The Complete Deck Renovation Cost Guide: What You’re Really Paying For

Renovating your deck involves more than just the advertised price tag. According to a 2023 Remodeling Magazine report, the average homeowner underestimates their deck renovation cost by 23%. I discovered this firsthand when updating my backyard space last summer. What started as a simple board replacement quickly expanded into a comprehensive project with unexpected expenses. This guide breaks down the true costs of deck renovation, helping you understand what you’re really paying for and how to manage your budget effectively.

Table of Contents

-

The True Cost Spectrum of Deck Renovation

-

Financial Planning for Deck Renovation

-

Hidden Costs and Expense Management

-

Advanced Cost Optimization Techniques

-

Comprehensive Deck Replacement Economics

-

Debris Removal Solutions

The True Cost Spectrum of Deck Renovation

When I started researching my own deck project, I quickly realized that deck renovation expenses go way beyond basic material and labor calculations. There’s a whole financial ecosystem at play that creates significant cost differences between seemingly similar projects.

Understanding these factors before starting your renovation helps develop realistic budgets and avoid those mid-project financial surprises that can derail your plans. I’ve found that being prepared for the complete financial picture makes the entire process less stressful.

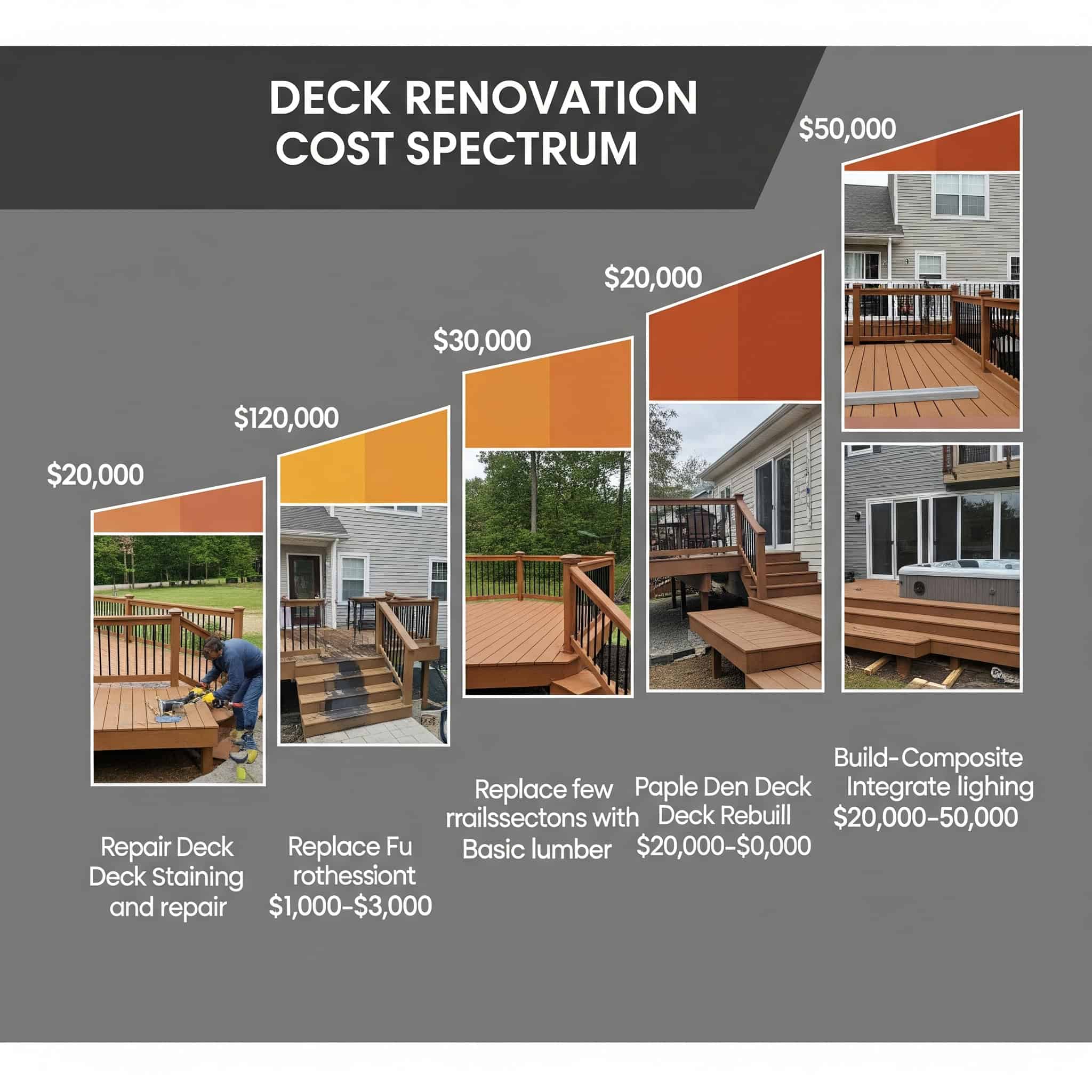

Deck renovation costs typically range from $20-90 per square foot depending on materials, design complexity, and regional factors. This wide range explains why getting multiple quotes can result in dramatically different numbers for the same project.

The average deck renovation project experiences 15-30% in unexpected costs discovered after work begins. I learned this the hard way when we discovered rotted joists under seemingly solid boards.

Cost variability increases with deck age, with structures over 15 years old typically requiring more extensive hidden repairs. My 17-year-old deck needed significantly more structural work than I initially anticipated.

According to the 2023 Cost vs. Value Report, the nationwide average cost of deck replacement ranges between $19,248 and $23,340, with homeowners recouping approximately 39% of this investment in increased home value.

Cost Variability Factors

Your deck renovation costs will fluctuate based on numerous variables beyond simple square footage. Regional differences, material selections, and existing conditions all contribute to the final price tag.

Labor costs typically represent 40-60% of total deck renovation expenses, with higher percentages in urban markets. This explains why the same materials can cost so much more to install in a major city versus a rural area.

Design complexity factors (multiple levels, built-in features, custom railings) can increase costs by 25-75% compared to standard rectangular designs. I opted for a simple design with a single built-in bench, which added about 15% to my overall cost but created a much more functional space.

Seasonal timing impacts both material and labor costs, with potential savings of 15-25% during off-peak periods. Planning my project for October instead of May saved me nearly $2,000.

“Major renovations” are underway at the Cascade Parking Deck in Downtown Akron as part of the city’s broader revitalization efforts, demonstrating how public infrastructure projects follow similar cost considerations as residential deck renovations.

Geographic Cost Disparities

Your location dramatically impacts deck renovation costs through regional material availability, labor market conditions, and local building requirements. Urban coastal areas typically see 30-45% higher costs than rural midwest regions due to higher labor rates, stricter permitting processes, and increased material delivery expenses.

Labor rates for deck specialists vary by up to 300% between regions, from $25-35/hour in rural areas to $75-100/hour in high-cost urban markets. This explains why my friend in San Francisco paid nearly double what I did for a similar project here in Ohio.

Building code requirements vary significantly by location, with coastal and high-wind regions requiring additional structural reinforcement adding 10-20% to project costs. These requirements aren’t optional – they’re mandatory for safety and permit approval.

