25 Stunning Basement Wall Ideas for 2025: Transform Your Space

Basement renovations are surging in popularity, with a 47% increase in basement remodeling projects since 2020. I recently helped a friend transform their dark, uninspiring basement into a gorgeous entertainment space, and the wall treatments made the biggest difference. Whether you’re planning a complete renovation or just want to refresh your basement walls, this comprehensive guide covers everything from moisture-resistant solutions to budget-friendly options and innovative trends for 2025.

Table of Contents

-

What to Consider When Choosing Basement Wall Ideas

-

Moisture-Resistant Wall Solutions

-

Decorative and Aesthetic Wall Treatments

-

Practical and Functional Wall Solutions

-

Budget-Friendly Wall Ideas

-

Innovative and Trending Wall Treatments

-

How Jiffy Junk Can Help Prepare Your Space

-

Final Thoughts

What to Consider When Choosing Basement Wall Ideas

Before diving into specific basement wall treatments, you need to evaluate several critical factors that will impact your decision. Basements present unique challenges compared to above-grade spaces. Moisture management must be your top priority, followed by insulation requirements appropriate for your climate zone. Your budget will significantly influence available options, while the intended function of your basement should guide material selections.

Building codes, aesthetic preferences, maintenance requirements, environmental impact, installation method, and long-term durability all play important roles in making the right choice for your specific situation. When planning your basement renovation, consider starting with a thorough basement cleanout to create a clean slate for implementing your wall ideas.

Moisture management in basements requires specialized approaches as below-grade spaces typically experience 10-15% higher relative humidity than above-grade rooms. Concrete walls absorb and transmit ground moisture through capillary action, creating unique challenges for basement wall ideas.

R-value requirements vary by climate zone, with northern regions typically requiring R-15 to R-19 for basement walls, while southern zones may only need R-5 to R-10 according to Department of Energy guidelines. Understanding these requirements will help you select appropriate insulation for your basement walls.

|

Factor |

Importance |

Considerations |

|---|---|---|

|

Moisture Management |

Critical |

Relative humidity, water intrusion history, drainage |

|

Insulation |

High |

Climate zone, R-value requirements, vapor barrier needs |

|

Budget |

Variable |

Material costs, installation expenses, long-term value |

|

Intended Use |

High |

Entertainment, storage, living space, home office |

|

Building Codes |

Critical |

Local requirements, permits, egress, fire safety |

Moisture-Resistant Wall Solutions

1. Waterproof Concrete Sealer

Waterproof concrete sealers create an effective moisture barrier directly on your existing concrete walls. Products like DRYLOK Extreme Waterproofer can withstand significant water pressure while providing a paintable surface. This solution offers excellent moisture protection at an affordable price point and is relatively DIY-friendly.

The application process requires thorough cleaning and patching of the concrete surface before applying multiple coats. While not particularly exciting aesthetically on its own, it creates a solid foundation for additional decorative treatments.

Quality waterproof sealers penetrate 1/8″ to 1/4″ into concrete pores to form a chemical barrier that can withstand up to 15 psi of hydrostatic pressure, equivalent to a 33-foot column of water. This level of protection is crucial for basement walls that face constant moisture exposure.

Application coverage typically ranges from 75-100 square feet per gallon on porous concrete, with two coats recommended for optimal performance and a 24-hour curing time between applications. This makes planning your basement wall project timeline important.

2. Dimpled Membrane Systems

Dimpled membrane systems create a physical separation between your foundation wall and interior finishes. Products like Delta-MS membrane establish an air gap that allows moisture to drain downward to floor drains rather than entering your living space. These systems provide superior moisture management but typically require professional installation.

While more expensive than simple sealers, they deliver excellent long-term protection against water damage and create an ideal substrate for various finishing materials. I’ve seen these systems transform chronically damp basement walls into perfectly dry surfaces ready for any finish.

Dimpled membranes typically feature high-density polyethylene (HDPE) with 8mm-10mm dimples creating an air gap of approximately 1/3″ between the foundation wall and interior finishes. This physical separation is what makes these systems so effective for basement walls.

These systems manage both liquid water and water vapor, reducing relative humidity by up to 20% compared to direct-applied wall finishes while providing a thermal break with an R-value of approximately 0.5. The combination of moisture management and thermal benefits makes dimpled membranes a comprehensive solution.

3. Mold-Resistant Drywall

Specially formulated gypsum panels with fiberglass facing instead of paper provide significant resistance to moisture and mold growth. Products like USG Sheetrock® Brand Mold Tough® panels create a smooth, paintable surface similar to standard drywall but with enhanced moisture performance.

