DIY Pool Heater Systems That Actually Work: The Complete Guide to Building Efficient Backyard Heating Solutions

Pool heating costs can drain your summer budget faster than you’d expect, but I’ve discovered that smart material sourcing and proper system design can create heating solutions that rival commercial equipment at a fraction of the cost. When you’re dealing with a substantial pool – say a 16 x 32 foot in-ground pool with 330 square feet of surface area – building an effective diy pool heater becomes both an engineering challenge and an opportunity for massive savings through intelligent component selection and thermal optimization.

Table of Contents

- The Hidden Economics of Pool Heating Materials

- Wood-Fired Systems: Beyond the Basic Fire Box

- Solar Collection: The Thermodynamics Most Guides Skip

- Control Systems and Automation: The Intelligence Layer

- Advanced Heat Exchange Configurations: Beyond Basic Coil Systems

TL;DR

- Material sourcing from salvage operations can reduce your DIY pool heater costs by 60-80% while providing superior components

- Wood-fired systems require precise combustion chamber design and air control to achieve clean burning and maximum heat transfer

- Solar collector performance depends on optimal flow rates, thermal stratification, and proper hydraulic balancing across multiple panels

- Modern control systems with differential temperature controllers and weather integration maximize efficiency while preventing system damage

- Advanced heat exchanger configurations using counterflow designs and multi-stage recovery can triple heating efficiency compared to basic coil systems

The Hidden Economics of Pool Heating Materials

Building an effective diy pool heater starts with understanding material lifecycle costs and strategic sourcing opportunities. Professional contractors discard valuable heating components daily, while construction sites and restaurant renovations provide access to premium materials at fraction of retail costs. Smart material selection based on thermal cycling performance prevents expensive failures and extends system lifespan significantly.

HVAC contractors regularly replace copper coils and heat exchangers that retain 80-90% of their useful life, making salvage sourcing your most cost-effective material strategy. Understanding thermal expansion coefficients prevents joint failures – copper’s 0.000016 inches per inch per degree expansion requires strategic accommodation in long collector runs.

The Salvage-First Philosophy for Heat Exchangers

Professional pool installers and HVAC contractors generate thousands of dollars worth of discarded copper tubing, heat exchangers, and pumps annually. These materials often represent the majority of your DIY heater budget when purchased new. I’ve found that establishing relationships with local contractors and monitoring construction sites provides access to food-grade stainless steel components and functional heating equipment at dramatically reduced costs.

Clean, straight runs of 3/4″ to 1″ copper tubing from HVAC replacements provide ideal material for solar collector construction at 10-20% of retail pricing. Restaurant renovations yield food-grade stainless steel heat exchangers that exceed pool heating requirements and resist corrosion better than standard materials. Construction sites discard functional boilers, water heaters, and radiant heating components during new installations, providing complete system components for repurposing.

When planning your project timeline, consider that scrap metal removal services can help clear your workspace quickly as you accumulate salvaged materials and old equipment during the sourcing phase.

| Material Source | Typical Savings | Component Quality | Availability |

|---|---|---|---|

| HVAC Contractor Discards | 80-90% | Excellent (80-90% useful life) | High – Regular replacement cycles |

| Restaurant Renovations | 70-85% | Superior (Food-grade materials) | Seasonal – Spring/Fall peaks |

| Construction Sites | 60-80% | Good to Excellent | Variable – Project dependent |

| Plumbing Contractors | 65-75% | Good | Moderate – Upgrade cycles |

| Industrial Facilities | 75-90% | Excellent | Low – Infrequent availability |

Copper Tubing Reclamation Networks

HVAC contractors replace copper coils regularly during system upgrades and maintenance. These discarded coils often contain long, straight sections perfect for DIY solar collectors. Building relationships with local contractors ensures steady access to premium materials while helping them reduce disposal costs.

Establish pickup schedules with 3-5 local HVAC contractors to secure consistent copper tubing supply throughout building season. Focus on 3/4″ to 1″ diameter tubing which provides optimal flow rates for pool heating applications without excessive pressure drops. Clean and straighten salvaged copper immediately to prevent work hardening and maintain workability for your heating system construction.

A homeowner in Austin established relationships with three local HVAC contractors by offering to pick up their copper waste weekly during peak installation season. Over six months, he collected 800 feet of 3/4″ copper tubing, 400 feet of 1″ tubing, and two intact heat exchangers – materials that would have cost $2,400 retail but were obtained for just the cost of gas for pickup trips. The contractors saved $150 in disposal fees while the homeowner built a complete solar heating system for under $300 in additional materials.

Commercial Kitchen Equipment Graveyards

Restaurant renovations and closures generate substantial quantities of stainless steel heat exchangers, pumps, and insulated tanks. These food-grade materials exceed pool heating requirements for corrosion resistance and thermal performance. Strategic sourcing from restaurant equipment dealers and renovation contractors provides access to premium components at significant savings.

Food-grade stainless steel components resist chlorine corrosion better than standard pool equipment, extending system lifespan by years. Commercial kitchen heat exchangers handle higher temperatures and pressures than residential pool applications require, providing built-in safety margins. Insulated tanks from commercial operations often include temperature controls and safety systems that enhance DIY pool heater performance.

Construction Site Heat Recovery

New construction projects frequently discard perfectly functional heating equipment during installation of upgraded systems. Boilers, water heaters, and radiant heating components removed during construction often retain substantial useful life. Monitoring construction sites and building relationships with contractors provides access to complete heating systems for repurposing.

New construction sites discard functional equipment to meet updated efficiency codes, not due to equipment failure or wear. Radiant heating components from construction sites adapt well to pool heating applications with minimal modification required. Building relationships with general contractors provides advance notice of equipment availability before disposal occurs.

Material Performance Under Thermal Cycling

Different materials respond uniquely to repeated heating and cooling cycles that characterize pool heating systems. Understanding thermal expansion coefficients, joint failure patterns, and material degradation prevents costly system failures. Strategic material selection and joint design accommodates thermal movement while maintaining system integrity over years of operation.

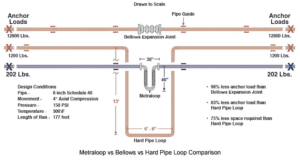

Thermal expansion calculations determine required accommodation for temperature swings – a 100-foot copper loop experiencing 80°F swings moves nearly 1.5 inches. Joint failures occur at connection points experiencing differential thermal expansion between dissimilar materials or constrained movement. Strategic placement of expansion loops and flexible connectors prevents 90% of thermal cycling failures in DIY pool heating systems.

Thermal Expansion Coefficients in Practice

Copper expands 0.000016 inches per inch per degree Fahrenheit, creating substantial movement in long collector runs during temperature cycling. Understanding these expansion rates allows proper system design that accommodates thermal movement without stress failures. Calculating expansion for your specific installation prevents joint failures and maintains system integrity.

