Mobile Home Renovation Costs: The Hidden Economics You Need to Know

Mobile home renovations operate under different economic rules than traditional homes. According to recent industry data, mobile homeowners spend an average of $15,000 on renovations, yet many projects go over budget by 30-40%. I discovered this firsthand when helping my brother renovate his 1990s double-wide last year. We thought we’d spend $10,000 but ended up at $16,500 because we didn’t understand the unique cost factors specific to manufactured housing. This guide breaks down the true economics of mobile home renovations to help you budget accurately and maximize your investment.

Table of Contents

-

The True Cost Landscape of Mobile Home Renovations

-

Value-Driven Renovation Strategies

-

Alternative Financing Approaches

-

DIY vs. Professional Assessment Framework

-

Renovation Adaptation for Different Mobile Home Types

-

Climate-Specific Renovation Priorities

-

Long-Term Value Preservation Strategies

The True Cost Landscape of Mobile Home Renovations

Mobile homes follow different economic patterns during renovation because of how they’re built. The integrated construction means changes to one system often affect others, creating a domino effect of expenses. This happens because mobile homes built after 1976 follow HUD code standards rather than local building codes, which creates different regulatory requirements and inspection processes.

Mobile home parks often impose additional fees and approval requirements too. These can add 5-15% to your total renovation costs – something I didn’t account for when helping my brother. His park required an architectural review that delayed our project by three weeks and added $800 in fees we hadn’t budgeted for.

According to data from Braustin Homes, remodeling a single-wide mobile home typically costs between $15,000 to $25,000, while double-wide renovations range from $20,000 to $40,000 depending on the scope of work.

Baseline Cost Expectations

Setting realistic cost expectations is your first step toward a successful mobile home renovation. Mobile home renovations typically cost 15-25% less per square foot than traditional homes, but they require specialized knowledge and sometimes custom materials that can be hard to find.

Labor costs often represent 60-70% of total renovation expenses. This happens because contractors need specialized skills for manufactured housing modifications. Many contractors charge premium rates for mobile home work because they understand the unique challenges involved.

Material quantities for mobile homes are calculated differently due to non-standard dimensions. For example, standard 8-foot drywall sheets often need extra trimming for mobile home walls, creating more waste and increasing costs.

Average Cost Ranges by Scope

Mobile home renovation costs vary significantly based on what you’re trying to accomplish. Kitchen renovations in mobile homes cost 30-40% less than traditional homes of comparable size due to smaller footprints and cabinet dimensions. My brother’s kitchen renovation came in at $6,200, which included new cabinets, countertops, and appliances – about 35% less than a similar renovation would cost in a traditional home.

Bathroom renovations often include plumbing updates that represent 40-50% of the total cost due to access challenges and non-standard fixture sizes. When we renovated my brother’s bathroom, we spent $4,800, with nearly half going toward updating the plumbing system that had deteriorated over time.

Exterior renovations deliver the highest ROI in mobile homes, with siding replacement typically returning 70-90% of investment while extending home lifespan by 10-15 years. This makes exterior work particularly valuable for mobile homeowners looking to maximize their investment.

According to Home Remodeling Expert, kitchen remodels in single-wide mobile homes typically cost between $3,000 to $8,000, while bathroom renovations range from $2,000 to $5,000, significantly less than similar projects in traditional homes.

Before beginning any renovation project, consider what you’ll do with all the debris. Many homeowners find that professional services like those detailed in our remodeling scrap and furniture removal guide can save time and ensure proper disposal of old materials.

|

Room Type |

Single-Wide Cost Range |

Double-Wide Cost Range |

Primary Cost Drivers |

|---|---|---|---|

|

Kitchen |

$3,000-$8,000 |

$5,000-$15,000 |

Cabinets, countertops, appliances |

|

Bathroom |

$2,000-$5,000 |

$4,000-$10,000 |

Fixtures, plumbing, waterproofing |

|

Living Areas |

$1,000-$5,000 |

$2,000-$7,000 |

Flooring, wall treatments, lighting |

|

Exterior |

$2,000-$8,000 |

$3,000-$10,000 |

Siding, skirting, roof treatments |

|

Full Home |

$15,000-$25,000 |

$20,000-$40,000 |

Comprehensive updates to all systems |

The Age Factor in Cost Calculation

Your mobile home’s age significantly impacts renovation costs. Pre-1976 homes (before HUD code implementation) typically cost 20-40% more to renovate due to outdated systems, non-standard dimensions, and potential hazardous materials.

Pre-1976 mobile homes often contain aluminum wiring that requires complete replacement to meet current safety standards, adding $1,800-$3,500 to renovation costs. This isn’t just a convenience issue – it’s a safety requirement that can’t be ignored.

Homes built between 1976-1994 frequently have particle board subfloors that require replacement before installing modern flooring. This adds $2-$4 per square foot to flooring projects. I discovered this when helping my brother – we had to replace about 60% of his subfloor before installing new vinyl plank flooring, adding nearly $2,000 to our budget.

Newer mobile homes (post-2000) typically feature standard-sized doors, windows and fixtures, reducing the need for custom materials that can increase costs by 25-40%. This makes newer homes significantly easier and more affordable to renovate.

According to Braustin Homes, “Manufactured homes can certainly be remodeled much like a traditional built in place house,” though pre-1976 mobile homes may require additional work to bring them into compliance with modern HUD regulations.

Hidden Cost Factors

Beyond obvious expenses like materials and labor, mobile home renovations include several hidden cost factors that can derail your budget if not identified early. Mobile home renovations often require specialized insurance coverage during the construction phase, adding 5-10% to project costs. This is something many homeowners don’t discover until they’re already committed to the project.

Transportation costs for materials can be 15-25% higher for mobile home projects in rural areas where many manufactured homes are located. This happens because delivery services often charge premium rates for remote locations, and many mobile home communities are situated outside urban centers.

Waste removal from mobile home renovations costs 20-30% more than traditional homes due to space constraints and specialized material disposal requirements. The limited space around most mobile homes makes dumpster placement challenging, often requiring alternative waste management solutions that cost more.

When Sarah renovated her 1992 single-wide in Arizona, she budgeted $12,000 for a complete bathroom and kitchen update. After demolition began, her contractor discovered significant water damage to the subfloor beneath both rooms, requiring complete replacement and reinforcement. The park’s management also required an engineering inspection before approving structural work. These hidden factors added $3,800 to her budget—a 32% increase she hadn’t anticipated. Sarah now recommends all mobile homeowners set aside at least 25% of their renovation budget for unexpected issues, particularly in homes older than 20 years.

Permit and Regulatory Expenses

Mobile homes face unique regulatory hurdles that traditional homes don’t encounter. Mobile home parks typically require pre-approval of exterior modifications, adding 2-4 weeks to project timelines and increasing carrying costs. This delay can significantly impact your renovation schedule and budget.

HUD code compliance often requires specialized inspections beyond local building department requirements, adding $150-$300 per inspection. These additional inspections ensure that renovations maintain compliance with federal manufactured housing standards.

Zoning regulations in some areas restrict the extent of mobile home modifications, potentially limiting value-adding improvements that would be permitted for traditional homes. This regulatory limitation can affect your renovation ROI and should be researched before planning extensive modifications.

A survey by Home Remodeling Expert found that unexpected expenses like electrical or plumbing repairs in mobile homes can cost between $500-$2,000, while mold or water damage remediation can add $500-$3,000 to renovation costs, particularly in homes over 20 years old.

Utilities Reconfiguration

Mobile home utility systems are compact and integrated differently than site-built homes. Mobile home electrical systems typically operate on 100-150 amp service rather than the 200+ amps common in modern site-built homes, limiting the addition of high-draw appliances. This electrical limitation can restrict your renovation options or require costly service upgrades.

Plumbing in mobile homes often uses smaller diameter pipes (typically 1/2″ rather than 3/4″) that create pressure and flow challenges when adding fixtures. This plumbing constraint can affect bathroom and kitchen renovations, sometimes requiring complete system upgrades to support modern fixtures.

HVAC systems in mobile homes are sized differently than traditional homes, with cooling capacity calculations based on different metrics due to the unique thermal properties of manufactured housing. This means standard HVAC solutions may not work effectively in mobile homes, requiring specialized equipment and installation methods.

Structural Limitations

Mobile homes have weight and structural constraints that traditional homes don’t face. Mobile home floor systems typically support 40 pounds per square foot compared to 50-100 pounds in traditional construction, requiring reinforcement for heavy fixtures or appliances. This weight limitation affects everything from appliance selection to flooring options.

