material availability and quality. I’ve found that quarry operators are incredibly knowledgeable and willing to share expertise with serious DIYers.

Cost optimization strategies include timing purchases with quarry production cycles and potentially accessing premium materials that don’t meet commercial specifications but work perfectly for residential projects. Sometimes the “seconds” are actually higher quality than standard retail materials.

Creating Your Material Compatibility Matrix

Developing a material compatibility chart ensures all components expand and contract at similar rates, preventing cracking and structural failure. This systematic approach prevents the most common cause of fireplace structural problems.

Compatibility analysis involves researching thermal expansion coefficients for all materials and ensuring they fall within acceptable ranges for thermal cycling. Materials with vastly different expansion rates create stress points that lead to failure.

Matrix development creates a reference tool for material selection that prevents incompatible combinations and guides future repair or modification decisions. I keep this matrix handy throughout the project for quick reference when making material decisions.

Advanced Mortar and Binding Technologies

Modern mortar technology offers options far beyond traditional cement, with specialized high-temperature and flexible formulations that dramatically outperform standard approaches. Understanding these advanced options prevents expensive failures and extends fireplace life significantly, whether you’re building from scratch or enhancing a DIY outdoor fireplace kit.

Modern mortar formulations include refractory compounds, polymer additives, and fiber reinforcement that provide superior performance under thermal cycling and weather exposure. These advanced mortars cost more initially but save money through reduced maintenance and longer life.

Application techniques for advanced mortars require understanding mixing ratios, curing requirements, and compatibility with different stone types. Each mortar type has specific requirements that must be followed for optimal performance.

Performance benefits include reduced cracking, improved weather resistance, and extended service life compared to traditional cement-based mortars. I’ve seen 20-year-old fireplaces built with advanced mortars that look better than 5-year-old fireplaces built with standard materials.

High-Temperature Mortar Chemistry

Understanding the chemistry behind refractory mortars and recognizing when standard masonry mortar fails can save thousands in future repairs. These specialized formulations handle extreme temperature differentials that destroy conventional mortars.

Refractory mortar chemistry involves understanding how different compounds react to high temperatures and thermal cycling to maintain structural integrity. The key is selecting mortars that remain flexible under thermal stress rather than becoming brittle.

Application requirements include proper mixing techniques, curing protocols, and temperature management during installation to achieve optimal performance. I always follow manufacturer specifications exactly, as shortcuts lead to premature failure.

Weather-Resistant Additive Integration

Incorporating modern polymer and fiber additives dramatically improves mortar performance in freeze-thaw cycles and extreme weather conditions. These additives provide flexibility and strength that traditional mortars cannot match.

Additive selection involves choosing polymers and fibers that enhance specific performance characteristics such as flexibility, water resistance, or thermal stability. Different additives serve different purposes, so understanding your specific needs is crucial.

Integration techniques require understanding proper mixing procedures and compatibility with base mortar formulations to achieve desired performance improvements. Some additives require specific mixing sequences or temperatures to be effective.

Planning for Aging and Color Changes

Planning for how mortar color will change over time and weather exposure helps select formulations that age gracefully with your chosen stone. This foresight prevents disappointment and maintains aesthetic appeal over decades.

Color stability analysis involves understanding how different mortar formulations respond to UV exposure, weather cycling, and thermal stress over time. Some mortars fade dramatically while others maintain their color for decades.

Aging planning includes selecting colors and formulations that complement your stone selection as both materials develop patina and weather naturally. I prefer mortars that age to complement the stone rather than contrast with it.

Advanced Construction Techniques That Prevent Costly Failures

Professional-level construction methods that DIYers can implement create structures rivaling expensive contractor builds while avoiding common failure points. These techniques focus on managing thermal stress, water infiltration, and structural integrity through proven methods that extend DIY outdoor fireplace life and performance. Understanding how to build an outdoor fireplace properly involves mastering these advanced techniques.

During construction, managing construction waste disposal efficiently keeps your DIY outdoor fireplace project site organized and safe throughout the building process.