Calculate total expansion for your longest pipe runs using material coefficients and expected temperature ranges to determine required accommodation. Install expansion loops or flexible connectors at calculated intervals to absorb thermal movement without stressing joints or connections. Position fixed anchor points strategically to control expansion direction and prevent random stress concentration throughout the system.

Joint Failure Patterns and Prevention

Most DIY pool heater failures occur at joints experiencing differential thermal expansion between connected components. Different materials expand at different rates, creating stress concentrations at connection points. Understanding failure patterns and implementing prevention strategies eliminates the majority of thermal cycling problems in heating systems.

Differential expansion between copper and steel components creates the highest stress concentrations and most frequent failure points. Flexible connectors and expansion joints absorb thermal movement while maintaining watertight seals under cycling conditions. Strategic joint placement away from maximum temperature zones reduces thermal stress while maintaining system performance and reliability.

The Waste Heat Integration Opportunity

Your property generates substantial waste heat through air conditioning systems, hot water heating, and refrigeration equipment that can be captured and redirected to pool heating. Integrating waste heat recovery with your primary heating system improves overall efficiency while reducing operating costs. Understanding heat sources and recovery methods maximizes available thermal energy.

Air conditioning condensers reject substantial heat during cooling season that can be captured and transferred to pool water. Hot water systems lose heat through distribution lines and tank standby losses that can be recovered for pool heating applications. Refrigeration equipment generates consistent waste heat year-round, providing steady thermal input for pool temperature maintenance.

Wood-Fired Systems: Beyond the Basic Fire Box

Wood fired pool heater systems combine traditional heating knowledge with modern efficiency principles to create powerful, cost-effective heating solutions. Success requires understanding combustion dynamics, heat transfer optimization, and safety systems. Proper combustion chamber design eliminates smoke while maximizing heat output, while automated systems provide convenience and safety comparable to commercial equipment.

Combustion chamber geometry and air control systems determine whether wood burns cleanly and efficiently or produces smoke and wastes fuel. Heat exchanger positioning in flue gas streams captures thermal energy that would otherwise escape, dramatically improving system efficiency.

Combustion Chamber Design for Maximum Heat Transfer

The difference between smoky, inefficient wood burning pool heater operation and clean heat generation lies in precise air-to-fuel ratios and combustion chamber geometry. Proper design creates complete combustion while maximizing heat transfer to your pool water. Understanding primary and secondary air systems eliminates smoke production while reducing wood consumption significantly.

Primary air feeds the fuel bed directly for initial combustion, while secondary air burns volatile gases for complete fuel utilization. Proper air balance eliminates visible smoke while reducing wood consumption by 30-40% compared to conventional fire box designs. Combustion chamber geometry creates turbulent mixing zones that ensure complete fuel burning and maximum heat release.

Primary and Secondary Air Control Systems

Primary air feeds the fuel bed directly, supporting initial combustion and maintaining the fire base. Secondary air burns off volatile gases released during wood pyrolysis, eliminating smoke while capturing additional thermal energy. Balancing these air supplies creates clean, efficient combustion that maximizes heat output while minimizing fuel consumption.

Primary air dampers control burn rate and fuel bed temperature, requiring adjustment based on wood type and moisture content. Secondary air injection above the fuel bed burns volatile gases at high temperature, eliminating smoke and capturing additional heat. Automated air control systems maintain optimal ratios throughout the burn cycle, reducing manual adjustment requirements while improving efficiency.

Heat Exchanger Positioning and Flow Dynamics

Water tubes positioned in the flue gas stream capture heat that would otherwise escape through the chimney. Counterflow design maximizes temperature differential between hot gases and pool water, improving heat transfer efficiency. Strategic positioning balances heat capture with proper draft maintenance for reliable combustion.

Counterflow arrangements maintain maximum temperature differential throughout the heat exchanger length, extracting more thermal energy from flue gases. Heat exchanger positioning must balance thermal capture with maintaining adequate draft for proper combustion and smoke evacuation. Water flow rates through heat exchangers require optimization to prevent overheating while ensuring adequate heat transfer and temperature rise.

As sustainable home solutions gain popularity, “solar pool heaters can be an excellent addition” ZME Science reports, with research showing that optimized systems in Australia could potentially avoid 180 GWh of electricity consumption and 150 kilotonnes of CO2 emissions annually if operated under optimal conditions.

Automated Feed and Safety Systems

Modern wood burning pool heater designs can incorporate automated feeding systems, temperature controls, and safety shutoffs that rival commercial heating equipment. Gravity-fed pellet systems enable automated operation for hours without manual intervention. Safety systems prevent overheating and equipment damage during pump failures or system malfunctions.

Automated feeding systems maintain consistent burn rates and heat output without constant manual attention and fuel loading. Safety systems prevent catastrophic overheating during pump failures or closed valve conditions that could damage equipment or create hazards. Temperature control systems integrate with pool equipment to maintain desired water temperatures while preventing overheating or energy waste.

Gravity-Fed Pellet Integration

Converting traditional wood-fired designs to accept wood pellets enables automated feeding and consistent burn rates. Simple auger systems maintain optimal fire conditions for extended periods without manual intervention. Pellet systems provide more consistent heat output while reducing labor requirements compared to traditional wood firing.

Gravity-fed hoppers provide consistent pellet delivery to the combustion chamber without requiring electric auger systems or complex mechanisms. Pellet burning creates more consistent heat output compared to traditional wood firing, improving temperature control and reducing manual attention. Simple auger or screw conveyor systems can automate pellet feeding for hours of unattended operation while maintaining optimal combustion conditions.

A DIY builder in Colorado converted a basic wood-fired heater to accept pellets by adding a 50-pound gravity-fed hopper and simple auger system. The modification cost $180 in materials but enabled 8-hour unattended operation while maintaining consistent 140°F water temperatures. Wood consumption dropped from 40 pounds per heating session to 25 pounds of pellets, while temperature fluctuations decreased from ±15°F to ±3°F.

Thermal Overload Protection

Pool water provides excellent thermal mass for absorbing heat, but pump failures or closed valves can create dangerous overheating conditions. Thermostatic bypass valves and emergency dump systems prevent catastrophic failures by providing alternative heat dissipation paths. Safety systems protect equipment while preventing hazardous conditions.

Thermostatic bypass valves automatically open when water temperatures exceed safe limits, providing alternative circulation paths during pump failures. Emergency dump systems discharge overheated water safely while introducing cool makeup water to prevent equipment damage. Temperature monitoring systems with automatic shutoffs prevent combustion chamber overheating when water circulation stops or becomes restricted.