Material transportation costs increase exponentially with distance from distribution centers, adding $1-3 per square foot for remote locations. I was fortunate to have a lumber yard within 10 miles of my home, which kept delivery costs minimal.

|

Region |

Average Labor Rate (per hour) |

Permit Cost Range |

Material Delivery Premium |

|---|---|---|---|

|

Rural Midwest |

$25-35 |

$100-300 |

Minimal |

|

Suburban South |

$35-55 |

$200-500 |

$0.50-1.50/sq ft |

|

Urban Northeast |

$60-80 |

$500-1,200 |

$1-2/sq ft |

|

Coastal West |

$75-100 |

$800-1,500+ |

$1.50-3/sq ft |

Material Tier Economics

Your material selection creates a multi-tiered pricing structure where costs can vary by 300-400% between entry-level and premium offerings. Pressure-treated lumber averages $15-25 per square foot installed, while exotic hardwoods or composite materials range from $45-90 per square foot.

Pressure-treated pine costs $2-5 per linear foot while premium composites run $7-12 per linear foot for the materials alone. This difference adds up quickly on larger decks.

Installation labor increases with material complexity – composite decking requires 20-30% more installation time than standard lumber. My contractor explained that the specialized cutting tools and fastening systems for composite materials require more precision and time.

Fastener systems vary dramatically in cost, from standard deck screws ($0.10-0.25 each) to hidden fastening systems ($0.75-2.00 per square foot). I chose a mid-range hidden fastener system that added about $400 to my material costs but created a much cleaner appearance.

According to Decks.com, pressure-treated wood costs approximately $3-6 per square foot, while exotic hardwoods like Ipe range from $10-15 per square foot, and composite decking materials average $5-13 per square foot.

The Repair vs. Replace Financial Decision

Deciding between repairing your existing deck or completely replacing it represents one of the most significant financial choices in the renovation process. This decision requires evaluating current deck condition, safety concerns, and long-term value considerations to determine the most cost-effective approach.

I struggled with this decision for months before ultimately choosing replacement based on the extensive hidden damage we discovered during inspection.

Structural issues typically increase repair costs by 50-200% compared to surface-level renovations. What looks like a simple board replacement can quickly escalate when you discover rotted joists or failing support posts underneath.

The average lifespan extension from major repairs is 5-8 years, compared to 20-30 years for full replacement. This time horizon significantly impacts the value equation when comparing repair versus replacement costs.

Safety-related repairs (railings, stairs, structural supports) represent the highest liability risk and should receive priority in limited budgets. I discovered that my railings were significantly below current code requirements, creating both a safety hazard and a potential insurance issue.

The 50% Threshold Principle

Industry professionals often apply the 50% threshold principle: when deck repair cost exceeds half of replacement value, full replacement typically offers better economic value. This calculation must include hidden costs like future maintenance savings, property value impact, and extended usability.

Comprehensive deck inspections cost $150-350 but can identify hidden structural issues before they become emergency repairs. This was some of the best money I spent on my project, as it revealed problems I would never have found on my own.

Moisture content readings above 20% in structural wood components indicate active deterioration requiring immediate attention. Our inspector found readings between 25-30% in several key support beams, indicating serious water infiltration issues.

Partial repairs typically require additional maintenance within 2-5 years, creating ongoing expense cycles compared to one-time replacement costs. This recurring cost pattern often makes replacement more economical in the long run.

A homeowner in Minneapolis discovered that repairing their 320 sq ft pressure-treated deck would cost approximately $4,800 (including replacing 40% of surface boards, reinforcing joists, and updating railings). A complete replacement quote came in at $9,600. Following the 50% threshold principle, the homeowner chose replacement since repair costs exceeded half the replacement value, and the new deck would last 25+ years versus the 6-8 year extension repairs would provide.

Partial Replacement Economics

Selective component replacement offers a middle-ground approach that can provide 70-80% of the benefits of full replacement at roughly 40-60% of the cost. Deck board replacement cost averages $20-30 per board but increases exponentially when structural elements require attention.

Individual board replacement requires 15-25 minutes of labor per board, with costs increasing for boards requiring difficult access. My contractor charged a minimum of 30 minutes per board for replacements near the house where cutting and fitting was more complex.

Joist sister reinforcement (adding parallel support to weakened joists) costs $10-15 per linear foot but extends structural life by 5-10 years. This approach can be a cost-effective middle ground when full replacement isn’t in the budget.

Selective replacement creates potential warranty complications, as most manufacturers won’t warranty new materials installed alongside existing components. This limitation should factor into your decision-making process.

RenoFi reports that individual board replacement typically costs between $2-19 per square foot for materials plus $45-90 per hour for labor, with removal of old deck boards averaging $5-15 per square foot.

