DIY Playhouse Psychology: The Hidden Science Behind Building Spaces That Actually Work for Kids

Building a DIY playhouse goes way deeper than just hammering boards together. I’ve discovered that understanding how children’s developing minds interact with their environment makes all the difference between creating a structure that collects dust and one that becomes the center of your child’s world.

Most DIY guides focus purely on construction basics, but the real magic happens when you apply psychological principles to create spaces that genuinely support childhood development. Research shows that strategic design choices can increase independent play by up to 40%, transforming a simple structure into a powerful tool for cognitive growth.

After years of building and observing how kids actually use these spaces, I’ve learned that the most successful DIY playhouse projects incorporate elements that most builders never consider. We’re talking about sight line psychology, material science, community dynamics, and even planning for the day you’ll need to take the whole thing down.

Table of Contents

- Building Beyond the Blueprint: The Emotional Architecture of Play Spaces

- The Hidden Costs of DIY: Total Lifecycle Economics

- Community Integration and Social Dynamics

- The Material Science Revolution: Beyond Traditional Lumber

- The Deconstruction Dilemma: End-of-Life Planning

TL;DR

- Children’s brain development directly influences playhouse design requirements, with strategic window placement increasing independent play by 40%

- True DIY playhouse costs extend beyond materials to include maintenance, upgrades, and disposal – most structures undergo major modifications within 18 months

- Successful playhouses integrate with neighborhood dynamics through acoustic design and visual impact mitigation strategies

- Modern composite materials and reversible fastening systems create stronger, more adaptable structures than traditional lumber approaches

- Planning for eventual disassembly during initial construction reduces disposal costs by 80% while maximizing material recovery

Building Beyond the Blueprint: The Emotional Architecture of Play Spaces

When I first started building playhouses, I thought success meant straight walls and a roof that didn’t leak. I was completely wrong. The most impactful DIY playhouse projects understand that these structures serve as tools for cognitive development that must evolve alongside growing minds.

Children’s spatial reasoning and risk assessment skills develop through controlled exploration, making playhouse design a critical component of cognitive growth rather than just entertainment. Strategic design choices that align with developmental psychology create lasting value by supporting multiple stages of childhood development within the same structure.

The Neuroscience of Safe Exploration

Your child’s brain develops spatial reasoning and risk assessment through controlled exploration, making your playhouse design a critical component of cognitive development. The structure itself becomes a learning tool that shapes how kids understand space, safety, and independence.

Controlled risk environments in playhouses activate specific neural pathways responsible for decision-making and spatial awareness development. When children navigate elevated platforms or squeeze through appropriately sized openings, they’re literally building the brain connections that will serve them throughout life.

The balance between safety and challenge in playhouse design directly correlates with children’s confidence building and problem-solving skill development. Too safe, and kids get bored. Too challenging, and they become anxious. Finding that sweet spot requires understanding how to build a playhouse that grows with your child’s developing capabilities.

Environmental psychology principles applied to playhouse construction create measurable improvements in independent play duration and creative thinking. When considering how to build a playhouse that supports cognitive development, understanding furniture removal vs donation principles can inform decisions about which play features to keep, modify, or replace as your child grows.