Installation requires first creating a framed wall with proper vapor barrier, then installing and finishing the drywall. This option costs slightly more than standard drywall but delivers much better durability in basement environments.

A client in Portland, Oregon struggled with recurring mold issues in their finished basement despite having no obvious water leaks. After removing the standard paper-faced drywall, we discovered condensation was forming inside the wall cavity during seasonal temperature changes. We rebuilt the walls using a proper vapor barrier behind mold-resistant drywall with fiberglass facing. Three years later, the space remains completely mold-free despite the region’s high humidity, demonstrating how the right materials can solve persistent moisture problems even in challenging climates.

Mold-resistant drywall achieves a score of 10 (highest resistance) on the ASTM D3273 mold resistance test compared to scores of 0-3 for standard paper-faced drywall. This dramatic improvement makes it ideal for basement walls where moisture is a concern.

The fiberglass mat facing eliminates cellulose (paper) that serves as a food source for mold while maintaining similar installation characteristics to standard drywall, including compatibility with standard joint compounds and fasteners. This makes it an easy substitute in your basement wall construction.

4. Cement Board Walls

Cement board provides exceptional durability and moisture resistance for basement applications. Products like HardieBacker® create a solid, water-resistant base for various finishes including paint, texture, or tile. These inorganic panels contain cement and reinforcing fibers, making them highly resistant to water damage and mold growth.

While heavier than standard drywall and more difficult to cut, cement board offers superior performance in high-moisture environments and excellent longevity. I’ve installed cement board in several basement wall projects, and it’s particularly valuable in areas prone to occasional water intrusion.

Cement board maintains dimensional stability when exposed to moisture, with less than 0.07% linear expansion when saturated compared to up to 0.5% for standard drywall. This stability prevents warping and cracking of your basement wall finishes.

Most cement board products are completely inorganic, eliminating any food source for mold growth and offering fire resistance ratings up to 2 hours when properly installed in wall assemblies. This combination of moisture resistance, fire safety, and durability makes cement board an excellent choice for basement wall ideas.

5. Basement Wall Drainage Panels

Comprehensive systems like Basement Systems WaterGuard® combine wall and floor drainage components to manage moisture holistically. The wall panels direct water to a concealed drainage channel at the floor perimeter, which leads to a sump pump system. This approach addresses serious water intrusion issues at their source rather than simply trying to block moisture.

While representing a significant investment, these systems provide peace of mind in problematic basements with active water issues. For homes with chronic water problems, these basement wall ideas can be life-changing.

Interior drainage systems can collect and remove up to 15 gallons of water per minute when properly designed and installed, preventing water accumulation even during heavy precipitation events. This capacity ensures your basement walls stay dry even during the worst weather conditions.

Professional installation includes pressure relief systems that reduce hydrostatic pressure by up to 95%, significantly decreasing the likelihood of foundation cracks and structural damage over time. By addressing the root cause of moisture problems, these systems protect both your basement walls and your foundation.