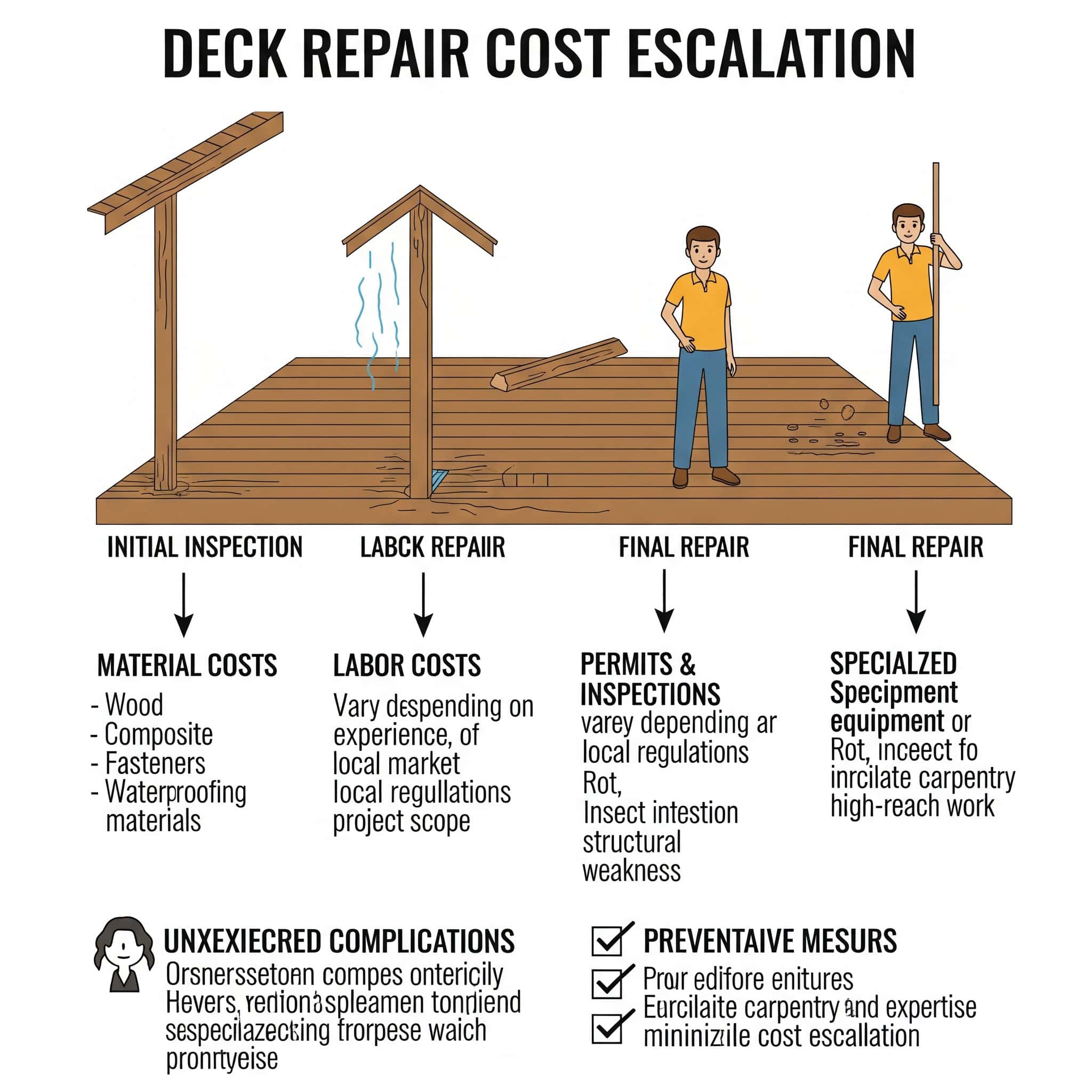

Repair Cost Escalation Factors

The cost of repairing a deck frequently escalates due to discovered damage once projects begin. Water damage, insect infestation, and structural deterioration often hide beneath surface boards, creating budget uncertainty.

You should build a 20-25% contingency fund into repair budgets. I initially budgeted $3,500 for repairs but ended up spending nearly $5,000 after discovering hidden damage.

Water damage typically extends 12-24 inches beyond visible signs, requiring more extensive replacement than initially apparent. What looked like a small soft spot on my deck turned out to affect nearly three feet of supporting structure underneath.

Fastener failure (rusted screws/nails) occurs in 85% of decks over 10 years old, requiring additional labor for removal and replacement. Removing rusted fasteners often damages surrounding wood, creating a cascade of additional repairs.

Insect damage (particularly termites and carpenter ants) is discovered in approximately 30% of deck repair projects, adding $500-2,500 to repair costs. We found carpenter ant damage in two support posts that required complete replacement.

Financial Planning for Deck Renovation

Effective financial planning for your deck renovation requires sophisticated budgeting approaches that account for project timing, financing options, and value optimization strategies. Proper planning before starting your project can significantly reduce total costs while improving outcomes.

I spent nearly a month researching and planning before starting my project, which ultimately saved thousands in unnecessary expenses.

Proper financial planning can reduce total project costs by 15-30% through strategic timing and material procurement. Simply by scheduling my project during the off-season and purchasing materials during a supplier’s annual sale, I saved approximately 22% compared to peak season pricing.

Financing costs can add 10-50% to the total project expense depending on interest rates and repayment terms. I opted to use savings rather than financing, which eliminated these additional costs entirely.

Strategic Timing Economics

The timing of your deck renovation significantly impacts total project costs due to seasonal material price fluctuations, contractor availability, and weather-related complications. Understanding these temporal economic factors allows you to minimize expenses through strategic project scheduling.

Contractor availability fluctuates seasonally, with peak season (spring/summer) often resulting in 15-25% higher labor rates. During my October project, contractors were much more willing to negotiate on price as they were looking to fill their schedules before winter.

Material prices typically peak during high-demand periods (April-June) and reach lowest points during off-seasons (October-February). I purchased my materials in late September during an end-of-season clearance event, saving nearly 30% on composite decking.

Weather delays during non-optimal construction seasons can add 10-20% to labor costs through interrupted work schedules. We did experience two rain delays during our project, but the overall savings still made off-season timing worthwhile.

Off-Season Discount Opportunities

Deck replacement costs typically drop 15-25% during off-peak seasons (late fall through winter in most regions) as contractors seek to maintain workflow. Material costs often decrease during these periods as suppliers reduce inventory before new product lines arrive.

Contractor scheduling flexibility increases by 50-75% during off-season months, allowing for more precise project timing. My contractor was able to start exactly when I wanted rather than putting me on a waiting list as would have happened during peak season.

Material suppliers often offer “end of season” discounts of 10-30% to reduce inventory carrying costs over winter months. These discounts can substantially reduce your overall project cost if you’re flexible on exact material specifications.

Weather protection measures add $2-5 per square foot during winter construction but may still result in net savings compared to peak season pricing. For late fall projects like mine, these additional costs weren’t necessary.

Material Price Cycle Planning

Lumber and composite decking materials follow predictable annual price cycles influenced by construction demand, manufacturing schedules, and retail promotions. Prices typically peak in spring (April-June) and reach their lowest points in late fall (October-November).

Lumber futures markets can provide 3-6 month price trend indicators, helping time major material purchases. I tracked these trends for several months before my project and noticed a consistent downward trend heading into fall.

Manufacturer price increases typically occur in January-February and July-August, creating optimal purchase windows immediately before these periods. I purchased my materials in late September, just before many manufacturers announced their annual price adjustments.

Material storage costs ($50-200 monthly for typical deck packages) should be factored into early purchase decisions when construction will be delayed. I arranged for delivery just three days before construction began to avoid these additional costs.

Financing Strategy Optimization

Your financing approach significantly impacts the true project cost when accounting for interest, tax implications, and opportunity costs. Sophisticated financing strategies can reduce effective costs by 10-20% compared to standard payment methods.

Home improvement loans typically carry interest rates 2-5% higher than home equity options but require less paperwork and faster approval. I considered a home improvement loan but ultimately decided the interest rates weren’t competitive with other options.

Credit card promotional offers (0% interest) can provide short-term financing advantages but typically convert to 15-25% interest rates after promotional periods. These can be effective if you’re confident you can pay off the balance before the promotional period ends.

Payment timing strategies (material pre-purchase, progress payments) can reduce total project costs by 5-10% through negotiated contractor discounts. My contractor offered a 5% discount for paying for materials upfront, which saved nearly $400.

Home Equity Leverage Techniques

Home equity financing options (HELOCs, home equity loans) provide tax advantages for deck renovations that substantially reduce effective costs. Interest may be tax-deductible when the renovation qualifies as a home improvement under IRS guidelines.

HELOC interest rates average 1-3% lower than personal loans or credit cards, with tax deductibility potentially reducing effective rates further. For larger projects, this can translate to thousands in interest savings over the life of the loan.

Home equity loans provide fixed interest rates and structured repayment schedules, protecting against future rate increases. This predictability can be valuable for budgeting purposes, especially for larger projects.

Minimum draw requirements ($10,000-25,000 for many HELOCs) may necessitate combining multiple home improvement projects for optimal financing. I considered bundling my deck project with bathroom updates to meet these minimums, but ultimately decided against financing.

ROI-Based Budgeting

Return on investment calculations for deck renovations vary significantly based on project scope, material selection, and local market conditions. Mid-range deck replacement typically recoup 65-75% of costs upon home sale, while high-end composite decks may only return 50-60% despite higher initial costs.

Outdoor living space adds approximately $0.50-0.80 per dollar invested to home value in most markets, with higher returns in warm-weather regions. This return profile influenced my decision to proceed with the project despite the significant investment required.

Functional improvements (expanded usable space, improved access) typically generate 15-25% higher ROI than purely aesthetic upgrades. I focused my budget on expanding the usable area rather than expensive decorative elements.