Sight Line Psychology in Enclosed Spaces

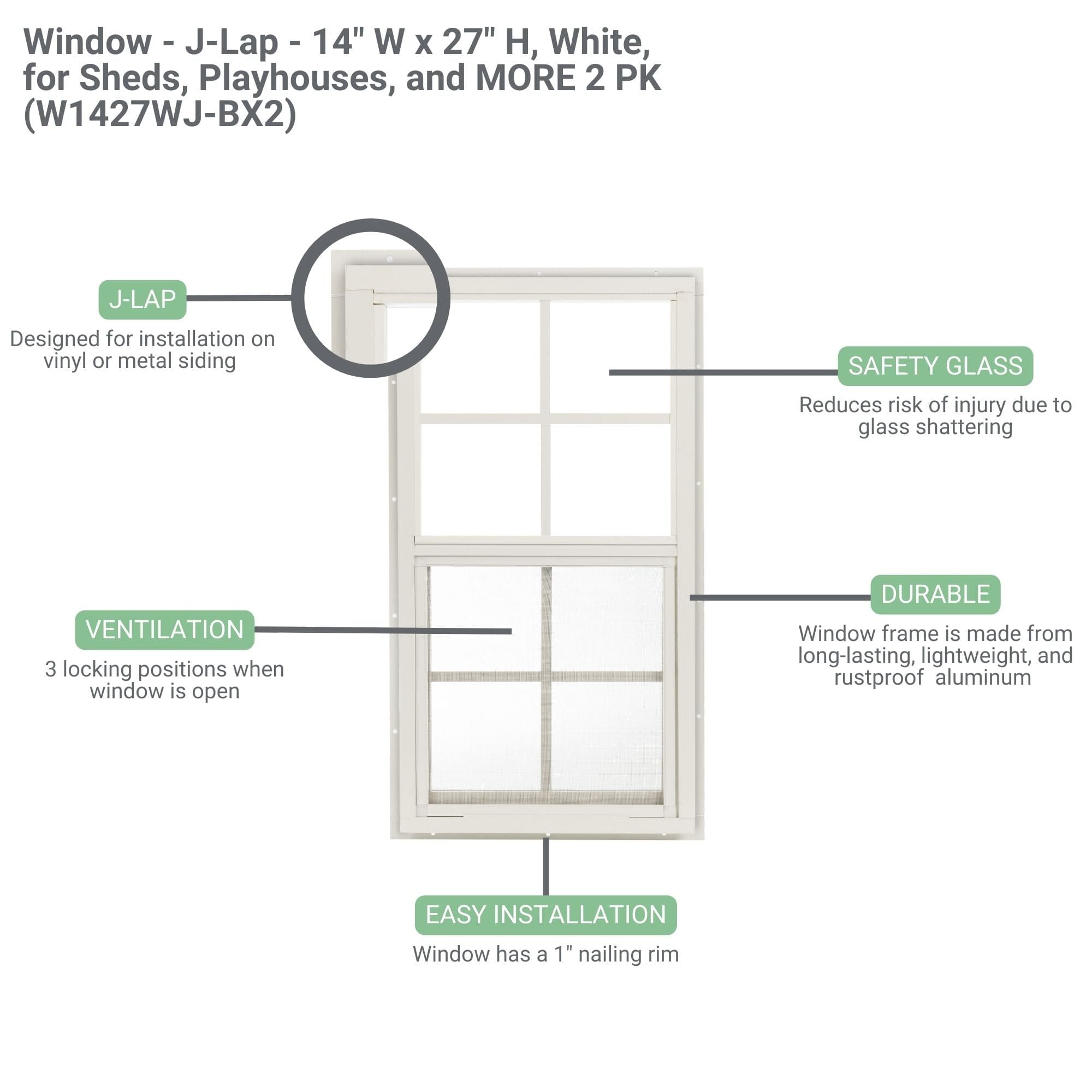

Strategic window placement affects children’s comfort levels and play patterns more than most parents realize. Research shows that partial visibility to caregivers increases independent play duration by up to 40%. The positioning and size of openings in your playhouse directly influence how secure children feel while exploring independence.

Window height and positioning should align with children’s eye level when seated to maintain visual connection with caregivers during independent play. I’ve seen too many playhouses with windows placed at adult height, leaving kids feeling isolated when they need that reassuring glimpse of mom or dad.

Partial visibility windows create the optimal balance between security and privacy that encourages extended play sessions. Full exposure windows make kids feel like they’re on display, while no windows can trigger anxiety in children who struggle with enclosed spaces.

Multiple sight line options allow children to control their level of interaction with the outside world, supporting autonomy development. Strategic placement of openings can reduce anxiety in children who struggle with enclosed spaces while maintaining the cozy feel that makes playhouses special.

Height Dynamics and Power Perception

Elevated playhouses trigger different neural pathways than ground-level structures, influencing children’s confidence and imaginative play scenarios. When kids climb up into their space, they experience a psychological shift that affects how they see themselves and their capabilities.

Elevated structures activate the brain’s reward centers associated with achievement and accomplishment, boosting self-confidence during play. Height differences create natural role-playing opportunities where children can practice leadership and decision-making from their “elevated” position.

The physical act of climbing to reach the play space serves as a transition ritual that helps children mentally shift into imaginative play mode. Different elevation levels within the same structure can accommodate various comfort levels while still providing the psychological benefits of height.

Adaptive Design for Growing Minds

The most successful DIY playhouses incorporate modular elements that can be reconfigured as children’s interests and abilities evolve. Rather than building a static structure that becomes obsolete, smart design anticipates developmental changes and creates flexibility for adaptation.

Modular design principles allow the same structure to serve multiple functions across different developmental stages, from toddler exploration to teenage retreat. Adaptable features reduce the need for complete reconstruction while maintaining engagement as children’s interests mature and change. Future-focused construction techniques create opportunities for expansion and modification without compromising structural integrity.

When planning how to build a playhouse that adapts over time, consider how to build a playhouse with these developmental stages in mind:

| Age Range | Primary Play Needs | Design Considerations | Recommended Features |

|---|---|---|---|

| 2-4 years | Sensory exploration, basic motor skills | Low entry points, rounded edges, bright colors | Ground-level access, textured surfaces, simple shapes |

| 5-7 years | Imaginative play, social interaction | Multiple activity zones, role-play elements | Kitchen sets, store fronts, multiple rooms |

| 8-10 years | Independence, complex games | Privacy options, challenging features | Elevated platforms, secret compartments, club spaces |

| 11+ years | Retreat space, study area | Mature aesthetics, functional furniture | Desks, comfortable seating, technology integration |

Convertible Interior Configurations

Removable walls and adjustable features allow the same structure to serve as a fort, reading nook, art studio, or teenage retreat over its lifetime. The key lies in designing flexibility into the original construction rather than trying to retrofit adaptability later.