Roof structures in mobile homes use lightweight truss systems that cannot support additional loads without engineering modifications, limiting options for roofing materials. This structural constraint can restrict your ability to install certain roofing products or solar panels without costly reinforcement.

Wall removal in mobile homes affects the entire structural system due to the integrated design, requiring comprehensive structural assessment rather than simple header installation. This interconnected design means that seemingly simple modifications can have far-reaching structural implications.

With interest rates recently dropping, RetailWire reports that “spending on home improvements and repairs is set to expand once again by the middle of next year,” potentially making this an opportune time to plan mobile home renovations.

Value-Driven Renovation Strategies

Mobile homes operate under different value dynamics than traditional homes, with renovations typically yielding lower returns on investment. Mobile homes typically depreciate rather than appreciate, requiring renovation strategies focused on slowing depreciation rather than building equity. This fundamental difference shapes how you should approach renovation planning.

The mobile home resale market values practical improvements over luxury features, with a different hierarchy of valued upgrades than traditional housing. Understanding this value hierarchy helps you prioritize improvements that deliver the most return for your investment.

ROI Hierarchy for Mobile Homes

Not all renovations yield equal returns in the mobile home context. Mobile home buyers prioritize energy efficiency improvements 2-3 times more heavily than traditional home buyers due to the higher relative utility costs. This preference makes energy-focused renovations particularly valuable in the mobile home market.

Exterior improvements deliver 15-25% higher ROI in mobile homes than traditional homes because they address the stigma and perceived value challenges of manufactured housing. A well-maintained exterior signals that the entire home has been properly cared for, increasing buyer confidence and willingness to pay premium prices.

Functional improvements consistently outperform aesthetic upgrades in mobile home ROI calculations, with a 2:1 value ratio for improvements that reduce operating costs. This practical value orientation reflects the budget-conscious nature of most mobile home buyers.

Miguel invested $18,000 renovating his 2005 double-wide in Florida, carefully prioritizing improvements based on ROI potential. He spent $5,000 on energy efficiency upgrades (insulation, window sealing, and HVAC optimization), $4,000 on exterior improvements (siding repair and painting), $6,000 on bathroom and kitchen modernization focusing on functionality rather than luxury, and $3,000 on cosmetic interior updates. When he sold two years later, the home appraised for $27,000 more than comparable unrenovated units in his community—a 150% return on his strategic investment. The buyers specifically cited the lower utility bills and modern, functional spaces as key selling points.

High-Return Essentials

Energy efficiency upgrades typically return 110-150% of investment through utility savings and increased value. Belly insulation upgrades reduce heating and cooling costs by 25-35% in mobile homes compared to 10-15% in traditional construction due to the exposed undercarriage. This dramatic efficiency improvement makes insulation one of the highest-ROI investments for mobile homeowners.

Window replacements in mobile homes address thermal bridging issues that account for 30-40% of energy loss, a significantly higher percentage than in traditional construction. The impact of window improvements is particularly pronounced in mobile homes, making this upgrade especially valuable.

Bathroom renovations that focus on water efficiency can reduce water usage by 30-50%, creating ongoing savings that contribute to the high ROI calculation. These functional improvements address both comfort and operating costs, appealing strongly to future buyers.

For effective energy efficiency improvements, proper insulation is crucial. Once you’ve removed old materials, you’ll need to dispose of them properly. Our guide on carpet removal considerations provides valuable insights that apply to insulation disposal as well.

|

Improvement Type |

Average Cost |

Typical ROI |

Value Added |

Primary Benefit |

|---|---|---|---|---|

|

Belly Insulation |

$1,200-$3,000 |

120-150% |

Energy savings + value |

25-35% reduction in heating/cooling costs |

|

Window Replacement |

$3,000-$7,000 |

110-130% |

Energy savings + comfort |

Eliminates drafts and thermal bridges |

|

Bathroom Modernization |

$2,000-$4,000 |

80-100% |

Functional improvement |

Updates high-use space with modern fixtures |

|

Exterior Siding |

$4,000-$8,000 |

70-90% |

Protection + appearance |

Extends home life by 10-15 years |

|

Kitchen Updates |

$3,000-$8,000 |

65-85% |

Functional improvement |

Modernizes highest-value interior space |

|

Roof Replacement |

$3,500-$7,500 |

60-80% |

Protection + efficiency |

Prevents water damage and improves insulation |

Luxury Upgrades to Avoid

Custom cabinetry exceeding $5,000 typically returns only 40-50% in mobile homes, compared to 65-75% in traditional homes. The mobile home resale market has price ceilings that limit the value of luxury upgrades, with most markets capping at 70-80% of replacement cost regardless of improvements.

High-end appliances over $3,000 return just 30-45% of investment at resale. High-end materials often require structural modifications to support their weight, adding hidden costs that further reduce ROI. This weight consideration is particularly relevant in mobile homes, where floor systems have lower load ratings than traditional construction.

Extensive floor plan modifications costing $10,000+ generally recoup only 25-40% of expenses. Luxury upgrades in mobile homes typically depreciate at 15-20% per year compared to 5-10% in traditional homes due to market perception issues. This accelerated depreciation makes luxury investments particularly poor choices for mobile home renovations.

Phased Renovation Planning

Taking a strategic, phased approach to mobile home renovations can optimize both cash flow and value creation. Phased renovations allow for discovery and addressing of hidden issues before cosmetic work begins, preventing the 30-40% cost overruns common in mobile home projects. This methodical approach has saved me thousands on multiple renovation projects.

Sequential improvements create compounding benefits, with early structural and system improvements enhancing the performance and longevity of later cosmetic upgrades. For example, addressing insulation and moisture issues before installing new drywall prevents future mold problems and extends the life of your wall finishes.

Phased approaches allow for material cost optimization through strategic purchasing and storage, avoiding the 10-15% premium often paid for rush orders. This planning advantage can significantly reduce your overall project costs while improving quality.

Structural-First Sequencing

Begin with foundational elements that affect all subsequent work. Mobile home subfloors typically show signs of water damage 5-7 years earlier than traditional homes due to their exposure to ground moisture. Identifying and addressing these issues early prevents having to tear out finished work later.

Roof systems in mobile homes have an average lifespan of 15-20 years compared to 25-30 years for traditional roofing, making them a priority in homes over 15 years old. Addressing roof issues before interior work prevents water damage to your new improvements.

Wall stability issues in mobile homes often manifest as door misalignment and window operation problems, providing early warning signs of structural concerns. Correcting these issues before cosmetic work ensures your finished surfaces won’t crack or separate due to ongoing structural movement.

Mobile Home Renovation Phasing Checklist:

Phase 1: Assessment & Structural Integrity (Month 1-2)

-

[ ] Complete professional inspection of subfloor, roof, and structural elements

-

[ ] Address water damage and moisture issues

-

[ ] Repair/replace damaged subfloor sections

-

[ ] Reinforce floor system if needed for planned upgrades

-

[ ] Address roof leaks and structural issues

-

[ ] Stabilize any compromised walls

-

[ ] Upgrade insulation in belly and attic spaces

Phase 2: Systems Upgrades (Month 2-3)

-

[ ] Update electrical system to handle modern appliances

-

[ ] Replace outdated plumbing components

-

[ ] Seal and repair HVAC ductwork

-

[ ] Upgrade ventilation systems

-

[ ] Install energy-efficient windows and doors

-

[ ] Address any code compliance issues

Phase 3: Functional Spaces (Month 3-5)

-

[ ] Renovate bathroom(s) with water-efficient fixtures

-

[ ] Update kitchen with practical, durable materials

-

[ ] Install energy-efficient appliances

-

[ ] Replace flooring with appropriate weight-rated materials

-

[ ] Add storage solutions throughout home

Phase 4: Finishing Touches (Month 5-6)

-

[ ] Paint interior walls and ceilings

-

[ ] Install trim and moldings

-

[ ] Update lighting fixtures

-

[ ] Replace hardware and fixtures

-

[ ] Exterior painting and siding repair

-

[ ] Skirting replacement or repair

-

[ ] Final inspections and documentation

Systems-Before-Surfaces Approach

After structural elements, address all systems that live within walls and floors. Mobile home electrical systems typically need updating every 20-25 years compared to 30-40 years for traditional homes due to vibration and temperature fluctuation effects. This accelerated aging makes electrical updates particularly important in older mobile homes.