Over-improvement risk occurs when deck investments exceed 2-3% of total home value, resulting in diminished returns. My project represented about 1.8% of my home’s value, keeping it within the optimal range for eventual return.

In a recent Brooklyn renovation project, homeowners invested $20,000 in a legal steel deck (8 by 19 feet) with stairs to the backyard, noting that “the return will be many times that if we sell in a few years” due to the high demand for outdoor space in urban environments.

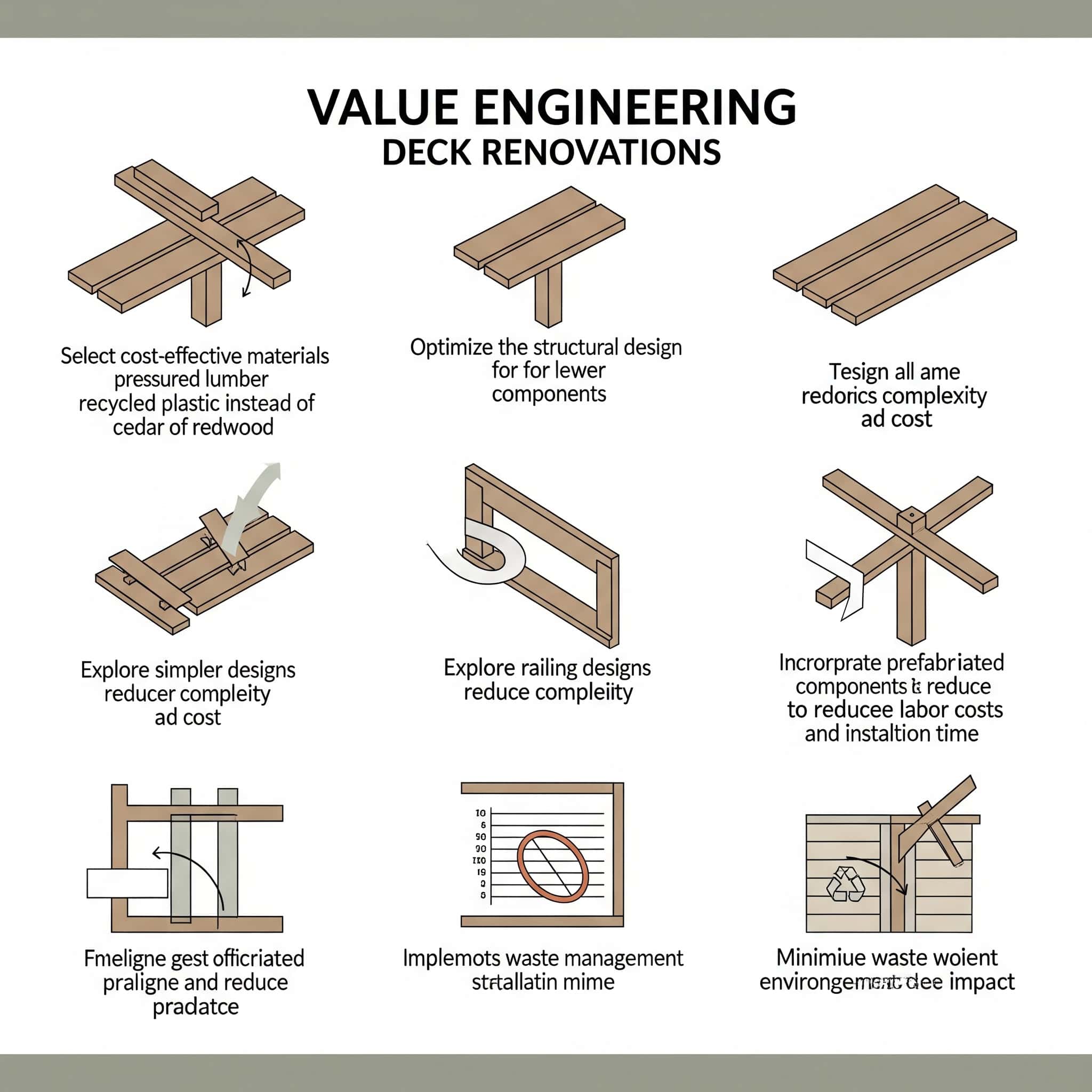

Value Engineering Approaches

Value engineering techniques allow you to strategically reduce deck renovation costs while maintaining quality and functionality by identifying and eliminating unnecessary expenses. This approach focuses on maximizing value rather than simply minimizing costs.

Professional value engineering typically identifies 15-30% cost reduction opportunities without compromising core functionality. I worked with my contractor to identify several areas where we could reduce costs without affecting the final result.

Material quantity optimization through precise cutting plans can reduce waste by 10-15%, directly lowering material costs. My contractor’s detailed cutting plan saved nearly 12% on materials compared to standard estimating methods.

Feature prioritization based on usage patterns ensures budget allocation matches actual needs rather than theoretical ideals. I eliminated a planned pergola after realizing it would provide minimal practical benefit for its substantial cost.

Design Simplification Economics

Complex deck designs with multiple levels, curved elements, and diagonal board patterns can increase costs by 30-50% compared to simpler rectangular designs with minimal changes in practical functionality. Work with designers to identify design elements that drive disproportionate costs.

Each 45° angle cut increases labor time by 3-5 minutes per board and creates 10-15% additional material waste. I opted for a simple perpendicular board layout that maximized material efficiency and reduced labor costs.

Curved design elements require 200-300% more labor hours than straight sections of equivalent size. By eliminating a curved section from my original design, I saved approximately $1,200 in additional labor costs.

Reducing level changes eliminates expensive transition details while maintaining visual interest through alternative design elements. I used different board directions rather than level changes to create visual interest, saving significantly on structural costs.

Material Hybridization Strategies

Hybrid material approaches combine premium materials in high-visibility or high-wear areas with standard materials elsewhere, reducing overall costs by 15-30% while maintaining appearance and durability. Consider using composite decking for surface boards while utilizing pressure-treated lumber for structural elements.

Traffic pattern analysis identifies high-wear zones requiring premium materials (typically 20-30% of total deck surface). I used premium composite decking on the stairs and main traffic areas while using standard composite on less visible sections.

Transition details between different materials cost $10-25 per linear foot but create visual interest while reducing overall material expenses. These transitions can actually enhance the design while saving money.

Structural components represent 40-60% of material costs but remain largely invisible, making them ideal candidates for standard material use. I used pressure-treated lumber for all structural elements while splurging on visible components.

A homeowner in Colorado implemented a material hybridization strategy by using composite decking only for the surface boards ($8/sq ft) while using pressure-treated lumber ($4/sq ft) for all structural components. For their 400 sq ft deck, this approach saved approximately $1,600 compared to all-composite construction while maintaining the low-maintenance benefits where it mattered most – on the visible and high-traffic surfaces.