Removable wall panels using reversible fastening systems allow for complete interior reconfiguration without tools or permanent modifications. Adjustable shelving and storage solutions accommodate different activity types while maintaining organization and functionality across various uses.

Modular furniture elements designed specifically for the space can be rearranged to support different play patterns and age-appropriate activities. Built-in flexibility points enable easy addition of new features as interests develop.

The Johnson family built their playhouse with removable interior panels using heavy-duty velcro strips and magnetic catches. When their 4-year-old daughter outgrew the “kitchen” setup, they easily reconfigured the space into an art studio by removing one wall panel and installing a fold-down desk. Two years later, the same space became a reading nook with built-in bookshelves. The total modification time for each change? Less than 30 minutes.

Sensory Integration Opportunities

Incorporating varied textures, acoustic elements, and lighting options supports children with different sensory processing needs. Every child processes sensory information differently, and your playhouse design can either support or hinder their comfort and engagement.

Varied texture applications on walls and surfaces provide tactile stimulation opportunities while supporting sensory regulation for children with processing differences. Acoustic design elements create calming environments or stimulating play opportunities based on individual needs.

Adjustable lighting systems allow children to control their sensory environment, supporting both high-energy play and quiet, focused activities. Natural material integration provides organic sensory experiences that support grounding and emotional regulation.

Future-Proofing Through Universal Design

Building with accessibility principles ensures the playhouse remains usable regardless of temporary injuries or diverse abilities among playmates. Universal design expands the social value of your playhouse investment by creating spaces that work for everyone.

Ramp access and wide doorways accommodate wheelchairs, mobility aids, and children with different physical abilities without compromising the play experience. Multiple interaction levels within the structure ensure that children who can’t climb stairs or ladders still have full access to play opportunities.

Sensory-friendly design elements support children with autism, ADHD, or other neurological differences while enhancing the experience for all users. Flexible seating and activity areas accommodate different body sizes and mobility levels throughout the structure’s lifetime.

The Indoor Playhouse Phenomenon

Indoor playhouses present unique challenges and opportunities that outdoor structures don’t, requiring different approaches to ventilation, materials, and integration with home aesthetics. Building inside your home creates year-round play opportunities but demands careful consideration of factors that outdoor builders never face.

Indoor construction must prioritize air quality and ventilation to prevent moisture buildup and maintain healthy play environments within existing home systems. Material selection for indoor playhouses requires different considerations around off-gassing, durability, and integration with existing home décor and safety standards. Space optimization techniques for indoor structures focus on maximizing play value within limited square footage while maintaining household functionality.

Recent trends show growing interest in indoor play spaces, with “colder months ahead prompting many families to seek indoor alternatives” according to Family Handyman. This shift reflects changing family dynamics and the need for year-round play solutions that don’t depend on weather conditions.

Climate Control Considerations

Indoor structures need careful attention to air circulation and humidity control to prevent mold and maintain healthy play environments. Your home’s existing HVAC system may not adequately serve an enclosed play structure, creating potential health and comfort issues.

Passive ventilation systems using strategic air gaps and breathable materials maintain air quality without requiring mechanical systems or major home modifications. Humidity monitoring and control prevents mold growth in enclosed spaces while maintaining comfortable play conditions year-round.

Integration with existing home climate systems requires careful planning to avoid creating dead air zones or temperature imbalances in surrounding rooms. Material selection prioritizes breathable, non-toxic options that won’t trap moisture or release harmful chemicals in enclosed indoor environments.

When planning a DIY indoor playhouse, these climate considerations become even more critical than outdoor builds where natural ventilation handles most air quality concerns.

The Hidden Costs of DIY: Total Lifecycle Economics

The true cost of a DIY playhouse extends far beyond initial materials, encompassing maintenance, upgrades, and eventual disposal considerations that most builders overlook. I’ve watched families get shocked by ongoing expenses they never saw coming during the planning phase.