Decorative and Aesthetic Wall Treatments

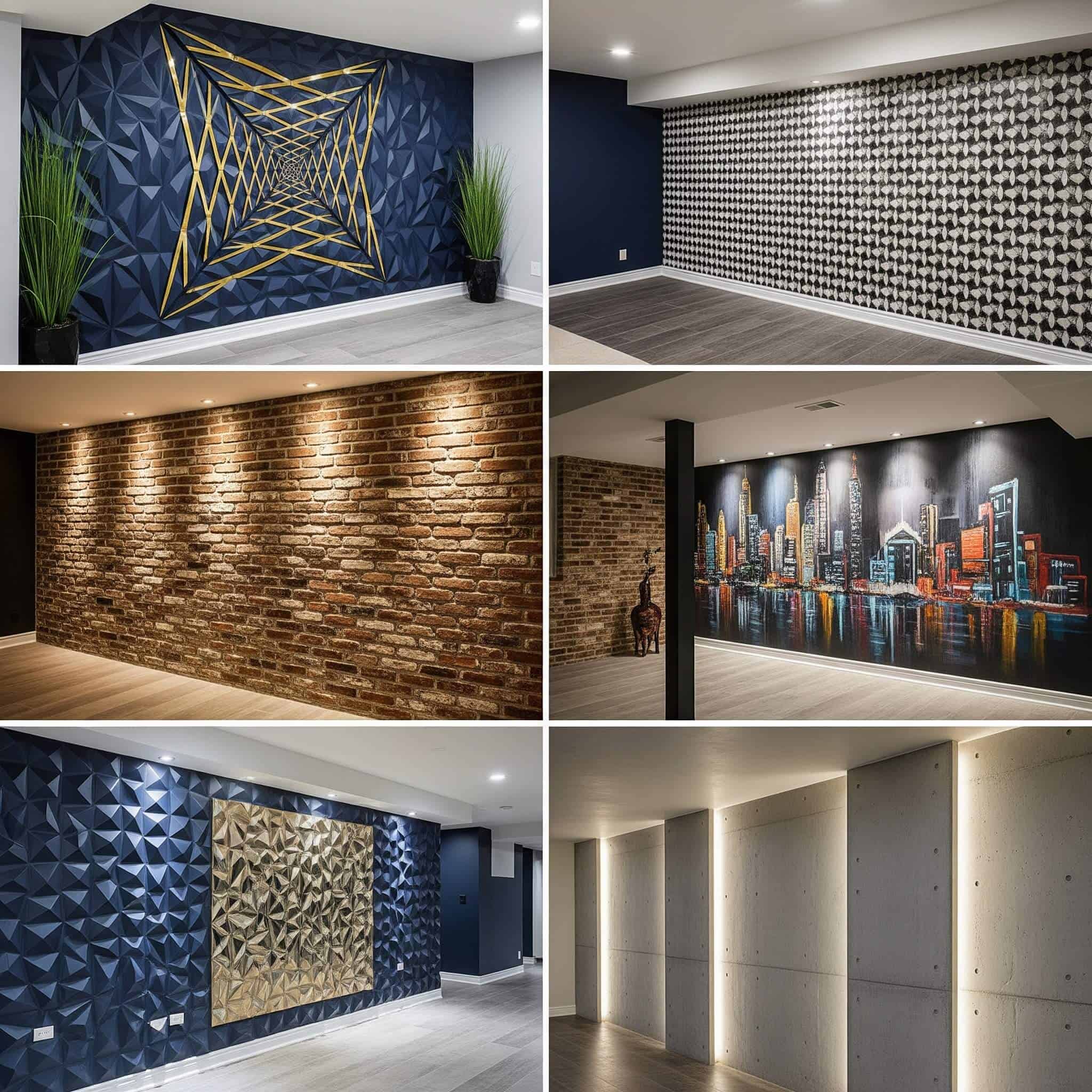

6. Exposed Brick Accent Walls

Exposed brick creates a timeless, industrial charm that adds character to basement spaces. You can either remove existing wall coverings to expose original foundation brick or add brick veneer panels for a similar look without the structural requirements. Real exposed brick requires careful sealing to prevent dust and moisture issues, while modern veneer products offer easier installation with good aesthetic appeal.

This treatment creates significant visual interest and texture that works with various design styles. Before installing a brick accent wall, you may need to address construction debris removal from your basement to ensure a clean installation surface.

I recently helped a client transform their basement with a brick accent wall behind their home theater setup. The warm tones and texture created the perfect backdrop for movie nights and completely changed the feel of the space.

Brick veneer panels typically weigh 4-8 pounds per square foot compared to 40-50 pounds for traditional brick, eliminating the need for additional structural support in basement applications. This makes them much more practical for basement accent wall ideas.

Proper sealing of exposed brick requires penetrating siloxane-based sealers that maintain the brick’s ability to “breathe” while reducing water absorption by up to 95%. This balance is crucial for basement spaces where moisture management remains important even with decorative treatments.

7. Shiplap Wall Treatments

Horizontal or vertical overlapping wood boards create a farmhouse or coastal aesthetic that adds warmth to basement spaces. Pre-primed pine boards offer a traditional look, while PVC versions provide better moisture resistance specifically for basement applications.

Installation involves measuring, cutting, and nailing boards to wall studs, with careful attention to level lines. This treatment provides strong visual texture and warmth while remaining relatively affordable and DIY-friendly for those with basic carpentry skills.

Traditional shiplap features a 1/4″ rabbet on opposing edges creating a 1/8″ reveal between boards that produces distinctive shadow lines while allowing for natural wood expansion and contraction. This detail is what gives shiplap its characteristic appearance.

PVC shiplap alternatives offer complete moisture immunity with zero water absorption and typically include UV inhibitors to prevent yellowing, maintaining color stability for 25+ years in interior applications. For basement spaces where moisture is a concern, these synthetic options provide peace of mind with the same visual appeal.

8. Stone Veneer Accent Walls

Manufactured stone veneer products like Eldorado Stone offer the realistic appearance of natural stone without structural requirements. These materials create dramatic visual interest and texture that becomes a focal point in basement designs. While installation costs are higher than many alternatives and professional installation is recommended, stone veneer provides exceptional durability with minimal maintenance requirements.