Advanced construction techniques involve understanding thermal management, water control, and structural engineering principles that prevent common DIY fireplace failures. These methods separate successful projects from expensive disasters.

Professional methods include specialized installation procedures, quality control measures, and systematic approaches that ensure consistent results. I’ve learned these techniques through years of trial and error, and they make the difference between amateur and professional results.

Failure prevention strategies address the most common causes of fireplace problems including thermal cracking, water damage, and structural settling. Prevention costs far less than repair or reconstruction.

Thermal Management Systems That Actually Work

Managing extreme temperature differentials prevents cracking and extends DIY outdoor fireplace life through strategic design elements that most DIY guides completely overlook. These systems distribute thermal stress and prevent the concentrated heating that causes structural failures.

Thermal management involves designing systems that distribute heat stress across multiple components rather than concentrating it in vulnerable areas. I’ve seen fireplaces crack within months because builders ignored thermal expansion principles.

Temperature differential control includes creating expansion joints, thermal breaks, and heat distribution channels that accommodate thermal movement. These elements must be planned during design, not added as afterthoughts.

System integration ensures thermal management components work together to create a cohesive approach to temperature control throughout the fireplace structure. Fire pit seating should be placed at a minimum of three feet from the fire pit according to Family Handyman, emphasizing the importance of proper thermal management in outdoor fire features.

Engineering Heat Distribution Channels

Engineering airflow channels within your fireplace structure distributes heat more evenly and reduces thermal stress on individual components. These channels also improve heat delivery to seating areas while protecting structural elements.

Channel design involves creating airflow paths that distribute heat evenly while preventing hot spots that cause thermal stress and material failure. I incorporate these channels during construction rather than trying to retrofit them later.

Integration methods include incorporating channels during construction without compromising structural integrity or creating maintenance access issues. The channels must be designed to handle thermal expansion without creating weak points in the structure.

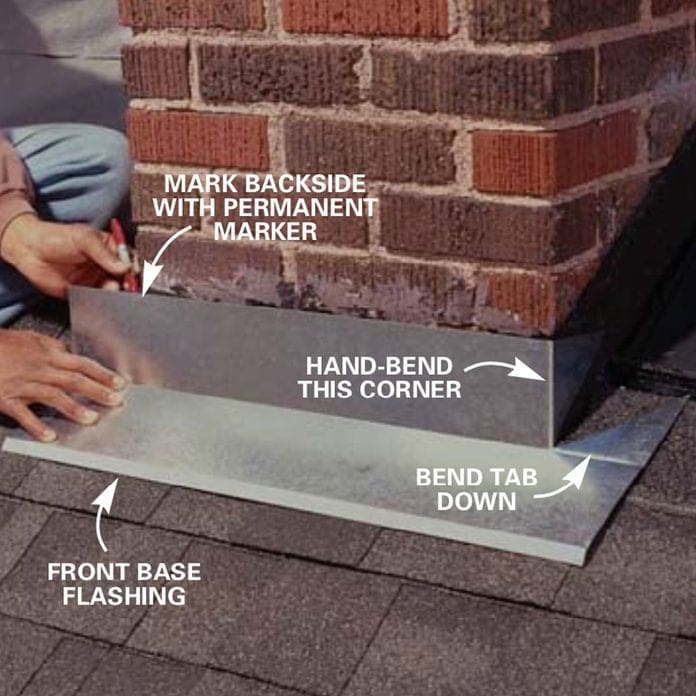

Comprehensive Water Management and Weatherproofing

Water infiltration causes more DIY outdoor fireplace failures than any other factor, making comprehensive moisture management essential for protecting your investment. Multiple defensive layers create redundant protection that prevents water damage even when individual components fail.

Water management systems involve multiple layers of protection including surface drainage, capillary breaks, and vapor barriers that work together to exclude moisture. I design these systems with redundancy so that failure of one component doesn’t compromise the entire system.

Weatherproofing strategies address different types of water intrusion including surface runoff, wind-driven rain, and ground moisture migration. Each type of water intrusion requires different defensive strategies.