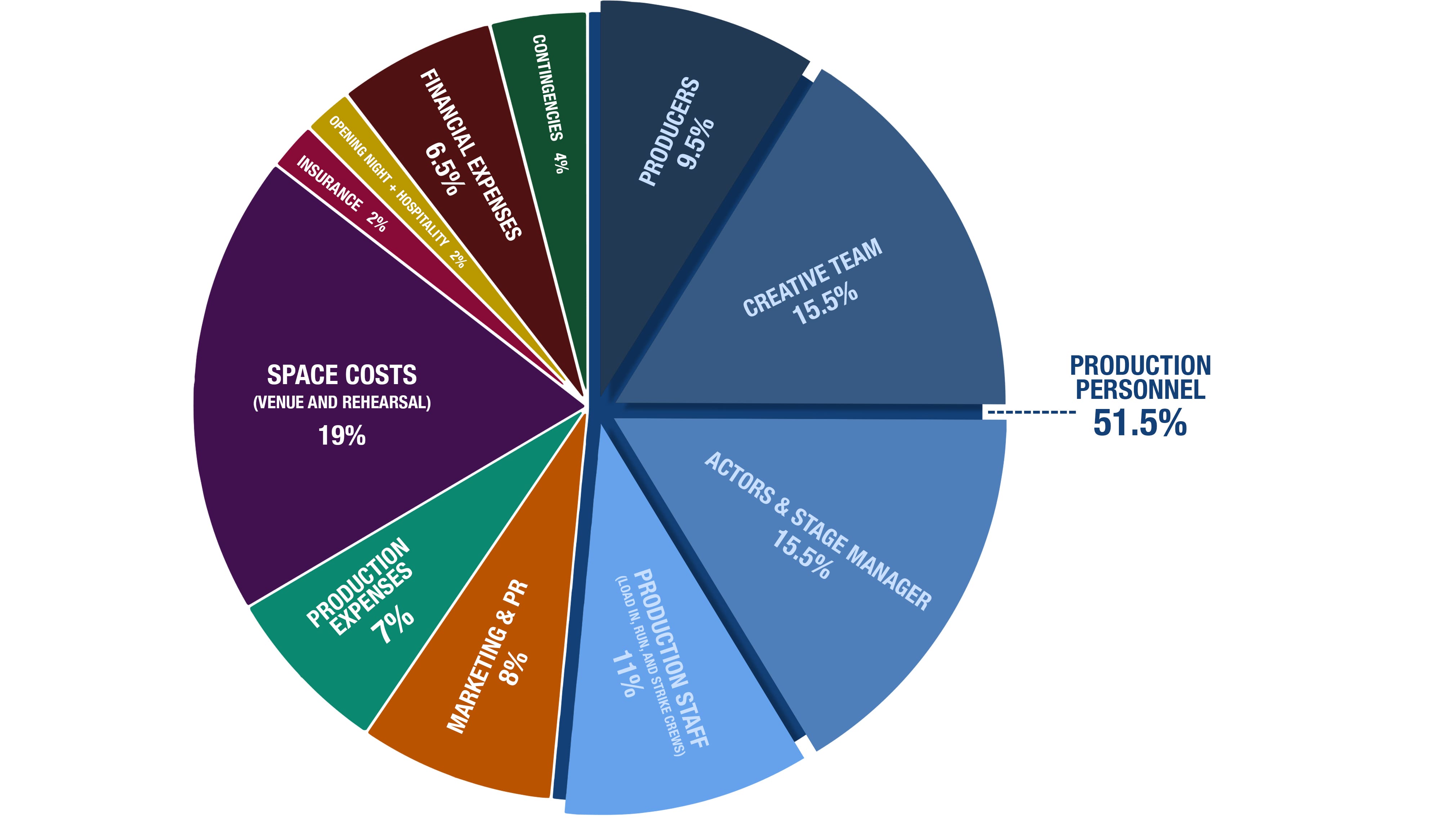

Total cost of ownership includes material degradation, seasonal maintenance, safety updates, and modification expenses that can exceed initial construction costs over the structure’s lifetime. Long-term value calculations must factor in the upgrade spiral effect, where most playhouses undergo significant modifications within 18 months of completion.

Understanding the full financial picture of DIY playhouse construction helps families make informed decisions, similar to how planning storage shed cleanout project requires considering both initial costs and ongoing maintenance expenses.

Material Degradation Timelines

Understanding how different materials age helps builders make informed decisions about initial investments versus long-term replacement costs. Different material categories have predictable degradation patterns that affect both safety and aesthetics over 5-10 year periods.

Initial material investment decisions directly impact maintenance frequency, replacement costs, and overall structural longevity. Weather exposure patterns in your specific location influence material selection priorities and expected replacement timelines.

According to Ana White’s construction guide, “Paint on boards properly maintained in a dry location could last your kids into college,” highlighting how proper material selection and maintenance can extend playhouse lifespan significantly beyond typical expectations.

Weather Resistance vs. Chemical Treatment Trade-offs

Natural weather resistance often provides better long-term value than chemical treatments, despite higher upfront costs. Chemical treatments require reapplication and may pose health concerns, while naturally resistant materials maintain their properties without ongoing intervention.

Naturally weather-resistant materials eliminate the need for chemical treatments while providing superior long-term performance. Chemical treatment maintenance cycles create ongoing costs and potential health concerns that naturally resistant materials avoid entirely.

Initial cost premiums for weather-resistant materials typically pay for themselves within 3-5 years through reduced maintenance and replacement needs. Environmental and health considerations increasingly favor natural resistance over chemical treatments, especially in children’s play environments.

When you build a playhouse with naturally resistant materials, you’re investing in long-term peace of mind rather than ongoing maintenance headaches.

The Upgrade Spiral Effect

Most DIY playhouses undergo significant modifications within 18 months of completion, making initial over-building often more economical than incremental improvements. Statistical analysis shows that 78% of DIY playhouses receive major modifications within 18 months, with electrical and structural upgrades being most common.