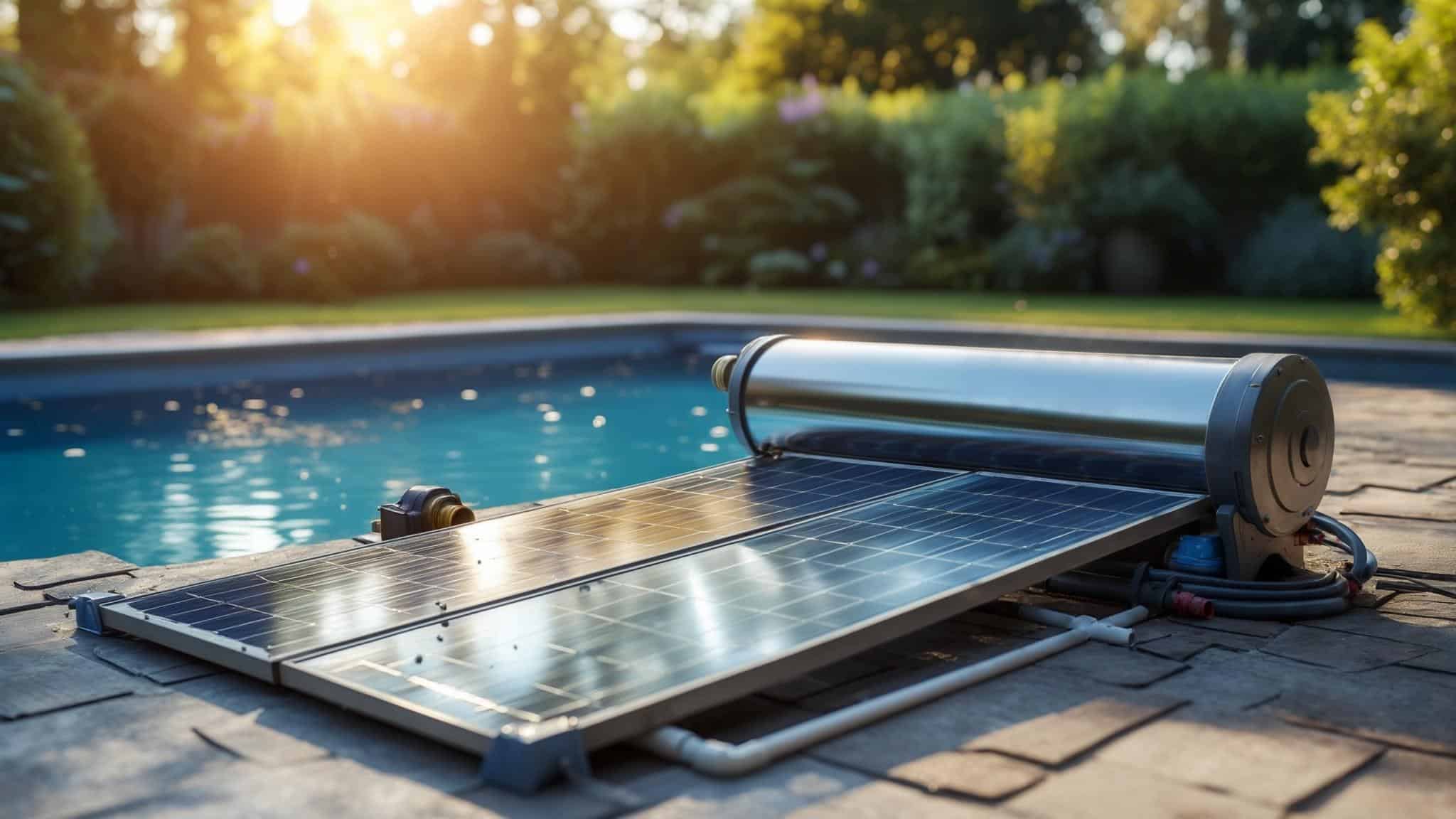

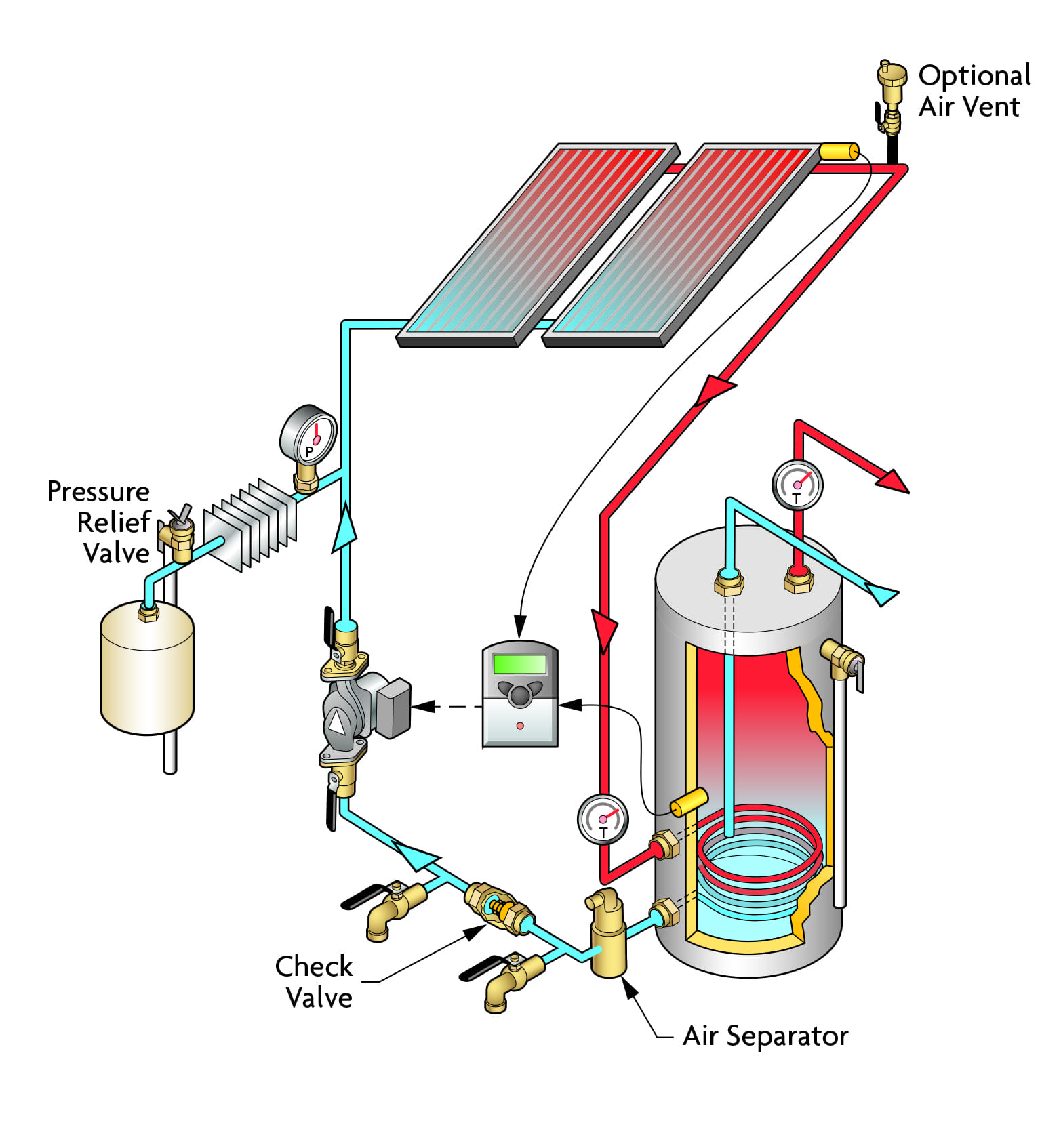

Solar Collection: The Thermodynamics Most Guides Skip

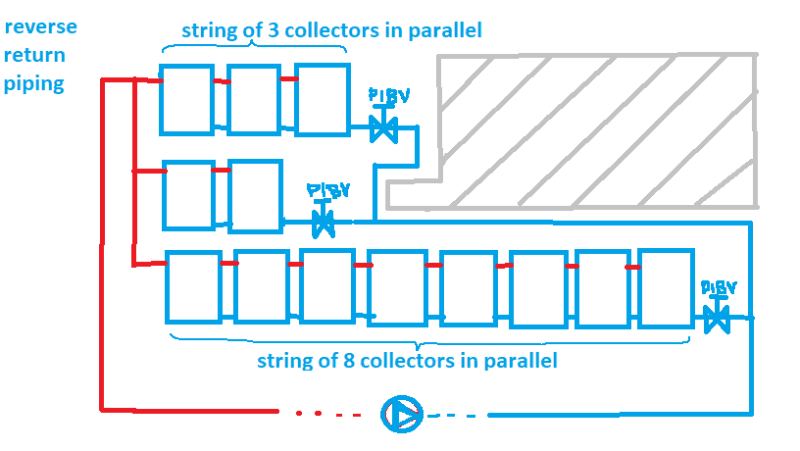

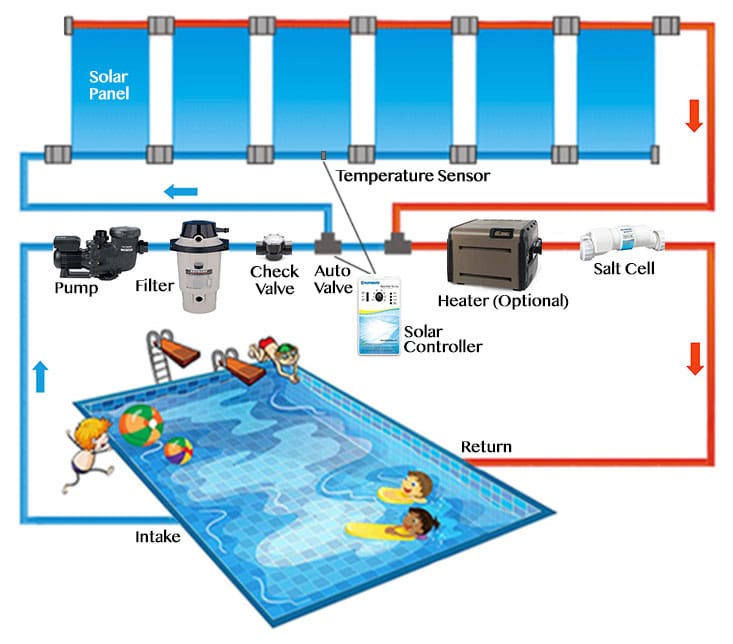

Diy solar pool heater installations involve complex interactions between collector angle, flow rates, and thermal stratification that determine system effectiveness. Most DIY installations fail because water moves too quickly through collectors or flow distribution across multiple panels creates short-circuiting. Understanding Reynolds numbers, hydraulic balancing, and glazed versus unglazed performance curves ensures your diy solar pool heater actually heats water instead of just circulating it.

Optimal flow rates create turbulent flow conditions (Reynolds number above 4,000) for maximum heat transfer while maintaining adequate residence time for temperature rise. Multiple collector panels require reverse-return piping and flow restrictors to prevent short-circuiting and ensure equal heat distribution across all collectors.

For effective solar pool heating, your hose length should equal at least 50% of your pool’s surface area – meaning a 16 x 32 foot pool with 512 square feet of surface area requires at least 256 feet of irrigation hose, as detailed in Swim University’s DIY solar pool heater guide.

Flow Rate Optimization and Thermal Stratification

Achieving effective diy solar pool heater performance requires balancing flow rates to create turbulent mixing for heat transfer while allowing sufficient residence time for temperature rise. Too much flow prevents adequate heating, while insufficient flow causes overheating and stagnation. Understanding fluid dynamics principles ensures your collectors operate at peak efficiency throughout varying solar conditions.