System redundancy ensures that failure of one protective element doesn’t compromise the entire moisture management system. Install a three-layer water management system: First, create a 2% slope away from the fireplace base for surface drainage. Second, install a capillary break using 6-mil plastic sheeting between the foundation and first course of masonry. Third, apply a breathable masonry sealer to the exterior surfaces annually. This redundant approach prevents water infiltration even if one protective layer fails.

Installing Effective Capillary Breaks

Installing physical barriers that prevent water from wicking up through masonry uses both traditional and modern membrane techniques. These breaks stop water migration that can cause freeze-thaw damage and structural deterioration.

Capillary break installation involves placing physical barriers at strategic locations to interrupt water migration paths through masonry materials. I install these breaks at multiple levels to provide comprehensive protection.

Material selection includes traditional options such as metal flashing and modern membrane systems that provide superior long-term performance. Modern membranes often outperform traditional materials while being easier to install.

Professional Flashing Integration

Properly integrating metal flashing systems sheds water while allowing thermal movement, preventing both water damage and metal fatigue. This integration requires understanding how different materials expand and move under thermal cycling.

Flashing integration involves designing systems that shed water effectively while accommodating thermal movement of different materials. The flashing must move with the structure without creating leak points.

Installation techniques include proper overlap sequences, fastening methods, and sealant application that maintain water exclusion over decades of thermal cycling. I pay special attention to flashing details because they’re the most common failure points.

Post-Construction Optimization for Maximum Enjoyment

Completion of construction marks the beginning of optimization and lifecycle management that ensures decades of reliable operation from your DIY outdoor fireplace. Understanding maintenance requirements, seasonal preparation, and performance tuning maximizes your investment and prevents small issues from becoming expensive problems. These considerations should be built into your initial outdoor fireplace plans.

Post-construction optimization involves systematic testing, adjustment, and fine-tuning to achieve optimal performance from your completed DIY outdoor fireplace. The real work begins after the mortar cures and you light your first fire.

Lifecycle management includes developing maintenance protocols, seasonal preparation procedures, and long-term care strategies that extend fireplace life. I’ve found that fireplaces receiving proper post-construction attention last decades longer than neglected ones.

Performance monitoring helps identify potential issues early when repairs are simple and inexpensive rather than complex and costly. Regular assessment prevents minor problems from escalating into major reconstruction projects.

Performance Tuning for Optimal Operation

Fine-tuning your completed fireplace backyard installation through systematic testing and adjustment maximizes heat output, minimizes smoke production, and optimizes fuel consumption. This process transforms a functional fireplace into an efficient and enjoyable outdoor heating system.

Performance optimization involves systematic testing of draft, combustion efficiency, and heat distribution to identify areas for improvement. I spend several weeks after completion testing different configurations and fuel types.

Tuning procedures include adjusting dampers, air intakes, and fuel loading techniques to achieve optimal combustion and heat output. Small adjustments often produce dramatic improvements in performance.

Efficiency monitoring helps track fuel consumption, heat output, and operational characteristics to maintain peak performance over time. I keep detailed records of performance metrics to identify trends and potential problems.

Post-Construction Optimization Checklist:

- ☐ Test initial draft and smoke evacuation patterns

- ☐ Verify proper combustion air intake

- ☐ Check heat distribution to seating areas

- ☐ Adjust damper positions for optimal performance

- ☐ Document baseline fuel consumption rates

- ☐ Establish maintenance schedule and procedures

- ☐ Test water management systems after first rain

- ☐ Verify structural integrity after initial thermal cycling

Optimizing Draft and Airflow

Adjusting dampers, air intake, and chimney height creates optimal airflow that burns fuel completely and draws smoke away effectively. These adjustments often make the difference between a smoky, inefficient fireplace and one that performs beautifully.

Draft optimization involves adjusting air intake and exhaust systems to create proper combustion air flow and smoke evacuation. I use simple smoke tests to visualize airflow patterns and identify problem areas.

Airflow testing includes using simple tools to measure and adjust air movement patterns for optimal combustion and smoke management. A properly tuned fireplace should draw smoke consistently upward without spillage into seating areas.