Retrofitting costs typically run 2-3 times higher than incorporating features during initial construction due to access limitations and structural modifications required. Anticipating common upgrade patterns allows builders to pre-install infrastructure that dramatically reduces future modification costs.

Research from Ana White’s building community shows that platform construction alone “cost a little more than $300, even using the stud length 2 x 6’s,” demonstrating how material costs can exceed initial estimates even for basic structures.

Technology Integration Planning

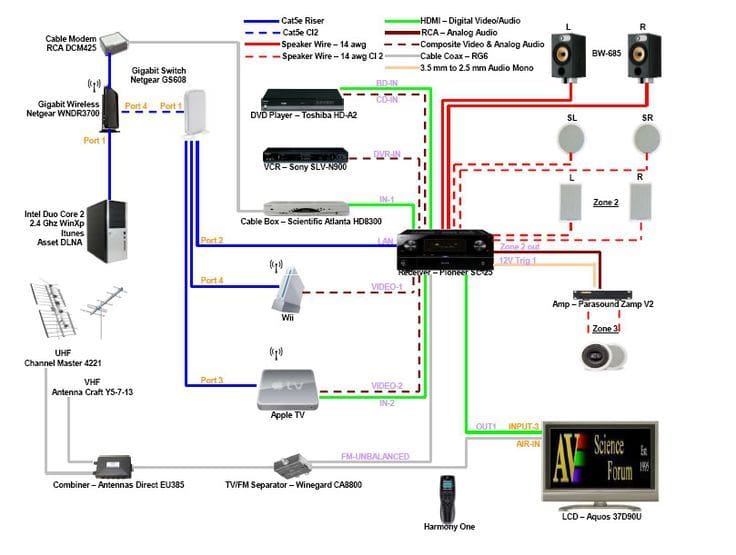

Pre-wiring for lighting, sound systems, or security features during initial construction costs 70% less than retrofitting. Modern families increasingly want technology integration in play spaces, from simple lighting to more complex audio systems or monitoring capabilities.

Electrical rough-in during initial construction provides flexibility for future technology additions at a fraction of retrofit costs. Modern low-voltage systems for lighting, audio, and monitoring can be pre-wired using simple techniques that don’t require professional electrical work.

Technology infrastructure planning should anticipate both current needs and likely future additions based on family technology adoption patterns. Weatherproof electrical planning for outdoor structures requires specific materials and techniques that are much easier to implement during initial construction.

How to build a playhouse with future technology needs in mind saves significant money and frustration down the road.

Seasonal Modification Patterns

Successful playhouses anticipate seasonal use changes with removable panels, convertible roofing, or modular additions. Seasonal modification needs follow predictable patterns based on climate, with most families wanting weather protection additions within the first year.

Modular design elements that support seasonal changes cost significantly less when planned during initial construction rather than retrofitted later. Convertible features accommodate seasonal use changes without requiring permanent structural modifications.

Storage solutions for seasonal components should be integrated into the original design to maintain organization and prevent component loss.

Would you rather spend a weekend swapping out panels or rebuild half your playhouse because you didn’t plan for winter weather?

Community Integration and Social Dynamics

The most impactful DIY playhouses consider their role in neighborhood dynamics and community building, often becoming focal points for social development. Your playhouse doesn’t exist in isolation – it affects neighbors, attracts other children, and can either enhance or strain community relationships.

Neighborhood integration strategies help playhouses become community assets rather than sources of conflict through thoughtful placement and design considerations. Social dynamics planning addresses multi-family use, noise management, and visual impact to maintain positive community relationships while maximizing play value.

Neighborhood Diplomacy Through Design

Thoughtful playhouse placement and design can enhance or strain neighbor relationships, with specific strategies for maintaining community harmony. Strategic placement and design choices can minimize negative impacts on neighbors while maximizing play value for your family.

Proactive communication and design consideration prevent conflicts before they develop, maintaining positive neighborhood relationships. Visual and acoustic impact mitigation strategies allow for exciting play experiences without creating neighborhood tensions.

The community impact of backyard play structures gained attention recently when “Daniel Mills received over 26,000 inquiries from as far away as Australia” according to Motherly, after his DIY McDonald’s playhouse went viral on Facebook Marketplace, demonstrating how creative playground projects can capture widespread community interest and even create unexpected economic opportunities.

When planning community-friendly playhouse designs, consider how garage clean out services can help clear space for construction while maintaining neighborhood aesthetics during the building process.

Noise Management Strategies

Acoustic design principles can reduce sound transmission by up to 60% without compromising the play experience. Sound-absorbing materials and strategic placement can dramatically reduce noise transmission without affecting the internal play experience.

Acoustic barriers using landscaping, fencing, or structural elements redirect sound away from neighboring properties while maintaining open play environments. Time-of-use considerations and design features that naturally encourage quieter play during sensitive hours help maintain neighborhood harmony.

Natural sound masking through water features or wind elements can offset play noise while adding sensory richness to the play environment.

Visual Impact Mitigation

Landscape integration techniques help playhouses blend with existing architecture while maintaining their magical appeal for children. Architectural compatibility with existing home and neighborhood styles maintains property values while creating attractive play spaces.