Plumbing systems in mobile homes experience 2-3 times more movement-related stress than traditional homes, accelerating wear and failure rates. This increased stress comes from the natural flexing of mobile home structures, which puts additional strain on rigid plumbing components.

HVAC ductwork in mobile homes loses efficiency at a rate of 5-7% per year compared to 2-3% in traditional homes, making regular inspection and sealing a high-priority maintenance item. This efficiency loss occurs because mobile home ductwork is more exposed to temperature extremes and physical disturbance.

The Johnson family learned the systems-before-surfaces lesson the hard way during their mobile home renovation. After spending $3,200 on new luxury vinyl plank flooring and $2,800 on drywall and paint throughout their 1995 single-wide, they discovered significant plumbing leaks that required cutting into both the new flooring and walls. The repair cost an additional $2,100, plus $1,800 to patch and repair the new surfaces—nearly doubling their original budget. Had they inspected and updated the plumbing system before the cosmetic renovations, they would have saved approximately $3,900 and completed the project three weeks sooner.

Cash Flow-Optimized Scheduling

Breaking renovations into 3-6 month phases aligned with financial capacity allows for better contractor rates. Mobile home renovations scheduled during off-peak seasons (typically fall and winter) can secure contractor discounts of 15-25% due to lower demand. This seasonal advantage can significantly reduce your labor costs.

Material purchasing for phased projects can take advantage of seasonal sales cycles, with flooring typically discounted in January, appliances in September, and building materials in November. Strategic purchasing based on these sales cycles can reduce material costs by 12-20%.

Phased renovations allow for real-world testing of improvements before proceeding to the next phase, reducing the risk of systemic issues that affect multiple renovation elements. This testing period helps identify and address problems early, preventing costly rework later in the project.

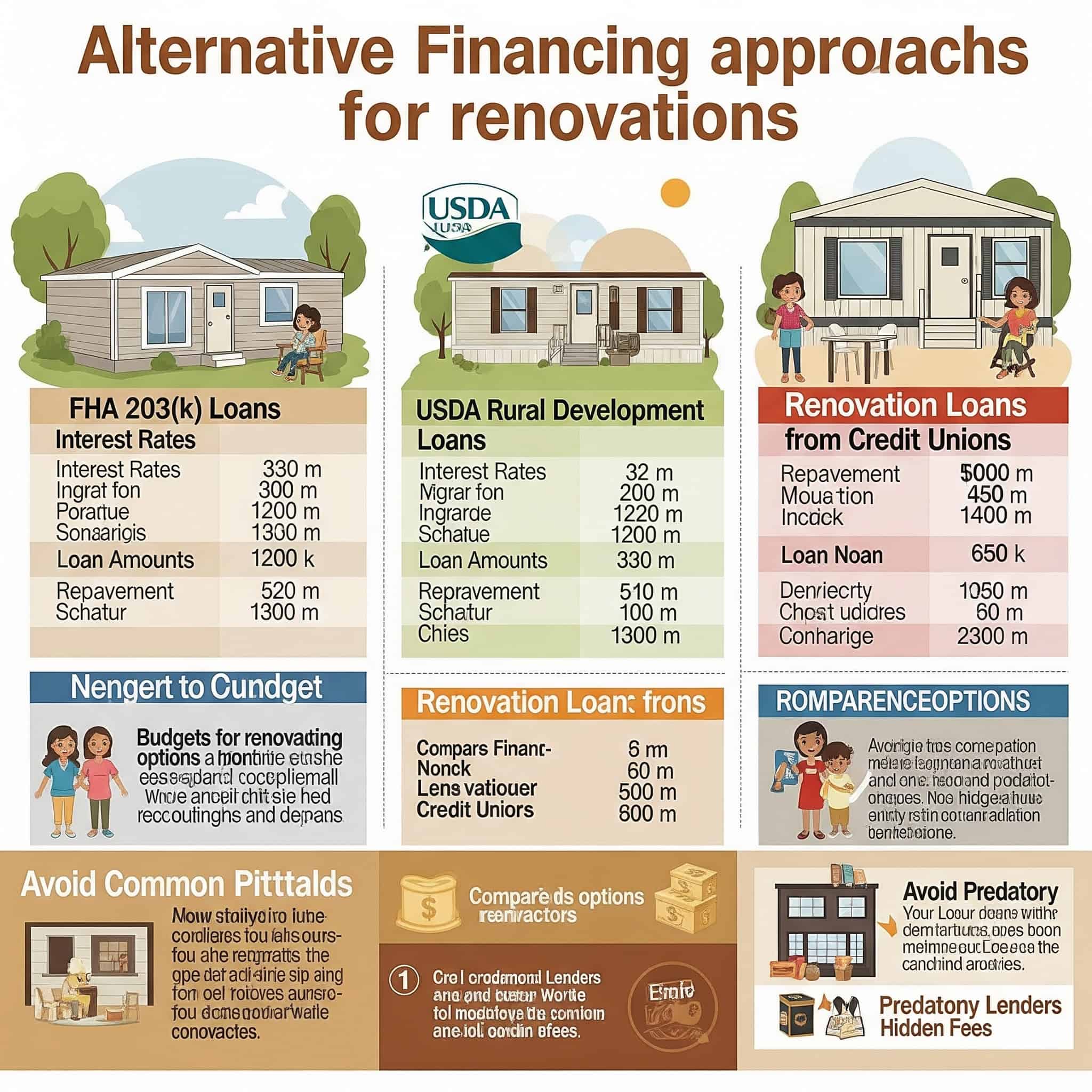

Alternative Financing Approaches

Mobile home renovations face unique financing challenges since traditional home equity products are often unavailable or unsuitable. Mobile homes are typically classified as personal property rather than real estate, disqualifying them from traditional home equity loans and lines of credit. This classification limitation significantly restricts financing options.

The average interest rate for mobile home improvement financing is 3-5% higher than rates for traditional home renovations due to perceived risk factors. This rate premium increases the importance of finding specialized financing options designed specifically for manufactured housing.

Specialized Mobile Home Lending

Several financial products specifically designed for mobile home renovations exist but remain underutilized due to lack of awareness. Mobile home-specific lending products typically offer interest rates 2-4% lower than general personal loans for the same credit profile. This rate advantage can save thousands over the life of the loan.

Specialized lenders understand the value-adding potential of specific mobile home improvements, allowing for higher loan-to-value ratios than general lenders. This increased lending flexibility makes it easier to finance comprehensive renovation projects.

Mobile home renovation loans often feature more flexible debt-to-income requirements, typically allowing ratios up to 45-50% compared to 36-43% for traditional mortgage products. This qualification flexibility makes financing more accessible to mobile homeowners with modest incomes.

Title I FHA Loans

These government-backed loans offer up to $25,000 for mobile home improvements with interest rates 2-4% lower than personal loans, 15-20 year terms, and no equity requirements. Title I loans are secured by the mobile home itself rather than the land, making them available to the 40% of mobile homeowners who rent their lots. This unique security arrangement opens financing doors for park residents.

These loans require contractors to be FHA-approved, ensuring work meets minimum quality standards and protecting against substandard renovations. While this requirement limits contractor selection, it provides valuable quality assurance for homeowners.

Title I loans can be combined with energy efficiency tax credits and rebates, effectively reducing the cost of qualifying improvements by 10-30%. This combination of favorable financing and tax incentives can make energy-focused renovations particularly affordable.

According to The Mortgage Reports, “FHA Title 1 loans are meant for home improvements only. You can borrow up to $25,090 for homes on owned land and up to $7,500 for manufactured homes on leased land.”

Chattel Refinancing with Cash-Out

For mobile homes with existing chattel loans (personal property loans), refinancing with cash-out options can provide $5,000-$20,000 for renovations while potentially lowering the interest rate on the existing debt. Chattel refinancing typically requires the mobile home to have maintained at least 80% of its original value, making this option more viable for newer units or well-maintained older homes.

The cash-out portion of these loans is typically limited to 75-80% of the home’s appraised value minus the existing loan balance. This limitation helps prevent over-leveraging the property while still providing substantial renovation funding.

Processing times for chattel refinancing average 3-5 weeks compared to 6-8 weeks for traditional mortgage refinancing due to simplified appraisal requirements. This faster processing can help you start your renovation sooner, reducing interim housing costs if you’re renovating before moving in.

Community-Based Funding Solutions

Beyond traditional lending, community-focused programs can provide alternative paths to renovation funding, particularly for low to moderate-income households or those in underserved areas. Community-based funding programs typically focus on health, safety, and energy efficiency improvements rather than cosmetic upgrades. This focus aligns with the highest-ROI improvements for mobile homes.