Fuel Selection and Storage Systems

Matching wood species and seasoning levels to your specific fireplace design while creating storage systems that maintain optimal fuel conditions dramatically improves performance. Proper fuel management affects everything from heat output to smoke production.

Fuel selection involves understanding how different wood species burn in your specific fireplace design and choosing options that optimize heat output and minimize smoke. Hardwoods generally provide better heat output and longer burn times than softwoods.

Storage system design includes creating conditions that maintain proper moisture content and protect fuel from weather while providing convenient access. Well-seasoned wood with moisture content below 20% burns cleaner and produces more heat.

Systematic Maintenance for Long-Term Success

Developing systematic maintenance routines prevents small issues from becoming expensive problems while extending overall fireplace lifespan. These protocols identify potential problems when repairs are simple rather than waiting until major reconstruction becomes necessary for your DIY outdoor fireplace project.

Maintenance protocols involve regular inspection schedules, preventive care procedures, and systematic documentation of fireplace condition over time. I recommend monthly inspections during active use periods and comprehensive annual assessments.

Problem identification includes recognizing early warning signs of common issues such as mortar deterioration, water infiltration, or structural movement. Early detection allows for simple repairs rather than expensive reconstruction.

Preventive care strategies address potential problems before they cause damage, extending fireplace life and maintaining optimal performance. Regular cleaning, sealing, and minor repairs prevent major problems from developing.

Winter Preparation That Protects Your Investment

Implementing specific steps to protect your fireplace during freeze-thaw cycles includes drainage, covering, and material protection strategies. These preparations prevent the most common seasonal damage that affects outdoor fireplaces.

Winter preparation involves protecting vulnerable components from freeze-thaw damage through proper drainage and covering techniques. Water trapped in masonry joints can cause significant damage during freezing cycles.

Seasonal protection includes strategies for preventing water accumulation and protecting materials from thermal cycling damage during winter months. I recommend comprehensive winterization procedures for areas experiencing regular freeze-thaw cycles.

Annual Inspection Protocols

Creating detailed inspection protocols identifies potential problems early, when repairs are simple and inexpensive rather than complex and costly. These systematic checks catch issues before they compromise fireplace safety or performance.

Inspection protocols involve systematic examination of all fireplace components including structure, mortar, flashing, and drainage systems. I use a detailed checklist to ensure nothing gets overlooked during inspections.

Documentation methods include recording inspection findings and tracking changes over time to identify developing problems before they become serious. Photographic records help track deterioration patterns and plan maintenance activities.

Construction Sequencing That Saves Time and Money

Strategic build ordering prevents rework and material waste while maintaining momentum through complex multi-phase construction that can span weeks or months. Proper sequencing coordinates weather windows, material deliveries, and curing requirements to avoid costly delays and quality compromises in your DIY outdoor fireplace project. Understanding how to build an outdoor fireplace efficiently requires mastering these sequencing principles.

Effective project management includes planning for demolition waste removal when clearing existing structures to make space for your new DIY outdoor fireplace.

Construction sequencing involves coordinating multiple phases of work to optimize efficiency and prevent conflicts between different construction activities. Poor sequencing leads to expensive delays and quality compromises.

Project management includes timeline development, resource coordination, and contingency planning that keeps projects moving forward despite weather and material challenges. I’ve learned that successful projects require as much planning as execution.

Quality control measures ensure each phase meets standards before proceeding to dependent work, preventing expensive rework and material waste. Never rush to the next phase without verifying the current work meets specifications.

Timeline Development and Weather Coordination

Coordinating construction phases with seasonal weather patterns and material curing requirements avoids costly delays and quality compromises when building your DIY outdoor stone fireplace. Understanding weather windows and material requirements prevents scheduling conflicts that can shut down work for weeks.

Timeline development involves understanding weather requirements for different construction phases and scheduling work within optimal conditions. Concrete work requires specific temperature ranges while masonry work can tolerate broader conditions.

Weather coordination includes planning for seasonal variations and having contingency strategies for unexpected weather during critical work phases. The concrete foundation should cure for 24 hours before continuing construction according to Farrell’s Landscaping, making proper timeline coordination essential for project success.