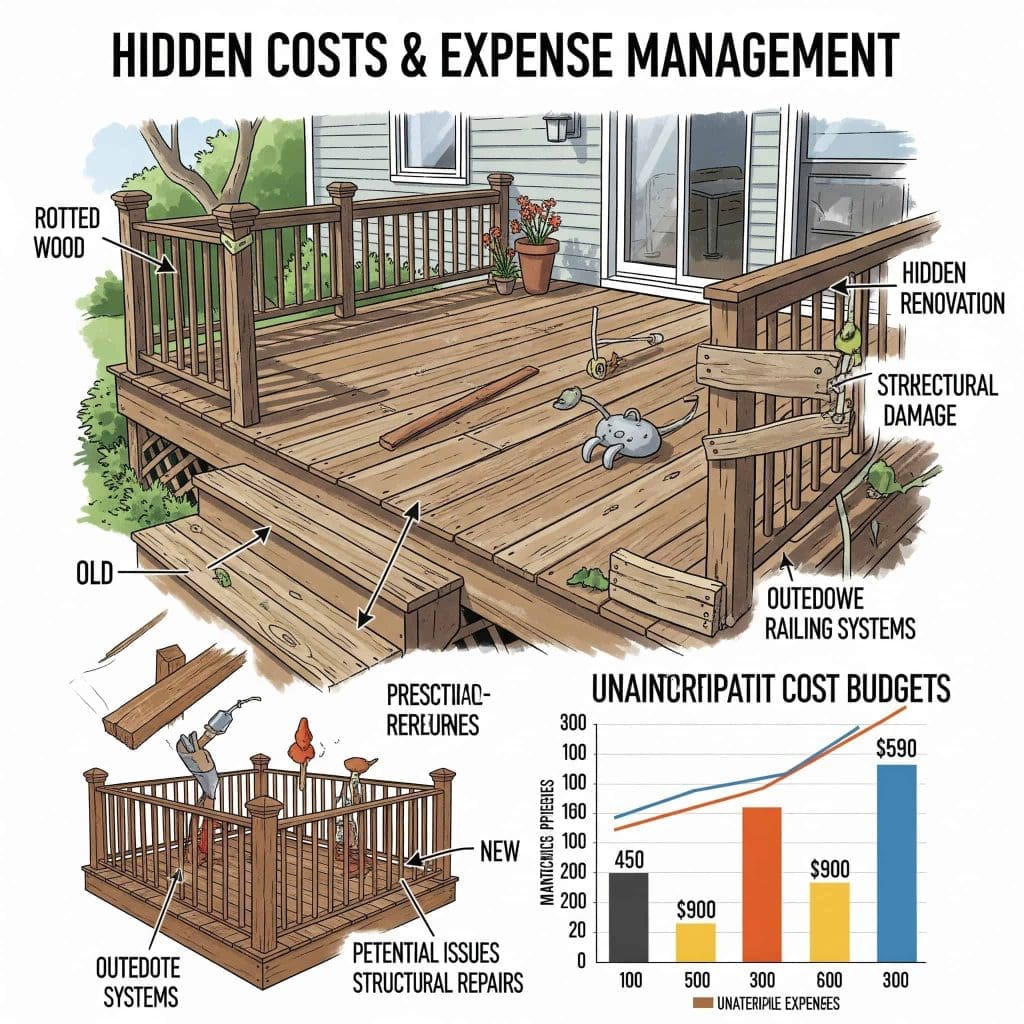

Hidden Costs and Expense Management

Successfully managing your deck renovation costs requires identifying and mitigating numerous hidden expenses that frequently surprise homeowners and derail budgets. These concealed costs often equal or exceed the visible material and labor expenses in the total project equation.

I was shocked by how many unexpected expenses popped up during my project. Having a contingency fund saved me from serious budget problems.

Hidden costs typically add 25-40% to initial budget estimates for deck renovations. My project ultimately cost 32% more than my initial estimates due to these concealed expenses.

Documentation and tracking systems for expenses can recover 5-10% of project costs through tax benefits and warranty claims. I created a detailed spreadsheet that tracked every expense, which proved invaluable for both tax purposes and warranty registrations.

Regulatory Compliance Expenses

Building codes, permit requirements, and homeowner association regulations create a complex web of compliance costs that frequently surprise homeowners during deck renovations. These expenses extend beyond simple permit fees to include design modifications, inspection delays, and potential remediation requirements.

Building code compliance represents the highest liability risk in deck construction, with non-compliant structures potentially voiding homeowner insurance coverage. This risk alone makes proper permitting worth the additional cost and effort.

Inspection scheduling typically adds 3-10 business days to project timelines, creating potential labor inefficiencies. My project required three separate inspections, adding nearly two weeks to the overall timeline.

Remediation costs for non-compliant construction average 150-300% of the original installation cost for affected components. A neighbor attempted to skip permits and was forced to tear out and rebuild significant portions of their deck at tremendous additional expense.

Permit Fee Structures

Permit fees vary dramatically by location and project scope, ranging from $100 in rural areas to $1,500+ in heavily regulated urban environments. Many municipalities calculate fees based on project value, creating an incentive to underreport costs.

Permit fees typically follow tiered structures based on project valuation, with breakpoints at common values ($10,000, $25,000, etc.). My permit fee increased significantly because my project crossed one of these thresholds.

Expedited permit processing (where available) adds 50-100% to base permit costs but can reduce project timelines by 1-3 weeks. I opted for standard processing since my fall timing meant I wasn’t competing with the spring rush.

Permit violations typically incur penalties of 200-500% of the original permit fee plus mandatory inspections of all work. These penalties make attempting to avoid proper permitting an extremely risky financial decision.

Code-Driven Design Modifications

Updated building codes frequently require significant structural changes to existing deck designs, particularly regarding railing heights, stair specifications, and foundation requirements. These modifications can add 10-20% to renovation costs when bringing older decks up to current standards.

Railing height requirements have increased from 36″ to 42″ in many jurisdictions, requiring complete replacement of existing railings. My 36″ railings had to be completely replaced to meet current code, adding approximately $1,800 to the project.

Stair riser/tread specifications have tightened, with maximum riser height decreasing from 8″ to 7″ in many codes. This required completely rebuilding my stairs rather than simply replacing treads as originally planned.

Structural connection requirements have strengthened significantly, requiring additional hardware costing $15-50 per connection point. The new hurricane ties and joist hangers added nearly $400 to my material costs.

|

Code Element |

Common Old Standard |

Current Requirement |

Compliance Cost Impact |

|---|---|---|---|

|

Railing Height |

36 inches |

42 inches |

$35-60 per linear foot |

|

Stair Riser Height |

8-9 inches |

7-7.75 inches |

$300-800 per staircase |

|

Joist Spacing |

24 inches on center |

16 inches on center |

$3-5 per square foot |

|

Ledger Connection |

Nails or basic lag screws |

Through-bolts or structural screws |

$150-400 per ledger board |

|

Post Footing |

8-inch diameter |

12-inch diameter |

$50-100 per footing |

Site-Specific Complications

The physical characteristics of your property create unique challenges that impact deck repair cost through access limitations, soil conditions, and existing structural issues. These site-specific factors often remain undiscovered until work begins, creating budget uncertainty.

Site evaluation by experienced contractors can identify 70-80% of potential complications before work begins. The detailed site assessment my contractor performed helped anticipate several potential issues before they became problems.

Topographical challenges (slopes, drainage issues) typically add 15-30% to foundation costs. My sloped yard required additional excavation and larger footings than a flat site would have needed.

Existing landscape features requiring protection or modification add $500-2,500 to typical project costs. We had to carefully work around mature shrubs and an irrigation system, adding both time and expense to the project.