Qualification for these programs is usually based on household income rather than credit scores, with most programs serving households at 80% or below of area median income. This income-based qualification makes these programs accessible to many mobile homeowners who might not qualify for traditional financing.

Application processes for community programs typically take 1-3 months, requiring planning ahead for seasonal improvement needs. This extended timeline means you’ll need to apply well before you plan to start your renovation, particularly for weather-dependent improvements like roofing or insulation.

Weatherization Assistance Programs

Federal and state weatherization programs provide an average of $3,500-$7,000 in free energy efficiency upgrades for qualifying mobile homes, including insulation, window improvements, and HVAC optimization. Weatherization programs use energy audits to identify the most cost-effective improvements, typically achieving a savings-to-investment ratio of 4:1 or better. This rigorous cost-benefit analysis ensures the improvements deliver maximum value.

Mobile homes qualify for specialized weatherization techniques not available to traditional homes, including belly wrap systems and roof cavity insulation methods. These specialized approaches address the unique construction characteristics of manufactured housing.

Program improvements include both materials and professional installation, eliminating the need for homeowner technical expertise. This turnkey approach makes weatherization assistance particularly valuable for homeowners without DIY skills or physical ability to perform the work themselves.

Manufacturer Renovation Partnerships

Several mobile home manufacturers offer renovation programs for their legacy models, providing 15-30% discounts on materials and connecting owners with certified installers. Manufacturer programs often include proprietary parts and materials designed specifically for their home models, ensuring proper fit and function. This perfect-fit advantage eliminates many of the challenges associated with finding compatible replacement parts.

These partnerships typically provide detailed documentation of improvements that can increase resale value and insurability. This documentation can be particularly valuable when selling your home, providing evidence of professional-quality improvements.

Certified installers through these programs understand the specific construction methods used by the manufacturer, reducing the risk of installation errors. This specialized knowledge helps ensure that improvements integrate properly with your home’s existing systems and structure.

DIY vs. Professional Assessment Framework

The DIY approach to mobile home renovations presents unique considerations compared to traditional homes. Mobile home DIY projects typically require 15-25% more research time than traditional home projects due to specialized construction methods and materials. This increased preparation requirement should factor into your timeline planning.

The risk assessment for DIY projects in mobile homes must account for the integrated nature of systems, where modifications to one component often affect others. This interconnected design means that seemingly simple projects can have unexpected complications if you don’t understand how mobile home systems interact.

Mobile Home-Specific DIY Opportunities

Certain renovation aspects are particularly well-suited for DIY in the mobile home context, offering significant savings with manageable risk levels. DIY-friendly projects in mobile homes typically save 40-60% compared to professional installation due to the high labor-to-materials ratio. This substantial savings makes DIY particularly attractive for budget-conscious mobile homeowners.

Mobile home DIY projects often benefit from the smaller scale of manufactured housing, with most rooms requiring 30-50% less material than traditional homes. This reduced material requirement makes projects more manageable for solo DIYers or those with limited experience.

The lightweight materials used in mobile homes are typically easier to handle for DIY installation, with wall panels weighing 50-70% less than traditional drywall. This weight advantage reduces the physical demands of many renovation tasks, making them accessible to more homeowners.

Interior Surface Transformations

Wall paneling upgrades save $1,200-$2,500 in labor costs and require only basic tools. Mobile home wall panels are typically 1/4″ thick compared to 1/2″ drywall, requiring different fastening methods but making them easier to cut and install. This thickness difference actually makes installation easier for DIYers, as the panels are lighter and easier to handle.

Vinyl plank flooring installation saves $800-$1,800 in labor while accommodating the flexible nature of mobile home subfloors. Vinyl plank flooring is ideal for mobile homes because it accommodates the natural flexing of manufactured housing floors while providing waterproof protection. This flexibility makes it more forgiving for DIY installation than ceramic tile or hardwood.

Cabinet refacing rather than replacement saves 60-70% of total cabinet costs while working within the non-standard dimensions often found in mobile homes. Cabinet refacing in mobile homes must account for the non-standard 32″ height common in older units compared to the 36″ standard in traditional homes. This dimension difference makes standard replacement cabinets problematic, while refacing works with the existing cabinet boxes.

For homeowners without access to a kitchen during renovation, House Beautiful reports on “Kitchen Cubes,” mobile trailers that provide fully functional temporary kitchens during remodels, though currently only available in the UK.

DIY-Friendly Energy Improvements

Belly insulation replacement saves $800-$1,500 in labor costs and addresses a mobile home-specific issue. Belly insulation in mobile homes typically degrades 30-50% faster than attic insulation due to ground moisture exposure, making it a high-priority maintenance item. This accelerated degradation means most mobile homes over 10 years old would benefit from insulation replacement.

Window sealing and storm window installation costs $30-$50 per window in materials while saving $75-$150 per window in professional installation. Window sealing in mobile homes addresses infiltration issues that account for 25-35% of heating/cooling loss, a higher percentage than in traditional construction. This high impact makes window improvements particularly valuable in mobile homes.

Roof reflective coating application costs $300-$600 in materials while saving $700-$1,200 in professional application. Roof coatings for mobile homes are formulated differently than traditional roof coatings, with enhanced flexibility to accommodate the greater thermal expansion of mobile home roofs. This specialized formulation addresses the unique movement characteristics of mobile home roofs.

After completing energy improvements like insulation replacement, you’ll need to dispose of old materials properly. Consider checking out our guide on green junk removal options to ensure your renovation waste is handled in an environmentally responsible way.

DIY Mobile Home Energy Improvement Checklist:

Preparation:

-

[ ] Take “before” photos for documentation

-

[ ] Measure and calculate materials needed with 10% extra

-

[ ] Research mobile home-specific products and techniques

-

[ ] Gather proper safety equipment (gloves, masks, eye protection)

-

[ ] Check weather forecast for optimal conditions

Belly Insulation Replacement:

-

[ ] Remove skirting for access

-

[ ] Inspect and repair belly wrap/vapor barrier

-

[ ] Remove damaged insulation

-

[ ] Install new insulation (R-19 or higher recommended)

-

[ ] Secure with proper fasteners

-

[ ] Seal all seams with appropriate tape

-

[ ] Reinstall skirting with proper ventilation

Window Sealing:

-

[ ] Clean all window frames thoroughly

-

[ ] Check for structural issues around windows

-

[ ] Apply appropriate caulking for mobile homes

-

[ ] Install weatherstripping around operable parts

-

[ ] Consider adding storm windows for additional efficiency

-

[ ] Test windows for proper operation after sealing

Roof Coating Application:

-

[ ] Clean roof surface thoroughly

-

[ ] Repair any damage or leaks

-

[ ] Apply primer if recommended by manufacturer

-

[ ] Apply mobile home-specific reflective coating

-

[ ] Ensure proper coverage (typically 2 coats)

-

[ ] Allow full curing time before rain exposure

Final Steps:

-

[ ] Document all improvements with photos

-

[ ] Save product information and warranties

-

[ ] Monitor energy bills to track savings

-

[ ] Schedule annual maintenance checks

Professional Necessity Areas

Certain aspects of mobile home renovation should remain in professional hands due to specialized knowledge requirements, safety concerns, or code compliance issues specific to manufactured housing. Professional mobile home specialists typically have 40-60% faster completion times for complex projects due to their familiarity with manufactured housing systems. This efficiency advantage can actually make professional work more cost-effective for complex projects, despite higher hourly rates.

The integrated design of mobile homes means that errors in one system often cascade to others, increasing the risk factor for DIY work. This cascading effect can turn minor mistakes into major problems, making professional expertise particularly valuable for system-related work.

Professional work on mobile homes typically includes warranty protection that covers both labor and consequential damage, providing financial protection against unforeseen issues. This warranty protection can be particularly valuable given the interconnected nature of mobile home systems.

Structural Modifications

Wall removal or modification requires understanding of mobile home-specific load distribution. Mobile home walls use different load distribution systems than traditional homes, with marriage walls carrying up to 40% of the total roof load. This concentrated load distribution makes structural modifications particularly risky without professional assessment.

Roof structure alterations must account for the integrated truss system unique to manufactured housing. Roof modifications in mobile homes must account for the bow truss design common in manufactured housing, which behaves differently than traditional rafter systems. This unique design requires specialized knowledge to modify safely.