Material scheduling ensures deliveries arrive when needed without extended storage periods that can compromise material quality. Coordinating deliveries with work phases prevents storage problems and material degradation.

Managing Concrete Curing in Different Temperatures

Scheduling foundation pours within optimal temperature ranges (50-90°F) and planning protection strategies for unexpected weather during the critical 7-day curing period prevents weak foundations that compromise entire projects.

Temperature management involves monitoring weather forecasts and scheduling concrete work within optimal temperature ranges for proper curing. Extreme temperatures require special procedures to achieve proper concrete strength.

Protection strategies include methods for maintaining proper curing conditions during unexpected temperature extremes or precipitation. I always have insulation blankets and heating equipment ready for unexpected cold snaps during curing periods.

Coordinating Material Deliveries

Sequencing stone, sand, and cement deliveries minimizes storage time and prevents material degradation while ensuring adequate workspace access. Poor delivery coordination creates storage problems and material quality issues.

Delivery coordination involves scheduling materials to arrive when needed without creating storage problems or workspace congestion. I coordinate with suppliers to ensure deliveries align with construction phases.

Material protection includes strategies for maintaining quality during temporary storage and preventing degradation from weather exposure. Proper tarping and elevated storage prevent moisture problems and material contamination.

Tool and Equipment Strategy

Balancing tool investment against rental costs while ensuring you have professional-grade equipment for critical structural work affects both project quality and long-term performance of your DIY outdoor fireplace. Strategic tool selection prevents quality compromises that create expensive problems later.

Equipment strategy involves analyzing which tools justify purchase versus rental based on project requirements and future use potential. Some tools are worth buying while others make more sense to rent for short-term use.

Quality considerations include understanding when professional-grade tools are essential for achieving acceptable results versus when standard tools are adequate. Critical structural work requires professional-grade equipment.

Safety requirements include ensuring all equipment meets safety standards and operators have proper training for specialized tools. Never compromise on safety equipment or training to save money.

| Tool Category | Purchase vs Rent | Estimated Cost | Critical Quality Factors |

|---|---|---|---|

| Masonry Trowels | Purchase | $50-150 | Blade flexibility, handle comfort |

| Wet Tile Saw | Rent | $40-60/day | Diamond blade quality, water system |

| Concrete Mixer | Rent | $35-50/day | Capacity, mixing efficiency |

| Level (4-foot) | Purchase | $80-200 | Accuracy, durability |

| Angle Grinder | Purchase | $60-150 | Motor power, disc compatibility |

| Wheelbarrow | Purchase | $100-300 | Load capacity, tire quality |

| Safety Equipment | Purchase | $100-200 | OSHA compliance, comfort |

Essential Masonry Tool Requirements

Investing in quality trowels, levels, and cutting equipment specific to stone work produces superior results compared to generic tools, especially in high-temperature applications where precision affects long-term performance.

Tool selection involves choosing masonry-specific equipment that handles the demands of stone work and high-temperature applications. Generic tools often fail under the stress of masonry work.

Quality investment includes understanding which tools affect final results enough to justify higher initial costs for professional-grade equipment. A quality trowel makes masonry work significantly easier and produces better results.

Comprehensive Safety Equipment

Implementing comprehensive safety protocols including respiratory protection for silica dust, burn protection for hot work, and proper lifting techniques for heavy stone placement prevents injuries that can shut down projects and create long-term health issues.

Safety equipment includes specialized protection for masonry work hazards including dust, heat, and heavy lifting requirements. Silica dust exposure requires proper respiratory protection to prevent long-term health problems.

Protocol development involves creating systematic safety procedures that protect workers throughout all phases of construction. I never compromise on safety procedures regardless of time pressure or cost considerations.

Efficient Workspace Organization

Creating efficient material staging areas and tool organization maintains productivity while keeping the job site safe and accessible for deliveries. Poor organization creates safety hazards and reduces work efficiency significantly.

Workspace design involves creating efficient material flow and tool access that maintains productivity while ensuring safety. Well-organized work areas reduce fatigue and improve work quality.