Reynolds number calculations determine optimal flow rates – for 1″ tubing, 3-5 GPM creates ideal turbulent conditions for heat transfer. Residence time in collectors must allow adequate temperature rise without causing stagnation or overheating during peak solar conditions. Flow balancing across multiple collectors prevents some panels from receiving excessive flow while others remain stagnant.

Reynolds Number Calculations for Pool Applications

Reynolds numbers above 4,000 create turbulent flow conditions necessary for maximum heat transfer in solar collectors. For typical 1-inch tubing used in DIY installations, this requires 3-5 GPM flow rates. Understanding these calculations helps size pumps and design piping systems that achieve optimal performance without excessive energy consumption.

Turbulent flow conditions dramatically improve heat transfer coefficients compared to laminar flow, making Reynolds number calculations critical for system design. Flow rates below turbulent thresholds result in poor heat transfer and minimal temperature rise despite adequate solar radiation. Pump sizing must provide adequate flow for turbulent conditions while avoiding excessive energy consumption that reduces overall system efficiency.

Collector Array Hydraulic Balancing

Multiple collector panels require careful hydraulic design to ensure equal flow distribution. Reverse-return piping configurations and strategically placed flow restrictors prevent short-circuiting where some collectors receive excessive flow while others remain nearly stagnant. Proper balancing maximizes total heat collection from your entire array.

Reverse-return piping ensures equal pressure drops to all collectors, promoting uniform flow distribution across the entire array. Flow restrictors or balancing valves fine-tune distribution when piping geometry creates unequal pressure conditions. Short-circuiting through low-resistance paths can reduce effective collector area by 50% or more in poorly designed arrays.