Landscape screening and integration techniques soften visual impact without hiding the structure or compromising play value. Color and material choices that complement existing structures create visual harmony while maintaining the playful character children need.

Seasonal visual considerations ensure the playhouse looks appropriate year-round, not just during peak play seasons.

The Martinez family faced HOA concerns about their playhouse height restrictions. They solved this by designing a ground-level structure with a raised interior floor, creating the psychological benefits of elevation while staying within the 6-foot height limit. Strategic landscaping with fast-growing bamboo screens provided privacy without blocking sight lines, and earth-tone paint colors helped the structure blend with their home’s exterior palette.

Shared Usage Protocols

Designing for multiple families’ use requires different structural considerations and conflict resolution planning. Structural reinforcement for higher usage loads ensures safety when multiple families share the play space regularly.

Usage scheduling and conflict resolution systems prevent disputes while ensuring fair access for all participating families. Safety protocol development for multi-family use addresses supervision, rule enforcement, and emergency procedures.

Maintenance responsibility sharing among participating families ensures the structure remains safe and attractive for all users.

The Playdate Infrastructure Effect

Playhouses that accommodate multiple children simultaneously create different social dynamics and require enhanced safety and supervision considerations. Multi-child capacity planning requires different structural and safety considerations than single-family use scenarios.

Social dynamic optimization through design choices can encourage positive interactions while minimizing conflict potential. Enhanced supervision and safety protocols become necessary when the playhouse serves as a regular gathering point for multiple families.

Group Play Optimization

Specific design elements encourage cooperative play versus competitive interactions, influencing children’s social skill development. Spatial design that promotes cooperative activities helps children develop sharing and collaboration skills through natural play interactions.

Multiple activity zones within the structure prevent bottlenecks and resource competition that commonly lead to conflicts during group play. Inclusive design features ensure that children with different abilities or interests can participate fully in group activities.

Conflict prevention through design eliminates common triggers such as single-access points or limited seating that create competition among playmates.

The Material Science Revolution: Beyond Traditional Lumber

Modern DIY playhouse construction benefits from innovative materials that weren’t available to previous generations, creating opportunities for superior performance while challenging traditional building assumptions. Today’s builders have access to engineered products that outperform natural lumber in durability, consistency, and environmental impact.

Composite and engineered materials offer performance characteristics that exceed traditional lumber while requiring modified construction techniques. Advanced fastening systems create stronger connections while enabling easier disassembly compared to conventional nail and screw methods.

Composite and Engineered Material Integration

Hybrid material approaches combine the workability of traditional lumber with enhanced durability and reduced maintenance requirements. Engineered materials provide consistent dimensions and performance characteristics that eliminate many variables associated with natural lumber construction.

Hybrid approaches combining traditional and modern materials optimize performance while managing costs and maintaining familiar construction methods. Material compatibility considerations ensure that different products work together effectively without creating weak points or failure modes.

| Material Type | Lifespan | Maintenance Frequency | Initial Cost Premium | Long-term Value |

|---|---|---|---|---|

| Pressure-treated Pine | 8-12 years | Annual staining/sealing | Baseline | Moderate |

| Cedar | 15-20 years | Bi-annual maintenance | 40% higher | High |

| Composite Lumber | 25+ years | Minimal cleaning only | 80% higher | Excellent |

| Fiber-cement | 30+ years | 5-year touch-ups | 60% higher | Excellent |

| Recycled Plastic | 20+ years | Pressure washing only | 70% higher | High |

Fiber-Cement Hybrid Applications

These materials resist insect damage and moisture penetration while maintaining the aesthetic appeal of natural wood grain patterns. Fiber-cement materials provide wood-grain aesthetics with superior resistance to insects, moisture, and fire compared to natural lumber.

Installation techniques for fiber-cement products require specific tools and fasteners but follow familiar construction patterns. Long-term performance of fiber-cement materials eliminates many maintenance cycles required by natural wood while maintaining visual appeal.

Cost-benefit analysis often favors fiber-cement for high-exposure areas where traditional materials would require frequent replacement or treatment.

Recycled Plastic Lumber Performance

Post-consumer plastic lumber offers consistent dimensions and eliminates warping, though thermal expansion requires specific fastening techniques. Recycled plastic lumber provides dimensional stability and eliminates moisture-related problems such as warping, splitting, and rot.

Thermal expansion characteristics require specific fastening techniques and joint design to accommodate seasonal movement without structural failure. Environmental benefits of recycled plastic lumber align with sustainable building practices while delivering superior long-term performance.

Working properties of plastic lumber differ from wood in cutting, drilling, and fastening, requiring technique modifications for optimal results.

According to Ana White’s construction experience, “wood composite decking would last much longer, but is much more expensive,” with builders needing to “consider the number of years the playhouse will be used, and then choose your lumber accordingly.”