Organization systems include strategies for managing materials, tools, and waste that keep work areas clean and accessible throughout the project. I designate specific areas for different materials and maintain organization throughout the project.

Seamless Landscape Integration Strategies

Blending your DIY outdoor fireplace with existing hardscaping, plantings, and outdoor structures creates cohesive outdoor living environments rather than isolated fire features. This integration approach transforms your entire outdoor space into a unified entertainment area that enhances property value and enjoyment from your DIY outdoor fireplace investment.

When planning landscape integration, consider how garden debris removal will be managed during the construction and ongoing maintenance phases of your fireplace project.

Landscape integration involves designing connections between your fireplace and existing outdoor elements to create unified outdoor living spaces. Fire pits and fireplaces are included in 70% of landscape designs according to Architectural Digest, highlighting the importance of proper integration in outdoor living spaces.

Design coordination includes material selection, elevation changes, and visual transitions that blend new construction with existing landscape features. Successful integration makes the fireplace appear as a natural part of the landscape rather than an added feature.

Functionality planning ensures integrated elements work together to support outdoor activities and entertainment while maintaining practical access and safety. The fireplace should enhance existing outdoor spaces rather than competing with them.

Hardscape Connectivity Planning

Designing pathways, seating areas, and material transitions that flow naturally from existing patios, decks, and walkways while maintaining practical functionality creates outdoor spaces that feel intentionally designed rather than randomly assembled around your DIY outdoor fireplace.

Connectivity planning involves designing physical and visual connections between your fireplace and existing hardscape elements. These connections should feel natural and support practical use patterns.

Material coordination includes selecting materials and installation techniques that create smooth transitions between different paving and structural elements. Matching or complementary materials create visual continuity throughout the outdoor space.

Functional design ensures pathways and connections support practical use while enhancing the overall aesthetic appeal of outdoor spaces. Wide pathways accommodate furniture movement and guest circulation during gatherings.

Creating Smooth Material Transitions

Creating smooth visual and physical transitions between different paving materials, elevation changes, and architectural styles prevents jarring discontinuities that make outdoor spaces feel disjointed and poorly planned.

Transition techniques include methods for blending different materials and elevation changes that create visual continuity. Gradual transitions work better than abrupt changes in materials or elevations.

Design principles involve understanding how different materials and architectural styles can be combined harmoniously without creating visual conflicts. I prefer using transitional materials that bridge different design elements.

Strategic Lighting Integration

Planning electrical rough-in during construction for accent lighting, pathway illumination, and safety lighting enhances both aesthetics and functionality while avoiding expensive retrofitting later. Proper lighting extends usable hours and improves safety.

Lighting planning involves designing electrical systems during construction to support accent, safety, and functional lighting requirements. Installing conduit during construction costs far less than retrofitting later.

Integration techniques include methods for incorporating lighting elements that enhance fireplace use while maintaining aesthetic appeal. Install a three-zone lighting system: Zone 1 includes low-voltage LED strips under seating walls for ambient lighting, Zone 2 features uplighting behind the fireplace to highlight architectural features, and Zone 3 provides pathway lighting with solar-powered fixtures. This layered approach creates atmosphere while maintaining safety and functionality.

Fire-Safe Plant Selection and Landscaping

Choosing vegetation that enhances your DIY outdoor fireplace area while maintaining appropriate clearances and selecting species that won’t create fire hazards or maintenance problems requires understanding plant characteristics and fire safety requirements.

Plant selection involves choosing species that thrive in altered soil and temperature conditions created by fireplace use while maintaining fire safety clearances. Plants near fireplaces experience different growing conditions than other landscape areas.

Fire safety planning includes understanding clearance requirements and selecting plants that don’t create fire hazards through flammable foliage or debris. Avoiding highly flammable species near fire features reduces risk and insurance concerns.

Maintenance considerations include choosing plants that don’t require excessive care or create ongoing maintenance problems in fireplace areas. Low-maintenance plants work best in areas that experience regular foot traffic and thermal stress.