Foundation leveling requires specialized equipment and knowledge of mobile home weight distribution. Foundation leveling for mobile homes requires understanding of the specific pier placement and load points unique to each manufacturer and model. This specialized knowledge helps prevent damage during the leveling process.

Systems Integration Expertise

Electrical panel upgrades in mobile homes must account for their unique power distribution systems and aluminum wiring common in older units. Mobile home electrical systems typically use branch circuits with different load calculations than traditional homes, requiring specialized knowledge for safe modifications. This electrical difference creates safety risks for DIYers without specific mobile home electrical knowledge.

Plumbing system modifications must navigate the belly wrap and insulation systems specific to mobile homes. Plumbing in mobile homes often uses a central manifold system rather than the trunk-and-branch approach common in traditional construction, requiring different modification techniques. This plumbing configuration difference requires specialized knowledge to modify effectively.

HVAC ducting modifications must work within the confined spaces and specialized dimensions of mobile home infrastructure. HVAC systems in mobile homes use smaller ducts (typically 6″ vs. 8″ in traditional homes) with different airflow calculations and balance requirements. These dimensional differences make HVAC modifications particularly challenging without specialized knowledge.

Professional Assessment Checklist

Before starting any DIY project, evaluate structural impact, systems interference, code compliance, and park regulations. Professional assessments typically include thermal imaging and moisture mapping that identify hidden issues invisible to the naked eye. These advanced assessment techniques can reveal problems that would go undetected in visual inspections.

HUD code compliance for mobile homes includes specific requirements for egress, ventilation, and fire safety that differ from local building codes. These specialized requirements create compliance challenges that many DIYers aren’t equipped to address without professional guidance.

Professional assessments provide documentation that can be valuable for insurance purposes and future sale, establishing that modifications were properly evaluated. This documentation can protect you from liability and support higher resale values by demonstrating professional oversight.

Renovation Adaptation for Different Mobile Home Types

The age, construction style, and manufacturer of your mobile home significantly influence renovation approaches, costs, and feasibility. Mobile home construction standards have evolved through distinct eras, with major shifts in 1976 (HUD Code implementation) and 1994 (enhanced energy and wind resistance requirements). These regulatory changes created significant differences in construction methods and materials.

Different manufacturers used proprietary building systems that create unique renovation considerations not addressed in generic renovation guides. Understanding your home’s specific manufacturer can help you anticipate challenges and identify appropriate solutions for your renovation.

Era-Specific Renovation Considerations

Mobile homes built in different decades feature unique construction methods, materials, and design philosophies that necessitate customized renovation techniques. Construction materials in mobile homes have evolved significantly, with pre-1976 homes often using higher quality solid wood components but outdated electrical and plumbing systems. This quality disparity creates both challenges and opportunities for renovation.

Wall construction methods changed dramatically between eras, with older homes using 2×2 or 2×3 framing compared to the 2×4 or 2×6 construction in newer models. This framing difference affects everything from insulation options to the feasibility of wall modifications.

Insulation standards improved with each era, with pre-1976 homes typically having R-7 wall insulation compared to R-11 in 1980s models and R-19+ in modern units. This insulation evolution means that older homes typically need more extensive energy efficiency improvements.

Pre-1976 Legacy Units

These vintage units often feature aluminum wiring that requires complete replacement. Pre-1976 mobile homes often used copper-clad aluminum wiring that presents unique fire risks as connections deteriorate over time. This wiring issue creates both safety concerns and renovation requirements.

Wall construction in these units typically used 16″ on-center spacing but with smaller dimensional lumber, creating challenges for modern insulation techniques. The smaller framing members limit insulation cavity depth and complicate the installation of modern electrical and plumbing systems.

Plumbing in pre-1976 units often used galvanized steel pipes that have a 40-50 year lifespan, meaning most are now beyond their intended service life. This plumbing obsolescence typically requires complete system replacement during comprehensive renovations.

1980s-1990s Double-Wide Adaptations

These homes feature marriage line connections that require special attention during renovations. Marriage lines in double-wides typically settle at different rates, creating height discrepancies of 1/4″ to 1″ that must be addressed before flooring installation. These settlement differences can create visible seams in flooring and wall finishes if not properly addressed.

Ceiling treatments at marriage lines used specialized molding systems that require matching when renovating to maintain a seamless appearance. Finding compatible replacement moldings can be challenging, sometimes requiring custom fabrication.

HVAC systems in double-wides were designed for the original floor plan, with airflow balanced for specific room configurations that change when walls are removed. This airflow dependency means that floor plan modifications often require HVAC rebalancing to maintain comfort throughout the home.

Manufacturer-Specific Quirks

Different manufacturers employed proprietary building systems, components, and materials that create unique renovation challenges and opportunities. Major manufacturers like Fleetwood, Champion, and Skyline each developed proprietary construction methods that affect how renovations must be approached. These manufacturer differences can significantly impact renovation feasibility and cost.

Replacement parts and materials often need to be compatible with manufacturer-specific dimensions and connection systems. This compatibility requirement can make finding suitable replacement components challenging for certain manufacturers or models.

Documentation of manufacturer specifications can be obtained through HUD’s Institute for Building Technology and Safety (IBTS) for homes built after 1976. This documentation access can provide valuable insights into your home’s specific construction details.

Fleetwood-Specific Considerations

Fleetwood homes (particularly 1985-2000) utilized a distinctive roof truss system that allows for ceiling raising in living areas without complete roof restructuring. Fleetwood’s roof truss design used a modified bow truss with reinforced center sections that can be partially reconfigured to create vaulted ceiling areas. This structural advantage creates unique design opportunities not available in other manufacturers’ homes.

Their plumbing manifold systems concentrate water lines for easier access during renovations but require specialized replacement parts that cost 20-30% more than standard components. The plumbing manifold system used in many Fleetwood homes centralizes water distribution, making it easier to add fixtures but requiring proprietary valves and connectors. This centralized design simplifies some aspects of plumbing renovation while complicating others.

Their wall construction typically permits removal of non-load-bearing partitions with minimal structural reinforcement. Interior wall construction in Fleetwood homes from this era typically used clearly marked load-bearing indicators inside wall cavities, simplifying identification during renovation. This clear marking system reduces the risk of inadvertently removing structural walls.

Champion/Redman Adaptation Techniques

These units frequently employed proprietary “quick-connect” electrical systems that complicate junction box relocations. Champion’s quick-connect electrical systems used proprietary plugs and receptacles that must be converted to standard NM connections when modifying circuits. This conversion requirement adds complexity to electrical modifications.

Their distinctive floor joist spacing (typically 24″ rather than 16″ on-center) necessitates subfloor reinforcement before installing ceramic tile or stone surfaces. The wider joist spacing used in these homes reduces material costs during construction but creates more flexible floors that require additional support for rigid surface materials. This flexibility limitation must be addressed for certain flooring types.

Their bathroom plumbing walls were designed with accessibility in mind, making bathroom reconfigurations 15-20% less expensive than in competitor models of the same era. Bathroom designs in these models typically included 2-3″ of additional cavity space in plumbing walls, allowing for easier reconfiguration of fixtures and supply lines. This extra space creates valuable flexibility for bathroom renovations.