Glazed vs. Unglazed Performance Curves

Choosing between glazed and unglazed collectors depends on your climate conditions and usage patterns rather than just initial cost considerations. Unglazed systems excel in warm conditions but lose efficiency rapidly as ambient temperatures drop. Glazed collectors maintain performance in cooler weather but cost significantly more initially.

Performance crossover points occur around 65°F ambient temperature – unglazed collectors outperform glazed systems above this threshold. Wind speed dramatically affects unglazed collector performance, with every 10 MPH increase reducing efficiency by 15-20%. Glazed collectors maintain efficiency down to 40°F ambient temperatures, extending useful heating season in cooler climates.

Solar collector sizing recommendations vary significantly based on swimming season goals, with systems requiring 50% surface area coverage for 3-4 month seasons, scaling up to 120-140% coverage for 9-10 month swimming seasons, according to Solar Pool Supply’s sizing guidelines.

Ambient Temperature Crossover Points

Unglazed collectors outperform glazed systems when ambient temperatures exceed 65°F, but glazed collectors maintain efficiency as temperatures drop toward 40°F. Understanding these crossover points helps select appropriate collector types for your climate and intended usage patterns. Regional weather data determines which technology provides better annual performance.

Temperature differential between pool water and ambient air determines collector efficiency – larger differentials favor glazed designs. Seasonal usage patterns affect collector selection – year-round heating favors glazed collectors while summer-only use suits unglazed systems. Local climate data analysis reveals which collector type provides superior annual heat collection for your specific location.

Wind Speed Impact on Collection Efficiency

Wind speed significantly impacts unglazed collector performance by increasing convective heat losses from absorber surfaces. Every 10 MPH wind speed increase reduces efficiency by 15-20%. Strategic windbreaks or protected collector positioning can recover this lost performance while maintaining adequate solar exposure.

Convective heat losses increase exponentially with wind speed, making wind protection crucial for unglazed collector performance. Strategic windbreaks can recover 10-15% efficiency without significantly reducing solar radiation reaching collector surfaces. Collector positioning relative to prevailing winds affects performance more than minor variations in solar orientation angles.

| Collector Type | Optimal Ambient Temp | Wind Sensitivity | Seasonal Efficiency | Initial Cost |

|---|---|---|---|---|

| Unglazed | Above 65°F | High (15-20% loss per 10 MPH) | Summer peak | Low |

| Glazed | 40-65°F | Low (5-8% loss per 10 MPH) | Extended season | High |

| Evacuated Tube | Below 40°F | Very Low (2-3% loss per 10 MPH) | Year-round | Very High |

| Hybrid | All temperatures | Moderate (8-12% loss per 10 MPH) | Consistent | Moderate |

Thermal Mass Integration and Night Cooling Prevention

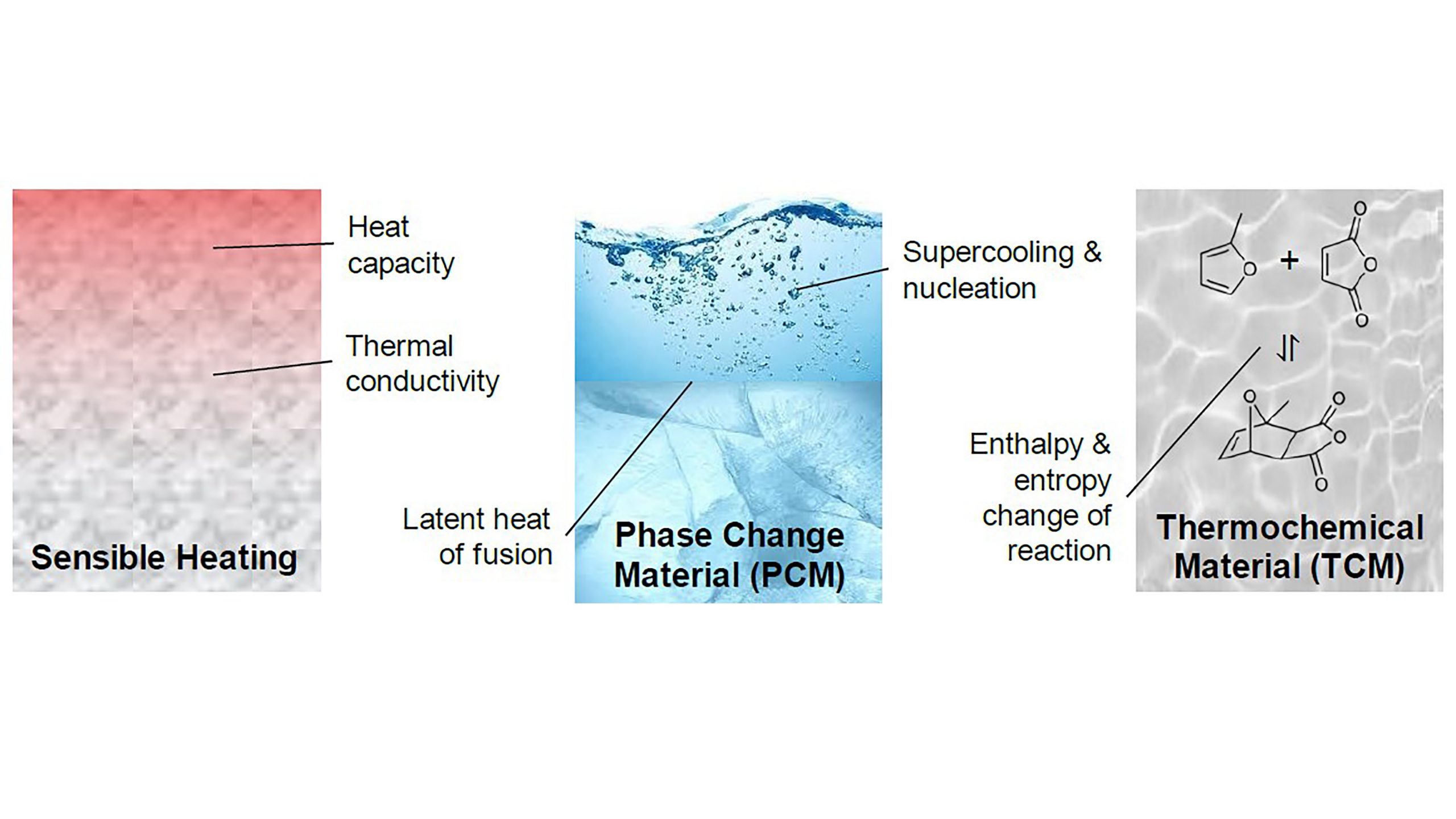

Solar collectors can actually cool your pool at night through radiative heat loss to the clear sky. Smart integration with thermal mass storage and control systems prevents this energy drain while extending effective heating hours. Phase change materials and underground storage systems provide thermal buffering that improves overall system performance.