Heat-Tolerant Species Selection

Identifying plants that thrive in elevated temperatures and altered soil conditions created by regular fireplace use while providing desired screening and aesthetic effects requires understanding plant heat tolerance and soil adaptation.

Species selection involves researching plants that tolerate elevated temperatures and altered soil conditions without compromising health or appearance. Native plants often adapt better to these challenging conditions.

Design integration includes using heat-tolerant plants to create screening, aesthetic enhancement, and functional landscape elements around fireplace areas. Strategic plant placement can direct airflow and provide natural windbreaks.

Irrigation System Modifications

Adjusting existing sprinkler systems to account for heat zones and changed water requirements while protecting irrigation components from thermal damage ensures landscape health without compromising irrigation system integrity.

System modification involves adjusting irrigation zones and schedules to account for changed water requirements in fireplace areas. Plants near fireplaces may need different watering schedules than other landscape areas.

Component protection includes strategies for protecting irrigation equipment from thermal damage while maintaining effective landscape watering. Heat-resistant components and strategic placement prevent equipment damage.

Seasonal Color Programming

Planning plantings that provide visual interest during fireplace season while considering how winter dormancy affects the overall composition of your outdoor space ensures year-round aesthetic appeal when the fireplace is most used.

Seasonal planning involves selecting plants that provide visual interest during peak fireplace use periods while maintaining overall landscape composition. Winter-blooming plants and evergreen species provide color during fireplace season.

Color coordination includes understanding how seasonal changes affect plant appearance and planning combinations that work throughout the year. I prefer plants that provide structure and interest even when dormant.

Troubleshooting Common Performance Issues

Systematically diagnosing and resolving common operational issues while implementing upgrades that improve efficiency, safety, and user experience transforms problematic DIY outdoor fireplace installations into reliable outdoor heating systems. Understanding these solutions prevents expensive contractor calls and maintains optimal performance from your DIY outdoor fireplace.

When troubleshooting involves major repairs or replacements, understanding scrap metal removal options helps dispose of damaged fireplace components responsibly during renovation work.

Troubleshooting involves systematic diagnosis of common fireplace problems including poor draft, smoke issues, and inadequate heat output. Most problems have identifiable causes and practical solutions that DIYers can implement.

Performance enhancement includes implementing modifications and upgrades that improve efficiency and user experience beyond basic functionality. Small modifications often produce dramatic improvements in fireplace performance.

Problem prevention strategies address root causes of common issues rather than just treating symptoms, providing long-term solutions. Understanding why problems occur helps prevent their recurrence.

Smoke Management Solutions

Addressing poor draft, backdrafting, and neighborhood smoke complaints through mechanical and design modifications improves combustion and airflow patterns in your DIY outdoor fireplace. These solutions often transform unusable fireplaces into enjoyable outdoor heating systems.

Smoke management involves identifying causes of poor draft and smoke spillage and implementing mechanical solutions that improve airflow. Most smoke problems result from inadequate draft or poor combustion air supply.

Draft improvement includes modifications to air intake, exhaust systems, and combustion chamber design that enhance smoke evacuation. Simple modifications often solve persistent smoke problems.

Neighbor relations include strategies for addressing smoke complaints and implementing solutions that minimize smoke impact on surrounding properties. Good neighbor relations prevent complaints and potential legal issues.

Chimney Cap and Wind Guard Installation

Installing specialized caps prevents downdrafts while protecting the chimney interior from weather infiltration and animal intrusion. These devices often solve persistent draft problems that make fireplaces difficult to use.

Cap selection involves choosing designs that prevent downdrafts while maintaining proper exhaust function and weather protection. Different cap designs work better in different wind conditions.

Installation techniques include proper sizing and mounting methods that ensure effective operation without creating maintenance problems. Properly installed caps require minimal maintenance while providing years of reliable service.

Air Intake Optimization Methods

Modifying or adding combustion air intakes provides adequate oxygen for complete burning while preventing smoke spillage into seating areas. Proper air intake design often solves multiple performance problems simultaneously.