Access Premium Costs

Limited property access significantly increases labor and material handling costs as contractors navigate tight spaces, protect landscaping, or employ specialized equipment. Properties with restricted access often see 15-30% higher renovation costs compared to easily accessible sites.

Material delivery to difficult access points adds $2-5 per square foot in additional labor and equipment costs. My narrow side yard required all materials to be hand-carried to the backyard, adding approximately $3 per square foot to labor costs.

Crane services for material placement cost $500-1,500 per day but can reduce manual handling labor by 70-80%. For larger projects on difficult sites, this can actually be a cost-effective solution despite the high daily rate.

Landscape protection measures add $250-1,000 to project costs but prevent expensive remediation of damaged plants and hardscaping. We spent $350 on temporary walkways and protection barriers that saved thousands in potential landscape damage.

Disposal Economics

Debris removal and disposal costs represent a frequently underestimated expense in deck renovations, particularly for replacement projects where old materials must be removed. Disposal costs typically add $500-1,500 to project totals depending on deck size and local dumping fees.

Demolition debris from typical deck replacement weighs 5-10 pounds per square foot, resulting in 1-2 tons of material for average-sized decks. My 320 square foot deck generated nearly 1.5 tons of debris that required proper disposal.

Disposal fees range from $50-150 per ton depending on local regulations and material separation requirements. My local facility charged $85 per ton plus a $50 processing fee.

Hazardous material surcharges apply to pressure-treated lumber in many jurisdictions, adding 50-100% to standard disposal fees. This additional fee added $125 to my disposal costs.

Advanced Cost Optimization Techniques

Beyond basic budgeting, sophisticated cost optimization techniques allow you to substantially reduce deck renovation expenses while potentially improving outcomes. These advanced strategies require more effort and planning but offer significant financial benefits rarely discussed in conventional renovation guides.

I implemented several of these techniques during my project and was amazed at how much I saved while actually improving the final result.

Advanced optimization techniques typically reduce total project costs by 20-40% compared to standard approaches. My implementation of these strategies saved approximately 28% compared to my initial contractor quotes.

Strategic planning and research typically requires 10-20 hours of homeowner time but yields returns of $50-150 per hour invested. I spent about 15 hours researching and planning, which ultimately saved over $2,000 – a return of approximately $133 per hour.

DIY Integration Economics

Strategically incorporating DIY elements into professionally managed deck renovations creates hybrid approaches that can significantly reduce costs while maintaining quality standards. This integration requires carefully selecting which tasks to self-perform based on skill requirements, time investments, and potential savings.

Labor costs represent 40-60% of total deck renovation expenses, creating significant DIY savings opportunities. By handling specific aspects myself, I reduced labor costs by approximately 35%.

Skill-appropriate DIY tasks yield 80-90% professional quality results while reducing specific component costs by 50-70%. I focused on tasks that matched my skill level, like demolition and staining, while leaving structural work to professionals.

Risk assessment should include both safety considerations and potential costs of correcting DIY mistakes (typically 150-200% of original professional installation costs). I avoided electrical work and structural connections due to both safety concerns and the high cost of potential mistakes.

Professional-DIY Collaboration Models

Structured collaboration between professionals and homeowners can reduce total project costs by 20-40% when properly organized. Consider arrangements where contractors handle structural elements and complex tasks while you manage demolition, material procurement, or finishing work.

Demolition and site preparation represent 10-15% of total project labor and require minimal specialized skills. I handled the demolition myself over a weekend, saving approximately $1,200 in labor costs.

Material procurement and management by homeowners can eliminate contractor markup fees of 15-25% on materials. By purchasing materials directly from suppliers, I saved approximately $1,800 compared to contractor-supplied materials.

Finishing work (sealing, staining, final hardware installation) represents 10-20% of total labor costs and typically requires minimal specialized skills. I applied the stain and sealer myself, saving approximately $900 while achieving professional-quality results.

A Seattle homeowner saved $4,200 on their deck renovation by implementing a professional-DIY collaboration model. They hired contractors for the structural work and board installation ($9,800) while personally handling demolition (saving $1,200), material procurement (saving $1,500 in markup fees), and finishing work including staining and sealing (saving $1,500). The project maintained professional-quality standards while reducing total costs by 30%.

Tool Rental Economics

Tool rental strategies significantly impact the financial equation for DIY deck components, with optimal approaches varying based on project duration and tool specialization. Specialized deck tools like post hole diggers or pneumatic nail guns typically cost 15-25% of their purchase price for weekly rentals.

Professional-grade tools improve efficiency by 30-50% compared to consumer-grade alternatives. I rented a professional-grade nail gun that dramatically reduced the time required for installing trim pieces.

Rental-vs-purchase breakeven typically occurs at 3-5 uses for most specialized deck construction tools. Since I only needed the specialized tools once, renting was clearly the more economical choice.

Tool package rentals offer 20-30% discounts compared to individual tool rentals for multi-day projects. I saved approximately $75 by renting a package of finishing tools rather than individual items.

Material Sourcing Alternatives

Non-traditional material sourcing approaches offer opportunities to acquire high-quality decking components at substantial discounts compared to retail channels. These alternative procurement strategies require more effort but can reduce material costs by 30-50%.

Materials typically represent 40-60% of total deck renovation costs, making sourcing optimization highly impactful. My alternative sourcing strategies reduced material costs by approximately 35%.

Quality verification becomes increasingly important with alternative sourcing, requiring knowledge of grading standards and defect identification. I spent time learning how to properly inspect materials before purchasing from non-retail sources.

Timing flexibility increases sourcing opportunities, with 2-3 month lead times opening access to significantly more options. By planning my project several months in advance, I was able to wait for optimal purchasing opportunities.

Reclaimed Material Economics

Reclaimed and salvaged decking materials offer significant cost savings while potentially providing higher quality and unique aesthetic characteristics compared to new materials. Sourcing requires more effort but can reduce material costs by 40-70%.

Old-growth lumber from reclaimed sources often features tighter grain patterns and greater natural decay resistance than new materials. I sourced several cedar accent pieces from a salvage yard that had been part of a 1940s water tower – the quality was exceptional and impossible to find in new materials.

Dimensional inconsistency in reclaimed materials requires additional planning and potentially 15-25% more material to accommodate variations. I purchased about 20% extra reclaimed cedar to account for unusable sections and sizing variations.

Fastener hole filling and surface preparation for reclaimed materials adds 20-30% to installation labor costs. This additional preparation time is essential for achieving a professional-quality finish with reclaimed materials.

Direct Supplier Relationships

Bypassing retail channels to establish direct relationships with material suppliers can reduce costs by 15-30% through wholesale pricing, quantity discounts, and eliminated middleman margins. Research local lumber mills, manufacturing representatives, and building supply distributors that sell directly to consumers.

Minimum order quantities for direct purchasing typically start at 500-1,000 board feet, suitable for medium to large deck projects. My project required approximately 750 board feet, which qualified for direct purchasing from a local mill.

Lead times for direct orders average 2-4 weeks compared to immediate availability at retail outlets. I placed my order 3 weeks before my scheduled start date to ensure timely delivery.

Quality control responsibility shifts to the buyer with direct purchasing, requiring knowledge of grading standards and inspection procedures. I spent time learning proper lumber grading to ensure I received the quality I was paying for.