Radiative cooling to clear night skies can remove substantial heat from unglazed collectors, requiring control systems to prevent reverse heat flow. Phase change materials store daytime solar gains and release heat during cooler periods, extending effective heating beyond daylight hours. Underground thermal storage systems maintain collected heat for days or weeks with minimal losses.

DIY pool heating solutions are gaining popularity as homeowners seek creative alternatives to expensive commercial systems, with innovative approaches like “creating your own solar pool heater for cheap using a black tarp and a collection of pool noodles” House Digest reports, demonstrating the growing interest in accessible heating solutions.

Phase Change Material Integration

Paraffin wax and commercial phase change materials store substantial thermal energy during melting and release it during solidification. Integrating these materials with easy diy solar pool heater designs extends heating capacity beyond daylight hours while providing thermal buffering during cloudy periods. Proper sizing and integration maximizes storage benefits.

Phase change materials store 5-10 times more energy per pound than sensible heat storage in water or rock. Melting temperatures must match your desired pool temperature range to maximize storage and release efficiency. Container design for phase change materials must accommodate volume expansion during melting while maintaining good heat transfer.

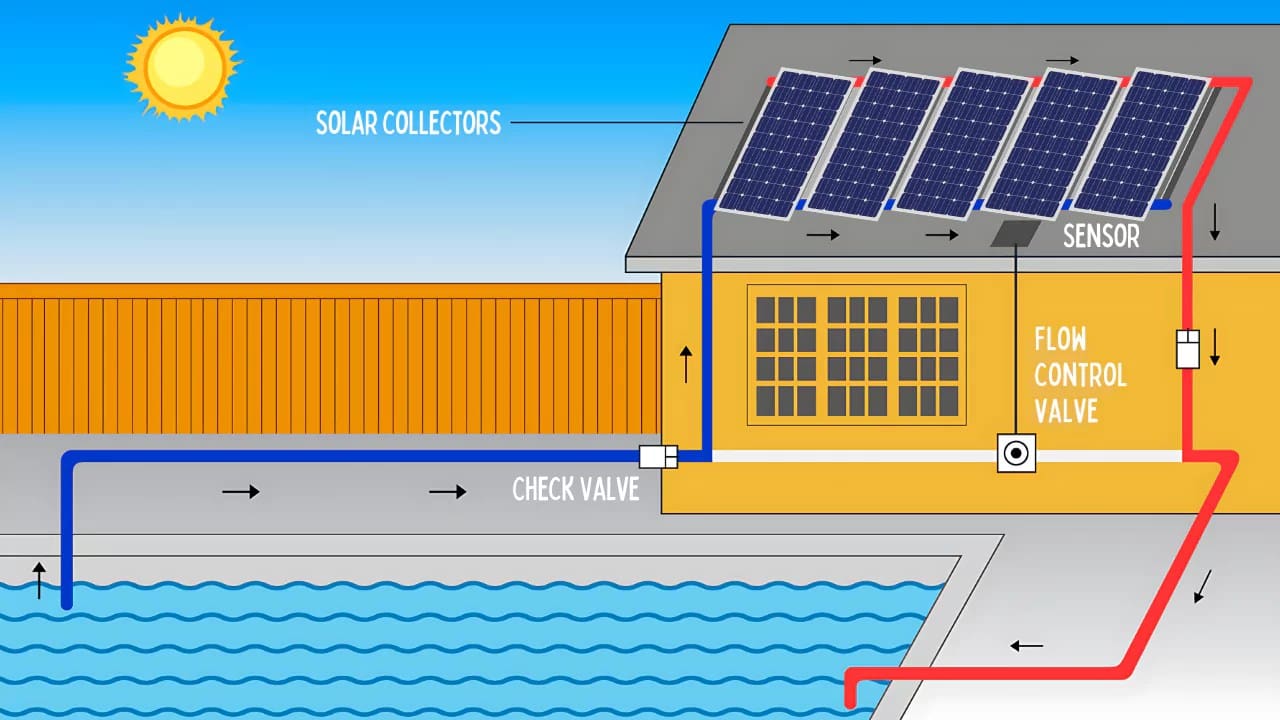

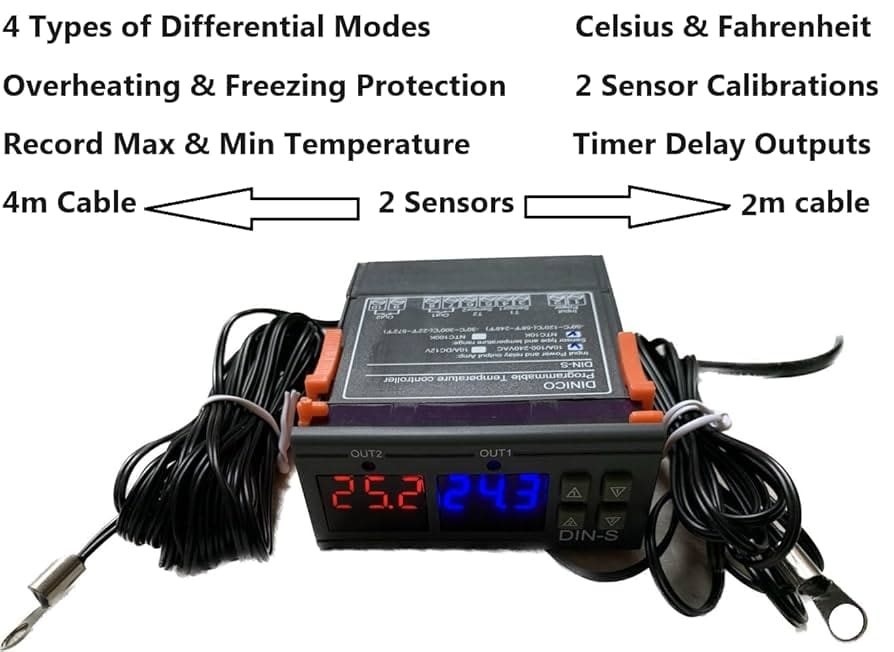

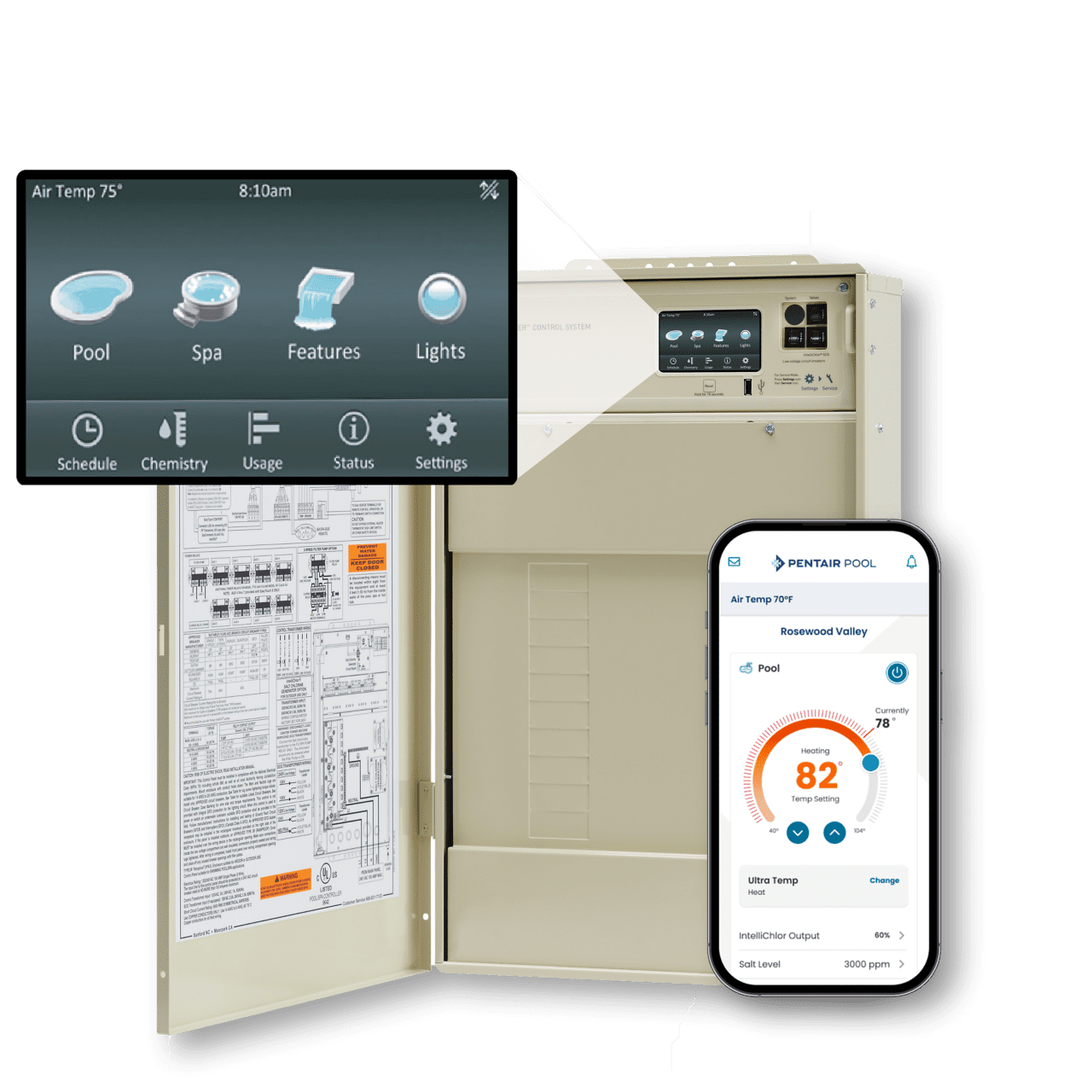

Control Systems and Automation: The Intelligence Layer

Modern diy pool heater systems benefit from sophisticated control systems that optimize performance, prevent damage, and provide remote monitoring using readily available components. Differential temperature controllers form the brain of efficient systems by comparing collector and pool temperatures to operate pumps only when heat gain occurs. Weather integration and predictive algorithms further enhance performance while reducing energy waste.

Differential temperature controllers prevent energy waste by operating circulation pumps only when collectors can actually heat pool water. Internet-connected systems access weather forecasts to optimize heating strategies and prevent freeze damage during cold snaps.

Differential Temperature Controllers

The brain of any efficient pool heating system compares collector temperature to pool temperature and operates circulation pumps only when heat gain is possible. Proper sensor placement and calibration ensures accurate temperature readings that drive optimal system operation. These controllers prevent energy waste while maximizing heat collection during favorable conditions.

Temperature differential settings determine when pumps start and stop – typically 8-10°F differential for startup and 3-5°F for shutdown. Sensor placement critically affects controller performance – collector sensors must read actual fluid temperature, not air or surface temperature. Calibration procedures ensure accurate temperature readings that drive proper system operation and prevent false cycling.