Intake design involves calculating proper air supply requirements and designing intake systems that provide adequate combustion air. Inadequate air supply causes incomplete combustion and smoke problems.

Installation methods include techniques for adding or modifying air intakes without compromising fireplace structure or creating safety hazards. Strategic intake placement improves combustion while maintaining structural integrity.

Heat Output Maximization

Implementing design modifications and operational techniques that increase useful heat delivery to occupied areas while reducing heat loss to surrounding areas dramatically improves DIY outdoor fireplace efficiency and user comfort.

Heat optimization involves implementing modifications that increase useful heat delivery while reducing waste heat loss to unoccupied areas. Strategic modifications can double effective heat output.

Efficiency improvements include techniques for maximizing fuel energy conversion to useful heat output through better combustion and heat transfer. Proper fuel selection and loading techniques significantly impact heat output.

Comfort enhancement includes strategies for directing heat to seating areas and creating more comfortable outdoor environments. Heat distribution modifications create more usable outdoor space during cold weather.

Reflective Surface Applications

Adding strategic metal or stone surfaces that redirect radiant heat toward seating areas rather than allowing it to dissipate into open space significantly improves heat delivery and user comfort without requiring major reconstruction.

Reflective design involves positioning surfaces that redirect radiant heat toward occupied areas while maintaining aesthetic appeal. Properly positioned reflectors can increase perceived heat output by 50% or more.

Material selection includes choosing reflective materials that handle thermal cycling and weather exposure while providing effective heat redirection. Stainless steel and polished stone work well for heat reflection applications.

Thermal Mass Enhancement

Increasing heat storage capacity through additional masonry mass continues radiating warmth long after the fire dies down, extending useful heating time and improving overall fireplace efficiency.

Thermal mass design involves adding heat storage capacity that absorbs energy during burning and releases it gradually over extended periods. Additional masonry mass stores heat during active burning and releases it slowly.

Integration methods include techniques for adding thermal mass without compromising existing structure or creating installation problems. Strategic mass placement maximizes heat storage while maintaining structural integrity.

How Jiffy Junk Supports Your DIY Success

Your DIY outdoor fireplace project generates significant debris and requires careful material management throughout construction. Professional removal services eliminate the stress of dealing with excavation debris, broken materials, and construction waste while keeping your work site organized and efficient.

Managing construction debris becomes overwhelming quickly. Excavation creates piles of soil and broken concrete. Stone deliveries include unusable pieces that don’t meet your standards. Mortar mixing generates waste materials that accumulate throughout the project.

Jiffy Junk’s same-day service keeps your project moving forward without debris management delays. Their eco-friendly approach ensures construction waste gets properly recycled when possible, supporting your project’s environmental responsibility. The white-glove service handles removal from wherever materials are located – whether hauling broken concrete from backyard excavation or clearing garage space for storing fireplace materials.

Ready to start your DIY outdoor fireplace project? Contact Jiffy Junk today to discuss debris removal services that keep your construction site clean and organized throughout the build process.

Final Thoughts

Building a DIY outdoor fireplace that performs beautifully for decades requires understanding principles that most guides completely overlook. Success depends more on site analysis, material compatibility, and systematic construction than on following basic building instructions.

The techniques covered here represent professional-level knowledge that’s completely achievable for dedicated DIYers. Your investment in proper planning, quality materials, and systematic construction pays dividends through decades of reliable operation and minimal maintenance requirements.

Remember that your fireplace project extends far beyond the construction phase. Performance optimization, seasonal maintenance, and ongoing care determine whether your fireplace becomes a beloved gathering spot or an expensive maintenance burden.

Professional-level results are achievable for DIYers who invest time in understanding the principles behind successful fireplace construction rather than just following basic instructions. Long-term success depends on systematic approaches to site analysis, material selection, and construction techniques that address root causes of common fireplace problems.

Ongoing optimization and maintenance transform completed fireplaces from functional structures into efficient, enjoyable outdoor heating systems that enhance property value and outdoor living. The knowledge and techniques presented here provide the foundation for creating outdoor fireplaces that rival professional installations while providing the satisfaction of personal accomplishment.