The timeless appeal works with various design styles from rustic to contemporary. I’ve used stone veneer in several basement wall ideas projects, and it consistently creates a wow factor that transforms ordinary spaces into something special.

Modern manufactured stone veneers are created from Portland cement, lightweight aggregates, and iron oxide pigments, achieving compressive strengths of 1,800-2,500 psi while weighing 8-12 pounds per square foot. This combination of strength and relatively light weight makes them ideal for basement wall applications.

Installation systems include metal lath (2.5 lb/square yard expanded metal) and two-coat mortar application with scratch coat and setting bed, creating a total installed thickness of approximately 1.5 inches. While more complex than some other basement wall ideas, the results are worth the effort.

9. 3D Textured Wall Panels

Decorative panels with geometric patterns create dimensional interest that transforms flat walls into architectural features. Available in materials ranging from PVC to bamboo fiber, these panels typically come in 2’x2′ or 2’x4′ sections for easy installation. Many options are moisture-resistant and easy to clean, making them well-suited for basement environments.

Installation is quick compared to traditional wall finishing methods, with immediate visual impact that can dramatically change the feel of your space. These panels have become one of my go-to recommendations for clients wanting to add visual interest to their basement walls without major construction.

3D panels create surface variations of 0.5″-2″ depth, diffusing sound waves across multiple frequencies and reducing echo by up to 40% compared to flat surfaces. This acoustic benefit is particularly valuable in basement environments where sound can otherwise bounce off hard surfaces.

Installation systems include direct adhesive application using construction adhesives with initial grab strength of 50-100 pounds per square inch, eliminating the need for mechanical fasteners in most applications. This makes 3D panels one of the easier basement wall ideas to implement, even for DIYers.

10. Wood Plank Feature Walls

Wood plank walls add natural warmth and texture to basement spaces. Reclaimed barn wood offers unique character with historical patina, while new treated lumber provides a cleaner, more consistent look. Proper sealing is essential for basement applications to prevent moisture issues.

This treatment creates a warm, organic aesthetic that adds significant character to otherwise plain spaces. The visual impact is substantial while material costs remain moderate, making this an attractive option for many homeowners.

I recently completed a basement renovation where we used thermally-modified pine for a feature wall. The rich color and subtle grain created a focal point that anchored the entire design, while the special treatment ensured the wood would remain stable despite the basement’s humidity fluctuations.

|

Wood Type |

Moisture Resistance |

Aesthetic |

Cost |

Maintenance |

|---|---|---|---|---|

|

Reclaimed Barn Wood |

Moderate |

Rustic, unique |

$-$$ |

Medium |

|

Thermally-Modified Wood |

High |

Rich, consistent |

$ |

Low |

|

Cedar/Redwood |

High |

Natural, warm |

$-$$ |

Low |

|

PVC/Composite |

Excellent |

Modern, consistent |

$ |

Minimal |

|

Pine with Sealer |

Moderate |

Traditional, paintable |

$ |

Medium-High |

Thermally-modified wood undergoes heating to 350-450°F in an oxygen-free environment, altering the cellular structure to reduce equilibrium moisture content by 50-80% compared to untreated wood. This makes it particularly suitable for basement applications where moisture resistance is crucial.

Proper installation includes a 1/4″ expansion gap at perimeters and maintaining wood moisture content below 12% through acclimation in the installation environment for at least 72 hours. These technical details might seem minor, but they’re essential for ensuring your wood plank basement walls remain beautiful for years.

Practical and Functional Wall Solutions

11. Sound-Absorbing Acoustic Panels

Decorative fabric-wrapped panels reduce echo and improve sound quality, making them ideal for home theaters or music rooms. Products like Acoustimac’s DMD Acoustic Panels combine functional acoustic benefits with aesthetic appeal in various colors and patterns. These panels significantly improve acoustics while adding decorative elements that can enhance your design scheme.

Installation is typically straightforward, involving adhesive mounting or hanging panels like artwork, making this a practical DIY project with professional results. If you’re creating a media room, consider how acoustic panels can complement your basement wall ideas while improving sound quality in your newly reclaimed living space.

Acoustic panels with 2″ thickness typically achieve Noise Reduction Coefficients (NRC) of 0.85-0.95, absorbing up to 95% of sound energy across the 250Hz-4000Hz frequency range most critical for speech intelligibility. This technical performance translates to noticeably clearer conversations and better movie sound in your basement.

Core materials include mineral wool (8-10 pcf density) or open-cell acoustic foam (1.8-2.2 pcf density), with flame spread ratings of Class A (ASTM E84) for building code compliance. Safety and performance go hand-in-hand with these functional basement wall ideas.