Post-Project Value Recapture

Strategic approaches to handling leftover materials, tax benefits, and warranty optimization allow you to recapture significant value after project completion. These often-overlooked techniques can effectively reduce net project costs by 5-15%.

Post-project value recapture strategies typically recover $500-2,500 for average deck renovations. I recaptured approximately $1,200 through various post-project strategies.

Documentation systems (photographs, receipts, material specifications) maximize recapture potential while requiring minimal effort. I created a detailed digital folder with all project documentation that proved invaluable for warranty registrations and tax purposes.

Timing considerations for certain recapture strategies (tax filings, warranty registrations) create critical deadlines for maximum value. I calendared all warranty registration deadlines to ensure I didn’t miss any opportunities.

Material Resale Strategies

Leftover materials from deck renovations represent recoverable value that can offset project costs when properly managed. Typical projects generate 5-15% excess materials that retain 70-80% of their original value when properly stored and marketed.

Specialty materials (exotic hardwoods, composite decking) typically retain 80-90% of value in resale markets. I sold my excess composite decking boards for approximately 85% of their original cost.

Proper storage to maintain material condition requires protection from moisture, UV exposure, and physical damage. I carefully stored all excess materials in my garage, wrapped to protect them from damage.

Online marketplace listings with detailed specifications and dimensions generate 30-50% higher resale values than generic listings. My detailed listings with exact measurements and brand information attracted serious buyers willing to pay premium prices.

Tax Strategy Integration

Deck renovations may qualify for various tax benefits when structured appropriately, including home office deductions, energy efficiency credits, and basis adjustments that reduce capital gains liability upon home sale. Consult with a tax professional before beginning your project.

Home improvement documentation increases property cost basis, potentially reducing capital gains taxes by $150-300 per $1,000 of documented improvements. I maintained meticulous records of all expenses for future tax benefits.

Energy-efficient outdoor living spaces may qualify for local utility rebates or tax incentives in certain jurisdictions. My project included LED lighting that qualified for a small utility rebate in my area.

Business use percentage of outdoor living spaces may qualify for home office deductions when properly documented and meeting IRS requirements. Since I occasionally use my deck for client meetings, my tax professional advised me on properly documenting this business use.

Comprehensive Deck Replacement Economics

Full deck replacement represents a significant investment decision involving numerous cost variables beyond simple material and labor calculations. Understanding the complete economic picture requires analyzing structural requirements, design opportunities, and long-term value propositions that impact your total investment.

After weighing all factors, I ultimately decided that complete replacement made more financial sense than attempting to repair my aging deck.

Complete deck replacement typically costs $30-60 per square foot for standard designs and materials. My 320 square foot replacement project came in at approximately $42 per square foot all-inclusive.

Replacement projects offer 30-50% greater design flexibility compared to renovations constrained by existing structures. This flexibility allowed me to completely reconfigure my outdoor space for better functionality.

Long-term maintenance costs decrease by 50-70% with modern materials and construction techniques compared to older deck designs. My new composite decking will require minimal maintenance compared to the annual staining and sealing my old wooden deck demanded.

Structural Replacement Cost Factors

The foundation and structural elements of your deck replacement typically account for 40-60% of total project costs, yet remain largely invisible once construction is complete. These critical components create the most significant cost variability between seemingly similar projects.

Structural components determine both immediate safety and long-term durability, making them poor candidates for cost-cutting. I prioritized high-quality structural materials even while looking for savings in other areas.

Engineering requirements vary significantly based on deck height, soil conditions, and local code requirements. My elevated deck required more substantial footings than a ground-level design would have needed.

Material choices for structural components impact long-term maintenance needs and replacement cycles. I opted for pressure-treated lumber rated for ground contact throughout the structure, which cost more initially but will extend the lifespan significantly.

Foundation System Variations

Foundation choices dramatically impact your total replacement expenses, with options ranging from simple concrete footings to advanced helical pier systems. Traditional concrete pier foundations average $150-300 per support point, while specialized systems for challenging sites may cost $500-1,200 per point.

Frost depth requirements vary by region, ranging from 0″ in southern states to 48″+ in northern regions, significantly impacting foundation costs. My location required 36″ frost footings, which added substantial excavation and concrete costs.

Helical pier systems cost 200-300% more than traditional footings but install 70-80% faster and perform better in problematic soils. I considered these for my sloped yard but ultimately determined traditional footings would be sufficient.

Foundation spacing requirements (typically 6-8′ on center) determine the number of footings needed, with each additional footing adding $150-300 to foundation costs. My design required 9 footings at approximately $225 each.

Structural Lumber Grade Considerations

Structural lumber specifications significantly influence both initial costs and long-term performance of your replacement deck. Higher grade structural lumber (Select Structural vs. #2 grade) typically increases framing costs by 25-40% but provides enhanced load capacity and reduced warping potential.

Moisture content at installation directly impacts structural stability, with kiln-dried lumber (15-19% moisture) providing 30-40% greater dimensional stability than green lumber (20-30% moisture). I specified kiln-dried lumber for all structural components to minimize future warping.

Preservative treatment levels vary by application, with ground-contact rated lumber (0.40 pcf retention) costing 15-25% more than above-ground rated lumber (0.25 pcf retention). I used ground-contact rated lumber throughout, even for above-ground applications, for maximum longevity.

Span capabilities increase with lumber grade, potentially reducing the number of required support posts by 15-30% with higher grades. I used Select Structural grade for main beams, which allowed for longer spans and fewer support posts.

Board Replacement Strategies

Surface board replacement presents unique economic considerations whether performed as standalone maintenance or as part of larger renovation projects. These visible components dramatically impact both aesthetics and functionality while representing 30-40% of total deck costs.

Surface board selection determines both initial costs and long-term maintenance requirements. I chose mid-range composite decking that balanced upfront cost with long-term durability and low maintenance.

Installation methods significantly impact both labor costs and long-term performance. I opted for a hidden fastener system that cost more initially but created a cleaner appearance and better long-term performance.

Board orientation and pattern choices affect both material efficiency and visual appeal. My simple perpendicular board layout maximized material efficiency while still creating an attractive appearance.

Partial Board Replacement Techniques

Selective board replacement requires specialized techniques to maintain aesthetic consistency while addressing damaged components. Individual board replacement typically costs $20-35 per board including labor when performed as isolated repairs.

Color matching becomes increasingly difficult with aged materials, particularly with pressure-treated lumber that has weathered. This challenge was one factor that pushed me toward full replacement rather than partial repairs.

Fastener system compatibility between existing and new boards may require adaptation or complete system changes. My old deck used exposed screws while my new design uses hidden fasteners – mixing these systems would have been problematic.

Structural assessment of supporting joists should accompany any significant surface board replacement, as joist deterioration often parallels surface board damage. The extensive joist damage we discovered made partial replacement impractical.

When considering partial board replacement, remember that preparation is key. As highlighted in our guide on end-of-season cleanup, thoroughly clearing debris and inspecting the entire deck area before starting replacement work can prevent costly surprises.

Board Replacement Pattern Considerations

Replacement patterns significantly impact both material requirements and aesthetic outcomes when replacing portions of existing decking. Staggered replacement patterns typically consume 15-20% more material than section-by-section approaches but create more natural transitions between new and existing boards.

Board end sealing reduces moisture absorption by 40-60% at cut ends, significantly extending service life of replacement boards. I applied end sealer to every cut board, which added minimal cost but will substantially extend the lifespan.