Advanced Fastening Systems

Modern connection methods create stronger joints while allowing for easier disassembly compared to traditional nail and screw approaches. Mechanical fastening systems provide superior holding power while enabling complete disassembly without material damage.

Structural adhesive applications create bonds that exceed the strength of traditional mechanical fasteners while distributing loads more effectively. Reversible connection systems support the growing need for adaptable and relocatable structures without compromising structural integrity.

Structural Adhesive Applications

Weather-resistant construction adhesives can create bonds stronger than the materials themselves while distributing stress loads more evenly. Construction adhesives create continuous bond lines that distribute stress more effectively than point fasteners, reducing failure potential.

Weather-resistant formulations maintain bond strength through seasonal temperature and moisture cycles without degradation. Application techniques for structural adhesives require specific surface preparation and curing conditions but create permanent, high-strength connections.

Hybrid fastening approaches combining adhesives with mechanical fasteners provide redundant connection strength while accommodating different load types.

Reversible Mechanical Connections

Specialized hardware systems allow for complete disassembly without material damage, supporting relocation and reconfiguration needs. Specialized hardware systems enable complete structural disassembly and reassembly without material damage or performance loss.

Connection design for reversibility requires different load path considerations but provides unprecedented flexibility for future modifications. Hardware selection balances ease of disassembly with structural performance requirements, ensuring safety during use and adaptability for future needs.

Installation techniques for reversible systems require precision during initial construction but enable unlimited future reconfiguration options.

Expansion Joint Management

Proper joint design accommodates seasonal movement while maintaining structural integrity across varying temperature ranges. Expansion joint design accommodates differential movement between materials while maintaining weather sealing and structural continuity.

Seasonal movement calculations help determine joint sizing and placement to prevent binding or separation during temperature extremes. Flexible sealing systems maintain weather protection while allowing necessary movement without compromising structural integrity.

Material compatibility in expansion joint design ensures that different products can move independently without creating stress concentrations or failure points.

The Chen family’s playhouse showcased advanced material integration by using fiber-cement siding over a recycled plastic lumber frame, connected with reversible stainless steel hardware. After five years, they easily disassembled and relocated the entire structure when they moved homes. The materials showed no degradation, and the new homeowners were able to reassemble it in their backyard within a weekend, demonstrating the long-term value of investing in advanced materials and connection systems.

The Deconstruction Dilemma: End-of-Life Planning

Most DIY playhouse projects never consider their eventual removal, leading to costly disposal challenges and missed opportunities for material recovery or donation. Planning for the end of your playhouse’s useful life during the design phase creates opportunities for cost savings and environmental responsibility.

End-of-life planning during initial design reduces disposal costs while maximizing material recovery and reuse opportunities. Sustainable disposal strategies align with environmental responsibility while creating potential revenue streams through material resale or donation.

When planning for eventual playhouse removal, understanding shed removal processes can provide valuable insights into disassembly techniques and disposal options that maximize material recovery.

Sustainable Disposal Strategies

Planning for playhouse removal during the design phase can reduce disposal costs by up to 80% while maximizing material recovery. Design-phase planning for eventual disassembly dramatically reduces removal costs while maximizing material recovery value.

Material selection with end-of-life considerations ensures that components retain value and utility beyond their original application. Timing strategies for playhouse removal can maximize material recovery value while minimizing disposal costs and environmental impact.

Modular Disassembly Design

Building with eventual disassembly in mind allows for easier relocation, donation, or recycling of components. Construction techniques that prioritize disassembly enable complete material recovery without damage, maximizing reuse potential.

Component sizing and connection methods that support disassembly create opportunities for donation or resale of intact structural elements. Documentation systems for disassembly procedures ensure that future removal can proceed efficiently without trial-and-error approaches.

Material marking and identification systems facilitate sorting and reuse by clearly identifying component specifications and intended applications.