Sensor Placement and Calibration

Collector sensors must read actual fluid temperature rather than air temperature or collector surface temperature to provide accurate control signals. Pool sensors should measure mixed water temperature instead of surface temperature that varies with weather conditions. Proper placement and regular calibration ensures reliable system operation.

Collector sensors require thermal wells or direct contact with fluid streams to read actual water temperature rather than ambient conditions. Pool sensors must measure mixed water temperature from return lines rather than surface temperature that fluctuates with weather. Regular calibration using reference thermometers ensures sensor accuracy and prevents system inefficiencies from temperature measurement errors.

A homeowner discovered their solar heating system was cycling unnecessarily after installing temperature sensors incorrectly. The collector sensor was reading air temperature instead of water temperature, causing the controller to run pumps even when collectors were cooler than pool water. Relocating the sensor to a thermal well in the collector outlet line immediately improved system efficiency by 25% and reduced pump runtime by 40%.

Weather Integration and Predictive Control

Internet-connected controllers access weather forecasts and adjust heating strategies to maximize efficiency while preventing freeze damage. Cloud cover prediction algorithms optimize thermal mass charging during clear periods and coast through cloudy weather without energy waste. These smart systems improve performance while reducing manual intervention requirements.

Weather forecast integration allows systems to pre-heat thermal mass during optimal conditions and coast through predicted cloudy periods. Freeze protection algorithms monitor weather forecasts and ambient temperatures to prevent system damage during cold snaps. Cloud cover prediction optimizes collector operation by avoiding pump cycling during intermittent solar conditions.

Cloud Cover Prediction Algorithms

Simple algorithms predict solar availability and adjust heating strategies to maximize thermal collection during clear periods while avoiding energy waste during cloudy weather. These systems pre-heat thermal mass when conditions are optimal and maintain temperatures during less favorable periods without constant pump cycling.

Solar irradiance forecasts allow systems to maximize thermal mass charging during predicted clear weather periods. Pump cycling reduction during intermittent cloud conditions prevents energy waste while maintaining system responsiveness to changing conditions. Thermal mass management strategies store excess heat during optimal conditions for use during cloudy periods or overnight.

Professional solar pool heaters can typically raise pool temperatures by 8 to 12 degrees Fahrenheit on average days, with properly sized and efficient systems providing noticeable and reliable heating performance, as documented by ZME Science’s comprehensive solar pool heater analysis.