12. Magnetic or Dry Erase Wall Surfaces

Specialized paints and primers transform ordinary walls into functional surfaces for home offices, creative spaces, or children’s play areas. Magnetic primer can be applied beneath regular paint, while dry erase paint creates writeable surfaces in any color. These treatments add significant functionality without sacrificing aesthetics, as they can be incorporated into your overall design scheme.

Application requires careful surface preparation and multiple coats for optimal performance, but the result is a highly practical surface that enhances how you use your basement. I’ve created magnetic walls in several basement projects, and they’re always a hit with families who appreciate the blend of fun and function.

Magnetic primers contain iron particles comprising 30-40% of volume solids, requiring 3-4 coats to achieve sufficient ferrous content for magnet adhesion with a pull force of 0.2-0.5 pounds per square inch. This technical detail explains why proper application is so important for these basement wall ideas to function as intended.

Quality dry erase coatings maintain writability/erasability performance for 5-10 years before requiring reapplication, with resistance to ghosting (ink residue) determined by resin system quality and proper curing time. For long-term satisfaction, investing in premium products makes a significant difference.

13. Built-in Storage Wall Systems

Custom shelving and cabinet systems integrated into wall framing maximize space efficiency in basements where every square foot counts. These systems transform walls into functional storage while maintaining a clean aesthetic that reduces visual clutter. Costs vary widely depending on materials and complexity, but the space-saving benefits often justify the investment.

Professional design and installation deliver optimal results, though modular systems offer DIY options for those with carpentry experience and a desire to customize their storage solutions.

When redesigning a 400 sq ft basement in Chicago, we faced the challenge of creating a multipurpose space that would serve as both a guest room and home office. The solution was a custom wall system that integrated a Murphy bed, desk space, and extensive storage. By building storage directly into the walls rather than using freestanding furniture, we recovered nearly 60 square feet of usable floor space. The built-in cabinetry was constructed with marine-grade plywood and finished with moisture-resistant laminate, ensuring durability in the basement environment while maintaining a cohesive design aesthetic that made the small space feel much larger and more functional.

Wall-mounted storage systems typically support 30-75 pounds per linear foot depending on mounting method, with French cleats or metal rail systems providing the highest load capacities. Understanding these weight limitations is crucial when planning what you’ll store on your basement walls.

Custom storage integration can increase usable space by 15-25% compared to freestanding furniture while maintaining clear floor area for building code compliance regarding egress paths. This space efficiency is particularly valuable in basements, which often have limited square footage.

14. Insulated Panel Systems (SIPs)

Engineered panels combine insulation, vapor barrier, and attachment points for finishing materials in a single product. Systems like InSoFast UX 2.0 panels provide excellent thermal performance while simplifying installation compared to traditional framing and insulation methods.

These panels attach directly to foundation walls, creating a continuous insulation layer with integrated attachment points for drywall or other finishes. The uniform surface creates an ideal substrate for various finishing options while improving energy efficiency.

Basement-specific SIPs typically incorporate closed-cell polyurethane or expanded polystyrene (EPS) with R-values of 4-6 per inch, achieving total assembly values of R-10 to R-13 in 2-2.5″ thickness. This thermal performance helps keep your basement comfortable year-round while reducing energy costs.

Integrated vapor management features maintain permeability ratings of 1-5 perms, allowing controlled drying while preventing condensation within the wall assembly at temperature differentials up to 70°F. This technical balance between moisture control and insulation makes SIPs an excellent foundation for various basement wall ideas.

15. Cork Wall Coverings

Natural cork tiles provide insulation, sound absorption, and visual warmth with inherent resistance to mold and moisture. Products from companies like WE Cork offer an eco-friendly option with natural antimicrobial properties. Installation involves adhering tiles to a clean, flat substrate using cork-compatible adhesive.

The material provides thermal insulation value and significant sound dampening properties while creating a unique textural element that stands out from conventional wall treatments. I’ve used cork in several basement projects, and clients are always surprised by how warm and inviting it makes the space feel.

Cork’s cellular structure contains approximately 40 million cells per cubic centimeter, creating natural thermal insulation with R-values of 1.5-2 per inch and sound absorption coefficients (SAC) of 0.3-0.5. These performance characteristics make cork particularly valuable for basement wall ideas where comfort is a priority.

Natural cork contains suberin, a hydrophobic compound that provides inherent resistance to moisture and microbial growth while maintaining indoor air quality with zero VOC emissions after installation. This combination of performance and sustainability makes cork an excellent choice for environmentally conscious homeowners.