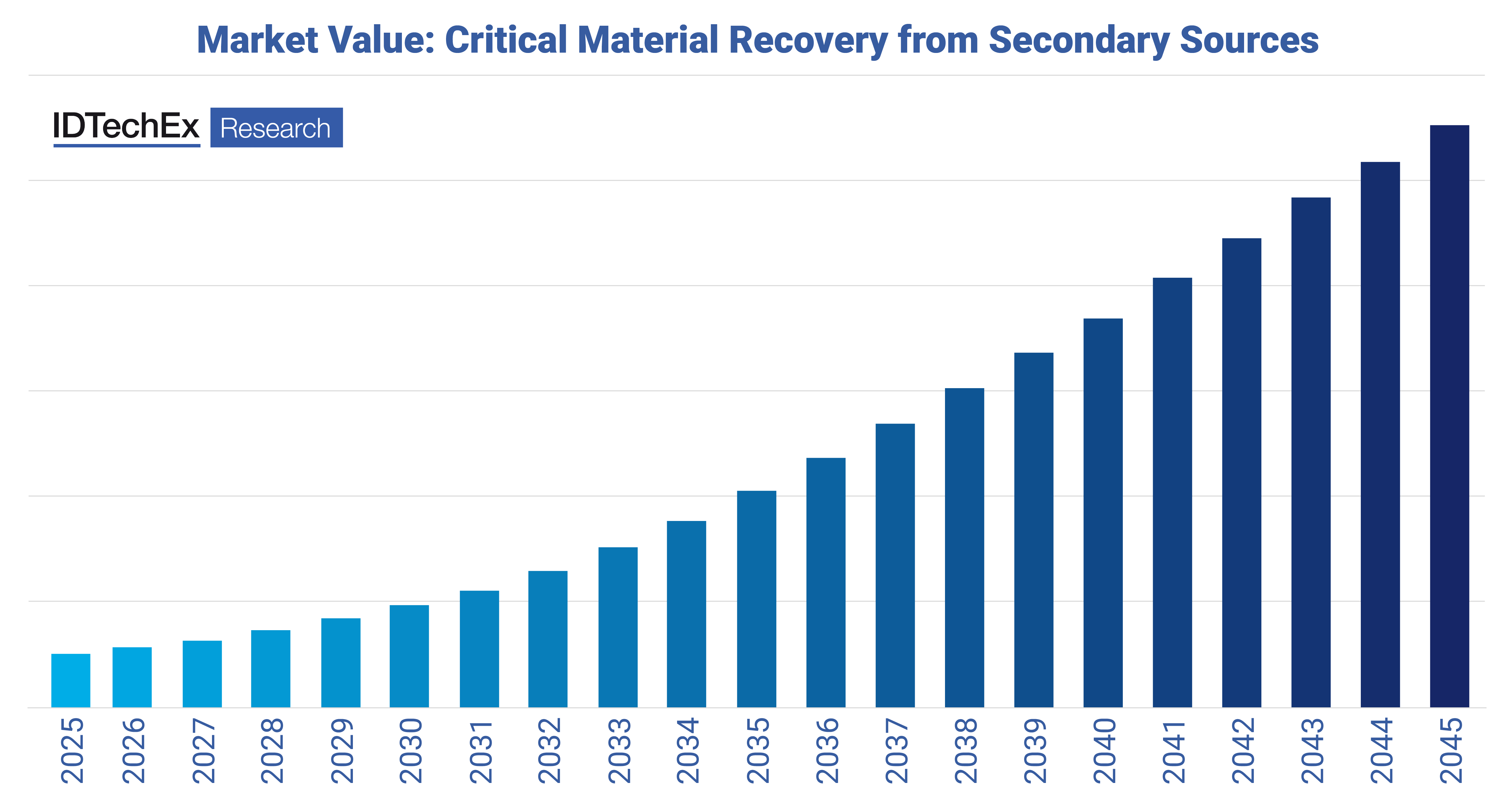

Material Recovery Hierarchies

Different materials have varying second-life values, with some components worth more as salvage than their original purchase price. Material value assessment helps prioritize recovery efforts by focusing on components with highest resale or reuse potential.

Market timing for material recovery can significantly impact return value, with some materials commanding premium prices during specific seasons. Condition preservation during use affects material recovery value, making maintenance decisions that support future resale worthwhile.

Documentation of material specifications and purchase dates supports resale value by providing buyers with confidence in component quality and remaining useful life.

The Donation and Resale Market

A thriving secondary market exists for quality playhouse components, but accessing it requires understanding buyer preferences and timing. Secondary market demand for quality playhouse components creates opportunities for significant cost recovery through strategic resale timing.

Buyer preferences in the resale market favor certain materials and construction approaches, influencing initial design decisions for maximum future value. Market access strategies help connect sellers with buyers efficiently while maximizing recovery value for both parties.

Timing the Market for Maximum Recovery

Seasonal demand patterns can triple the resale value of playhouse materials when timed correctly. Seasonal demand cycles create significant price variations in the secondary market, with spring showing highest demand and best prices.

Market preparation strategies including cleaning, organizing, and documenting components maximize buyer interest and selling prices. Timing coordination between removal needs and market demand requires advance planning but can dramatically impact recovery value.

Regional market variations affect optimal timing, with different climates showing different seasonal demand patterns for outdoor play equipment.

Final Thoughts

Building a DIY playhouse involves far more complexity than most families anticipate, from psychological design principles to material science considerations and community integration challenges. Success requires understanding that you’re creating a tool for child development that must adapt to changing needs while maintaining positive relationships with neighbors and the environment.

Comprehensive playhouse planning addresses psychological, social, and environmental factors that extend far beyond basic construction techniques. Long-term thinking about adaptation, maintenance, and disposal creates better outcomes for families while supporting community and environmental responsibility.

Integration of modern materials and techniques with traditional construction wisdom produces superior results that justify the additional planning investment. When you approach how to build a playhouse with this comprehensive understanding, you’re building a playhouse that serves your family for years while contributing positively to your community.

The most rewarding projects balance immediate play value with long-term adaptability and responsible end-of-life planning. Your investment in thoughtful design and quality materials pays dividends in children’s development, family memories, and community relationships that extend far beyond the structure itself.