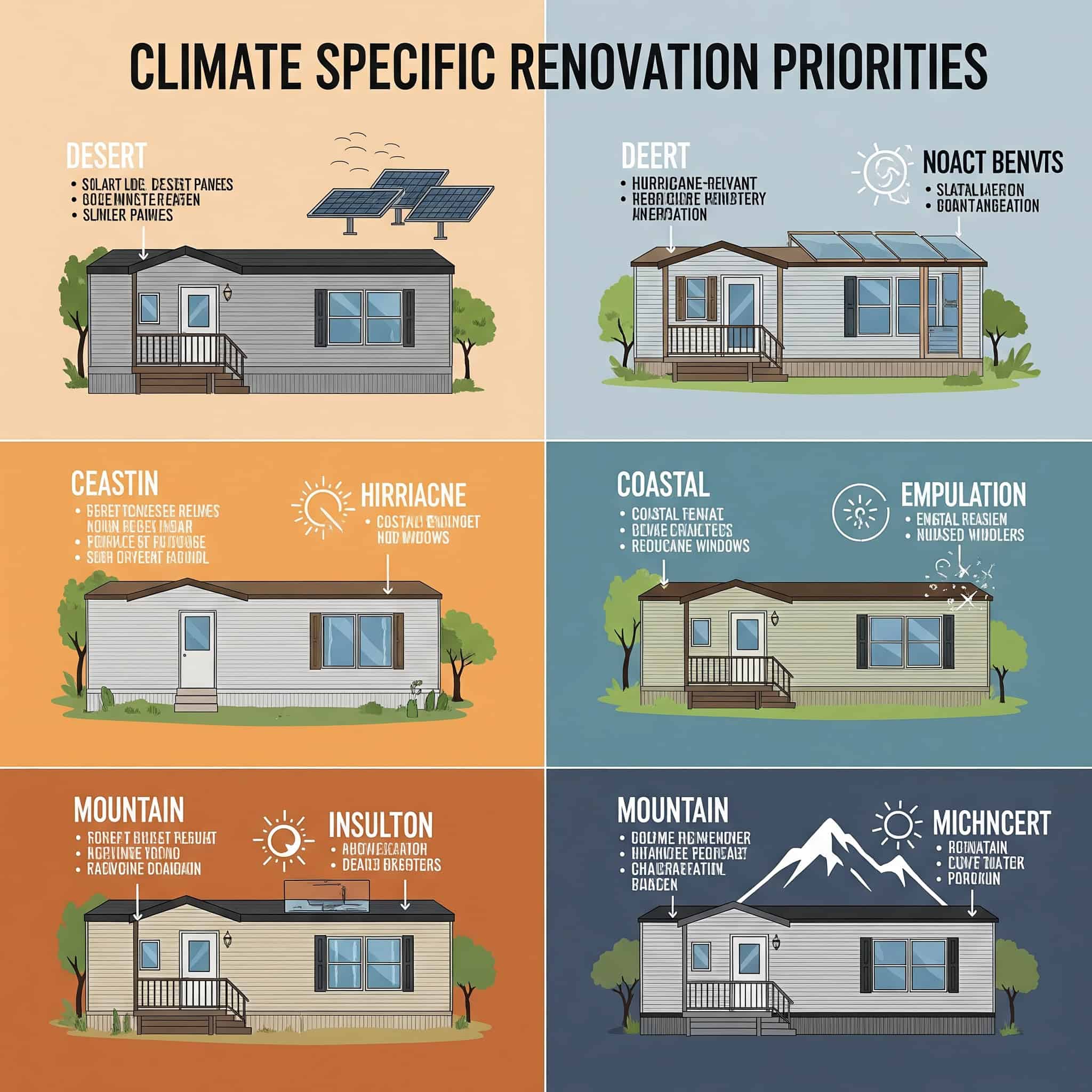

Climate-Specific Renovation Priorities

Mobile home renovation requirements vary dramatically based on geographic climate zones. Mobile homes are more vulnerable to climate extremes than traditional construction due to their lighter building envelope and elevated position. This increased vulnerability makes climate-appropriate renovations particularly important for mobile homes.

Climate-specific renovations can reduce energy costs by 30-50% when properly targeted to regional conditions. This substantial savings potential makes climate-focused improvements some of the highest-ROI renovations for mobile homeownersHot Climate Adaptation

In southern and desert regions, mobile homes face extreme heat challenges that demand specialized renovation approaches. Mobile homes in hot climates experience roof temperatures 20-30°F higher than traditional homes due to their direct sun exposure and minimal attic space. These extreme temperatures accelerate roofing deterioration and increase cooling costs.

Cooling systems in mobile homes typically operate at 70-80% efficiency compared to traditional homes due to duct placement and insulation challenges. This efficiency disadvantage makes cooling-focused improvements particularly valuable in hot climates.

Heat-related deterioration accounts for 40-60% of mobile home structural issues in hot climates, making heat mitigation a structural priority, not just a comfort issue. Addressing heat exposure can significantly extend your home’s lifespan while improving comfort and reducing operating costs.

Thermal Envelope Transformation

Roof radiant barriers deliver exceptional ROI in hot climates, costing $1,200-$2,500 but reducing attic temperatures by 20-30°F and cutting cooling costs by 15-25%. Radiant barriers in mobile home roofs reflect up to 97% of radiant heat compared to 80-85% in traditional attic installations due to the closer proximity to living spaces. This increased effectiveness makes radiant barriers particularly valuable for mobile homes.

Low-E window films provide 70% of the benefit of window replacement at just 15-20% of the cost. Low-E window films reduce solar heat gain coefficient (SHGC) from typical 0.7-0.8 in older mobile homes to 0.3-0.4, comparable to new energy-efficient windows. This dramatic performance improvement makes window films one of the highest-ROI improvements for hot climate mobile homes.

Underbelly insulation upgrades with moisture barriers prevent ground heat transfer while protecting against the humidity that accelerates floor deterioration in warm climates. Underbelly systems in hot, humid climates must address both thermal and vapor barriers, as moisture accumulation can reduce insulation effectiveness by 40-60%. This dual protection extends floor system life while improving energy efficiency.

Ventilation Optimization

Whole-house fan installations create evening cooling capabilities that reduce AC dependency, particularly effective in desert climates with significant day-night temperature swings. Whole-house fans in mobile homes can exchange the entire air volume in 2-3 minutes compared to 5-7 minutes in traditional homes due to the smaller cubic footage. This rapid air exchange capability makes whole-house fans particularly effective in mobile homes.

Soffit ventilation enhancement addresses the inadequate factory ventilation that contributes to premature roof deterioration in hot regions. Factory-installed ventilation in mobile homes typically provides only 50-60% of the optimal ventilation area needed in hot climates. This ventilation deficiency accelerates roof deterioration and increases cooling costs.

Solar-powered attic fans provide ventilation without increasing electricity costs, typically paying for themselves within 3-4 years through extended roof life and reduced cooling expenses. Solar-powered attic fans operate when needed most—during peak sun hours—and can reduce attic temperatures by 30-40°F, extending roof component life by 5-10 years. This self-powering capability makes them particularly suitable for mobile homes, where electrical capacity may be limited.

Cold Climate Imperatives

Northern region mobile homes require focused winterization strategies to address their vulnerability to cold, which can lead to heating costs 40-60% higher per square foot than conventional homes if left unaddressed. Mobile homes lose heat 2-3 times faster than traditional homes of similar size due to their elevated position and higher surface-to-volume ratio. This accelerated heat loss makes insulation improvements particularly valuable.

Cold climate mobile homes face unique condensation challenges due to the temperature differential between interior and exterior surfaces. This condensation risk creates both comfort and durability concerns that must be addressed through proper insulation and ventilation.

Freeze-thaw cycles affect mobile homes more severely than traditional construction, accelerating deterioration of exterior components. This increased vulnerability makes weather-resistant exterior improvements particularly important for cold climate mobile homes.

Thermal Boundary Reinforcement

Belly insulation replacement with closed-cell foam prevents frozen pipes while reducing heat loss through floors by 60-70%. Closed-cell foam insulation provides both thermal protection and vapor barrier properties, addressing the dual challenges of heat loss and condensation. This dual benefit makes closed-cell foam particularly valuable for cold climate mobile homes.

Thermal skirting installation creates a crucial insulated boundary between outdoor air and undercarriage components, improving overall heating efficiency by 15-25%. Properly installed thermal skirting creates a semi-conditioned crawlspace that maintains temperatures 15-20°F warmer than ambient air, protecting plumbing and ductwork. This temperature buffer prevents frozen pipes and reduces heat loss through the floor system.

Window replacement with triple-pane units addresses the severe thermal bridging common in factory-installed windows, reducing condensation issues that lead to mold and frame deterioration. Triple-pane windows in mobile homes improve interior surface temperatures by 8-12°F compared to double-pane units, significantly reducing condensation potential. This condensation reduction protects window frames and surrounding wall areas from moisture damage.

Moisture Management Systems

Controlled ventilation upgrades through heat recovery ventilators address the condensation challenges unique to tightly-sealed mobile homes in cold climates. Heat recovery ventilators in mobile homes provide 80-90% heat retention while exchanging moisture-laden indoor air with fresh outdoor air. This efficient air exchange removes excess humidity without significant heat loss.

Roof ice dam prevention through improved attic insulation and ventilation protects against the water damage that accounts for 35-45% of mobile home roof failures in northern regions. Ice dam formation occurs more readily on mobile home roofs due to their lower slope and reduced attic space, requiring specialized prevention strategies. Proper insulation and ventilation prevent the temperature differentials that cause ice dams.