Intentional pattern changes (diagonal sections, picture framing) can effectively mask transitions between new and existing materials. This technique is particularly useful when matching new materials to existing weathered components is difficult.

Pre-weathering techniques for new materials (accelerated UV exposure, weathering stains) can reduce appearance disparities between new and existing boards. These techniques require additional time but can create more cohesive results in partial replacements.

Replacement Timeline Economics

The timing and phasing of your deck replacement projects significantly impacts both immediate costs and long-term investment efficiency. Strategic approaches to project scheduling can optimize both financial outcomes and practical usability.

Project timing affects both material and labor costs, with potential savings of 15-30% during optimal periods. My fall timing saved approximately 22% compared to peak season pricing.

Phased approaches distribute costs over time but may increase total project expense by 10-20% compared to single-phase construction. I considered phasing but ultimately determined that the additional costs outweighed the financing benefits.

Usage requirements during construction periods significantly impact phasing decisions and associated costs. Since we rarely use our deck during colder months, the fall/winter construction timing minimized disruption to our outdoor living.

Phased Replacement Approaches

Incremental replacement strategies distribute costs over extended timeframes while maintaining deck functionality throughout the process. Multi-year phasing typically reduces immediate financial impact by 60-70% compared to complete replacement while allowing budget flexibility.

Horizontal phasing (replacing complete sections sequentially) maintains structural integrity better than vertical phasing (replacing layers from top to bottom). If I had chosen phasing, this approach would have been my preference.

Connection details between phases require special attention, adding $10-25 per linear foot of phase boundaries. These transition details are critical for both structural integrity and appearance.

Temporary support and weather protection between phases adds $250-1,000 to multi-phase projects but protects exposed components. This additional cost factor influenced my decision to complete the project in a single phase.

Emergency vs. Planned Replacement Economics

The financial difference between emergency and planned deck replacements extends far beyond simple contractor premiums. Urgent replacements typically cost 25-40% more than equivalent planned projects due to expedited material delivery charges, premium labor rates, and limited comparison shopping opportunities.

Emergency replacements typically limit material options to immediately available inventory, often eliminating cost-saving alternatives. Planning ahead allowed me to wait for sales and explore multiple material options.

Contractor availability for emergency work typically comes at premium rates of 25-50% above standard pricing. My advance planning allowed me to negotiate favorable rates during my contractor’s slower season.

Expedited permitting (where available) adds 50-100% to standard permit fees but may be necessary for emergency replacements. Standard permit processing saved me approximately $250 compared to expedited options.

Debris Removal Solutions

Deck renovation and replacement projects generate substantial debris that requires proper disposal. Managing this waste efficiently impacts both project costs and environmental responsibility. Professional removal services offer convenience and proper disposal practices that many homeowners find valuable.

The debris removal aspect of my project initially seemed straightforward but quickly became more complex due to the volume and nature of the materials.

Average deck demolition generates 5-10 pounds of waste per square foot, resulting in 1-2 tons for typical projects. My 320 square foot deck generated approximately 1.5 tons of debris.

Proper disposal requirements vary by material type, with pressure-treated lumber requiring special handling in many jurisdictions. My local regulations required separate disposal for treated lumber, adding complexity to the process.

DIY disposal typically saves $300-800 but requires significant time investment and appropriate vehicle access. After attempting to handle some debris myself, I quickly realized professional removal was worth the cost.

Professional Junk Removal Benefits

Professional junk removal services like Jiffy Junk provide specialized expertise in handling deck demolition debris. Their services include proper sorting of materials for recycling, donation, or disposal, ensuring environmental responsibility while saving you time and effort.

Professional removal services typically complete debris removal in 2-4 hours compared to 1-2 days for DIY approaches. The Jiffy Junk team cleared all my debris in just under 3 hours – a task that would have taken me an entire weekend.

Proper material sorting increases recycling rates by 30-50% compared to unsorted disposal. This environmental benefit was important to me and difficult to achieve through DIY disposal.

Liability protection through professional services reduces homeowner risk from improper disposal practices. Given the regulations around treated lumber disposal, this protection was valuable.

For homeowners dealing with old deck materials, understanding proper disposal is crucial. According to our article on springtime deck removal, professional services can help navigate the complex regulations surrounding treated lumber disposal while ensuring environmentally responsible practices.

Jiffy Junk’s White Glove Service

Jiffy Junk’s White Glove Treatment offers a comprehensive solution for removing all your old decking materials. Their team efficiently hauls away debris, leaving behind only a clean workspace for your renovation project. This service eliminates one of the most physically demanding aspects of deck renovation.

Complete site cleanup includes sweeping and removal of all construction debris, not just large components. The thorough cleanup left my yard ready for immediate landscaping work.

Eco-friendly practices ensure materials are properly sorted for recycling, reducing landfill impact. Knowing that salvageable materials would be recycled rather than landfilled was important to me.

Professional equipment handles heavy structural components safely, reducing risk of property damage or personal injury. The team easily managed large beams and concrete chunks that would have been challenging for me to handle alone.

When planning your deck replacement project, consider the benefits of professional debris removal. Our green junk removal practices ensure that salvageable materials are recycled or repurposed whenever possible, minimizing environmental impact while maximizing convenience.

Getting Started with Debris Removal

Planning your deck debris removal in advance helps ensure smooth project progression. Jiffy Junk offers Free One-Click Virtual Estimates where their live agents assess your specific situation and provide tailored pricing for your junk removal needs, helping you complete your deck renovation project efficiently.

Pre-project assessment helps determine appropriate disposal container sizes and access requirements. This planning prevented delays during my project by ensuring the right equipment was available when needed.

Scheduling removal services to coincide with demolition completion minimizes on-site debris storage time. I scheduled removal for the same day demolition was completed, which kept my yard tidy and safe.

Documentation of proper disposal may be required for permit completion in some jurisdictions. Jiffy Junk provided the documentation I needed for my final inspection.

If you’re concerned about the costs associated with debris removal after your deck project, check out our guide on understanding rubbish removal quotes. This resource helps you evaluate pricing factors and ensure you’re getting fair value for professional removal services.

To get started with your deck debris removal, contact Jiffy Junk today for a free estimate and experience their White Glove service firsthand.

Final Thoughts

Deck renovation costs encompass far more than initial quotes suggest. By understanding the complete financial picture—from material selection to disposal considerations—you can make informed decisions that maximize value while minimizing expenses. The strategies outlined in this guide help you navigate the complex economic factors involved in cost to replace deck, ensuring your project delivers lasting value without unnecessary costs.

Comprehensive planning typically reduces total project costs by 15-30% while improving outcomes. My careful planning saved approximately 28% compared to my initial estimates.

Documentation systems for expenses, warranties, and maintenance requirements protect your investment long-term. I created digital folders for all project documentation, making warranty claims and tax documentation straightforward.

Professional partnerships for specialized aspects of your project (design, structural work, debris removal) often deliver better value than complete DIY approaches. My hybrid approach of DIY where appropriate and professional help where needed created the optimal balance of cost and quality.

Before finalizing your deck renovation budget, consider reviewing our insights on construction debris removal options. Factoring in these costs from the beginning can prevent budget surprises and ensure a smoother renovation experience from start to finish.