Advanced Heat Exchange Configurations: Beyond Basic Coil Systems

Advanced heat exchanger configurations can triple efficiency through strategic thermal pathway management and multi-stage heat recovery systems. Counterflow designs achieve logarithmic mean temperature differences that parallel systems cannot match, while multi-stage cascades capture waste heat at multiple temperature levels. Underground thermal storage and heat pump integration extend these concepts further.

Counterflow arrangements maintain maximum temperature differential throughout heat exchanger length, extracting 40-60% more thermal energy than parallel configurations. Multi-stage heat recovery systems capture waste heat at different temperature levels, using high-grade heat for direct pool warming while lower-grade heat preheats incoming water.

Counterflow vs. Parallel Flow Dynamics

Fluid flow direction through heat exchangers dramatically impacts thermal transfer rates. Counterflow designs maintain maximum temperature differential throughout the entire exchanger length, while parallel flow systems experience diminishing temperature differences. Understanding these dynamics helps design systems that extract maximum thermal energy from available heat sources.

Logarithmic mean temperature differences in counterflow systems remain higher throughout the heat exchanger, improving overall thermal transfer rates. Parallel flow configurations experience rapidly diminishing temperature differentials that limit heat transfer effectiveness. Pressure drop calculations become critical in counterflow designs to ensure adequate flow rates without excessive pumping energy.

Temperature Gradient Optimization

Counterflow arrangements maintain maximum temperature differential throughout the entire heat exchanger length, extracting 40-60% more thermal energy from the same heating source compared to parallel configurations. This improved performance comes from maintaining higher logarithmic mean temperature differences that drive heat transfer rates.

Logarithmic mean temperature difference calculations show counterflow advantages increase with larger temperature spans between hot and cold fluids. Heat transfer coefficients remain higher throughout counterflow exchangers due to maintained temperature differentials. System efficiency improvements of 40-60% justify additional complexity in piping and control systems for counterflow configurations.

Pressure Drop Considerations in DIY Applications

Higher efficiency counterflow designs create increased pressure drops that require larger pumps and more energy consumption. Calculating pressure drops across complex heat exchanger geometries prevents oversized pumps that waste electricity while undersized units fail to deliver adequate flow rates for proper heat transfer.

Friction losses in counterflow systems typically run 2-3 times higher than parallel flow configurations due to flow path complexity. Pump sizing must balance increased pressure requirements against improved heat transfer efficiency to optimize overall system performance. Economic analysis comparing pump energy costs against improved heating efficiency determines optimal heat exchanger configuration for specific applications.

Multi-Stage Heat Recovery Cascades

Sophisticated DIY systems capture waste heat at multiple temperature levels, using high-grade heat for direct pool warming while lower-grade heat preheats incoming water or provides supplemental heating. Thermosiphon loops operate without pumping energy, providing continuous background heating even when main systems are offline.

During construction phases, professional construction debris removal services can help maintain organized work areas as you install complex multi-stage systems and manage material deliveries.

Heat recovery cascades maximize thermal utilization by matching heat source temperatures to appropriate heating loads. Natural convection thermosiphon loops require no electrical energy and operate continuously when temperature differentials exist. Heat pump integration can boost marginal heat sources to useful temperature levels for pool heating applications.

Thermosiphon Loop Integration

Natural convection loops require no pumping energy and operate continuously when temperature differentials exist between heat source and pool water. Proper sizing ensures adequate buoyancy forces overcome friction losses while providing steady heat transfer. These passive systems provide background heating that reduces primary system operating requirements.

Buoyancy force calculations determine minimum temperature differentials required to overcome friction losses in thermosiphon loops. Pipe sizing balances flow capacity against friction losses to optimize natural circulation rates. Integration with active systems provides backup heating capacity and reduces primary system cycling during marginal conditions.

Heat Pump Assisted Solar Systems

Small heat pumps boost easy diy solar pool heater output during marginal conditions by using ambient air or ground source heat to raise collector temperatures above pool temperature thresholds. This hybrid approach extends effective solar heating hours while maintaining reasonable equipment costs compared to larger standalone heat pump systems.

Heat pump integration extends solar heating season by boosting collector temperatures during cool ambient conditions. Coefficient of performance calculations show heat pumps operating most efficiently when boosting already-warm solar collectors rather than heating cold water directly. System controls coordinate heat pump operation with solar collection to optimize overall energy efficiency and operating costs.

Thermal Storage Beyond Simple Water Tanks

Advanced thermal storage systems use stratified tanks, phase change materials, and underground thermal banks to store heating capacity for extended periods. Underground rock beds store substantial thermal energy with minimal heat loss, maintaining useful temperatures for weeks while providing thermal buffering for variable heat sources.

Underground thermal storage systems maintain collected heat for extended periods with minimal losses due to earth’s insulating properties. Rock bed storage provides equivalent thermal capacity to water storage while offering better temperature stability and lower installation costs. Stratified storage tanks maximize usable heat by maintaining temperature layers that match different heating loads.

Underground Rock Bed Storage

Buried rock beds store substantial thermal energy with minimal heat loss over extended periods. A 10-cubic-yard rock bed stores equivalent heat to 1,000 gallons of hot water while maintaining useful temperatures for weeks. Underground installation provides natural insulation while eliminating above-ground space requirements.

Thermal mass calculations show rock beds store 20-30% of the thermal energy per cubic foot compared to water but maintain temperatures longer due to reduced surface losses. Underground installation eliminates heat losses to ambient air while providing natural insulation from surrounding earth. Air circulation systems through rock beds transfer stored heat to pool water or building heating systems as needed.

When your DIY pool heater project generates substantial construction debris, old equipment, or excess materials from sourcing operations, construction waste disposal services provide comprehensive cleanup that keeps your workspace organized and your project moving forward.

Final Thoughts

Building an effective diy pool heater requires understanding the interconnected systems that create reliable, efficient heating performance. Material sourcing strategies can reduce costs dramatically while providing superior components, but success depends on understanding thermal dynamics, proper system integration, and smart controls that optimize performance automatically.

Your wood burning pool heater or solar heating system represents a significant investment in time and materials, making proper planning and execution critical for long-term satisfaction. The principles covered here apply whether you’re building a simple solar collector or a sophisticated multi-stage heat recovery system with automated controls and thermal storage.

For ongoing maintenance and system optimization, consider that appliance removal services can help when upgrading components or replacing worn equipment, ensuring your heating system continues operating at peak efficiency.

System integration becomes more critical as complexity increases – each component must work harmoniously with others to achieve optimal performance. Long-term reliability depends on understanding material properties, thermal cycling effects, and proper maintenance procedures that prevent premature failures. Performance monitoring and optimization continue throughout system life, with data collection and analysis driving improvements and efficiency gains over time.

As your system evolves and components need replacement, professional scrap metal pickup services can help responsibly dispose of old heat exchangers, copper tubing, and other metallic components while supporting sustainable material recovery practices.