Exterior door replacement with insulated models eliminates the drafts responsible for 10-15% of heat loss in typical mobile home entrances. Exterior doors in mobile homes typically have twice the air leakage of traditional home doors due to lighter construction and more challenging weatherstripping requirements. Replacing these doors with insulated models can significantly improve comfort and efficiency.

Beyond the core improvements already mentioned, cold climate mobile homes benefit from crawlspace dehumidification systems that maintain optimal humidity levels below the home. Crawlspace humidity levels in mobile homes fluctuate more dramatically than in traditional construction, requiring active management rather than passive ventilation. Controlling this humidity prevents condensation on underfloor components.

Interior ventilation improvements through bathroom and kitchen exhaust upgrades remove moisture at its source before it can condense on cold surfaces. Interior moisture production in mobile homes creates approximately 4-6 gallons of water vapor daily that must be properly vented to prevent condensation damage. Effective exhaust ventilation removes this moisture before it can cause problems.

Long-Term Value Preservation Strategies

Unlike conventional homes that typically appreciate over time, mobile homes face unique depreciation challenges. Mobile homes typically depreciate at 3-7% annually compared to 3-5% appreciation for traditional homes in normal market conditions. This depreciation reality requires strategic approaches to preserve investment value.

Strategic improvements can reduce depreciation rates by 50-70% while extending useful life by 15-30 years. This depreciation reduction can significantly improve the long-term economics of mobile home ownership, transforming what might otherwise be a depreciating asset into a more stable investment.

Depreciation-Fighting Improvements

Certain renovation investments specifically counter the factors that accelerate mobile home depreciation, creating lasting value beyond immediate comfort or aesthetic benefits. Depreciation in mobile homes is primarily driven by structural deterioration, systems obsolescence, and market perception issues. Addressing these core factors can dramatically change your home’s financial trajectory.

Strategic improvements that address these core factors can transform the financial trajectory of a mobile home investment. The most effective depreciation-fighting improvements typically focus on envelope integrity, structural reinforcement, and systems modernization. These targeted improvements address the root causes of mobile home depreciation.

Structural Longevity Enhancements

Roof-over installations add a second roof structure over the existing one, extending watertight integrity by 15-25 years while improving insulation values by 30-40%. Roof-over systems add only 2-3 pounds per square foot to the structure while creating an insulating air gap that improves thermal performance by 30-40%. This minimal weight addition makes roof-overs suitable for most mobile homes without structural reinforcement.

Moisture barrier systems for crawlspaces prevent the ground moisture exposure responsible for 40-60% of floor system failures in aging units. Moisture barriers in crawlspaces reduce relative humidity levels from typical 70-90% to optimal 40-60%, extending floor system life by 10-15 years. This humidity reduction prevents the conditions that lead to subfloor deterioration and mold growth.

Tie-down and anchoring upgrades not only improve storm resistance but also reduce the structural movement that leads to plumbing leaks and drywall cracking over time. Modern tie-down systems distribute wind and seismic forces more evenly than factory installations, reducing point-load stress that contributes to structural fatigue. This improved force distribution extends the life of multiple home systems.

When upgrading your mobile home’s structural elements, you’ll likely need to dispose of old materials and debris. For efficient removal of construction waste, check out our construction debris and concrete junk removal guide to learn about professional disposal options that keep your renovation site clean and safe.

Conversion to Real Property

Foundation installation to replace temporary piers can legally convert a mobile home from personal property to real estate in many jurisdictions, potentially increasing its value by 15-30% while qualifying for improved financing options. Permanent foundation systems must meet FHA guidelines (HUD-4930.3G) to qualify for real property classification and conventional mortgage financing. These guidelines ensure the foundation provides permanent structural support comparable to site-built homes.

Permanent utility connection upgrades further support reclassification while eliminating the maintenance issues associated with temporary hookups. Utility connection upgrades typically include frost-protected water lines, permanent electrical service with proper grounding, and code-compliant sewer connections. These permanent connections improve reliability while supporting real property classification.

Land-home package development through landscaping and site improvements completes the transformation from “mobile home” to “manufactured home on permanent foundation.” Land improvements that support real property classification focus on drainage, access, and site stability rather than purely aesthetic enhancements. These functional improvements address key concerns of lenders and appraisers.

Documentation and Certification

Beyond physical improvements, proper documentation of renovations plays a crucial role in preserving and demonstrating value. Properly documented mobile home improvements can increase appraised values by 15-25% compared to identical undocumented improvements. This documentation premium reflects the value of verified quality and compliance.

Certification and documentation create a paper trail that supports insurance coverage, financing options, and eventual resale value. Professional documentation addresses the information asymmetry that typically disadvantages mobile home sellers in the marketplace. This information advantage helps you capture the full value of your improvements when selling.

Engineering Certifications

Structural modification certifications from licensed engineers provide crucial documentation that renovations meet or exceed HUD code requirements, addressing buyer and lender concerns about non-professional modifications. Engineering certifications typically include load calculations, connection details, and compliance statements that verify structural integrity. This technical documentation provides valuable assurance to future buyers and lenders.

Energy efficiency verification through professional energy audits documents the improved performance resulting from insulation and HVAC upgrades, supporting higher valuation during appraisals. Professional energy audits use blower door tests and infrared imaging to quantify improvement, typically documenting 20-40% efficiency gains from comprehensive renovations. This quantified improvement helps justify higher valuations.

Wind zone compliance documentation certifies that renovations maintain or improve the home’s original wind resistance rating, particularly valuable in coastal and tornado-prone regions. Wind zone compliance documentation addresses one of the primary insurance concerns for mobile homes, potentially reducing premiums by 10-25%. This insurance advantage creates ongoing financial benefits beyond the direct value of the improvements.

Digital Renovation Portfolios

Before-and-after documentation with professional photography creates visual evidence of improvements that significantly impacts buyer perception and willingness to pay premium prices. Professional photography should include in-progress images that document hidden improvements like insulation, wiring, and structural reinforcement. These in-progress photos provide valuable evidence of improvements that aren’t visible in the finished home.

Material specification archives preserve information about products, warranties, and maintenance requirements for future owners and appraisers. Material specifications should highlight any upgrades to commercial-grade or energy-efficient products that exceed typical mobile home standards. This documentation of quality helps justify premium pricing.

Maintenance scheduling systems demonstrate ongoing care that counters the “poor maintenance” stigma often attached to mobile homes, supporting higher resale values by 5-10% compared to identical homes without documented maintenance histories. Maintenance documentation should follow manufacturer-recommended schedules, creating evidence of proper care that addresses a primary concern of mobile home buyers.

Creating a comprehensive home systems map documents the location of junction boxes, plumbing access points, and structural elements for future reference. Home systems mapping prevents costly exploratory demolition during future repairs or modifications, saving $200-$500 per incident. This practical documentation adds significant value for future owners.

Warranty registration and tracking ensures you capture the full value of product warranties, some of which transfer to subsequent owners. Properly registered warranties can add $1,000-$3,000 in transferable value to a mobile home through remaining coverage on major components. This transferable protection represents real financial value to future owners.

Renovation Waste Management: The Jiffy Junk Solution

Mobile home renovations generate significant waste that requires proper handling and disposal. Mobile home renovations typically generate 3-5 cubic yards of waste per room renovated, including old paneling, flooring, fixtures, and packaging materials. This substantial waste volume can quickly overwhelm the limited space around most mobile homes.

Space constraints around mobile homes make traditional dumpster placement challenging, requiring alternative waste management solutions. Many mobile home materials require specialized disposal due to age-related hazards or recycling requirements. These disposal complexities make professional waste management particularly valuable for mobile home renovations.

Streamlining Your Renovation Process

Renovation debris can quickly overwhelm the limited space around a mobile home, creating safety hazards and slowing down your project. Prompt debris removal prevents moisture damage to materials awaiting disposal, a particular concern in the exposed areas around mobile homes. This protection from weather exposure prevents secondary damage to materials awaiting disposal.

Professional sorting of renovation waste typically identifies 30-40% of materials suitable for recycling or donation rather than landfill disposal. This sorting expertise maximizes the environmental benefits of proper waste management while potentially reducing disposal costs.

Specialized handling of potentially hazardous materials from older mobile homes ensures compliance with disposal regulations. This regulatory compliance protects you from potential fines while ensuring environmental protection.

Responsible Disposal Practices

Many mobile home renovation materials can be recycled or donated rather than sent to landfills. Pre-1976 mobile homes may contain materials requiring specialized disposal protocols, including asbestos-containing products and lead-based paints. These hazardous materials require expert handling to prevent environmental contamination and health risks.