Budget-Friendly Wall Ideas

16. Painted Concrete Walls

The most economical finished wall option involves applying specialized concrete paints directly to foundation walls. Products like BEHR Basement & Masonry Waterproofing Paint offer reasonable moisture resistance with a clean, finished appearance. Application requires thorough cleaning, patching, and often a primer coat before applying colored paint.

Various techniques like color washing, stenciling, or faux finishing can enhance basic painted concrete and create more visual interest without significantly increasing costs. For a cost-effective approach, consider painted concrete walls that can be enhanced with decorative techniques while providing basic moisture protection for your basement renovation.

Basement-grade masonry paints typically contain acrylic resins with 45-55% volume solids and permeability ratings of 10-15 perms, allowing moisture vapor transmission while resisting liquid water penetration. This balance is crucial for cheap basement wall ideas that still perform well.

Surface preparation requires reducing alkalinity to pH levels below 10 using muriatic acid solutions (1:10 dilution) or commercial etching products to ensure proper paint adhesion and prevent efflorescence. Don’t skip this step – proper prep is what separates successful painted concrete from peeling, flaking disappointments.

17. Fabric Wall Coverings

Stretched fabric over insulation boards creates soft, warm wall surfaces that add texture and color while improving acoustics. This method provides good sound absorption and can hide irregular wall surfaces at minimal cost. The fabric can be removed and replaced for easy updates when you want a design change.

Installation involves securing insulation boards to walls, then stretching and stapling fabric over the boards for a smooth, professional look. I’ve used this technique in several basement wall ideas projects, particularly for media rooms where the acoustic benefits are as valuable as the aesthetic improvement.

Fabric wall systems typically use 1″-2″ rigid fiberglass insulation boards (3-6 pcf density) providing both thermal benefits (R-4 to R-8) and acoustic absorption across mid-range frequencies. This dual functionality makes fabric walls particularly efficient basement wall ideas.

Proper installation includes maintaining 1/4″ spacing between insulation panels and using breathable synthetic fabrics with air permeability ratings of 50-150 CFM/ft² to prevent moisture accumulation. These technical details ensure your fabric walls remain beautiful and functional over time.

18. Peel-and-Stick Wallpaper

Removable wallpaper allows for easy pattern changes without damage to underlying surfaces. Products from brands like Tempaper and NuWallpaper offer moisture-resistant formulations specifically for challenging environments like basements. Application requires clean, smooth walls and careful alignment of patterns.

This option provides significant design impact at minimal cost, with modern peel-and-stick products offering better moisture resistance than traditional wallpapers. For homeowners who like to change their décor frequently, this flexibility is a major advantage.

Quality peel-and-stick wallpapers use acrylic adhesives with initial repositionability for 24-48 hours and ultimate adhesion strength of 2-4 ounces per inch width while maintaining removability without substrate damage. This balance of adhesion and removability is what makes these products so user-friendly.

Water-resistant formulations incorporate polyvinyl or polyester film layers with moisture vapor transmission rates below 1 perm, preventing moisture penetration while maintaining dimensional stability in humidity fluctuations. These technical improvements have made peel-and-stick wallpaper viable for basement wall ideas where traditional wallpaper would quickly fail.

19. Laminate Wall Panels

Interlocking panels in various finishes provide quick wall coverage with minimal preparation. Many options are moisture-resistant and require no painting or finishing after installation. These systems install much faster than traditional wall finishing methods, making them ideal weekend projects.

The click-together design simplifies installation for DIYers, while the wide range of available styles and finishes allows for customization to match your design vision. I’ve helped several clients install laminate wall panels as a quick basement wall ideas solution when they needed fast results on a limited budget.

Laminate wall panels typically feature high-density fiberboard (HDF) cores with densities of 800-900 kg/m³ and melamine resin surface layers with abrasion resistance ratings of AC3-AC4 (12,000-18,000 rotations). This durability ensures your walls will stand up to daily life.

Tongue-and-groove connection systems provide tensile strength of 15-20 kg/linear cm, maintaining seamless appearance through seasonal humidity changes of ±20% RH. This stability is particularly important for basement wall ideas where moisture conditions can fluctuate.

20. Stenciled Concrete Walls

Decorative stencils with concrete paint create patterns on existing walls at minimal material cost. Stencils can be reused multiple times, making this an economical way to cover large areas with custom designs. The process involves painting a base coat, applying stencils, then adding accent colors to create patterns ranging from subtle textures to bold geometric designs.

While time-intensive, this technique transforms plain concrete into custom designs that look much more expensive than their actual cost. I’ve seen stunning results with stenciled basement walls that completely changed the character of the space for less than $200 in materials.