Metal components from mobile home renovations are 95-100% recyclable, including aluminum siding, copper plumbing, and steel structural elements. This high recyclability makes proper sorting particularly valuable for metal-containing waste.

Many fixture and appliance components qualify for donation to habitat restoration programs, reducing landfill impact while supporting community initiatives. These donation opportunities create social benefits beyond the environmental advantages of recycling.

When renovating a mobile home, proper disposal of old appliances is essential. As explained in our guide to getting rid of old appliances, professional removal services ensure these bulky items are recycled or disposed of according to environmental regulations.

Ready to start your mobile home renovation without the headache of waste management? Contact Jiffy Junk today for a free estimate on renovation debris removal. Their team of professionals will ensure your project stays clean, safe, and environmentally responsible from demolition to completion.

Specialized Material Handling

Older mobile homes often contain materials requiring special disposal protocols. Approximately 30-40% of pre-1976 mobile homes contain asbestos in floor tiles, insulation, or ceiling textures that require specialized removal procedures. This asbestos presence creates both health risks and legal disposal requirements.

Lead-based paint was commonly used in mobile homes manufactured before 1978, creating disposal requirements that differ from standard construction waste. This lead content requires specialized handling to prevent environmental contamination.

Formaldehyde-containing insulation and paneling in older mobile homes requires proper handling to prevent environmental contamination. These formaldehyde-containing materials were common in older mobile homes and require appropriate disposal methods.

Convenience Factor

Jiffy Junk’s one-click virtual estimates make it easy to budget for removal services before renovation begins. Virtual estimates are typically accurate within 10-15% of final costs, providing reliable budgeting information without requiring an in-person visit. This accuracy helps you plan your renovation budget with confidence.

Professional junk removal services complete in 1-2 hours what typically takes homeowners 4-6 hours of sorting, loading, and transporting. This time efficiency allows you to focus on the renovation itself rather than waste management logistics.

Scheduled removal services can be timed to coincide with renovation phase completions, maintaining a clean workspace throughout the project. This scheduling flexibility helps maintain a safe and efficient work environment throughout your renovation.

For homeowners undertaking mobile home renovations, managing the resulting waste can be challenging. Our junk removal estimate guide explains how to quickly get an accurate quote for clearing renovation debris, helping you budget properly for your project.

Additional Considerations for Special Situations

Beyond the standard renovation considerations, certain special situations require additional planning and expertise. Special situations often involve regulatory requirements beyond standard HUD code compliance. These additional requirements can significantly impact renovation planning and execution.

Specialized renovations typically require 15-25% additional planning time but prevent costly mid-project adjustments. This additional planning investment typically pays for itself by preventing expensive surprises and regulatory complications.

Flood Zone Adaptations

Mobile homes in flood-prone areas face unique renovation requirements. Flood insurance for mobile homes costs 3-5 times more than standard homeowner’s insurance without proper elevation and adaptations. This insurance premium difference creates significant financial incentive for flood-appropriate renovations.

Water-resistant materials for flood zone mobile homes include closed-cell foam insulation, PVC wainscoting, and ceramic tile flooring. These water-resistant materials can withstand occasional flooding without requiring complete replacement, reducing the cost of flood recovery.

Electrical system modifications for flood zones typically include raising outlets and service panels 12-24″ above standard height. These elevated electrical components remain functional even during minor flooding events, improving both safety and resilience.

Accessibility Modifications

Creating accessible mobile homes requires specialized approaches due to their elevated design and compact layouts. Accessible ramps for mobile homes require approximately 30-36 feet of run to accommodate the typical entry height while maintaining ADA-compliant slopes. This substantial ramp length requires careful site planning to implement effectively.

Bathroom accessibility modifications in mobile homes often utilize specialized compact fixtures that provide accessibility in 30-40% less space than traditional accessible fixtures. These space-efficient solutions address the unique challenges of creating accessibility within the limited dimensions of mobile home bathrooms.

Doorway widening in mobile homes frequently requires header reinforcement due to the critical structural role of many interior walls. This structural consideration makes doorway modifications more complex than in traditional homes, where non-load-bearing walls are more common.

Park Approval Navigation

Mobile home parks often impose renovation restrictions beyond local building codes. Park approval processes typically add 2-4 weeks to project timelines and require submission of detailed plans and material specifications. This approval delay must be factored into your renovation schedule.

Contractor requirements in mobile home parks often exceed local licensing standards, with many communities requiring specific mobile home certification. These enhanced requirements can limit your contractor options while ensuring quality work.

Construction hour limitations in parks (typically 8am-5pm weekdays only) can extend project timelines by 20-30% compared to unrestricted properties. These schedule limitations must be considered when planning your renovation timeline.

Beyond basic approval requirements, many mobile home communities have specific aesthetic guidelines that impact renovation choices. Architectural review committees in mobile home communities typically meet monthly, making timing crucial for project scheduling. This meeting schedule can create significant delays if you miss a submission deadline.

Some parks require contractors to provide proof of experience with manufactured housing, limiting the pool of available professionals. This experience requirement helps ensure quality work but can make finding qualified contractors more challenging.

Non-compliance penalties in mobile home parks can range from daily fines ($25-$100) to legal action for removal of unapproved modifications. These penalties make proper approval particularly important for park residents.

Final Thoughts

Mobile home renovations require specialized knowledge and strategic planning, but the rewards justify the effort. Mobile home renovations typically deliver 15-25% higher ROI when following the specialized approaches outlined in this guide compared to applying traditional home renovation strategies. This ROI advantage comes from addressing the specific needs and opportunities of manufactured housing.

The most successful mobile home renovations address the specific vulnerabilities of manufactured housing while capitalizing on their unique strengths and opportunities. Proper documentation and certification of improvements can increase resale values by 10-30% compared to identical undocumented renovations. This documentation premium highlights the importance of proper record-keeping throughout your renovation process.

The economics of mobile home renovations present both unique challenges and opportunities. The manufactured housing industry continues to evolve, with newer homes featuring construction methods increasingly similar to site-built homes. This evolution is gradually reducing the differences between manufactured and site-built housing, potentially improving future renovation options.

Renovation investments that focus on structural integrity and energy efficiency consistently outperform purely cosmetic upgrades in terms of long-term value. This performance difference reflects the practical priorities of mobile home buyers and the physical realities of manufactured housing.

The growing interest in affordable housing options has begun to shift market perceptions of well-renovated mobile homes, particularly in high-cost housing markets. This perception shift creates potential for increased appreciation in well-maintained and thoughtfully renovated mobile homes.

Remember that every mobile home renovation is unique, influenced by the home’s age, manufacturer, location, and your personal goals. By understanding the true economics behind these projects, you can make informed decisions that maximize your investment while creating a comfortable, efficient, and valuable living space that will serve you well for years to come.

Historic Mobile Home Preservation

Certain vintage mobile homes, particularly mid-century models from the 1950s-1960s, have developed cult followings and historical significance. Vintage mobile homes from manufacturers like Spartan, Airstream, and early Skyline models can command 200-300% price premiums when properly restored. This collectible status creates unique renovation considerations that balance modernization with historical authenticity.

Sourcing authentic replacement hardware often costs $200-$800 more than standard options, but preserves the distinctive character that collectors value. Period-appropriate materials frequently require specialized fabrication or salvage sourcing from dedicated restoration suppliers. These authentic components maintain the historical integrity that drives premium pricing.

Preserving distinctive exterior features like aluminum siding patterns costs $1,500-$3,000 more than standard replacements but significantly enhances value for enthusiasts. Historical documentation including original manuals, photographs, and ownership history can increase collectible value by 15-25%. This documentation premium reflects the importance of provenance in the vintage mobile home market.

Off-Grid Adaptations

Converting mobile homes for off-grid living presents unique renovation considerations. Mobile homes typically require 30-40% less energy for basic functions than traditional homes, making solar self-sufficiency more achievable. This efficiency advantage makes mobile homes particularly suitable for off-grid conversion.

Solar system integration requires reinforced roof mounting and specialized electrical configurations. Roof reinforcement for solar panels adds approximately $1,200-$2,000 to installation costs but prevents potential structural issues. This reinforcement investment protects both your roof and solar equipment.

Rainwater harvesting systems can be incorporated into roof redesigns with minimal additional structural requirements. Water conservation modifications can reduce consumption by 50-60%, making limited rainwater collection viable for daily needs. These conservation improvements dramatically reduce water requirements, making self-sufficiency more achievable.