Stencil materials include 10-12 mil mylar with laser-cut precision of ±0.005″ for crisp edge definition and reusability for 15-25 applications before degradation affects pattern quality. This durability makes stenciling one of the most cost-effective basement wall ideas for large areas.

Specialized stencil adhesives provide temporary bond strength of 0.5-1.5 ounces per square inch, sufficient to prevent bleed-under while allowing clean removal without residue on porous concrete surfaces. This technical detail is what separates professional-looking results from messy disappointments.

Innovative and Trending Wall Treatments

21. Living Walls/Vertical Gardens

Modular living wall systems support plants in a vertical orientation, creating dramatic biophilic design elements with potential air-purifying benefits. Systems like LiveWall include integrated irrigation to simplify maintenance. These installations create a unique connection to nature in below-grade spaces where natural elements are typically lacking.

Proper lighting (natural or supplemental) is essential for plant health, as is selecting appropriate species that can thrive in basement conditions. I recently installed a small living wall in my own basement office, and the psychological benefits of having living plants in the space have been remarkable.

|

Plant Type |

Light Requirements |

Maintenance |

Air Purification |

Moisture Needs |

|---|---|---|---|---|

|

Pothos |

Low (100-300 lux) |

Minimal |

Good |

Low-Medium |

|

Snake Plant |

Low (100-250 lux) |

Minimal |

Excellent |

Very Low |

|

ZZ Plant |

Very Low (75-150 lux) |

Minimal |

Good |

Very Low |

|

Peace Lily |

Medium (300-800 lux) |

Medium |

Excellent |

Medium |

|

Spider Plant |

Medium (300-500 lux) |

Low |

Very Good |

Low-Medium |

Interior living wall systems typically incorporate hydroponic growing media with water retention capacities of 40-60% by volume and pH buffering to maintain levels between 5.5-6.5 for optimal plant nutrient availability. This technical foundation is what allows plants to thrive in vertical installations.

Plant selection for basement applications focuses on species with low light requirements (50-250 foot-candles) and high air purification capabilities, removing 50-90% of benzene, formaldehyde, and trichloroethylene from ambient air. These functional benefits make living walls one of the most beneficial basement wall ideas for overall wellness.

22. Backlit Wall Panels

Translucent materials illuminated from behind create ambient lighting effects that transform ordinary walls into architectural features. Materials range from onyx and alabaster to engineered resins and acrylics with integrated LED lighting systems. These installations create dramatic lighting effects that can completely transform the mood of a basement space.

The combination of light and texture adds depth and interest to otherwise plain walls while providing functional illumination. I’ve used backlit panels to create stunning focal points in several basement projects, and they consistently deliver a wow factor that elevates the entire space.

LED backlighting systems for translucent panels typically operate at 24V DC with power densities of 1.5-3 watts per square foot, producing 80-150 lumens per watt with color temperatures ranging from 2700K (warm) to 5000K (cool). This efficiency makes backlit basement walls surprisingly economical to operate.

Light transmission through panels varies by material: engineered resins (30-70%), alabaster (15-40%), and onyx (5-25%), with thickness determining both structural integrity and light diffusion characteristics. Understanding these properties helps you select the right material for your specific basement wall application.

23. Reclaimed Material Walls

Salvaged architectural elements repurposed as wall features create unique character impossible to replicate with new materials. From old doors and windows to industrial machinery parts, these elements tell a story through materials with history and patina. Sourcing materials requires time and creativity, often involving architectural salvage yards or deconstruction sites.

The result is a completely unique wall treatment with environmental benefits from material reuse. For an eco-friendly approach to your basement renovation, consider using reclaimed materials for your wall treatments, which reduces waste while creating unique character in your space.

During a basement renovation in Boston, we discovered the homeowner had inherited several wooden doors from his grandfather’s 1920s farmhouse that had been stored in the basement for years. Instead of discarding them, we repurposed these doors into a stunning accent wall. We removed the hardware, cut the doors to uniform heights while preserving their original width, and mounted them side-by-side on furring strips attached to the concrete wall. The varied patinas, colors, and original hardware mounting points created a compelling visual story. We sealed the wood with clear water-based polyurethane to preserve the aged appearance while protecting against moisture. The wall became not just a design element but a conversation piece that preserved family history within a modern space.

Reclaimed wood typically has 30-40% lower moisture content (6-8%) than new lumber due to decades of natural air drying, resulting in enhanced dimensional stability with minimal movement in humidity fluctuations. This stability makes reclaimed materials particularly suitable for basement wall features.

Proper preparation of reclaimed materials includes heat treatment to 130°F core temperature for pest elimination and application of borate-based preservatives providing protection against future infestation while maintaining non-toxic status for indoor use. These preparation steps are essential for ensuring your reclaimed basement walls remain beautiful and problem-free.

24. Smart Walls with Integrated Technology

Walls incorporating speakers, charging stations, and home automation controls create high-tech functionality with minimal visible technology. These installations provide significant convenience while maintaining clean aesthetics. Planning should include future access for technology updates or repairs, as well as proper power and data infrastructure.

The result is a sophisticated, integrated approach to technology that enhances how you interact with your basement space. I’ve designed several smart walls for tech-savvy clients, and the ability to control lighting, sound, and climate from seamlessly integrated controls makes a huge difference in how they use their basements.

Integrated wall technology systems typically incorporate low-voltage (12-24V) power distribution networks with power over ethernet (PoE) capabilities delivering up to 100 watts per port for connected devices. This infrastructure supports current technology while providing flexibility for future upgrades.

Wireless control systems operate on mesh network protocols (Zigbee, Z-Wave, Thread) with 128-bit AES encryption and transmission ranges of 35-70 feet through typical basement wall assemblies. These technical specifications ensure reliable performance for your integrated basement wall ideas.

25. Concrete Microtopping Finish

Thin-layer decorative concrete creates a contemporary, industrial aesthetic over existing surfaces. Applied in layers just 1/8″ thick, microtopping can transform damaged or unattractive concrete into a smooth, modern surface. Various coloring and finishing techniques customize the appearance from subtle earth tones to bold metallics.

This technique creates a high-end look with excellent durability and minimal thickness addition, making it ideal for basements with limited ceiling height. I’ve used microtopping to transform rough, damaged basement walls into sleek, modern surfaces that look like they belong in a high-end loft.

Microtopping formulations contain polymer-modified cementitious compounds with compression strengths of 4,500-6,000 psi and flexural strengths of 1,200-1,800 psi, exceeding typical concrete by 15-30%. This superior performance ensures your basement wall ideas will stand the test of time.

Application techniques include steel trowel (smooth), float (light texture), or burnished (polished) finishes with topical sealers providing stain resistance to ASTM D1308 standards against common household chemicals and moisture vapor transmission rates of 3-5 perms. These options allow you to customize both the appearance and performance of your microtopped basement walls.

How Jiffy Junk Can Help Prepare Your Space

Before implementing any basement wall ideas, you’ll likely need to clear out accumulated items and prepare your space. Jiffy Junk specializes in efficient, eco-friendly junk removal for both residential and commercial properties. Their White Glove Treatment ensures all unwanted items are removed with care, leaving your basement clean and ready for transformation.

From old furniture and appliances to construction debris, their fully licensed and insured teams handle everything while prioritizing donation and recycling over landfill disposal. Before starting your basement renovation project, consider scheduling a professional basement cleanout service to remove old furniture, appliances, and debris, creating a blank canvas for your new wall treatments.

Professional junk removal services can clear basement spaces 4-6 times faster than DIY methods, with trained teams efficiently removing 15-20 cubic yards of material in a single service appointment. This efficiency can save you days of work and significantly accelerate your basement renovation timeline.

Responsible disposal practices divert 60-80% of basement cleanout materials from landfills through partnerships with donation centers, recycling facilities, and material recovery operations. This environmental benefit adds value beyond just the convenience of professional junk removal.

Final Thoughts

Selecting the ideal basement wall treatment requires balancing practical concerns like moisture management and insulation with your aesthetic vision and budget constraints. Consider combining multiple approaches—perhaps waterproofing treatments beneath decorative finishes or mixing practical storage walls with accent features.

Taking time to address underlying moisture issues before applying decorative treatments will ensure your renovation’s longevity and success. With proper planning and material selection, your basement walls can transform from a design challenge into a stunning feature that enhances your entire home.

I’ve seen countless basement renovations where the walls made all the difference between a space that feels like an afterthought and one that becomes a favorite part of the home. Which of these basement wall ideas resonates most with your vision? The possibilities are endless, and the transformation can be truly remarkable.

Successful basement wall treatments typically incorporate multiple layers addressing distinct functions: moisture management (0.5-1″ thickness), thermal insulation (1-3″ thickness), and aesthetic finishing (0.25-1″ thickness). This layered approach ensures both performance and appearance.

Long-term performance depends on maintaining basement relative humidity below 60% through proper ventilation (0.5-1 air changes per hour) and temperature control (minimum 5°F above dew point) to prevent condensation within wall assemblies. These environmental controls are the final piece of the puzzle for successful basement renovations.